How to Reduce HDPE Odors in Consumer Products?

HDPE Odor Challenges

High-density polyethylene (HDPE) is widely used in consumer products due to its durability, chemical resistance, and cost-effectiveness. However, one significant challenge faced by manufacturers and consumers alike is the persistent odor associated with HDPE products. This odor issue can negatively impact user experience and product acceptance, making it a critical concern for the industry.

The primary source of HDPE odors is the presence of volatile organic compounds (VOCs) that are generated during the manufacturing process or released over time from the polymer matrix. These VOCs can include residual monomers, additives, and degradation products. The complex nature of these odor-causing compounds makes their elimination a multifaceted challenge.

One of the main difficulties in addressing HDPE odors is the variability in consumer sensitivity to different odor profiles. What may be perceived as an unpleasant odor by one individual might go unnoticed by another, making it challenging to establish universal standards for acceptable odor levels in consumer products.

The persistence of HDPE odors over time presents another significant hurdle. Unlike some materials that off-gas quickly, HDPE can continue to release odorous compounds slowly over extended periods. This long-term emission of VOCs necessitates solutions that not only address initial odors but also prevent or mitigate ongoing odor development.

Environmental factors such as temperature, humidity, and exposure to UV light can exacerbate the odor problem by accelerating the degradation of HDPE and the release of odorous compounds. This environmental sensitivity adds another layer of complexity to the development of effective odor reduction strategies.

The regulatory landscape surrounding odor control in consumer products is another challenge. While there are regulations governing the use of certain chemicals and VOC emissions, specific guidelines for odor control in HDPE products are often lacking or inconsistent across different regions and markets.

From a manufacturing perspective, implementing odor reduction techniques without compromising the desirable properties of HDPE or significantly increasing production costs is a delicate balancing act. Techniques that effectively reduce odors must also be scalable and economically viable for mass production.

Lastly, the recycling of HDPE products introduces additional odor-related challenges. Recycled HDPE can often have stronger or more complex odor profiles due to contamination and degradation during its lifecycle. Developing odor reduction strategies that are effective for both virgin and recycled HDPE is crucial for promoting sustainable practices in the industry.

Market Demand Analysis

The market demand for reducing HDPE odors in consumer products has been steadily increasing in recent years. This trend is driven by growing consumer awareness of product quality and safety, as well as stricter regulations on volatile organic compounds (VOCs) emissions. The global market for odor control solutions in plastics is expected to grow significantly, with a particular focus on high-density polyethylene (HDPE) due to its widespread use in packaging, containers, and other consumer goods.

Consumer preferences are shifting towards products with minimal odor, especially in food packaging, personal care items, and household containers. This shift is particularly evident in developed markets such as North America and Europe, where consumers are more sensitive to product aesthetics and sensory experiences. As a result, manufacturers are under pressure to improve their HDPE formulations and processing techniques to reduce or eliminate unpleasant odors.

The healthcare and pharmaceutical sectors are also driving demand for low-odor HDPE products. These industries require packaging materials that do not interfere with the integrity or perception of their products. The COVID-19 pandemic has further accelerated this trend, as consumers become more health-conscious and demand higher standards of hygiene and safety in their everyday products.

Environmental concerns are another factor influencing market demand. As governments worldwide implement stricter regulations on VOC emissions, manufacturers are seeking innovative solutions to reduce odors in HDPE products. This regulatory pressure is creating new opportunities for companies specializing in odor reduction technologies and additives.

The e-commerce boom has also contributed to the demand for odor-free HDPE packaging. With more products being shipped directly to consumers, the importance of maintaining product freshness and eliminating any off-putting odors during transit has become crucial. This trend is expected to continue as online shopping becomes increasingly prevalent.

In emerging markets, such as Asia-Pacific and Latin America, the demand for odor-free HDPE products is growing alongside rising disposable incomes and changing consumer preferences. These regions represent significant growth opportunities for companies offering odor reduction solutions.

The market for odor-free HDPE products is not limited to end-consumers. Industrial buyers, such as food and beverage manufacturers, are also seeking improved HDPE materials for their production processes. This B2B segment represents a substantial portion of the overall market demand.

As sustainability becomes a key focus for many industries, there is a growing interest in bio-based and recycled HDPE materials that also address the odor issue. This intersection of sustainability and odor reduction is expected to drive innovation and create new market opportunities in the coming years.

Current Odor Reduction

Current odor reduction strategies for HDPE in consumer products primarily focus on addressing the root causes of odor formation and implementing effective mitigation techniques. One of the most common approaches is the use of additives and stabilizers during the manufacturing process. These additives, such as antioxidants and UV stabilizers, help prevent the degradation of HDPE molecules, which can lead to the formation of odorous compounds.

Another widely employed method is the optimization of processing conditions. This includes carefully controlling temperature, pressure, and residence time during extrusion and molding processes. By minimizing thermal and mechanical stress on the polymer, manufacturers can reduce the likelihood of odor-causing degradation reactions.

Post-production treatments have also gained popularity in recent years. These may involve surface treatments, such as corona discharge or plasma treatment, which can modify the surface properties of HDPE and potentially reduce odor emission. Additionally, some manufacturers employ degassing techniques to remove volatile organic compounds (VOCs) that contribute to odor.

The use of scent masking agents is another approach, although it is generally considered less desirable as it does not address the underlying cause of the odor. These agents work by either neutralizing odorous molecules or overpowering them with more pleasant scents.

Advanced purification techniques for raw materials have shown promise in reducing HDPE odors. By ensuring the highest quality of input materials and removing potential contaminants, manufacturers can minimize the formation of odor-causing compounds during processing and in the final product.

Some companies have explored the use of bio-based additives and natural odor absorbers. These environmentally friendly options, such as activated carbon or zeolites, can be incorporated into the HDPE matrix to trap and neutralize odorous molecules.

Improved packaging and storage methods also play a role in current odor reduction strategies. Proper sealing and controlled atmosphere packaging can help prevent the absorption of external odors and the emission of inherent odors from HDPE products.

Lastly, ongoing research in polymer science has led to the development of modified HDPE formulations with inherently lower odor profiles. These innovations often involve tweaking the molecular structure or incorporating odor-resistant co-polymers to create more stable and less odorous materials for consumer products.

Existing Odor Solutions

01 Odor reduction through additives

Various additives can be incorporated into HDPE to reduce or eliminate odors. These may include antioxidants, stabilizers, or specific odor-neutralizing compounds. The additives work by preventing the formation of odor-causing compounds or by neutralizing existing odors in the material.- Odor reduction through additives: Various additives can be incorporated into HDPE to reduce or eliminate odors. These may include antioxidants, stabilizers, or specific odor-neutralizing compounds. The additives work by preventing the formation of odor-causing compounds or by neutralizing existing odors in the material.

- Processing techniques for odor control: Specific processing techniques can be employed during HDPE production to minimize odor formation. These may include optimizing temperature profiles, controlling residence time, or implementing specialized degassing procedures. Such techniques aim to reduce the formation of volatile organic compounds that contribute to odors.

- Surface treatment for odor reduction: Post-production surface treatments can be applied to HDPE products to reduce odors. These treatments may involve chemical processes, plasma treatment, or coating applications that modify the surface properties of the material to prevent odor absorption or emission.

- Blending with other polymers: HDPE can be blended with other polymers or materials to create composites with improved odor resistance. These blends may incorporate polymers with inherent odor-resistant properties or materials that can absorb or neutralize odors within the composite structure.

- Scenting and masking techniques: Scenting agents or odor-masking compounds can be incorporated into HDPE to counteract unpleasant odors. These additives work by either overpowering existing odors with more pleasant scents or by chemically neutralizing odor-causing molecules within the material.

02 Processing techniques for odor control

Specific processing techniques can be employed during HDPE production to minimize odor formation. These may include optimizing temperature and pressure conditions, using specialized equipment, or implementing specific cooling and degassing procedures to remove volatile compounds that contribute to odors.Expand Specific Solutions03 Surface treatment for odor reduction

Post-production surface treatments can be applied to HDPE products to reduce odors. These treatments may involve chemical processes, plasma treatments, or the application of odor-absorbing coatings to the surface of the HDPE material.Expand Specific Solutions04 Blending with other polymers

HDPE can be blended with other polymers or materials that have inherent odor-reducing properties. This approach can help to minimize the overall odor profile of the resulting composite material while maintaining desired physical properties.Expand Specific Solutions05 Odor encapsulation technologies

Advanced encapsulation technologies can be used to trap or contain odor-causing molecules within the HDPE matrix. These technologies may involve the use of molecular sieves, cyclodextrins, or other encapsulating agents that prevent the release of odorous compounds from the material.Expand Specific Solutions

Key Industry Players

The market for reducing HDPE odors in consumer products is in a growth phase, driven by increasing consumer demand for odor-free plastics. The global market size for odor control technologies in plastics is expanding, with significant potential in packaging and consumer goods sectors. Technologically, the field is moderately mature, with ongoing innovations. Key players like Dow Global Technologies LLC, LG Chem Ltd., and Eastman Chemical Co. are leading research efforts, focusing on advanced additives and processing techniques. Companies such as Kimberly Clark and International Paper Co. are applying these technologies in consumer products, while specialized firms like Inhance Technologies LLC are developing novel surface treatment methods. The competitive landscape is diverse, with both chemical giants and niche players contributing to technological advancements.

Dow Global Technologies LLC

Eastman Chemical Co.

Innovative Odor Control

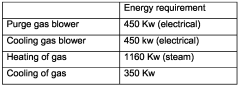

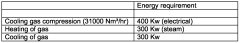

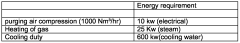

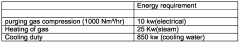

- A continuous pellet treatment unit with a constant silo level, where heated gas is recycled to reduce energy consumption and minimize purge gas release, and the use of a plug-flow heating silo with controlled temperature and residence time to efficiently remove volatiles without melting the pellets.

- The use of hydrophobic polymers of intrinsic microporosity (HPIMs) with integrated colorants, which can absorb volatile odorous compounds and are aesthetically pleasing, allowing for easy incorporation into various product forms like films, fibers, and coatings.

Environmental Regulations

Environmental regulations play a crucial role in addressing the issue of HDPE odors in consumer products. As governments and regulatory bodies worldwide become increasingly aware of the potential health and environmental impacts of volatile organic compounds (VOCs) emitted from plastic products, stricter guidelines and standards are being implemented to control these emissions.

In the United States, the Environmental Protection Agency (EPA) has established regulations under the Clean Air Act to limit VOC emissions from various sources, including plastic manufacturing processes. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically targets the synthetic organic chemical manufacturing industry, which includes HDPE production. These regulations require manufacturers to implement best available control technologies (BACT) to reduce emissions and odors associated with HDPE production and processing.

The European Union has also taken significant steps to address this issue through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. REACH mandates that manufacturers and importers of chemical substances, including those used in HDPE production, must assess and manage the risks associated with their products. This includes evaluating the potential for odor emissions and implementing measures to mitigate them.

In addition to federal regulations, many states and local governments have implemented their own air quality standards and odor control requirements. For example, California's Air Resources Board (CARB) has established stringent VOC limits for consumer products, which indirectly impact HDPE manufacturers and processors operating in the state.

The increasing focus on environmental regulations has led to the development of new technologies and processes aimed at reducing HDPE odors. These include advanced scrubbing systems, thermal oxidizers, and bio-filtration methods designed to capture and neutralize odorous compounds before they are released into the environment. Manufacturers are also exploring the use of low-odor additives and improved resin formulations to minimize the generation of odorous compounds during the production and use of HDPE products.

As environmental awareness continues to grow, it is likely that regulations governing HDPE odors will become even more stringent in the future. This trend is driving innovation in the plastics industry, pushing manufacturers to invest in research and development of cleaner, more environmentally friendly production methods and materials. The challenge for the industry lies in balancing these regulatory requirements with the need for cost-effective and efficient production processes.

Consumer Safety Standards

Consumer safety standards play a crucial role in addressing the issue of HDPE odors in consumer products. These standards are designed to protect consumers from potential health risks associated with exposure to harmful chemicals and odors. In the context of HDPE odors, regulatory bodies have established specific guidelines and limits for volatile organic compounds (VOCs) and other odor-causing substances.

The U.S. Consumer Product Safety Commission (CPSC) has set forth regulations that require manufacturers to ensure their products do not emit excessive levels of VOCs or other potentially harmful substances. These standards often include specific thresholds for odor intensity and chemical emissions. For HDPE products, manufacturers must adhere to these guidelines to ensure their items meet safety requirements before entering the market.

Similarly, the European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to protect human health and the environment from risks posed by chemicals. This regulation impacts the production and use of HDPE in consumer goods, requiring manufacturers to assess and manage the risks associated with the chemicals used in their products, including those responsible for odors.

In addition to government regulations, industry-specific standards have been developed to address odor issues in HDPE products. For instance, the American Society for Testing and Materials (ASTM) has established test methods for evaluating odors in plastic materials, including HDPE. These standardized tests help manufacturers assess and control odor levels in their products, ensuring compliance with safety standards and consumer expectations.

To meet these safety standards, manufacturers often implement rigorous quality control measures throughout the production process. This includes careful selection of raw materials, optimizing processing conditions, and conducting regular odor assessments. Some companies have also adopted advanced technologies, such as gas chromatography-mass spectrometry (GC-MS), to identify and quantify odor-causing compounds in HDPE products.

Consumer safety standards also emphasize the importance of proper labeling and disclosure of product information. Manufacturers are required to provide clear information about the materials used in their products, including any potential odor-related issues. This transparency allows consumers to make informed decisions and helps regulatory bodies monitor compliance with safety standards.

As consumer awareness and demand for safer products continue to grow, safety standards are likely to evolve. Future regulations may impose stricter limits on odor-causing substances in HDPE products or require more comprehensive testing protocols. This ongoing development of safety standards will drive innovation in odor reduction technologies and manufacturing processes, ultimately leading to improved consumer products with minimal HDPE odors.