How to Select the Best HDPE Grade for Your Application?

HDPE Grade Selection Background and Objectives

High-density polyethylene (HDPE) has become an indispensable material in various industries due to its exceptional properties and versatility. The selection of the most suitable HDPE grade for a specific application is a critical process that can significantly impact product performance, manufacturing efficiency, and overall cost-effectiveness. This technical research report aims to provide a comprehensive overview of the HDPE grade selection process, exploring its historical development, current trends, and future objectives.

The development of HDPE can be traced back to the 1950s when Karl Ziegler discovered the catalytic polymerization of ethylene. Since then, HDPE has undergone continuous improvements in its properties and manufacturing processes. The evolution of HDPE grades has been driven by the growing demand for materials with enhanced mechanical, thermal, and chemical resistance properties across various sectors, including packaging, automotive, construction, and healthcare.

In recent years, the HDPE market has witnessed a shift towards more specialized grades tailored for specific applications. This trend is fueled by the increasing complexity of end-use requirements and the need for optimized performance in diverse environments. Manufacturers are now focusing on developing HDPE grades with improved processability, better environmental sustainability, and enhanced functional properties.

The primary objective of this technical research is to establish a systematic approach for selecting the most appropriate HDPE grade for a given application. This involves understanding the intricate relationship between the molecular structure of HDPE, its processing characteristics, and the final product properties. By doing so, we aim to bridge the gap between material science and practical application, enabling more informed decision-making in product development and manufacturing processes.

Furthermore, this research seeks to address the growing emphasis on sustainability in material selection. As environmental concerns become increasingly prominent, there is a need to consider the entire lifecycle of HDPE products, from raw material sourcing to end-of-life disposal or recycling. Therefore, our objectives extend to exploring eco-friendly HDPE grades and evaluating their potential to meet both performance requirements and sustainability goals.

Another crucial aspect of this research is to analyze the impact of emerging technologies on HDPE grade development and selection. Advancements in polymer science, such as the use of nanotechnology and the development of novel catalysts, are opening up new possibilities for creating HDPE grades with unprecedented properties. Understanding these technological trends is essential for anticipating future market demands and staying ahead in the competitive landscape of polymer materials.

Market Demand Analysis for HDPE Applications

The global market for High-Density Polyethylene (HDPE) continues to expand, driven by its versatile applications across various industries. The demand for HDPE is primarily fueled by its excellent mechanical properties, chemical resistance, and recyclability. In the packaging sector, HDPE remains a preferred choice for bottles, containers, and films due to its durability and moisture barrier properties. The construction industry also contributes significantly to HDPE demand, utilizing it for pipes, fittings, and geomembranes.

The automotive sector presents a growing market for HDPE applications, particularly in fuel tanks and interior components, as manufacturers seek lightweight materials to improve fuel efficiency. In agriculture, HDPE is widely used for irrigation systems, greenhouse films, and storage tanks, with increasing adoption in developing countries driving market growth.

Environmental concerns and sustainability initiatives are shaping the HDPE market landscape. The push for circular economy practices has led to increased demand for recycled HDPE, creating new market opportunities and influencing product development strategies. Manufacturers are investing in advanced recycling technologies to meet this growing demand and comply with stricter environmental regulations.

Regional market dynamics play a crucial role in HDPE demand analysis. Asia-Pacific remains the largest consumer and producer of HDPE, with China leading the market. The region's rapid industrialization, urbanization, and population growth continue to drive demand across various applications. North America and Europe maintain stable markets, with a focus on high-performance HDPE grades for specialized applications.

Emerging economies in South America, Africa, and Southeast Asia present significant growth potential for HDPE applications, particularly in infrastructure development and consumer goods packaging. These markets are characterized by increasing disposable incomes and changing consumer preferences, driving demand for HDPE products.

The selection of the best HDPE grade for specific applications is becoming increasingly critical as end-users demand tailored solutions. This trend is evident in the growing market for specialty HDPE grades with enhanced properties such as improved impact resistance, UV stability, or processing characteristics. Manufacturers are investing in research and development to create innovative HDPE formulations that meet these specific application requirements.

Market analysis indicates a shift towards higher-performance HDPE grades in mature markets, while developing regions show strong demand growth for standard grades. This dichotomy presents challenges and opportunities for HDPE producers in terms of product portfolio management and market positioning. Understanding these market dynamics is crucial for selecting the most appropriate HDPE grade for specific applications and regions.

Current HDPE Grade Landscape and Challenges

The current HDPE grade landscape is characterized by a diverse range of options tailored to meet specific application requirements. High-density polyethylene (HDPE) grades are classified based on their molecular weight, density, and melt index, which directly influence their mechanical, thermal, and processing properties. The market offers a spectrum of HDPE grades, from general-purpose to specialized formulations, catering to various industries such as packaging, construction, automotive, and healthcare.

One of the primary challenges in selecting the best HDPE grade lies in the complexity of matching material properties with application demands. Different applications require specific combinations of strength, stiffness, impact resistance, and chemical resistance. For instance, blow molding applications may prioritize melt strength and environmental stress crack resistance, while injection molding might focus on flow properties and dimensional stability.

The ever-evolving regulatory landscape poses another significant challenge. Stringent regulations, particularly in food contact and medical applications, necessitate careful consideration of HDPE grades that comply with specific standards such as FDA, EU, or ISO requirements. This compliance often narrows the selection pool and may require extensive testing and documentation.

Processing challenges also play a crucial role in HDPE grade selection. The chosen grade must be compatible with the intended manufacturing process, whether it's extrusion, injection molding, or rotational molding. Factors such as melt flow rate, thermal stability, and die swell characteristics can significantly impact processability and final product quality.

The global supply chain dynamics present additional complexities. Availability of specific HDPE grades can fluctuate due to raw material shortages, production capacity constraints, or geopolitical factors. This volatility can affect lead times and pricing, potentially necessitating the evaluation of alternative grades or suppliers.

Sustainability considerations have become increasingly important in recent years. The push towards circular economy models has led to the development of recycled and recyclable HDPE grades. However, balancing sustainability with performance requirements presents a new set of challenges, as recycled content may affect certain material properties.

Customization and specialty grades add another layer of complexity to the HDPE landscape. While these tailored solutions offer optimized performance for specific applications, they often come with higher costs and longer lead times. Evaluating the trade-offs between standard and specialty grades requires careful cost-benefit analysis.

Lastly, the rapid pace of technological advancements in polymer science continually expands the HDPE grade landscape. New additives, processing aids, and molecular architectures are constantly being developed, offering improved properties but also necessitating ongoing education and reevaluation of material selection criteria.

Existing HDPE Grade Selection Methodologies

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

- Processing techniques for HDPE: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each method offers unique advantages and is suited for different product types. Advanced processing techniques can improve the material's performance, reduce production costs, or enable the creation of complex shapes.

- Recycling and sustainability of HDPE: HDPE is recyclable and can be reprocessed multiple times without significant loss of properties. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve recycling efficiency, develop new recycling technologies, and increase the use of recycled HDPE in various applications to promote sustainability.

- Applications of HDPE in various industries: HDPE finds applications in numerous industries due to its versatile properties. It is widely used in packaging for bottles, containers, and films. In construction, HDPE is used for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, household items, and medical devices. Ongoing research focuses on expanding HDPE's use in new and innovative applications.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites often aim to improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advanced processing techniques may involve multi-layer structures or specialized surface treatments to enhance performance or appearance.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is widely recycled due to its thermoplastic nature, allowing it to be melted and reformed multiple times. Recycling processes for HDPE include mechanical recycling, chemical recycling, and the development of upcycling techniques. Efforts are being made to improve the efficiency of HDPE recycling and to incorporate recycled HDPE into new products, contributing to circular economy initiatives.Expand Specific Solutions05 HDPE applications in various industries

HDPE finds applications across numerous industries due to its versatile properties. It is commonly used in packaging for food and beverages, household chemicals, and personal care products. In construction, HDPE is utilized for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, and medical devices, showcasing the material's adaptability to different product requirements.Expand Specific Solutions

Key HDPE Manufacturers and Market Players

The market for selecting the best HDPE grade is in a mature stage, with a significant global market size driven by diverse applications across industries. The technology is well-established, with ongoing innovations focusing on enhancing performance and sustainability. Key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and DuPont de Nemours, Inc. are at the forefront of HDPE grade development, leveraging their extensive R&D capabilities. Emerging companies such as Borealis AG and NOVA Chemicals Corp. are also making strides in specialized HDPE formulations. The competitive landscape is characterized by a mix of established petrochemical giants and innovative specialty chemical firms, all vying to meet the evolving needs of various industries through tailored HDPE solutions.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Critical HDPE Properties and Testing Standards

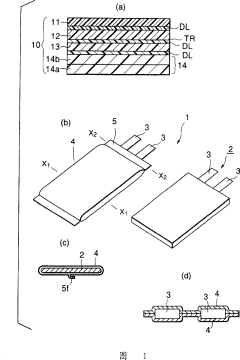

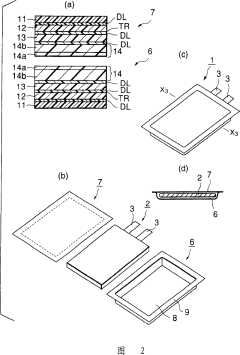

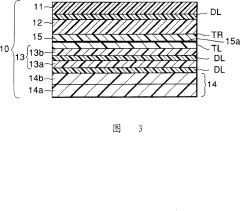

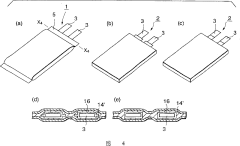

- Multi-layer laminated structure packaging materials are used, including the outermost layer, barrier layer, middle layer and innermost layer. The barrier layer is composed of soft aluminum foil or metal foil. The surface has been degreased or deoxidized and coated with acid-resistant coating. The middle layer of the film is composed of thermal adhesive resin, and the innermost layer is composed of unsaturated carboxylic acid-grafted polyolefin resin. A stable adhesive layer is formed through dry lamination or thermal lamination technology.

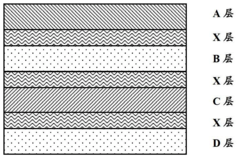

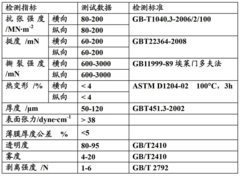

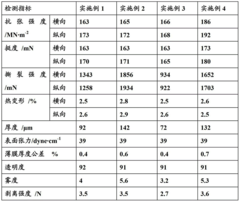

- A propylene polymer-ethylene polymer multi-layer composite film is used, with a specific layer structure and draw ratio combination, including A layer, B layer, C layer and D layer, using different or the same propylene and ethylene polymers. The material is biaxially stretched in the longitudinal and transverse directions, combined with the use of a binder layer, to form a film with high stiffness, high transparency and low temperature resistance.

Environmental Impact of HDPE Grade Selection

The selection of HDPE grade for specific applications has significant environmental implications. Different grades of HDPE exhibit varying properties that influence their environmental impact throughout the product lifecycle.

Recycling potential is a crucial factor in HDPE grade selection. Grades with higher recyclability contribute to a circular economy, reducing waste and conserving resources. Some HDPE grades are more easily recycled due to their molecular structure and additives, allowing for multiple reuse cycles without significant degradation in properties.

Energy consumption during production and processing is another environmental consideration. Certain HDPE grades require less energy to manufacture and mold, resulting in a lower carbon footprint. The melt flow index and processing temperature of the chosen grade directly affect energy requirements during product manufacturing.

Durability and lifespan of the final product also play a role in environmental impact. HDPE grades with superior mechanical properties and resistance to environmental stressors can lead to longer-lasting products, reducing the need for frequent replacements and minimizing waste generation over time.

The use of additives in HDPE formulations affects both performance and environmental aspects. Some additives may improve product functionality but could hinder recyclability or introduce potential environmental hazards. Selecting grades with environmentally friendly additives or those that minimize additive use can mitigate these concerns.

Transportation efficiency is another factor influenced by HDPE grade selection. Grades that allow for thinner-walled products or lighter designs can reduce material usage and transportation costs, thereby decreasing the overall carbon footprint of the supply chain.

End-of-life considerations are crucial when evaluating the environmental impact of HDPE grades. Some grades may be more suitable for biodegradation or chemical recycling, offering alternative disposal methods when mechanical recycling is not feasible.

The environmental impact of HDPE grade selection extends to water and soil pollution. Grades with higher resistance to chemical leaching and degradation can minimize the release of microplastics and other pollutants into ecosystems during the product's use phase and after disposal.

In conclusion, selecting the appropriate HDPE grade involves balancing performance requirements with environmental considerations. By carefully evaluating factors such as recyclability, energy efficiency, durability, and end-of-life options, manufacturers can minimize the environmental footprint of their HDPE products while meeting application-specific needs.

Regulatory Compliance for HDPE Applications

Regulatory compliance is a critical aspect of selecting the appropriate HDPE grade for various applications. The use of HDPE in different industries is subject to numerous regulations and standards that ensure product safety, environmental protection, and quality control.

In the food and beverage industry, HDPE materials must comply with FDA regulations in the United States and EU food contact regulations in Europe. These regulations specify the acceptable composition of HDPE resins and additives that can be used in food packaging applications. Manufacturers must ensure that their HDPE grades meet these requirements to prevent potential contamination of food products.

For medical and pharmaceutical applications, HDPE grades must adhere to stringent regulatory standards set by organizations such as the FDA, EMA, and ISO. These standards govern the biocompatibility, sterilization methods, and chemical resistance of HDPE materials used in medical devices and pharmaceutical packaging. Compliance with these regulations is essential to ensure patient safety and product efficacy.

In the construction industry, HDPE pipes and fittings must meet specific standards set by organizations like ASTM International and ISO. These standards define the physical properties, performance requirements, and testing methods for HDPE materials used in water distribution, gas distribution, and sewage systems. Compliance with these standards ensures the longevity and reliability of HDPE products in infrastructure applications.

Environmental regulations also play a significant role in HDPE grade selection. Many countries have implemented regulations regarding the recyclability and environmental impact of plastic materials. Manufacturers must consider these regulations when selecting HDPE grades, ensuring that their products can be recycled or disposed of in an environmentally responsible manner.

When selecting an HDPE grade for a specific application, it is crucial to consider the relevant regulatory landscape. This involves researching applicable regulations, standards, and certifications required for the intended use of the HDPE product. Manufacturers should work closely with material suppliers and regulatory experts to ensure that the chosen HDPE grade meets all necessary compliance requirements.

Furthermore, it is essential to maintain documentation of regulatory compliance throughout the product development and manufacturing process. This includes obtaining necessary certifications, conducting regular testing, and maintaining traceability of raw materials and production processes. By prioritizing regulatory compliance in HDPE grade selection, manufacturers can mitigate risks, ensure product safety, and maintain market access for their HDPE-based products.