How to Strengthen HDPE Products with Additives?

HDPE Additive Tech Background and Objectives

High-density polyethylene (HDPE) has been a cornerstone material in various industries since its commercial introduction in the 1950s. Known for its high strength-to-density ratio, chemical resistance, and versatility, HDPE has found applications ranging from packaging to construction. However, as industry demands evolve, there is a growing need to enhance the mechanical properties of HDPE products, particularly in terms of strength and durability.

The use of additives to strengthen HDPE products has emerged as a key area of research and development in polymer science. This technological approach aims to overcome the inherent limitations of HDPE, such as its relatively low stiffness and impact resistance compared to some other engineering plastics. By incorporating carefully selected additives, researchers and manufacturers seek to create HDPE composites that exhibit superior mechanical properties while maintaining the material's desirable characteristics.

The evolution of HDPE additive technology has been driven by several factors, including the push for lighter yet stronger materials in automotive and aerospace industries, the need for more durable packaging solutions, and the demand for high-performance plastics in extreme environments. As global sustainability concerns grow, there is also an increasing focus on developing additives that not only enhance HDPE's properties but also improve its recyclability and reduce its environmental footprint.

Recent technological trends in HDPE additives include the exploration of nanoparticles, such as carbon nanotubes and graphene, which have shown promising results in significantly improving the material's strength and stiffness. Additionally, the development of bio-based additives aligns with the growing emphasis on sustainable materials, offering potential solutions that balance performance enhancement with environmental considerations.

The primary objectives of current research and development efforts in HDPE additive technology are multifaceted. These include enhancing the material's tensile strength, impact resistance, and thermal stability without compromising its processability or increasing its density significantly. Furthermore, there is a focus on developing cost-effective additive solutions that can be easily integrated into existing HDPE manufacturing processes, ensuring widespread adoption across various industries.

As the field progresses, researchers are also exploring synergistic effects between different types of additives, aiming to create tailored HDPE composites that meet specific performance requirements for diverse applications. This holistic approach to HDPE enhancement through additives represents a critical pathway for expanding the material's capabilities and ensuring its continued relevance in an ever-evolving technological landscape.

Market Analysis for Enhanced HDPE Products

The market for enhanced HDPE products has been experiencing significant growth in recent years, driven by increasing demand for high-performance plastics across various industries. The global HDPE market size was valued at approximately $84 billion in 2020 and is projected to reach $109 billion by 2028, growing at a CAGR of 3.5% during the forecast period. This growth is largely attributed to the rising adoption of HDPE in packaging, construction, and automotive sectors, where enhanced properties such as improved strength and durability are highly valued.

The packaging industry remains the largest consumer of enhanced HDPE products, accounting for over 40% of the market share. This sector's demand is fueled by the need for lightweight, durable, and recyclable packaging solutions, particularly in food and beverage, personal care, and household products. The construction industry follows closely, with a market share of around 30%, driven by the material's excellent chemical resistance, weather durability, and impact strength in applications such as pipes, fittings, and geomembranes.

Geographically, Asia-Pacific dominates the enhanced HDPE market, holding approximately 35% of the global market share. This region's growth is propelled by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe follow, with market shares of 25% and 20% respectively, driven by technological advancements and stringent regulations promoting the use of high-performance, environmentally friendly materials.

The automotive industry presents a particularly promising growth opportunity for enhanced HDPE products. With the increasing focus on vehicle weight reduction to improve fuel efficiency and reduce emissions, automakers are turning to high-strength, lightweight plastics. Enhanced HDPE components are finding applications in fuel tanks, interior trims, and under-the-hood parts, with the potential to replace traditional materials like metal and rubber.

Consumer preferences are shifting towards sustainable and eco-friendly products, creating a growing demand for bio-based and recycled HDPE. This trend is expected to drive innovation in additive technologies that can improve the properties of recycled HDPE, making it suitable for high-performance applications. Manufacturers who can successfully develop and market such environmentally friendly enhanced HDPE products are likely to gain a competitive edge in the coming years.

Current Challenges in HDPE Strengthening

Despite the widespread use of High-Density Polyethylene (HDPE) in various industries, strengthening HDPE products with additives remains a complex challenge. One of the primary obstacles is achieving a balance between enhanced mechanical properties and maintaining the desirable characteristics of HDPE, such as its chemical resistance and processability.

A significant challenge lies in the uniform dispersion of additives within the HDPE matrix. Inadequate dispersion can lead to weak points in the material, potentially compromising its overall strength and durability. This issue is particularly pronounced when incorporating nanoscale additives, which tend to agglomerate due to their high surface energy.

The compatibility between HDPE and various additives presents another hurdle. Many strengthening agents, such as inorganic fillers or fibers, have poor interfacial adhesion with the hydrophobic HDPE matrix. This incompatibility can result in stress concentration points and reduced overall mechanical performance, limiting the effectiveness of the additives.

Temperature sensitivity during processing is a critical challenge when strengthening HDPE with additives. The relatively low melting point of HDPE restricts the use of high-temperature processing techniques, which are often necessary for the effective incorporation of certain additives. This limitation narrows the range of potential strengthening agents and processing methods available.

The long-term stability of strengthened HDPE products is another area of concern. Some additives may degrade over time or under specific environmental conditions, leading to a gradual loss of the enhanced properties. This degradation can be accelerated by factors such as UV exposure, temperature fluctuations, or chemical interactions, making it challenging to maintain consistent performance throughout the product's lifecycle.

Cost-effectiveness remains a significant challenge in the strengthening of HDPE products. While certain additives can dramatically improve mechanical properties, their high cost may render the final product economically unviable for many applications. Striking a balance between performance enhancement and cost-efficiency is crucial for widespread adoption of strengthened HDPE materials.

Environmental concerns also pose challenges in HDPE strengthening efforts. As sustainability becomes increasingly important, there is a growing need for additives that not only enhance performance but also maintain or improve the recyclability of HDPE products. Finding eco-friendly strengthening solutions that do not compromise the material's end-of-life options is a complex task facing researchers and manufacturers alike.

Existing HDPE Strengthening Solutions

01 Composition modifications for improved strength

HDPE products can be strengthened by modifying their composition. This includes adding reinforcing materials, such as fibers or nanoparticles, or blending with other polymers to create composites. These modifications can enhance mechanical properties, including tensile strength, impact resistance, and overall durability of HDPE products.- Composition modifications for improved strength: Various additives and fillers can be incorporated into HDPE to enhance its strength properties. These may include reinforcing agents, nanoparticles, or other polymers that can improve the mechanical performance of HDPE products. The specific composition adjustments can lead to increased tensile strength, impact resistance, and overall durability of HDPE materials.

- Processing techniques for strength enhancement: Different processing methods can be employed to improve the strength of HDPE products. These may include optimized extrusion parameters, specialized molding techniques, or post-processing treatments. By controlling factors such as temperature, pressure, and cooling rates during manufacturing, the molecular structure and orientation of HDPE can be manipulated to achieve superior strength characteristics.

- Reinforcement structures in HDPE products: Incorporating reinforcement structures within HDPE products can significantly enhance their strength. This may involve the use of ribbing, honeycomb designs, or other structural elements that distribute stress more effectively. Such reinforcement techniques can improve load-bearing capacity and resistance to deformation in HDPE products without substantially increasing weight or material usage.

- Surface treatments for improved strength: Various surface treatments can be applied to HDPE products to enhance their strength properties. These may include chemical treatments, plasma treatments, or the application of protective coatings. Such treatments can modify the surface characteristics of HDPE, improving its resistance to wear, chemical attack, and environmental degradation, thereby indirectly contributing to the overall strength and longevity of the product.

- Multi-layer and composite HDPE structures: Developing multi-layer or composite structures that incorporate HDPE can lead to products with enhanced strength properties. This approach may involve combining HDPE with other materials or creating layered structures with varying densities or orientations of HDPE. Such designs can leverage the strengths of different materials or configurations to create products with improved mechanical performance and durability.

02 Processing techniques to enhance strength

Various processing techniques can be employed to improve the strength of HDPE products. These include optimizing molding conditions, using advanced extrusion methods, and applying post-processing treatments. Such techniques can result in better molecular orientation, increased crystallinity, and improved overall mechanical properties of HDPE products.Expand Specific Solutions03 Surface treatments for enhanced strength

Surface treatments can be applied to HDPE products to improve their strength and durability. These treatments may include plasma treatment, chemical etching, or the application of coatings. Such modifications can enhance surface properties, improve adhesion, and increase resistance to wear and environmental factors.Expand Specific Solutions04 Design optimization for structural strength

The strength of HDPE products can be improved through optimized design strategies. This includes incorporating structural reinforcements, optimizing wall thickness, and utilizing advanced CAD/CAE tools for stress analysis. These design approaches can lead to products with enhanced load-bearing capacity and improved overall structural integrity.Expand Specific Solutions05 Additives and stabilizers for long-term strength

Incorporating specific additives and stabilizers into HDPE formulations can enhance long-term strength and durability. These additives may include antioxidants, UV stabilizers, and impact modifiers. Such additions can help maintain the mechanical properties of HDPE products over time, even when exposed to challenging environmental conditions.Expand Specific Solutions

Key Players in HDPE Additive Industry

The market for strengthening HDPE products with additives is in a growth phase, driven by increasing demand for high-performance plastics across various industries. The global HDPE market size is projected to reach significant volumes, with additives playing a crucial role in enhancing material properties. Technologically, the field is advancing rapidly, with companies like SABIC Global Technologies BV, Dow Global Technologies LLC, and China Petroleum & Chemical Corp. leading innovation. These industry giants, along with specialized firms such as Kingfa Sci. & Tech. Co., Ltd. and Sobute New Materials Co., Ltd., are developing advanced additive formulations to improve HDPE's mechanical, thermal, and chemical resistance properties. The competitive landscape is characterized by a mix of multinational corporations and regional players, each contributing to the evolving technological maturity of HDPE additives.

SABIC Global Technologies BV

China Petroleum & Chemical Corp.

Innovative Additives for HDPE Reinforcement

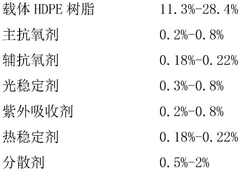

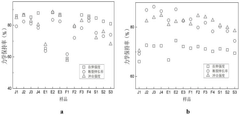

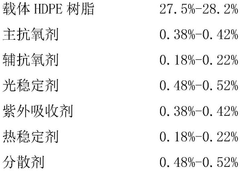

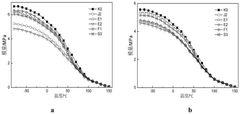

- Use HDPE composite stabilizer, mix it with HDPE base material, and select antioxidant 1076, light stabilizer 2020, UV absorber 326 and heat stabilizer CaSt2/ZnSt2 to form a multifunctional composite stabilizer to improve HDPE Photothermal stability and aging resistance.

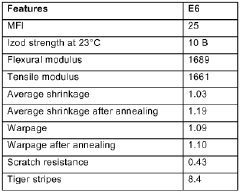

- A thermoplastic composition comprising a combination of polypropylenes, heterophasic propylene copolymers, ethylene-a-olefin elastomers, talc, and high-density polyethylene, with specific ratios and additives to balance mechanical and melt flow properties, minimizing tiger stripes and maintaining esthetic qualities.

Environmental Impact of HDPE Additives

The environmental impact of additives used to strengthen HDPE products is a critical consideration in the development and application of these materials. While additives can significantly enhance the performance and durability of HDPE, their potential effects on the environment throughout the product lifecycle must be carefully evaluated.

One of the primary environmental concerns associated with HDPE additives is their potential for leaching. Some additives, particularly those that are not chemically bound to the polymer matrix, may gradually migrate out of the material over time. This leaching process can be accelerated by exposure to heat, UV radiation, or certain chemicals. As a result, these additives may find their way into soil, water systems, or even food products, potentially causing contamination and ecological disruption.

The biodegradability of HDPE additives is another crucial factor to consider. Many traditional additives are not biodegradable, which means they can persist in the environment for extended periods after the HDPE product has been discarded. This persistence can lead to long-term accumulation in ecosystems, potentially affecting wildlife and natural habitats. Some additives may also interfere with the recycling process of HDPE, reducing the overall recyclability of the material and contributing to plastic waste accumulation.

Certain additives used in HDPE products have been identified as potential endocrine disruptors or carcinogens. While the concentrations of these additives in HDPE products are typically low, their cumulative effect over time and potential bioaccumulation in living organisms raise concerns about long-term environmental and health impacts. This has led to increased scrutiny and regulation of certain additives, particularly in applications involving food contact or children's products.

The production and disposal of HDPE additives also contribute to the overall environmental footprint of HDPE products. The manufacturing processes for some additives may involve energy-intensive steps or the use of hazardous chemicals, leading to increased carbon emissions and potential environmental risks. Additionally, the presence of certain additives can complicate the end-of-life management of HDPE products, potentially requiring specialized disposal or recycling processes.

In response to these environmental concerns, there is a growing trend towards the development of more eco-friendly additives for HDPE. These include bio-based additives derived from renewable resources, as well as additives designed to enhance the biodegradability of HDPE without compromising its performance. Researchers are also exploring ways to improve the chemical stability of additives within the HDPE matrix, reducing the risk of leaching and environmental contamination.

The regulatory landscape surrounding HDPE additives is evolving, with increasing emphasis on environmental safety and sustainability. Many countries have implemented stricter regulations on the use of certain additives, particularly those with known environmental or health risks. This regulatory pressure is driving innovation in the additive industry, encouraging the development of safer and more environmentally friendly alternatives.

Cost-Benefit Analysis of HDPE Strengthening

The cost-benefit analysis of HDPE strengthening with additives is a crucial consideration for manufacturers and product developers. This analysis encompasses both the financial implications and the performance enhancements achieved through the incorporation of various additives into HDPE products.

From a cost perspective, the addition of strengthening agents to HDPE typically increases the raw material expenses. These additives, such as carbon nanotubes, glass fibers, or mineral fillers, often come at a premium compared to the base HDPE resin. The exact cost increase varies depending on the type and quantity of additive used, but it can range from 5% to 30% or more of the base material cost.

However, the benefits of strengthened HDPE products can often justify the additional expense. Enhanced mechanical properties, including improved tensile strength, impact resistance, and stiffness, allow for the production of thinner-walled parts without compromising performance. This reduction in material usage can partially offset the higher cost of the additive-enhanced resin.

Strengthened HDPE products also tend to have longer lifespans and better durability, which can lead to reduced replacement and maintenance costs for end-users. This improved longevity is particularly valuable in applications such as outdoor furniture, industrial containers, and automotive components, where exposure to harsh environments is common.

In terms of processing, some additives may require adjustments to manufacturing parameters, potentially leading to increased energy consumption or longer cycle times. However, others can improve processability, allowing for faster production speeds or lower processing temperatures, which can result in energy savings and increased output.

The market value of strengthened HDPE products is another important factor to consider. Products with enhanced properties often command higher prices in the marketplace, allowing manufacturers to improve profit margins. This premium pricing can help offset the increased production costs associated with additive incorporation.

When evaluating the overall cost-benefit ratio, it's essential to consider the specific application and market demands. For high-performance applications where strength and durability are critical, the benefits of additive strengthening often outweigh the costs. In contrast, for low-stress applications or disposable items, the additional expense may not be justified.

In conclusion, while the incorporation of strengthening additives into HDPE products does increase upfront costs, the potential for improved performance, reduced material usage, extended product lifespan, and higher market value often results in a favorable cost-benefit ratio. Manufacturers must carefully assess their specific product requirements and target markets to determine the optimal balance between cost and performance enhancements.