How to Strengthen Polymers Using Graphene Oxide?

Graphene Oxide Polymer Reinforcement: Background and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in polymer reinforcement, offering unprecedented opportunities to enhance the mechanical, thermal, and electrical properties of polymers. The journey of GO in polymer science began with the isolation of graphene in 2004, which sparked intense research into its derivatives and applications. As a two-dimensional carbon nanomaterial, GO possesses unique characteristics that make it an ideal candidate for polymer reinforcement.

The primary objective of incorporating GO into polymers is to create composite materials with superior strength, stiffness, and durability. This goal aligns with the growing demand for lightweight yet robust materials in industries such as aerospace, automotive, and construction. By leveraging the exceptional mechanical properties of GO, researchers aim to develop polymers that can withstand higher loads, resist deformation, and exhibit improved longevity.

Another critical objective is to enhance the functional properties of polymers. GO's high surface area and oxygen-containing functional groups offer the potential to improve the thermal stability, electrical conductivity, and barrier properties of polymer composites. These enhancements could lead to the development of advanced materials for applications in electronics, packaging, and energy storage.

The evolution of GO-polymer composites has been driven by advancements in synthesis methods and characterization techniques. Early research focused on simple mixing of GO with polymer matrices, while recent efforts have explored more sophisticated approaches such as in-situ polymerization and chemical functionalization of GO. These developments aim to optimize the interfacial interaction between GO and the polymer matrix, which is crucial for effective reinforcement.

Understanding the fundamental mechanisms of GO-polymer interactions remains a key research focus. Scientists are investigating how factors such as GO concentration, dispersion quality, and surface chemistry influence the overall performance of the composite. This knowledge is essential for tailoring GO-polymer composites to specific applications and for scaling up production processes.

The field of GO-polymer reinforcement is also addressing sustainability concerns. By improving the strength and durability of polymers, GO incorporation can potentially reduce material consumption and extend product lifespans. Additionally, researchers are exploring the use of GO in biodegradable polymers to create environmentally friendly composites with enhanced properties.

As the technology progresses, the objectives extend beyond mere mechanical reinforcement. There is growing interest in developing multifunctional GO-polymer composites that combine strength with other desirable properties such as self-healing capabilities, stimuli-responsiveness, and antimicrobial activity. These advanced materials could open up new possibilities in fields like biomedical engineering and smart textiles.

Market Analysis for Graphene-Enhanced Polymers

The market for graphene-enhanced polymers has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials across various industries. Graphene oxide, a derivative of graphene, has emerged as a promising additive to strengthen polymers, offering exceptional mechanical, thermal, and electrical properties.

The global market for graphene-enhanced polymers is projected to expand rapidly, with applications spanning aerospace, automotive, electronics, and packaging sectors. This growth is fueled by the need for lightweight yet strong materials that can improve fuel efficiency, reduce carbon emissions, and enhance overall product performance.

In the automotive industry, graphene-enhanced polymers are being explored for use in structural components, reducing vehicle weight while maintaining or improving strength. This aligns with the industry's push towards electric vehicles and improved fuel economy. The aerospace sector is also showing keen interest in these materials for similar reasons, with potential applications in aircraft interiors and non-critical structural parts.

The electronics industry represents another significant market for graphene-enhanced polymers. These materials offer improved thermal management and electromagnetic shielding properties, making them ideal for use in smartphones, laptops, and other electronic devices. As the demand for smaller, more powerful electronic devices continues to grow, so does the potential market for graphene-enhanced polymers in this sector.

Packaging is emerging as a promising application area, particularly in the food and beverage industry. Graphene-enhanced polymers can provide improved barrier properties against gases and moisture, potentially extending the shelf life of products and reducing food waste.

However, the market faces challenges, including high production costs and scalability issues. The price of graphene oxide remains a significant barrier to widespread adoption, although ongoing research and development efforts are focused on reducing production costs and improving manufacturing processes.

Regulatory considerations also play a crucial role in market development. As with any new material, safety assessments and environmental impact studies are necessary before widespread commercial adoption can occur. This process can be time-consuming but is essential for ensuring the long-term viability of graphene-enhanced polymers in various applications.

Despite these challenges, the market outlook remains positive. As research progresses and manufacturing techniques improve, the cost of graphene oxide is expected to decrease, potentially opening up new application areas and driving further market growth. The unique properties offered by graphene-enhanced polymers position them as a key material in the development of next-generation products across multiple industries.

Current Challenges in Graphene Oxide-Polymer Composites

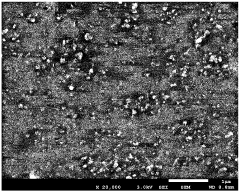

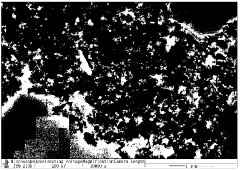

Despite the promising potential of graphene oxide (GO) in polymer reinforcement, several significant challenges persist in the development and application of GO-polymer composites. One of the primary obstacles is achieving uniform dispersion of GO within the polymer matrix. Due to its high surface area and strong van der Waals forces, GO tends to agglomerate, leading to inhomogeneous distribution and reduced reinforcement efficiency. This aggregation not only diminishes the mechanical properties of the composite but also affects its thermal and electrical conductivity.

Another critical challenge lies in the interfacial interaction between GO and the polymer matrix. While GO's oxygen-containing functional groups can potentially enhance compatibility with polymers, achieving strong and stable bonding remains difficult. Weak interfacial adhesion can result in poor stress transfer from the polymer to the GO reinforcement, limiting the overall strength and toughness of the composite.

The scalability of GO-polymer composite production presents a significant hurdle for industrial applications. Current methods for GO synthesis and incorporation into polymers are often limited to laboratory scales, and scaling up these processes while maintaining consistent quality and properties is challenging. This issue is compounded by the high cost of GO production, which can make large-scale applications economically unfeasible.

Controlling the orientation of GO sheets within the polymer matrix is another technical challenge. The alignment of GO platelets can significantly influence the mechanical, thermal, and barrier properties of the composite. However, achieving controlled orientation, especially in complex-shaped products, remains difficult with current processing techniques.

The stability of GO-polymer composites under various environmental conditions is also a concern. GO's tendency to reduce or deoxygenate under certain conditions can lead to changes in its properties over time, potentially affecting the long-term performance and reliability of the composite materials.

Furthermore, the potential toxicity and environmental impact of GO-polymer composites are not fully understood. As these materials gain traction in various applications, addressing safety concerns and developing eco-friendly production and disposal methods become increasingly important.

Lastly, the lack of standardized characterization and testing methods for GO-polymer composites hinders the comparison of results across different studies and the establishment of reliable performance benchmarks. This absence of standardization complicates the assessment of improvements and the development of optimized formulations for specific applications.

Existing Methods for Incorporating Graphene Oxide in Polymers

01 Polymer blends for enhanced strength

Combining different polymers can create blends with improved strength properties. This approach allows for the synergistic effects of multiple polymers, resulting in materials with enhanced mechanical performance. The blending process often involves careful selection of compatible polymers and optimization of their ratios to achieve desired strength characteristics.- Polymer blends for enhanced strength: Combining different polymers can result in materials with improved strength properties. This approach allows for the synergistic effects of multiple polymers, creating composites with enhanced mechanical characteristics. The blending process often involves careful selection of compatible polymers and optimization of their ratios to achieve desired strength outcomes.

- Cross-linking techniques for polymer strengthening: Cross-linking is a method used to increase polymer strength by forming chemical bonds between polymer chains. This process can be achieved through various means, including radiation, heat, or chemical additives. Cross-linking typically results in improved mechanical properties, such as increased tensile strength and resistance to deformation.

- Reinforcement with nanoparticles or fibers: Incorporating nanoparticles or fibers into polymer matrices can significantly enhance their strength. These reinforcing agents can include carbon nanotubes, graphene, glass fibers, or other nanomaterials. The resulting nanocomposites often exhibit improved mechanical properties, including increased tensile strength and impact resistance.

- Molecular weight control for optimized strength: Controlling the molecular weight of polymers during synthesis or processing can lead to improved strength characteristics. Higher molecular weights often correlate with increased strength, but there is typically an optimal range for each polymer type. Techniques such as controlled polymerization or post-processing methods can be used to achieve the desired molecular weight distribution.

- Surface treatments for enhanced interfacial strength: Surface treatments can be applied to polymers to improve their interfacial strength, especially in composite materials or adhesive applications. These treatments may include plasma treatment, chemical etching, or the application of coupling agents. By enhancing the surface properties, the overall strength and adhesion of the polymer in various applications can be improved.

02 Cross-linking techniques for polymer strengthening

Cross-linking is a method used to increase polymer strength by forming chemical bonds between polymer chains. This process can be achieved through various means, such as radiation, heat, or chemical additives. Cross-linking typically results in improved mechanical properties, including increased tensile strength and resistance to deformation.Expand Specific Solutions03 Reinforcement with nanoparticles or fibers

Incorporating nanoparticles or fibers into polymer matrices can significantly enhance their strength. These reinforcing agents can include carbon nanotubes, graphene, glass fibers, or other nanomaterials. The addition of these materials often results in improved mechanical properties, such as increased tensile strength, modulus, and impact resistance.Expand Specific Solutions04 Molecular weight control for optimized strength

Controlling the molecular weight of polymers can have a significant impact on their strength properties. Higher molecular weight polymers often exhibit improved mechanical strength due to increased chain entanglement and intermolecular forces. Techniques for molecular weight control include adjusting polymerization conditions or post-polymerization treatments.Expand Specific Solutions05 Surface modification for enhanced interfacial strength

Modifying the surface of polymers or reinforcing agents can improve interfacial adhesion in composite materials, leading to enhanced overall strength. This can be achieved through various methods such as plasma treatment, chemical functionalization, or the use of coupling agents. Improved interfacial strength results in better load transfer between components and increased mechanical performance.Expand Specific Solutions

Key Players in Graphene Oxide and Polymer Composite Industry

The field of strengthening polymers using graphene oxide is in a rapidly evolving phase, with significant market potential due to the wide-ranging applications in industries such as aerospace, automotive, and electronics. The global market for graphene-enhanced polymers is expanding, driven by the demand for lightweight, high-strength materials. Technologically, the field is progressing from early-stage research to more advanced applications, with varying levels of maturity across different sectors. Key players like Massachusetts Institute of Technology, Zhejiang University, and XG Sciences, Inc. are at the forefront of innovation, developing novel techniques for graphene oxide integration and polymer enhancement. Other institutions such as Rutgers State University and Qingdao University are contributing to the advancement of this technology through collaborative research efforts.

Massachusetts Institute of Technology

XG Sciences, Inc.

Breakthrough Technologies in Graphene Oxide-Polymer Interfaces

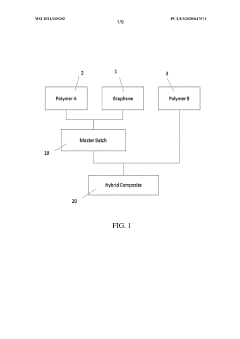

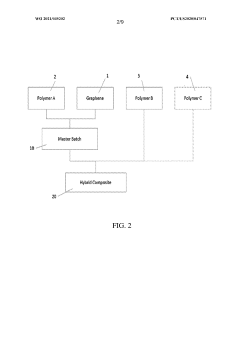

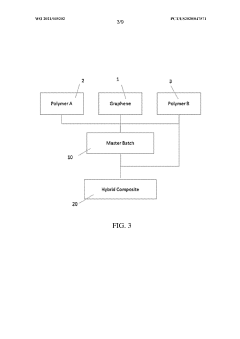

- A process involving direct dispersion or master batch formation of graphene nanoplatelets into multiple polymer resins, followed by let-down ratios, to achieve high homogeneity and improved mechanical, thermal, and electric properties in hybrid composites.

- A graphene supported silica hybrid filler is developed using plant polyphenol-assisted liquid phase peeling to modify graphene, combined with silica chemically modified by silane coupling agents, enhancing electrical and thermal conductivity while reducing costs and environmental impact through improved dispersion and bonding.

Environmental Impact of Graphene Oxide-Enhanced Polymers

The incorporation of graphene oxide into polymers not only enhances their mechanical properties but also raises important environmental considerations. The production process of graphene oxide-enhanced polymers involves chemical treatments that may generate hazardous waste, potentially impacting air and water quality if not properly managed. However, the improved durability and strength of these materials can lead to longer-lasting products, potentially reducing overall waste generation and resource consumption in the long term.

The use of graphene oxide in polymers may contribute to reduced environmental impact through weight reduction in various applications, particularly in the automotive and aerospace industries. Lighter materials translate to improved fuel efficiency and reduced emissions during the use phase of products. Additionally, the enhanced barrier properties of graphene oxide-polymer composites can improve packaging materials, potentially extending the shelf life of food products and reducing food waste.

Recycling and end-of-life management of graphene oxide-enhanced polymers present both challenges and opportunities. The complex nature of these composites may complicate traditional recycling processes, requiring the development of new recycling technologies. However, the improved properties of these materials may also enable more efficient recycling and recovery of valuable components, potentially supporting circular economy principles.

The potential release of graphene oxide nanoparticles into the environment during the lifecycle of products is a concern that requires further investigation. While initial studies suggest limited toxicity, the long-term environmental fate and potential bioaccumulation of these nanoparticles in ecosystems remain areas of ongoing research. Proper risk assessment and management strategies are essential to mitigate any potential negative impacts on biodiversity and ecosystem health.

From a lifecycle perspective, the environmental benefits of graphene oxide-enhanced polymers may outweigh the potential risks, particularly if they lead to significant improvements in energy efficiency, material performance, and product longevity. However, a comprehensive lifecycle assessment is necessary to fully understand the net environmental impact of these materials across their entire lifecycle, from raw material extraction to end-of-life disposal or recycling.

Scalability and Cost Analysis of Graphene Oxide Reinforcement

The scalability and cost analysis of graphene oxide reinforcement in polymers is a critical factor in determining the feasibility of large-scale industrial applications. The production of graphene oxide (GO) has seen significant advancements in recent years, with various methods developed to increase yield and reduce costs. However, challenges remain in scaling up production to meet potential industrial demands.

Current production methods for GO, such as the modified Hummers method, can produce high-quality GO but are limited in scale. Efforts to increase production capacity have focused on optimizing reaction conditions, developing continuous flow processes, and exploring alternative oxidation methods. These improvements have led to a reduction in production costs, but further advancements are necessary to make GO reinforcement economically viable for widespread use in polymer composites.

The cost of GO production remains a significant barrier to large-scale adoption. While the raw material, graphite, is relatively inexpensive, the chemical processes and purification steps required to produce GO contribute substantially to the overall cost. Additionally, the energy-intensive nature of some production methods further impacts economic feasibility. Recent research has explored more environmentally friendly and cost-effective production techniques, such as electrochemical exfoliation and microwave-assisted synthesis, which show promise for reducing both environmental impact and production costs.

Scalability issues also extend to the incorporation of GO into polymer matrices. Achieving uniform dispersion of GO in polymers at industrial scales presents challenges, as agglomeration can occur during processing. Various techniques, including solution mixing, melt blending, and in-situ polymerization, have been investigated to address this issue. Each method has its advantages and limitations in terms of scalability and the resulting composite properties.

The cost-benefit analysis of using GO as a polymer reinforcement must consider not only the production costs but also the potential improvements in material properties. Enhanced mechanical strength, thermal stability, and barrier properties offered by GO reinforcement can lead to reduced material usage, extended product lifetimes, and improved performance in various applications. These benefits may offset the higher initial costs associated with GO incorporation, particularly in high-value or performance-critical applications.

As research progresses and production techniques improve, the scalability and cost-effectiveness of GO reinforcement in polymers are expected to increase. Collaborative efforts between academia and industry are crucial for addressing current limitations and developing innovative solutions. The potential for GO to revolutionize polymer composites remains high, but realizing this potential on an industrial scale will require continued advancements in production methods, processing techniques, and cost reduction strategies.