Improving HDPE Performance in Extreme Weather Conditions

HDPE Weather Challenges

High-density polyethylene (HDPE) is widely used in various applications due to its excellent mechanical properties and chemical resistance. However, when exposed to extreme weather conditions, HDPE can face significant challenges that affect its performance and longevity. These weather-related challenges primarily stem from temperature fluctuations, UV radiation, and moisture exposure.

Temperature variations pose a major challenge for HDPE in extreme weather conditions. In cold environments, HDPE can become brittle and lose its flexibility, increasing the risk of cracking and fracture. Conversely, in high-temperature conditions, HDPE may soften and experience dimensional instability, leading to deformation and reduced structural integrity. These temperature-induced changes can compromise the material's ability to maintain its intended shape and function.

UV radiation from sunlight is another critical factor affecting HDPE performance in outdoor applications. Prolonged exposure to UV rays can cause photo-oxidation, leading to the degradation of the polymer chains. This degradation process results in the loss of mechanical properties, discoloration, and surface embrittlement. Over time, UV-induced degradation can significantly reduce the service life of HDPE products and compromise their structural integrity.

Moisture exposure presents additional challenges for HDPE in extreme weather conditions. Although HDPE is generally considered hydrophobic, prolonged exposure to moisture can lead to water absorption and potential hydrolysis of the polymer. This can result in dimensional changes, reduced mechanical strength, and increased susceptibility to environmental stress cracking. In freeze-thaw cycles, trapped moisture within HDPE structures can expand and contract, potentially causing internal stresses and micro-cracks.

The combination of these weather-related factors can have synergistic effects on HDPE performance. For instance, the simultaneous exposure to UV radiation and high temperatures can accelerate the degradation process, while moisture ingress can exacerbate the effects of temperature fluctuations. These interactions make it challenging to predict and mitigate the long-term performance of HDPE in extreme weather conditions.

To address these challenges, researchers and manufacturers have been exploring various strategies to improve HDPE's weather resistance. These include the development of advanced UV stabilizers, antioxidants, and other additives to enhance the material's resistance to photo-oxidation and thermal degradation. Additionally, efforts are being made to optimize the molecular structure and crystallinity of HDPE to improve its overall weather resistance and mechanical properties under extreme conditions.

Market Demand Analysis

The market demand for High-Density Polyethylene (HDPE) with improved performance in extreme weather conditions has been steadily increasing in recent years. This growth is primarily driven by the expanding applications of HDPE in various industries, particularly those operating in harsh environments.

The construction sector represents a significant portion of this demand, as HDPE is widely used in outdoor applications such as pipes, tanks, and geomembranes. With climate change leading to more frequent extreme weather events, there is a growing need for HDPE products that can withstand severe temperature fluctuations, intense UV radiation, and prolonged exposure to moisture without compromising their structural integrity or performance.

The automotive industry is another key driver of demand for weather-resistant HDPE. As vehicle manufacturers seek to reduce weight and improve fuel efficiency, they are increasingly turning to high-performance plastics like HDPE for both interior and exterior components. However, these materials must be able to maintain their properties in a wide range of environmental conditions, from sub-zero temperatures to scorching heat.

In the agriculture sector, the demand for durable HDPE products is rising due to the need for irrigation systems, greenhouse covers, and storage containers that can withstand harsh outdoor conditions. Farmers and agricultural businesses require materials that can endure prolonged sun exposure, temperature extremes, and chemical exposure without degrading or leaching harmful substances into the soil or water supply.

The packaging industry is also contributing to the market demand for improved HDPE performance. As global supply chains become more complex and products are transported across diverse climate zones, there is an increasing need for packaging materials that can maintain their protective properties regardless of the environmental conditions they encounter.

Market research indicates that the global HDPE market is expected to grow significantly in the coming years, with a substantial portion of this growth attributed to the demand for enhanced weather-resistant properties. Regions with extreme climates, such as the Middle East, Northern Europe, and parts of North America and Asia, are showing particularly strong interest in these advanced HDPE formulations.

The push for sustainability is also influencing market demand. Consumers and regulatory bodies are calling for more durable and long-lasting plastic products to reduce waste and environmental impact. This trend is driving research and development efforts to create HDPE formulations that not only perform better in extreme weather but also have extended lifespans and improved recyclability.

As industries continue to expand into more challenging environments and climate change impacts become more pronounced, the market for HDPE with superior weather resistance is projected to experience robust growth. This presents significant opportunities for manufacturers and researchers to develop innovative solutions that meet these evolving market needs.

Current HDPE Limitations

High-density polyethylene (HDPE) has become a ubiquitous material in various industries due to its versatility and durability. However, when exposed to extreme weather conditions, HDPE exhibits several limitations that hinder its performance and longevity. One of the primary challenges is its susceptibility to thermal expansion and contraction, which can lead to warping, cracking, or dimensional instability in applications subjected to significant temperature fluctuations.

In cold environments, HDPE tends to become brittle and less impact-resistant. This increased brittleness can result in reduced structural integrity and a higher likelihood of failure under stress or impact. Conversely, in high-temperature conditions, HDPE may soften and lose its shape, compromising its load-bearing capacity and overall structural stability.

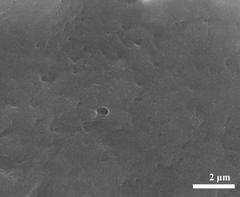

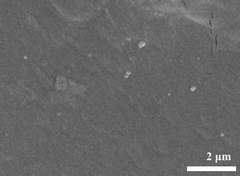

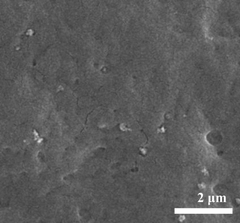

UV radiation presents another significant challenge for HDPE in outdoor applications. Prolonged exposure to sunlight can cause photo-oxidation, leading to degradation of the polymer chains. This degradation manifests as discoloration, loss of mechanical properties, and surface embrittlement, ultimately reducing the material's lifespan and performance.

Moisture absorption is an additional concern for HDPE in extreme weather conditions. Although HDPE is generally considered hydrophobic, it can still absorb small amounts of moisture over time, particularly in high-humidity environments. This absorption can lead to dimensional changes, reduced mechanical properties, and potential degradation of the material's performance.

Chemical resistance, while generally a strength of HDPE, can be compromised in certain extreme weather scenarios. For instance, exposure to acid rain or other corrosive environmental factors may accelerate the degradation of HDPE, particularly in areas with high industrial emissions or coastal regions with salt spray.

The limitations of HDPE in extreme weather conditions also extend to its thermal insulation properties. While HDPE provides some level of insulation, it may not be sufficient in extreme temperature environments, potentially leading to energy inefficiencies in applications such as piping systems or storage containers.

Furthermore, the performance of HDPE in extreme weather conditions can be affected by the presence of additives or fillers used to enhance specific properties. These additives may degrade or leach out over time when exposed to harsh environmental conditions, potentially compromising the material's intended performance characteristics.

Addressing these limitations requires innovative approaches to material science and engineering, focusing on enhancing HDPE's resistance to thermal cycling, UV radiation, and environmental stressors while maintaining its desirable properties such as chemical resistance and processability.

Existing Solutions

01 Improved mechanical properties of HDPE

Various methods are employed to enhance the mechanical properties of HDPE, including tensile strength, impact resistance, and elongation at break. These improvements are achieved through the addition of specific additives, modification of the polymerization process, or blending with other materials.- Improved mechanical properties of HDPE: Various methods are employed to enhance the mechanical properties of HDPE, including tensile strength, impact resistance, and stiffness. These improvements are achieved through techniques such as blending with other polymers, adding reinforcing agents, or modifying the molecular structure of HDPE.

- Enhanced thermal stability and heat resistance: Techniques are developed to improve the thermal stability and heat resistance of HDPE, allowing it to maintain its properties at higher temperatures. This is often achieved through the incorporation of heat stabilizers, antioxidants, or by modifying the polymer structure.

- Improved chemical resistance and barrier properties: Methods are explored to enhance the chemical resistance and barrier properties of HDPE, making it more suitable for applications involving harsh chemicals or requiring improved gas and moisture barrier performance. This can involve surface treatments, blending with other materials, or modifying the polymer structure.

- Enhanced processability and moldability: Techniques are developed to improve the processability and moldability of HDPE, allowing for easier manufacturing and shaping of products. This can involve the use of processing aids, modification of molecular weight distribution, or the development of new grades of HDPE with optimized flow properties.

- Improved environmental performance and recyclability: Methods are explored to enhance the environmental performance of HDPE, including improved recyclability, biodegradability, or the incorporation of recycled content. This can involve the development of new additives, modification of the polymer structure, or the creation of composite materials.

02 Enhanced thermal stability and heat resistance

Techniques are developed to improve the thermal stability and heat resistance of HDPE, allowing it to maintain its properties at higher temperatures. This is particularly important for applications in hot environments or where the material may be exposed to heat during processing or use.Expand Specific Solutions03 Increased chemical resistance

Methods are explored to enhance the chemical resistance of HDPE, making it more suitable for use in harsh chemical environments. This includes resistance to acids, bases, solvents, and other corrosive substances, expanding its potential applications in various industries.Expand Specific Solutions04 Improved processing characteristics

Techniques are developed to enhance the processing characteristics of HDPE, such as melt flow rate and extrusion performance. These improvements allow for easier and more efficient manufacturing of HDPE products, potentially reducing production costs and expanding design possibilities.Expand Specific Solutions05 Environmental sustainability and recycling

Research is conducted on improving the recyclability and environmental sustainability of HDPE. This includes developing methods for more efficient recycling, incorporating recycled content into new products, and exploring bio-based alternatives to traditional HDPE.Expand Specific Solutions

Key Industry Players

The market for improving HDPE performance in extreme weather conditions is in a growth phase, driven by increasing demand for durable materials in challenging environments. The global HDPE market size is projected to expand significantly, with a focus on enhancing weather resistance. Technologically, the field is advancing rapidly, with major players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV leading innovation. These companies, along with others such as Borealis AG and NOVA Chemicals Corp., are investing heavily in R&D to develop advanced HDPE formulations. The competitive landscape is characterized by a mix of established petrochemical giants and specialized materials companies, all vying to create more resilient and versatile HDPE products for extreme weather applications.

Dow Global Technologies LLC

Saudi Basic Industries Corp.

Core HDPE Innovations

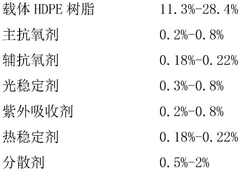

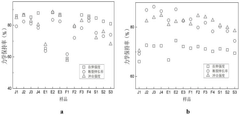

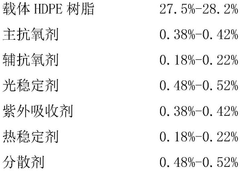

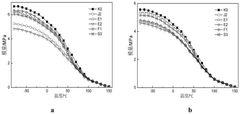

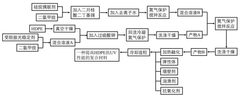

- Use HDPE composite stabilizer, mix it with HDPE base material, and select antioxidant 1076, light stabilizer 2020, UV absorber 326 and heat stabilizer CaSt2/ZnSt2 to form a multifunctional composite stabilizer to improve HDPE Photothermal stability and aging resistance.

- By introducing light stabilizers, silane cross-linking technology and melt blending technology, HDPE materials are modified to improve their UV resistance, mechanical properties, water resistance, flexibility and braidability. Specific methods include chemical grafting to firmly bind the light stabilizer to the HDPE molecular structure, enhancing the mechanical properties and waterproofness of the material through silane cross-linking technology, and improving the flexibility and impact resistance of the material through a melt blending process.

Environmental Impact

The environmental impact of improving HDPE performance in extreme weather conditions is a critical consideration in the development and application of this material. As HDPE is widely used in various industries, including packaging, construction, and automotive, its enhanced performance can lead to both positive and negative environmental consequences.

One of the primary environmental benefits of improving HDPE's performance in extreme weather conditions is the potential for increased durability and longevity of products. This enhanced resilience can result in reduced material consumption and waste generation over time. For instance, HDPE pipes and containers that can withstand harsh weather conditions are less likely to degrade or fail prematurely, thereby reducing the need for frequent replacements and minimizing the overall environmental footprint.

However, the process of enhancing HDPE's performance may involve the use of additional additives or chemical modifications, which could potentially introduce new environmental concerns. These additives might affect the recyclability of the material or introduce harmful substances into the environment during the product's lifecycle. It is crucial to carefully assess the environmental impact of any new formulations or manufacturing processes developed to improve HDPE's weather resistance.

The improved performance of HDPE in extreme weather conditions can also contribute to energy savings and reduced greenhouse gas emissions. For example, in building applications, weather-resistant HDPE materials can enhance insulation properties, leading to improved energy efficiency in heating and cooling systems. Similarly, in automotive applications, lightweight and durable HDPE components can contribute to fuel efficiency and vehicle longevity.

Another environmental consideration is the potential for HDPE with enhanced weather resistance to replace less environmentally friendly materials in certain applications. This substitution could lead to a reduction in the use of materials with higher environmental impacts, such as certain metals or composite materials that require more energy-intensive production processes.

The end-of-life management of improved HDPE products is an important aspect of their environmental impact. While HDPE is generally recyclable, modifications to enhance its weather resistance may affect its recyclability or the quality of recycled material. It is essential to develop recycling processes that can effectively handle these enhanced HDPE products to maintain a closed-loop system and minimize waste.

In conclusion, the environmental impact of improving HDPE performance in extreme weather conditions is multifaceted. While there are potential benefits in terms of product longevity, energy efficiency, and material substitution, careful consideration must be given to the entire lifecycle of the enhanced HDPE products. This includes assessing the environmental implications of new additives or manufacturing processes, as well as ensuring that end-of-life management strategies are in place to maximize recyclability and minimize waste.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of improved HDPE materials for extreme weather conditions. As manufacturers and researchers strive to enhance the performance of HDPE in challenging environments, they must navigate a complex landscape of regulations and standards across various jurisdictions.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are key regulatory bodies overseeing the use of HDPE in different applications. The EPA's regulations focus on environmental impact and safety, particularly in areas such as chemical resistance and potential leaching of substances from HDPE products. The FDA, on the other hand, regulates HDPE used in food contact applications, ensuring that materials meet stringent safety standards even under extreme temperature conditions.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and use of HDPE. This comprehensive framework requires manufacturers to assess and manage the risks associated with chemicals used in HDPE formulations, especially when developing new additives or modifying existing compositions to improve weather resistance.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have established specific guidelines for testing and evaluating HDPE performance. These standards include protocols for assessing thermal stability, UV resistance, and mechanical properties under various environmental conditions. Compliance with these standards is often mandatory for market entry and product certification.

In the context of extreme weather applications, additional regulations may come into play. For instance, building codes in regions prone to hurricanes or extreme cold may specify performance requirements for HDPE materials used in construction or infrastructure. Similarly, automotive industry standards may dictate specific weathering resistance criteria for HDPE components used in vehicles exposed to harsh environments.

As research progresses on improving HDPE performance, regulatory bodies are likely to update their guidelines to address new formulations and technologies. This dynamic regulatory environment necessitates ongoing compliance efforts and close collaboration between researchers, manufacturers, and regulatory agencies. Companies investing in HDPE innovation must stay abreast of evolving regulations and proactively engage with regulatory bodies to ensure their advanced materials meet all necessary requirements.

Moreover, the global nature of HDPE production and distribution requires consideration of international regulatory harmonization efforts. Initiatives aimed at aligning standards across different regions can facilitate the adoption of improved HDPE materials worldwide while ensuring consistent safety and performance benchmarks.