High Density Polyethylene for Eco-Friendly Product Design

HDPE Evolution and Objectives

High Density Polyethylene (HDPE) has undergone significant evolution since its discovery in the 1950s. Initially developed as a durable, low-cost plastic, HDPE has transformed into a versatile material with numerous applications across various industries. The journey of HDPE began with its use in simple household items and packaging, gradually expanding to more complex and demanding applications such as automotive parts, construction materials, and medical devices.

The evolution of HDPE has been driven by continuous improvements in polymerization techniques and catalyst technologies. Early production methods yielded HDPE with limited molecular weight distribution and relatively poor mechanical properties. However, advancements in catalyst systems, particularly the development of Ziegler-Natta and metallocene catalysts, have enabled the production of HDPE with tailored properties, including enhanced strength, durability, and processability.

In recent years, the focus of HDPE evolution has shifted towards sustainability and eco-friendliness. This shift aligns with growing global concerns about plastic pollution and the need for more environmentally responsible materials. Researchers and manufacturers are now exploring ways to make HDPE more recyclable, biodegradable, and less harmful to the environment throughout its lifecycle.

The primary objectives of current research on HDPE for eco-friendly product design are multifaceted. Firstly, there is a strong emphasis on improving the recyclability of HDPE products. This involves developing new grades of HDPE that maintain their properties even after multiple recycling cycles, as well as designing products that are easier to disassemble and recycle.

Secondly, researchers are working on incorporating bio-based content into HDPE to reduce its carbon footprint. This includes exploring the use of renewable feedstocks and developing hybrid materials that combine HDPE with natural fibers or biodegradable polymers.

Another key objective is to enhance the durability and longevity of HDPE products, thereby reducing the need for frequent replacements and minimizing waste generation. This involves improving the material's resistance to environmental factors such as UV radiation, temperature fluctuations, and chemical exposure.

Furthermore, there is a growing focus on developing HDPE formulations that are free from harmful additives and plasticizers, making the material safer for both consumers and the environment. This aligns with the broader trend of creating "greener" plastics that have minimal impact on ecosystems and human health.

Lastly, researchers are exploring innovative manufacturing processes for HDPE that consume less energy and produce fewer emissions. This includes advancements in extrusion and molding technologies, as well as the integration of renewable energy sources in HDPE production facilities.

Eco-Friendly HDPE Market Analysis

The market for eco-friendly High-Density Polyethylene (HDPE) products has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. This surge in demand is reshaping the HDPE industry, pushing manufacturers to innovate and adapt their production processes to meet sustainability goals.

Consumer preferences have shifted towards environmentally responsible products, creating a robust market for eco-friendly HDPE alternatives. This trend is particularly evident in packaging, where HDPE is widely used. Major retailers and consumer goods companies are committing to sustainable packaging goals, further fueling the demand for eco-friendly HDPE solutions.

The construction industry has also emerged as a key driver for eco-friendly HDPE products. HDPE's durability, chemical resistance, and recyclability make it an attractive material for sustainable building practices. The growing emphasis on green building certifications, such as LEED, has increased the adoption of eco-friendly HDPE products in construction projects.

In the automotive sector, the push for lightweight materials to improve fuel efficiency has created opportunities for eco-friendly HDPE components. Manufacturers are exploring bio-based HDPE and recycled HDPE options to reduce the carbon footprint of vehicles while maintaining performance standards.

The global market for eco-friendly HDPE is projected to grow steadily over the next decade. This growth is supported by technological advancements in recycling processes, which are improving the quality and availability of recycled HDPE. Additionally, innovations in bio-based HDPE production are expanding the range of sustainable options available to manufacturers.

Geographically, Europe leads in the adoption of eco-friendly HDPE products, driven by strict environmental regulations and consumer awareness. North America follows closely, with rapid growth observed in the Asia-Pacific region, particularly in countries like China and India, where environmental concerns are gaining prominence.

The competitive landscape of the eco-friendly HDPE market is characterized by a mix of established petrochemical companies and innovative startups. Major players are investing heavily in research and development to create more sustainable HDPE formulations and improve recycling technologies. Collaborations between material scientists, manufacturers, and end-users are accelerating the development of novel eco-friendly HDPE applications.

Despite the positive market outlook, challenges remain. The higher cost of eco-friendly HDPE compared to conventional HDPE is a significant barrier to widespread adoption. However, as production scales up and technologies improve, this cost gap is expected to narrow. Additionally, the need for consistent quality in recycled HDPE and the development of efficient collection and sorting systems are areas requiring further investment and innovation.

HDPE Challenges in Sustainability

High Density Polyethylene (HDPE) faces several challenges in sustainability, primarily due to its widespread use and the environmental concerns associated with plastic materials. One of the main issues is the persistence of HDPE in the environment, as it can take hundreds of years to decompose naturally. This longevity contributes to the accumulation of plastic waste in landfills and oceans, leading to pollution and harm to wildlife.

Another significant challenge is the energy-intensive production process of HDPE, which relies heavily on fossil fuels. The extraction and processing of these non-renewable resources contribute to greenhouse gas emissions and climate change. Additionally, the production of HDPE generates various pollutants and by-products that can have negative impacts on air and water quality if not properly managed.

Recycling HDPE presents its own set of challenges. While HDPE is technically recyclable, the efficiency and effectiveness of recycling processes are often limited by contamination, mixed plastic types, and the degradation of material quality through multiple recycling cycles. The lack of widespread and standardized recycling infrastructure further complicates the sustainable management of HDPE waste.

The use of additives and colorants in HDPE products also poses sustainability concerns. These additives can make recycling more difficult and may leach harmful chemicals into the environment over time. Furthermore, the lightweight nature of HDPE, while beneficial for transportation and energy efficiency, can lead to increased littering and dispersal in the environment.

Efforts to improve the sustainability of HDPE face economic challenges as well. The relatively low cost of virgin HDPE production often makes recycled HDPE less economically competitive, discouraging investment in recycling technologies and infrastructure. This economic barrier hinders the transition to a more circular economy for HDPE products.

Addressing these sustainability challenges requires a multifaceted approach. This includes improving recycling technologies and infrastructure, developing bio-based alternatives, enhancing product design for easier recycling, and implementing more effective waste management policies. Additionally, there is a growing need for consumer education and behavior change to promote responsible use and disposal of HDPE products.

Current Eco-HDPE Solutions

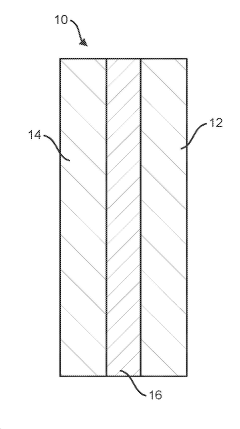

01 Manufacturing processes for HDPE

Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance.- Manufacturing processes for HDPE: Various manufacturing processes are used to produce high-density polyethylene (HDPE), including different polymerization techniques and reactor designs. These processes aim to control the molecular weight, density, and other properties of the resulting HDPE to suit specific applications.

- HDPE blends and composites: HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as strength, durability, and processability, making the resulting materials suitable for a wide range of applications in various industries.

- HDPE applications in packaging: HDPE is widely used in packaging applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly employed in the production of bottles, containers, and films for various products, including food, beverages, and household items.

- Recycling and sustainability of HDPE: Recycling processes and technologies for HDPE are being developed and improved to address environmental concerns and promote sustainability. These efforts focus on efficient collection, sorting, and reprocessing of HDPE waste to create new products or raw materials for various applications.

- HDPE modifications for enhanced properties: Various modification techniques are employed to enhance the properties of HDPE, such as crosslinking, grafting, and the addition of additives. These modifications can improve characteristics like impact strength, thermal stability, and UV resistance, expanding the range of applications for HDPE materials.

02 HDPE blends and composites

HDPE is often blended with other materials or additives to enhance its properties or create composites. These blends can improve characteristics such as impact resistance, thermal stability, or processability, making the resulting material suitable for a wider range of applications.Expand Specific Solutions03 HDPE applications in packaging and containers

HDPE is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used in the production of bottles, containers, and packaging materials for various industries, including food, beverage, and personal care products.Expand Specific Solutions04 Recycling and sustainability of HDPE

Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include improved recycling techniques, the use of recycled HDPE in new products, and the development of more environmentally friendly production methods.Expand Specific Solutions05 HDPE modifications for specific properties

HDPE can be modified through various techniques to enhance specific properties or tailor it for particular applications. These modifications may include crosslinking, the addition of specific additives, or surface treatments to improve characteristics such as wear resistance, electrical properties, or adhesion.Expand Specific Solutions

Key HDPE Industry Players

The research on High Density Polyethylene (HDPE) for eco-friendly product design is in a mature stage, with a growing market driven by sustainability trends. The global HDPE market is substantial, expected to reach $84.79 billion by 2023. Technologically, HDPE is well-established, but innovation continues in eco-friendly applications. Major players like Dow Global Technologies, ExxonMobil, and SABIC are leading research efforts, while companies such as Total Research Corp and Univation Technologies are focusing on advanced catalysts and process improvements. Chinese firms like Sinopec and emerging players from South Korea and Japan are also making significant contributions, indicating a competitive and globally diverse landscape in HDPE eco-friendly innovations.

Dow Global Technologies LLC

Univation Technologies LLC

Innovative HDPE Formulations

- Production of high-density polyethylene polymers using bio-based ethylene monomers derived from carbon-negative or carbon-neutral sources, such as biogas, biomass, and other sustainable resources, through processes like thermal decomposition, partial oxidation, and fermentation, ensuring high molecular weights and purity levels.

- Producing high density polyethylene polymers using bio-based ethylene monomers derived from carbon negative or carbon neutral sources, such as biomass, biogas, and vegetable oils, which are converted into ethylene through various processes like pyrolysis, hydrogenation, or fermentation, allowing for a significant reduction in carbon emissions while maintaining high molecular weights and purity levels.

HDPE Lifecycle Assessment

The lifecycle assessment of High Density Polyethylene (HDPE) is crucial for understanding its environmental impact and potential for eco-friendly product design. HDPE's lifecycle begins with the extraction of raw materials, primarily natural gas and petroleum. These fossil fuels undergo a series of refining and processing steps to produce ethylene, which is then polymerized to form HDPE.

During the production phase, HDPE manufacturing consumes significant energy and resources. However, advancements in production technologies have led to more efficient processes, reducing energy consumption and emissions. The use of catalysts and optimized reactor designs has improved yield and reduced waste generation.

The use phase of HDPE products is characterized by their durability and versatility. HDPE's resistance to chemicals, impact, and weathering contributes to its long lifespan in various applications. This longevity can be both an advantage and a challenge from an environmental perspective, as it reduces the need for frequent replacements but also leads to persistent plastic waste if not properly managed.

End-of-life considerations for HDPE are particularly important in the context of eco-friendly design. HDPE is highly recyclable, with established recycling streams in many countries. The recycling process involves collection, sorting, cleaning, shredding, and reprocessing into new products. However, the efficiency of HDPE recycling is often hampered by contamination and the mixing of different plastic types.

Recent innovations in HDPE recycling include advanced sorting technologies using near-infrared spectroscopy and artificial intelligence, which improve the purity of recycled HDPE. Additionally, chemical recycling methods are being developed to break down HDPE into its chemical components, allowing for the production of virgin-quality recycled material.

The environmental impact of HDPE throughout its lifecycle varies depending on factors such as production methods, transportation distances, and end-of-life management. Life Cycle Assessment (LCA) studies have shown that HDPE generally has a lower carbon footprint compared to some alternative materials, particularly when recycled content is incorporated or when the product is designed for multiple use cycles.

To enhance the eco-friendliness of HDPE products, designers are focusing on several key areas: increasing the use of recycled content, improving product design for easier recycling, and exploring bio-based alternatives that maintain HDPE's desirable properties while reducing reliance on fossil fuels. These efforts aim to create a more circular economy for HDPE, minimizing waste and maximizing resource efficiency throughout the material's lifecycle.

HDPE Recycling Technologies

HDPE recycling technologies have evolved significantly in recent years, driven by the increasing demand for sustainable packaging solutions and the need to reduce plastic waste. The recycling process for High Density Polyethylene (HDPE) typically involves several key stages: collection, sorting, cleaning, shredding, and reprocessing.

Collection systems have become more sophisticated, with many municipalities implementing curbside recycling programs that include HDPE products. Advanced sorting technologies, such as near-infrared (NIR) spectroscopy and X-ray fluorescence (XRF), have greatly improved the efficiency and accuracy of separating HDPE from other plastics and contaminants.

Cleaning processes have also seen advancements, with more effective washing systems that can remove labels, adhesives, and other impurities. This step is crucial for producing high-quality recycled HDPE that can be used in a wide range of applications, including eco-friendly product design.

Shredding technology has improved to produce more uniform flakes, which is essential for consistent quality in the recycled material. Modern shredders can handle a variety of HDPE products, from bottles to larger items like outdoor furniture.

The reprocessing stage has seen significant innovations, particularly in the development of chemical recycling methods. While mechanical recycling remains the most common approach, chemical recycling techniques such as pyrolysis and depolymerization are gaining traction. These methods break down HDPE into its chemical components, allowing for the production of virgin-quality recycled material.

One of the most promising developments in HDPE recycling is the use of compatibilizers. These additives help improve the properties of recycled HDPE, making it more suitable for high-performance applications. This technology has opened up new possibilities for incorporating recycled HDPE into eco-friendly product designs that require specific mechanical or aesthetic properties.

Another area of innovation is the development of multi-layer recycling technologies. Many HDPE products, especially in packaging, consist of multiple layers of different materials. New processes are being developed to separate and recycle these layers effectively, increasing the overall recyclability of HDPE products.

The integration of artificial intelligence and machine learning in recycling facilities is also enhancing the efficiency and quality of HDPE recycling. These technologies can optimize sorting processes, predict material quality, and adjust processing parameters in real-time.

As research continues, we can expect to see further advancements in HDPE recycling technologies, particularly in areas such as energy efficiency, closed-loop recycling systems, and the development of bio-based additives to enhance the properties of recycled HDPE. These innovations will play a crucial role in supporting the transition towards more sustainable and eco-friendly product designs using HDPE.