How to Utilize HDPE for Smart Packaging Solutions?

HDPE Smart Packaging Background and Objectives

High-density polyethylene (HDPE) has been a staple in the packaging industry for decades, valued for its durability, chemical resistance, and versatility. As the packaging sector evolves to meet modern consumer demands and sustainability goals, there is a growing interest in leveraging HDPE for smart packaging solutions. This technological shift aims to transform traditional HDPE packaging into interactive, intelligent systems that can enhance product protection, extend shelf life, and improve user experience.

The concept of smart packaging using HDPE represents a convergence of material science, digital technology, and consumer-centric design. It seeks to address the limitations of conventional packaging by incorporating advanced functionalities such as real-time monitoring, active preservation, and enhanced communication with consumers. This evolution is driven by the increasing need for food safety, waste reduction, and supply chain optimization in a globalized market.

The development of HDPE smart packaging solutions is closely aligned with broader industry trends, including the Internet of Things (IoT), sustainability initiatives, and the demand for enhanced product traceability. By integrating sensors, indicators, and other smart technologies into HDPE packaging, manufacturers aim to create responsive containers that can adapt to environmental conditions, provide valuable data throughout the supply chain, and engage consumers in new ways.

Key objectives in the utilization of HDPE for smart packaging include improving product freshness and safety through active monitoring of internal conditions, reducing food waste by providing accurate expiration information, and enhancing brand engagement through interactive packaging features. Additionally, there is a focus on maintaining the recyclability and eco-friendliness of HDPE while incorporating these smart elements, ensuring that the environmental benefits of the material are not compromised.

The technological landscape for HDPE smart packaging is rapidly evolving, with innovations in printable electronics, nanosensors, and biodegradable smart materials opening new possibilities. Research efforts are concentrated on developing cost-effective methods to integrate these technologies into HDPE packaging at scale, without significantly increasing production costs or compromising the material's inherent properties.

As the field progresses, it faces several challenges, including the need for standardization in smart packaging technologies, concerns about data privacy and security, and the requirement for infrastructure to support the widespread adoption of these intelligent systems. Overcoming these hurdles will be crucial in realizing the full potential of HDPE smart packaging solutions and their impact on the packaging industry as a whole.

Market Analysis for Smart Packaging Solutions

The smart packaging market has been experiencing significant growth in recent years, driven by increasing consumer demand for convenience, sustainability, and enhanced product information. The global smart packaging market is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) exceeding 5% during the forecast period. This growth is attributed to the rising adoption of smart packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods.

High-density polyethylene (HDPE) has emerged as a promising material for smart packaging solutions due to its excellent properties, such as durability, chemical resistance, and recyclability. The market for HDPE-based smart packaging is expected to witness robust growth, particularly in the food and beverage sector, where it can be utilized to extend shelf life and maintain product quality.

Consumer preferences are shifting towards more sustainable and environmentally friendly packaging options, creating opportunities for HDPE-based smart packaging solutions. The recyclability of HDPE aligns well with the growing emphasis on circular economy principles, making it an attractive choice for brands looking to improve their sustainability credentials.

The pharmaceutical industry is another key market segment for HDPE-based smart packaging solutions. With the increasing need for temperature-sensitive drug storage and transportation, HDPE packaging integrated with smart sensors and indicators can provide real-time monitoring and ensure product integrity throughout the supply chain.

E-commerce growth has also contributed to the demand for smart packaging solutions, including those utilizing HDPE. As online shopping continues to expand, there is a growing need for packaging that can withstand the rigors of shipping while providing enhanced security and traceability features.

The Asia-Pacific region is expected to witness the highest growth rate in the smart packaging market, driven by rapid urbanization, increasing disposable incomes, and the expansion of organized retail sectors in countries like China and India. North America and Europe are also significant markets for smart packaging solutions, with established retail and logistics infrastructures supporting the adoption of advanced packaging technologies.

Key market players in the smart packaging industry are investing heavily in research and development to create innovative HDPE-based solutions that incorporate smart features such as NFC tags, QR codes, and temperature sensors. These advancements are expected to drive market growth and open up new applications for HDPE in smart packaging across various industries.

HDPE Smart Packaging: Current State and Challenges

The current state of HDPE smart packaging is characterized by a growing interest in leveraging the material's properties for advanced packaging solutions. HDPE, known for its durability, chemical resistance, and recyclability, is being explored for its potential in creating intelligent packaging systems. However, the integration of smart technologies with HDPE packaging faces several challenges that need to be addressed.

One of the primary challenges is the development of effective sensor integration methods. While HDPE provides an excellent barrier against moisture and chemicals, it can be difficult to incorporate electronic components or sensors directly into the material without compromising its structural integrity or protective properties. Researchers are exploring various techniques, such as embedding sensors during the molding process or developing thin-film sensors that can be applied to the surface of HDPE packaging.

Another significant challenge lies in ensuring the longevity and reliability of smart components in HDPE packaging. The harsh conditions that many packaged products are exposed to, including temperature fluctuations, humidity, and physical stress, can potentially damage or degrade embedded smart technologies. Developing robust and durable smart components that can withstand these conditions while maintaining their functionality is a key area of focus.

The recyclability of HDPE smart packaging presents another hurdle. While HDPE itself is highly recyclable, the addition of electronic components or sensors can complicate the recycling process. Finding ways to easily separate smart components from the HDPE material or developing biodegradable smart technologies that do not interfere with HDPE recycling streams is crucial for maintaining the material's sustainability advantages.

Cost-effectiveness is also a significant challenge in the development of HDPE smart packaging solutions. The integration of smart technologies can substantially increase the overall cost of packaging, potentially limiting its widespread adoption. Balancing the added value of smart features with the increased production costs is essential for market viability.

Lastly, standardization and regulatory compliance pose challenges for HDPE smart packaging. As this technology is relatively new, there is a lack of established standards for the integration of smart components with HDPE packaging. Additionally, ensuring that these smart packaging solutions meet food safety regulations and other industry-specific requirements is crucial for their acceptance and implementation across various sectors.

Existing HDPE Smart Packaging Technologies

01 Composition and manufacturing of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from ethylene monomers. Various methods and compositions are used to manufacture HDPE with specific properties, including the use of catalysts, additives, and different polymerization techniques. These processes aim to enhance the material's strength, durability, and chemical resistance.- Composition and manufacturing of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from ethylene monomers. Its manufacturing process involves various catalysts and polymerization techniques to achieve desired properties such as high density, strength, and chemical resistance. Different compositions and additives can be incorporated to enhance specific characteristics for various applications.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to create composites with improved properties. These blends and composites often exhibit enhanced mechanical strength, thermal stability, or specific functional characteristics. The combination of HDPE with other polymers or additives allows for tailored material properties suitable for diverse applications.

- HDPE recycling and sustainability: Recycling of HDPE is an important aspect of sustainable materials management. Various techniques are employed to process and recycle HDPE products, including mechanical recycling, chemical recycling, and upcycling. These processes aim to reduce environmental impact and promote circular economy principles in plastic usage.

- HDPE applications in packaging and containers: HDPE is widely used in packaging and container applications due to its excellent chemical resistance, durability, and moisture barrier properties. It is commonly employed in the production of bottles, drums, tanks, and various types of packaging materials. The material's versatility allows for the creation of both rigid and flexible packaging solutions.

- HDPE in construction and infrastructure: HDPE finds extensive use in construction and infrastructure projects due to its durability, corrosion resistance, and long service life. It is utilized in applications such as pipes for water and gas distribution, geomembranes for environmental protection, and various construction components. The material's properties make it suitable for both above-ground and underground installations.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to improve its properties or create materials with specific characteristics. These blends and composites can include other polymers, fibers, or inorganic materials, resulting in enhanced mechanical properties, thermal stability, or specific functionalities for various applications.Expand Specific Solutions03 HDPE recycling and sustainability

Recycling processes for HDPE are developed to address environmental concerns and promote sustainability. These methods include mechanical recycling, chemical recycling, and the development of biodegradable or bio-based HDPE alternatives. The focus is on improving the efficiency of recycling processes and the quality of recycled HDPE materials.Expand Specific Solutions04 HDPE applications in packaging and containers

HDPE is widely used in packaging and container applications due to its excellent chemical resistance, durability, and moisture barrier properties. Innovations in this area focus on improving the design, manufacturing processes, and functionality of HDPE packaging solutions, including bottles, containers, and films for various industries.Expand Specific Solutions05 HDPE in construction and infrastructure

HDPE finds applications in construction and infrastructure projects due to its durability, chemical resistance, and flexibility. Innovations in this area include the development of HDPE pipes, geomembranes, and structural components for use in water management systems, landfills, and building materials.Expand Specific Solutions

Key Players in Smart Packaging and HDPE Manufacturing

The smart packaging solutions utilizing HDPE are in a growth phase, with increasing market size driven by demand for sustainable and innovative packaging. The global smart packaging market is projected to expand significantly, with HDPE playing a crucial role due to its versatility and recyclability. Technologically, the field is advancing rapidly, with companies like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and DuPont de Nemours, Inc. leading innovation. These industry giants, along with specialized firms like Inhance Technologies LLC, are developing advanced HDPE formulations and processing techniques to enhance smart packaging capabilities, including improved barrier properties, active packaging features, and integration with IoT technologies.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Smart Packaging Patents and Research

- A method involving fluorination of polyolefin containers using a fluorination gas and a second gas, such as oxygen or a halogen, in a controlled chamber to reduce perfluoroalkyl substances and enhance barrier properties, ensuring minimal extractable components and maintaining the weight of organic formulations over time.

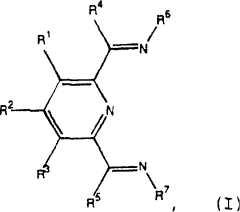

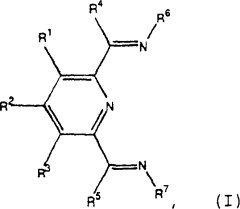

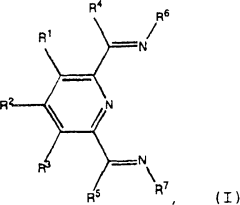

- High-density polyethylene is prepared during the polymerization of ethylene using a catalyst containing an iron or cobalt complex, by polymerizing ethylene in the presence of a polymerization catalyst component, to form HDPE with improved water vapor and lower oxygen transmission rates for replacement Or blend traditional HDPE to reduce the transmittance of packaging.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of utilizing HDPE for smart packaging solutions are crucial aspects that require thorough examination. HDPE, or High-Density Polyethylene, is a versatile plastic material widely used in packaging due to its durability and chemical resistance. However, its widespread use raises significant environmental concerns.

One of the primary environmental challenges associated with HDPE packaging is its persistence in the environment. HDPE is not biodegradable and can take hundreds of years to decompose naturally. This longevity contributes to the accumulation of plastic waste in landfills and oceans, posing threats to wildlife and ecosystems. The production of HDPE also involves the use of fossil fuels, contributing to greenhouse gas emissions and climate change.

Despite these challenges, HDPE offers several sustainability advantages when used in smart packaging solutions. Its durability allows for the creation of reusable packaging, reducing the need for single-use alternatives. HDPE is also highly recyclable, with established recycling infrastructure in many countries. When properly collected and processed, HDPE can be recycled multiple times without significant loss of quality, promoting a circular economy approach.

Smart packaging solutions utilizing HDPE can further enhance sustainability by incorporating technologies that extend product shelf life, reduce food waste, and optimize supply chain efficiency. For instance, HDPE packaging with embedded sensors can monitor product freshness, allowing for more accurate expiration dates and reducing unnecessary disposal. Additionally, smart HDPE packaging can facilitate better inventory management and reduce overproduction, minimizing resource waste.

To address environmental concerns, research and development efforts are focusing on improving the sustainability of HDPE in smart packaging. This includes exploring bio-based alternatives to traditional HDPE, developing advanced recycling technologies, and designing packaging for easier disassembly and recycling. Some companies are also investigating the use of recycled HDPE in smart packaging applications, closing the loop on material use.

The integration of smart technologies with HDPE packaging also presents opportunities for improved waste management. QR codes or RFID tags embedded in HDPE packaging can provide consumers with information on proper disposal methods and nearby recycling facilities. This can increase recycling rates and ensure that HDPE materials are properly sorted and processed at end-of-life.

As the industry moves towards more sustainable practices, life cycle assessments (LCAs) are becoming increasingly important in evaluating the overall environmental impact of HDPE smart packaging solutions. These assessments consider factors such as raw material extraction, manufacturing processes, transportation, use phase, and end-of-life management to provide a comprehensive view of environmental performance.

Regulatory Framework for Smart Packaging Materials

The regulatory framework for smart packaging materials utilizing HDPE (High-Density Polyethylene) is a complex and evolving landscape. As smart packaging solutions continue to advance, regulatory bodies worldwide are adapting their guidelines to ensure consumer safety, environmental protection, and product integrity.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating smart packaging materials. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about new packaging materials, including their composition, intended use, and potential migration of substances into food. For HDPE-based smart packaging, this process involves demonstrating the safety of any additives or sensors incorporated into the material.

The European Union has implemented stringent regulations through the European Food Safety Authority (EFSA) and the European Commission. The EU Regulation No. 1935/2004 sets out general principles for all food contact materials, including smart packaging. Additionally, EU Regulation No. 10/2011 specifically addresses plastic materials and articles intended to come into contact with food. These regulations require extensive testing and documentation to ensure the safety and inertness of smart packaging materials.

Environmental considerations are increasingly shaping the regulatory landscape for smart packaging. The EU's Circular Economy Action Plan and various national initiatives worldwide are pushing for more sustainable packaging solutions. This trend is influencing regulations on recyclability, biodegradability, and overall environmental impact of smart packaging materials, including those based on HDPE.

Standardization efforts are also underway to establish common guidelines for smart packaging. Organizations such as ISO (International Organization for Standardization) and CEN (European Committee for Standardization) are developing standards that address various aspects of smart packaging, including performance, safety, and interoperability. These standards aim to provide a unified framework for manufacturers and regulators alike.

Emerging technologies in smart packaging, such as nanosensors and active packaging systems, are presenting new regulatory challenges. Regulatory bodies are working to develop appropriate guidelines for these innovations, balancing the potential benefits with safety concerns. This includes assessing the long-term effects of nanomaterials and the potential for unintended interactions between active packaging components and food products.

As the field of smart packaging continues to evolve, regulatory frameworks are likely to become more comprehensive and nuanced. Manufacturers and researchers working on HDPE-based smart packaging solutions must stay informed about these regulatory developments and engage proactively with regulatory bodies to ensure compliance and facilitate innovation in this rapidly advancing field.