High Density Polyethylene: Key Developments in Material Science

HDPE Evolution and Objectives

High Density Polyethylene (HDPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a more durable and versatile alternative to low-density polyethylene, HDPE has become a cornerstone material in various industries due to its exceptional properties. The journey of HDPE began with Karl Ziegler's groundbreaking work on catalysts, which enabled the production of high molecular weight polyethylene with improved mechanical properties.

Over the decades, continuous advancements in catalyst technology and polymerization processes have led to the development of HDPE grades with enhanced performance characteristics. These improvements have expanded HDPE's applications across sectors such as packaging, construction, automotive, and healthcare. The material's evolution has been driven by the increasing demand for lightweight, durable, and environmentally friendly materials.

Recent developments in material science have focused on addressing the limitations of traditional HDPE, such as improving its barrier properties, enhancing its recyclability, and increasing its resistance to environmental stress cracking. Researchers have explored various strategies, including the incorporation of nanofillers, the development of multi-layer structures, and the modification of molecular architecture to achieve these objectives.

The current objectives in HDPE research and development are multifaceted. One primary goal is to further improve the material's sustainability profile by enhancing its recyclability and exploring bio-based alternatives. Another key objective is to develop HDPE grades with superior mechanical properties, allowing for the production of thinner, lighter products without compromising strength or durability.

Additionally, there is a growing focus on tailoring HDPE for specific high-performance applications. This includes developing grades with improved chemical resistance for industrial containers, enhanced impact strength for automotive components, and better processability for complex molded parts. The integration of smart technologies, such as incorporating sensors or conductive properties into HDPE, is also an emerging area of research.

Looking ahead, the evolution of HDPE is expected to continue with a strong emphasis on sustainability and advanced functionalities. The development of fully recyclable HDPE products, the reduction of energy consumption in production processes, and the creation of HDPE composites with novel properties are among the key objectives driving research in this field. As material science advances, HDPE is poised to maintain its position as a versatile and indispensable material, adapting to meet the changing needs of industries and consumers alike.

Market Demand Analysis for Advanced HDPE

The market demand for advanced High-Density Polyethylene (HDPE) has been steadily increasing due to its versatile properties and wide range of applications across various industries. HDPE's excellent strength-to-density ratio, chemical resistance, and durability make it a preferred choice in packaging, construction, automotive, and healthcare sectors.

In the packaging industry, there is a growing demand for sustainable and recyclable materials. Advanced HDPE formulations that offer improved barrier properties and recyclability are gaining traction. The food and beverage sector, in particular, is driving the demand for HDPE packaging solutions that extend shelf life and maintain product integrity.

The construction industry is another significant driver of HDPE demand. The material's resistance to corrosion and chemicals makes it ideal for pipes, fittings, and geomembranes. As urbanization continues and infrastructure projects expand globally, the demand for HDPE in construction applications is expected to rise.

In the automotive sector, the push for lightweight materials to improve fuel efficiency and reduce emissions has led to increased adoption of advanced HDPE components. From fuel tanks to interior parts, HDPE's ability to replace heavier materials while maintaining strength and durability is highly valued.

The healthcare industry is also contributing to the market demand for advanced HDPE. The material's biocompatibility and resistance to sterilization processes make it suitable for medical devices, pharmaceutical packaging, and laboratory equipment. As healthcare needs grow worldwide, so does the demand for HDPE in this sector.

Environmental concerns and regulatory pressures are shaping the market demand for advanced HDPE. There is a growing emphasis on developing HDPE grades with improved recyclability and incorporating recycled content. This trend is driven by both consumer preferences for eco-friendly products and government regulations aimed at reducing plastic waste.

The global HDPE market is expected to experience steady growth in the coming years. Emerging economies in Asia-Pacific and Latin America are projected to be key growth drivers, fueled by rapid industrialization, urbanization, and increasing consumer spending power. These regions present significant opportunities for advanced HDPE applications across various sectors.

Innovation in HDPE technology is also influencing market demand. Developments in catalyst systems and polymerization processes are enabling the production of HDPE with enhanced properties, such as higher impact strength, improved processability, and better environmental stress crack resistance. These advancements are opening up new application areas and driving demand for specialized HDPE grades.

Current HDPE Limitations and Challenges

High Density Polyethylene (HDPE) has been a cornerstone material in various industries for decades, yet it faces several limitations and challenges that hinder its further advancement and application. One of the primary constraints is its relatively low strength-to-weight ratio compared to other engineering plastics. This limitation restricts HDPE's use in high-performance applications where both strength and lightweight properties are crucial.

Another significant challenge lies in HDPE's limited temperature resistance. The material tends to soften and lose its structural integrity at elevated temperatures, typically above 80°C. This thermal sensitivity narrows its applicability in environments exposed to high heat or in products that require sterilization at high temperatures.

HDPE also exhibits poor resistance to certain chemicals and solvents, particularly hydrocarbons. This susceptibility to chemical degradation limits its use in specific industrial applications and storage solutions where chemical resistance is paramount. Additionally, the material's low surface energy results in poor adhesion properties, making it difficult to bond, print on, or coat without specialized surface treatments.

The environmental impact of HDPE presents another pressing challenge. While the material is recyclable, the recycling process often results in downcycling, where the recycled product has inferior properties compared to the original. This degradation in quality limits the number of recycling cycles and the range of applications for recycled HDPE.

From a processing standpoint, HDPE exhibits high shrinkage rates during cooling, which can lead to warping and dimensional instability in manufactured parts. This characteristic complicates the production of precision components and large-scale items, often requiring additional post-processing steps or specialized mold designs.

The material's inherent opacity and limited color options pose challenges in applications where transparency or vibrant aesthetics are desired. While additives can improve these properties to some extent, they often come at the cost of altering other desirable characteristics of HDPE.

Lastly, the growing demand for sustainable and bio-based materials puts pressure on traditional petroleum-derived HDPE. The industry faces the challenge of developing bio-based alternatives that can match or exceed the performance of conventional HDPE while reducing environmental impact and dependency on fossil resources.

Current HDPE Enhancement Techniques

01 Density range of high-density polyethylene

High-density polyethylene (HDPE) typically has a density range of 0.941-0.965 g/cm³. This higher density compared to other polyethylene types results from its linear molecular structure with minimal branching, leading to stronger intermolecular forces and increased crystallinity.- Density range of high-density polyethylene: High-density polyethylene (HDPE) typically has a density range of 0.941-0.965 g/cm³. This higher density compared to other polyethylene types results from its linear molecular structure with minimal branching, leading to stronger intermolecular forces and increased crystallinity.

- Factors affecting HDPE density: The density of HDPE can be influenced by various factors, including molecular weight, degree of branching, and processing conditions. Higher molecular weight and less branching generally result in higher density. Processing parameters such as cooling rate and pressure during polymerization can also impact the final density of the material.

- Density modification techniques: Techniques to modify HDPE density include copolymerization with alpha-olefins, incorporation of nucleating agents, and controlled thermal treatment. These methods can fine-tune the density to achieve specific material properties for various applications, balancing factors such as stiffness, impact strength, and chemical resistance.

- Relationship between density and properties: The density of HDPE directly correlates with its mechanical and physical properties. Higher density typically results in increased stiffness, tensile strength, and chemical resistance, but may reduce impact strength and stress crack resistance. Understanding this relationship is crucial for tailoring HDPE to specific end-use requirements.

- Measurement and characterization of HDPE density: Accurate measurement and characterization of HDPE density are essential for quality control and material specification. Common methods include density gradient column, pycnometry, and flotation techniques. Advanced characterization may involve differential scanning calorimetry (DSC) to analyze crystallinity, which is closely related to density.

02 Methods for increasing HDPE density

Various techniques can be employed to increase the density of HDPE, including using specific catalysts, controlling polymerization conditions, and incorporating certain additives. These methods aim to enhance the polymer's crystallinity and reduce chain branching, resulting in higher density materials.Expand Specific Solutions03 Impact of density on HDPE properties

The density of HDPE significantly influences its mechanical, thermal, and barrier properties. Higher density generally correlates with increased stiffness, tensile strength, and chemical resistance, but may reduce impact strength and processability. Understanding these relationships is crucial for tailoring HDPE to specific applications.Expand Specific Solutions04 Blending and copolymerization for density control

Blending HDPE with other polyethylene grades or copolymerizing ethylene with small amounts of α-olefins allows for fine-tuning of the polymer's density. This approach enables the production of materials with customized properties, balancing density-related characteristics with other desired attributes.Expand Specific Solutions05 Measurement and characterization of HDPE density

Accurate measurement and characterization of HDPE density are essential for quality control and material specification. Various techniques, including density gradient columns, pycnometry, and flotation methods, are used to determine the density of HDPE samples precisely. These measurements are critical for ensuring consistency in production and application performance.Expand Specific Solutions

Key Players in HDPE Innovation

The field of high-density polyethylene (HDPE) material science is in a mature yet evolving stage, with ongoing innovations driving market growth. The global HDPE market size is substantial, projected to reach $84.79 billion by 2023, with a CAGR of 4.5%. Technologically, the industry is advanced, with major players like Dow Global Technologies, ExxonMobil Chemical Patents, and SABIC Global Technologies leading research efforts. These companies, along with others such as Univation Technologies and China Petroleum & Chemical Corp., are focusing on enhancing HDPE properties, developing new catalysts, and improving processing techniques. The competitive landscape is characterized by intense R&D activities, with a focus on sustainability and performance optimization, reflecting the industry's maturity and ongoing technological advancements.

Dow Global Technologies LLC

China Petroleum & Chemical Corp.

Breakthrough HDPE Technologies

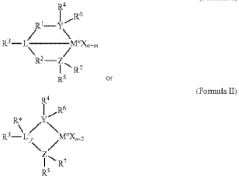

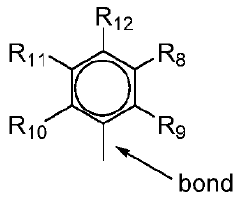

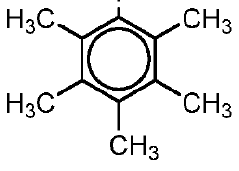

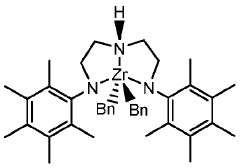

- Development of a bimodal ethylene-based polymer with a higher molecular weight component and a lower molecular weight component, characterized by a density greater than or equal to 0.949 g/cm3, a specific Mw/Mn ratio, and a bimodal weight average molecular weight distribution, achieved through copolymerization of ethylene and alpha-olefins using a metallocene catalyst system comprising bis(2-pentamethylphenylamido)ethyl)zirconium dibenzyl and other specific catalyst compounds.

- A single-site catalysed multimodal HDPE is produced with a density range of 952 to 970 kg/m³ by controlling bimodality, comprising two fractions: a lower molecular weight ethylene copolymer and a higher molecular weight ethylene homopolymer, using a multistage polymerisation process with specific catalysts and conditions.

Environmental Impact of HDPE Advancements

The advancements in High Density Polyethylene (HDPE) technology have brought significant environmental implications, both positive and negative. One of the most notable positive impacts is the improved durability and longevity of HDPE products. This increased lifespan reduces the frequency of replacement, ultimately decreasing waste generation and resource consumption.

Recent developments in HDPE material science have also led to enhanced recyclability. Improved sorting and processing techniques have made it easier to recycle HDPE products, reducing the amount of plastic waste that ends up in landfills or oceans. Additionally, advancements in chemical recycling methods have opened up new possibilities for converting HDPE waste back into its original monomers, allowing for true circular economy solutions.

However, the environmental impact of HDPE production remains a concern. While more efficient manufacturing processes have reduced energy consumption and emissions, the production of HDPE still relies heavily on fossil fuel feedstocks. This dependency contributes to greenhouse gas emissions and resource depletion. Efforts to develop bio-based alternatives and incorporate recycled content into HDPE production are ongoing but face challenges in terms of cost-effectiveness and performance.

The lightweight nature of HDPE has led to its increased use in packaging and transportation applications, potentially reducing fuel consumption and associated emissions. However, this benefit is offset by the persistence of HDPE in the environment when improperly disposed of, contributing to plastic pollution in terrestrial and marine ecosystems.

Advancements in HDPE additives and composites have improved the material's resistance to degradation, which can be both beneficial and problematic from an environmental perspective. While this characteristic extends product life, it also means that HDPE products persist longer in the environment if not properly managed at the end of their lifecycle.

The development of biodegradable and compostable HDPE alternatives is an area of active research, aiming to address the issue of plastic persistence. However, these materials often require specific conditions to degrade effectively, which are not always present in natural environments or standard waste management facilities.

In conclusion, while advancements in HDPE material science have brought about some environmental benefits, particularly in terms of durability and recyclability, significant challenges remain. The industry continues to work towards more sustainable solutions, balancing performance requirements with environmental considerations in the ongoing evolution of HDPE technology.

HDPE Recycling and Circular Economy

The recycling of High Density Polyethylene (HDPE) and its integration into the circular economy represent significant advancements in material science. HDPE, known for its durability and versatility, has become a focal point in sustainable materials management due to its widespread use in packaging, construction, and consumer goods.

Recent developments in HDPE recycling technologies have greatly improved the quality and efficiency of the recycling process. Advanced sorting techniques, such as near-infrared spectroscopy and artificial intelligence-driven systems, have enhanced the purity of recycled HDPE streams. This has led to higher-quality recycled materials that can be used in a broader range of applications, including food-grade packaging.

Chemical recycling methods, particularly solvent-based techniques and catalytic cracking, have emerged as promising approaches to tackle contaminated or mixed plastic waste streams. These processes break down HDPE into its molecular components, allowing for the production of virgin-quality recycled material. This breakthrough addresses one of the major challenges in mechanical recycling: the degradation of material properties over multiple recycling cycles.

The circular economy concept has driven innovation in HDPE product design. Manufacturers are now focusing on creating easily recyclable HDPE products by minimizing the use of additives, pigments, and multi-material components. This design-for-recycling approach ensures that HDPE products can be more effectively reintegrated into the production cycle at the end of their useful life.

Collaborative efforts between industry stakeholders have led to the development of closed-loop recycling systems for HDPE. These systems aim to create a continuous cycle where HDPE products are collected, recycled, and remanufactured into new products without loss of quality. Such initiatives not only reduce the demand for virgin HDPE but also minimize waste and environmental impact.

The integration of HDPE recycling into the circular economy has spurred research into bio-based and biodegradable alternatives. While these materials are not direct replacements for HDPE in all applications, they offer complementary solutions in specific use cases, further supporting the transition to a more sustainable materials economy.

As the circular economy for HDPE continues to evolve, challenges remain in scaling up recycling infrastructure, improving collection rates, and addressing the variability in recycled material quality. However, ongoing research and development in material science are paving the way for more efficient and effective HDPE recycling processes, bringing us closer to a truly circular economy for this ubiquitous plastic material.