Innovations in HDPE Adhesion Technologies

HDPE Adhesion Challenges

High-density polyethylene (HDPE) is widely used in various industries due to its excellent mechanical properties, chemical resistance, and low cost. However, its inherent non-polar nature and low surface energy pose significant challenges for adhesion applications. These challenges have long been a bottleneck in expanding HDPE's utility in composite materials, coatings, and multi-layer structures.

One of the primary obstacles in HDPE adhesion is its low surface energy, typically ranging from 30 to 32 mN/m. This characteristic makes it difficult for adhesives and coatings to wet and spread on the HDPE surface effectively. Consequently, achieving strong and durable bonds between HDPE and other materials or even itself becomes problematic.

The chemical inertness of HDPE, while beneficial in many applications, further complicates adhesion processes. The lack of reactive functional groups on the HDPE surface limits chemical bonding opportunities with adhesives or other materials. This absence of chemical interaction results in weak interfacial adhesion, often leading to premature failure of bonded structures or coatings.

Surface contamination presents another significant challenge. HDPE's non-polar nature makes it prone to attracting and retaining oils, greases, and other contaminants, which can interfere with adhesion processes. Removing these contaminants effectively without altering the HDPE surface properties is crucial for successful bonding but often proves difficult.

The crystalline structure of HDPE also contributes to adhesion difficulties. The high degree of crystallinity results in a dense, tightly packed polymer structure with minimal free volume. This characteristic not only reduces the surface area available for mechanical interlocking but also limits the diffusion of adhesive molecules into the HDPE substrate, further weakening potential bonding mechanisms.

Temperature sensitivity is another factor that complicates HDPE adhesion. The material's relatively low melting point and tendency to creep under stress can lead to bond failure, especially in applications involving elevated temperatures or sustained loads. This thermal behavior necessitates careful consideration in adhesive selection and joint design.

Lastly, the environmental resistance of HDPE, while generally an advantage, can pose challenges in achieving long-term bond durability. Exposure to UV radiation, moisture, and temperature fluctuations can degrade adhesive bonds over time, particularly at the interface between HDPE and dissimilar materials. Developing adhesion solutions that can withstand these environmental factors without compromising bond strength remains a significant challenge in HDPE adhesion technologies.

Market Demand Analysis

The market demand for innovations in HDPE adhesion technologies has been steadily growing, driven by the increasing use of HDPE in various industries and the need for more efficient and reliable bonding solutions. The global HDPE market is expected to reach significant growth in the coming years, with a substantial portion of this growth attributed to applications requiring advanced adhesion technologies.

In the packaging industry, there is a rising demand for HDPE adhesion solutions that can improve the performance and durability of flexible packaging, bottles, and containers. Manufacturers are seeking adhesives that can withstand harsh environmental conditions, provide excellent chemical resistance, and maintain strong bonds over extended periods. This demand is particularly pronounced in the food and beverage sector, where HDPE packaging is widely used due to its safety and versatility.

The automotive industry represents another significant market for HDPE adhesion technologies. As automakers strive to reduce vehicle weight and improve fuel efficiency, the use of HDPE components in automotive manufacturing has increased. This trend has created a need for adhesives that can effectively bond HDPE to various substrates, including other plastics and metals, while meeting stringent performance and safety requirements.

In the construction sector, HDPE is gaining popularity for applications such as geomembranes, pipes, and insulation materials. The demand for adhesion technologies in this industry focuses on solutions that can provide long-lasting bonds in challenging outdoor environments, resist UV degradation, and maintain structural integrity under varying temperature and moisture conditions.

The medical and healthcare industries are also driving market demand for HDPE adhesion innovations. HDPE is widely used in medical devices, pharmaceutical packaging, and laboratory equipment due to its chemical resistance and biocompatibility. Adhesives for these applications must meet strict regulatory requirements, maintain sterility, and provide reliable bonding performance in critical medical environments.

Environmental concerns and sustainability initiatives are influencing market trends in HDPE adhesion technologies. There is a growing demand for eco-friendly adhesives that can facilitate the recycling of HDPE products and reduce the environmental impact of bonding processes. This trend is particularly evident in the consumer goods and electronics industries, where manufacturers are seeking adhesion solutions that align with their sustainability goals.

The market for HDPE adhesion technologies is also being shaped by advancements in surface treatment techniques. Plasma treatment, corona discharge, and other surface modification methods are gaining traction as ways to improve the adhesion properties of HDPE. This has created opportunities for companies developing complementary adhesion technologies that can work in conjunction with these surface treatments to achieve optimal bonding results.

Current HDPE Bonding Tech

High-density polyethylene (HDPE) bonding technologies have evolved significantly in recent years, addressing the inherent challenges of adhering this non-polar, low surface energy material. Current HDPE bonding techniques can be broadly categorized into mechanical, chemical, and thermal methods, each with its own set of advantages and limitations.

Mechanical bonding methods, such as ultrasonic welding and friction stir welding, have gained prominence due to their efficiency and ability to create strong bonds without the need for adhesives. Ultrasonic welding uses high-frequency vibrations to generate heat at the interface, melting and fusing the HDPE surfaces. This technique is particularly effective for joining thin HDPE components and is widely used in packaging and automotive industries.

Chemical bonding approaches have seen considerable advancements, with the development of specialized adhesives and surface treatments. Plasma treatment has emerged as a highly effective method for increasing the surface energy of HDPE, thereby improving its adhesion properties. This process involves exposing the HDPE surface to ionized gas, which creates reactive sites for better adhesive bonding. Additionally, novel adhesive formulations, such as those based on polyolefin technology, have been engineered specifically for HDPE bonding, offering improved compatibility and bond strength.

Thermal bonding techniques, including hot plate welding and infrared welding, continue to be widely used in HDPE joining applications. These methods rely on heating the HDPE surfaces to their melting point and then pressing them together to form a strong bond upon cooling. Recent innovations in these techniques have focused on improving energy efficiency and precision, with the integration of advanced temperature control systems and automated processes.

A notable trend in current HDPE bonding technology is the growing emphasis on environmentally friendly solutions. This has led to the development of solvent-free adhesives and bonding methods that reduce volatile organic compound (VOC) emissions. Additionally, there is an increasing focus on creating reversible bonding solutions that allow for easier disassembly and recycling of HDPE products at the end of their lifecycle.

The integration of nanotechnology in HDPE bonding has opened up new possibilities for enhancing bond strength and durability. Nanoparticle-reinforced adhesives and nanostructured surface treatments have shown promising results in improving the mechanical properties of HDPE bonds, particularly in high-stress applications.

As industries continue to demand stronger, more durable, and environmentally sustainable bonding solutions for HDPE, research efforts are intensifying in areas such as bio-based adhesives, smart bonding technologies that respond to external stimuli, and hybrid bonding methods that combine multiple techniques for optimal performance. These ongoing developments underscore the dynamic nature of HDPE bonding technology and its critical role in various industrial applications.

Existing Adhesion Methods

01 Surface treatment methods for HDPE adhesion

Various surface treatment methods can be employed to improve the adhesion of HDPE. These include plasma treatment, corona discharge, flame treatment, and chemical etching. These techniques modify the surface properties of HDPE, increasing its surface energy and creating functional groups that enhance adhesion to other materials or coatings.- Surface treatment for improved adhesion: Various surface treatment methods can be applied to HDPE to enhance its adhesion properties. These treatments may include plasma treatment, corona discharge, or chemical etching. Such processes modify the surface of HDPE, increasing its surface energy and creating functional groups that improve bonding with adhesives or other materials.

- Adhesive formulations for HDPE: Specialized adhesive formulations have been developed to improve bonding with HDPE. These may include modified polyolefin adhesives, epoxy-based adhesives, or other polymer blends specifically designed to achieve strong adhesion to HDPE surfaces. The formulations often incorporate compatibilizers or coupling agents to enhance the interaction between the adhesive and the HDPE substrate.

- Composite materials incorporating HDPE: HDPE can be incorporated into composite materials to improve adhesion and overall performance. This may involve blending HDPE with other polymers, adding reinforcing fibers, or creating multilayer structures. The resulting composites often exhibit enhanced adhesion properties while maintaining the desirable characteristics of HDPE.

- Adhesion promoters for HDPE: Specific adhesion promoters or coupling agents can be used to enhance the bonding of HDPE to other materials. These additives are designed to create chemical bridges between the HDPE surface and the adhesive or coating, resulting in improved adhesion strength and durability.

- HDPE surface modification techniques: Various techniques can be employed to modify the surface of HDPE for improved adhesion. These may include grafting of functional groups, UV irradiation, or the application of specialized coatings. Such modifications aim to increase the surface energy and chemical compatibility of HDPE with adhesives or other materials.

02 Adhesive formulations for HDPE bonding

Specialized adhesive formulations can be developed to improve bonding to HDPE surfaces. These may include modified polyolefin adhesives, epoxy-based adhesives, or hybrid adhesive systems. The formulations often incorporate functional groups or additives that enhance compatibility and adhesion with the non-polar HDPE surface.Expand Specific Solutions03 Compatibilizers and coupling agents for HDPE adhesion

Compatibilizers and coupling agents can be used to improve the adhesion between HDPE and other materials. These additives act as intermediaries, creating chemical or physical bonds between the HDPE surface and the adhesive or substrate. Common examples include maleic anhydride-grafted polyolefins and silane coupling agents.Expand Specific Solutions04 Composite materials incorporating HDPE with improved adhesion

Composite materials can be developed that incorporate HDPE while addressing adhesion challenges. These may include multi-layer structures, polymer blends, or reinforced composites. The design of these materials often focuses on improving interfacial adhesion between HDPE and other components through various techniques such as co-extrusion or reactive processing.Expand Specific Solutions05 Testing and characterization methods for HDPE adhesion

Various testing and characterization methods can be employed to evaluate and optimize HDPE adhesion. These may include surface energy measurements, peel strength tests, lap shear tests, and surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) or atomic force microscopy (AFM). These methods help in understanding the adhesion mechanisms and optimizing treatment processes or adhesive formulations.Expand Specific Solutions

Key Industry Players

The HDPE adhesion technology market is in a growth phase, driven by increasing demand for high-performance adhesives in various industries. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with key players like Dow Global Technologies, ExxonMobil Chemical Patents, and SABIC Global Technologies leading innovation. These companies are developing novel adhesion techniques, improving bond strength, and enhancing environmental compatibility. Emerging players such as Borealis AG and Arkema, Inc. are also making significant contributions, particularly in specialized applications. The competitive landscape is characterized by a mix of established petrochemical giants and specialized adhesive manufacturers, with ongoing R&D efforts focused on improving adhesion properties, durability, and sustainability of HDPE-based products.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Core HDPE Bonding Patents

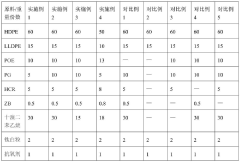

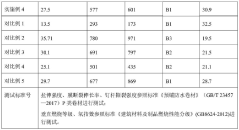

- A single-step manufacturing process using a blend of linear low-density polyethylene (LLDPE) and high-density polyethylene (HDPE) grafted with a functional monomer, along with an elastomer, optimized for specific density and melt flow index ranges, to create an adhesive composition that retains peel strength and resists cathodic disbondment, with LLDPE produced using Ziegler-Natta catalyst systems.

- Flame retardant materials such as antimony trioxide (PG), silicone rubber (HCR), decabromodiphenylethane and zinc borate (ZB) are added to the HDPE system to improve the flame retardant performance through compounding and blending technology, and adopt double The combined process of screw extruder and single-screw extruder is used for production to improve dispersion and production efficiency.

Environmental Impact

The environmental impact of innovations in HDPE adhesion technologies is a critical consideration in the development and implementation of these advancements. As industries strive for more sustainable practices, the environmental footprint of adhesion processes and materials used in HDPE applications has come under increased scrutiny.

One of the primary environmental concerns associated with traditional HDPE adhesion methods is the use of volatile organic compounds (VOCs) in adhesives and surface treatments. These compounds can contribute to air pollution and pose potential health risks to workers and surrounding communities. Recent innovations have focused on developing low-VOC and VOC-free adhesive systems, significantly reducing emissions and improving air quality in manufacturing environments.

Water-based adhesive technologies have emerged as a promising alternative to solvent-based systems, offering reduced environmental impact without compromising adhesion performance. These aqueous formulations minimize the release of harmful chemicals and reduce the overall carbon footprint of the adhesion process. Additionally, advancements in UV-curable adhesives for HDPE applications have led to faster curing times and lower energy consumption, further contributing to environmental sustainability.

The recyclability of HDPE products bonded with adhesives has been a longstanding challenge. However, recent innovations have focused on developing adhesives that are compatible with HDPE recycling processes. These new formulations allow for easier separation of adhesives from HDPE substrates during recycling, improving the overall recyclability of HDPE products and reducing waste sent to landfills.

Biobased adhesives derived from renewable resources have gained traction in HDPE adhesion applications. These eco-friendly alternatives reduce dependence on petroleum-based raw materials and offer a more sustainable solution. Research into adhesives made from plant-based polymers and natural resins has shown promising results in terms of both performance and environmental impact.

Innovations in surface treatment technologies for HDPE adhesion have also contributed to reduced environmental impact. Plasma treatment and corona discharge methods have been refined to consume less energy and produce fewer byproducts compared to traditional chemical etching processes. These advancements not only improve adhesion but also minimize the use of hazardous chemicals and reduce waste generation.

The development of more durable and long-lasting adhesive bonds for HDPE has indirect environmental benefits. By extending the lifespan of HDPE products and reducing the frequency of repairs or replacements, these innovations help conserve resources and minimize waste generation over time. This approach aligns with the principles of a circular economy and supports sustainable product design.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of innovations in HDPE adhesion technologies. As these technologies continue to evolve, manufacturers and researchers must navigate a complex landscape of regulations to ensure their products meet safety, environmental, and performance standards.

In the United States, the Food and Drug Administration (FDA) regulates adhesives used in food packaging applications, including those involving HDPE. Manufacturers must comply with FDA regulations 21 CFR 175.105 and 21 CFR 177.1520, which outline the requirements for adhesives and polyethylene materials in food contact applications. These regulations specify permissible ingredients, migration limits, and testing protocols to ensure the safety of food packaging materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which impacts the use of chemicals in adhesives and HDPE products. Manufacturers must register substances used in their adhesive formulations and comply with restrictions on certain hazardous substances. Additionally, the EU's Food Contact Materials Regulation (EC) No 1935/2004 sets forth requirements for materials intended to come into contact with food, including adhesives used in HDPE packaging.

Environmental regulations also play a significant role in shaping HDPE adhesion technologies. Many countries have implemented regulations to promote the recyclability and sustainability of plastic products. For instance, the EU's Circular Economy Action Plan aims to make all plastic packaging recyclable or reusable by 2030. This has led to increased focus on developing adhesives that are compatible with HDPE recycling processes and do not hinder the material's recyclability.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, impact the handling and application of adhesives in industrial settings. Manufacturers must provide appropriate safety measures and personal protective equipment for workers handling adhesives, as well as ensure proper ventilation and storage of adhesive materials.

As the global focus on sustainability intensifies, regulations surrounding the use of volatile organic compounds (VOCs) in adhesives have become more stringent. Many regions have implemented limits on VOC emissions from adhesives, driving innovation towards low-VOC and water-based adhesive formulations for HDPE applications.

Compliance with these regulations requires ongoing monitoring and adaptation of HDPE adhesion technologies. Manufacturers must invest in research and development to create adhesive solutions that not only meet performance requirements but also adhere to evolving regulatory standards. This regulatory landscape continues to shape the direction of innovation in HDPE adhesion technologies, encouraging the development of safer, more environmentally friendly, and sustainable adhesive solutions.