High Density Polyethylene in Sports Equipment Manufacturing

HDPE in Sports Equipment: Background and Objectives

High Density Polyethylene (HDPE) has emerged as a revolutionary material in the manufacturing of sports equipment, transforming the industry with its unique properties and versatile applications. The evolution of HDPE in sports equipment can be traced back to the mid-20th century when polymer science began to make significant strides. Initially used in simple applications, HDPE's potential in sports equipment manufacturing was gradually recognized due to its excellent strength-to-weight ratio, durability, and resistance to impact and chemicals.

The technological progression of HDPE in sports equipment has been driven by the increasing demands for lighter, stronger, and more performance-oriented gear. From its early uses in protective gear and simple accessories, HDPE has expanded its presence to become a crucial component in a wide range of sports equipment, including kayaks, snowboards, soccer goals, and high-performance skis. This expansion has been facilitated by advancements in polymer processing techniques, allowing for more complex shapes and improved material properties.

The primary objective of researching HDPE in sports equipment manufacturing is to enhance the performance, safety, and sustainability of sports gear. This involves exploring new formulations of HDPE that can offer improved strength, flexibility, and impact resistance while maintaining or reducing weight. Additionally, there is a growing focus on developing HDPE composites that combine the polymer with other materials to achieve superior properties tailored for specific sports applications.

Another critical aspect of HDPE research in sports equipment is the pursuit of more sustainable manufacturing processes and end-of-life solutions. As environmental concerns become increasingly prominent, the industry is exploring ways to incorporate recycled HDPE into high-performance sports equipment without compromising quality. This aligns with the broader trend of circular economy principles in manufacturing.

The future trajectory of HDPE in sports equipment manufacturing is likely to be shaped by several key factors. These include the development of nano-engineered HDPE materials with enhanced properties, the integration of smart technologies for performance monitoring, and the creation of bio-based HDPE alternatives. As research continues, the goal is to push the boundaries of what is possible with HDPE, creating sports equipment that is not only high-performing but also environmentally responsible and technologically advanced.

Market Analysis for HDPE Sports Equipment

The global market for High Density Polyethylene (HDPE) in sports equipment manufacturing has experienced significant growth in recent years, driven by the material's unique properties and the increasing demand for durable, lightweight sporting goods. HDPE's excellent strength-to-density ratio, impact resistance, and weather resistance make it an ideal choice for various sports equipment applications.

The sports equipment industry has shown a strong preference for HDPE due to its versatility and cost-effectiveness. Major market segments include water sports equipment, such as kayaks and paddleboards, winter sports gear like ski and snowboard bases, and protective equipment for contact sports. The growing popularity of outdoor recreational activities and the rise of adventure sports have further boosted the demand for HDPE-based products.

Market research indicates that the HDPE sports equipment sector is expected to maintain a steady growth trajectory over the next five years. This growth is attributed to several factors, including the increasing health consciousness among consumers, rising disposable incomes in emerging economies, and the growing trend of sports tourism. Additionally, the shift towards sustainable and eco-friendly materials has positioned HDPE favorably, as it is recyclable and has a lower environmental impact compared to some alternative materials.

Regional analysis reveals that North America and Europe currently dominate the HDPE sports equipment market, owing to the high participation rates in various sports and outdoor activities. However, the Asia-Pacific region is emerging as a lucrative market, with countries like China and India showing rapid growth in sports participation and equipment sales. This regional shift is expected to create new opportunities for manufacturers and suppliers in the coming years.

The competitive landscape of the HDPE sports equipment market is characterized by a mix of established sporting goods manufacturers and specialized HDPE product producers. Key players are focusing on product innovation, such as developing HDPE blends with enhanced properties, to gain a competitive edge. Collaborations between material suppliers and equipment manufacturers are becoming more common, driving technological advancements in the field.

Consumer trends indicate a growing preference for customized and performance-oriented sports equipment. This has led to increased investment in research and development by companies to create HDPE-based products that offer superior performance characteristics. The market is also witnessing a rise in demand for multi-functional sports equipment, where HDPE's versatility plays a crucial role in product design and manufacturing.

In conclusion, the market analysis for HDPE sports equipment reveals a promising outlook with substantial growth potential. The material's inherent properties, coupled with evolving consumer preferences and technological advancements, position HDPE as a key player in the future of sports equipment manufacturing. As the industry continues to innovate and expand, HDPE is expected to maintain its significance in the sports equipment market, offering opportunities for both established players and new entrants.

Current Challenges in HDPE Sports Equipment Manufacturing

The manufacturing of sports equipment using High Density Polyethylene (HDPE) faces several significant challenges in the current landscape. One of the primary issues is the balance between durability and weight. While HDPE offers excellent impact resistance and longevity, achieving the optimal weight for various sports applications remains a complex task. Manufacturers must fine-tune the material composition and processing techniques to create equipment that is both lightweight and robust enough to withstand intense use.

Another challenge lies in the thermal management of HDPE during the manufacturing process. The material's high melting point and thermal expansion characteristics can lead to warping or inconsistencies in the final product if not carefully controlled. This necessitates precise temperature regulation and cooling strategies throughout the production cycle, which can be both energy-intensive and time-consuming.

The environmental impact of HDPE sports equipment production is also a growing concern. While HDPE is recyclable, the incorporation of additives and reinforcements to enhance performance can complicate the recycling process. Manufacturers are under increasing pressure to develop more sustainable production methods and to improve the end-of-life recyclability of their products without compromising on quality or performance.

Surface finish and aesthetics present another hurdle in HDPE sports equipment manufacturing. The material's natural appearance can be perceived as less premium compared to other materials, and achieving a high-quality, consistent surface finish across large production runs can be challenging. This often requires additional post-processing steps or the application of coatings, which can add to production costs and time.

Customization and rapid prototyping capabilities are becoming increasingly important in the sports equipment industry. However, the traditional molding processes used for HDPE can be less flexible for small-batch production or quick design iterations. Manufacturers are exploring ways to integrate more agile production methods, such as 3D printing, with HDPE materials to meet the demand for personalized and quickly evolving product designs.

Lastly, the regulatory landscape poses ongoing challenges for HDPE sports equipment manufacturers. Compliance with evolving safety standards and material regulations across different markets requires constant vigilance and potential adjustments to manufacturing processes. This can lead to increased costs and complexity in product development and certification.

Existing HDPE Manufacturing Techniques for Sports Equipment

01 Manufacturing processes for HDPE

Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance.- Manufacturing processes for HDPE: Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance.

- HDPE blends and composites: HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and processability, making them suitable for a wide range of applications.

- HDPE applications in packaging and containers: HDPE is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used in the production of bottles, containers, and packaging materials for various industries.

- Recycling and sustainability of HDPE: Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE materials, as well as the development of bio-based alternatives.

- HDPE modifications and additives: Various modifications and additives are used to enhance the properties of HDPE. These can include crosslinking agents, stabilizers, and other additives that improve characteristics such as UV resistance, long-term stability, and processability.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and processability, making them suitable for a wide range of applications.Expand Specific Solutions03 HDPE applications in packaging and containers

HDPE is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used in the production of bottles, containers, and packaging materials for various industries.Expand Specific Solutions04 Recycling and sustainability of HDPE

Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE materials, as well as the development of bio-based alternatives.Expand Specific Solutions05 HDPE modifications and additives

Various modifications and additives are used to enhance the properties of HDPE. These can include crosslinking agents, stabilizers, and other additives that improve characteristics such as UV resistance, long-term stability, and processability.Expand Specific Solutions

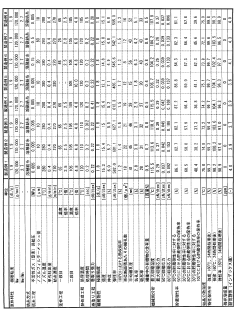

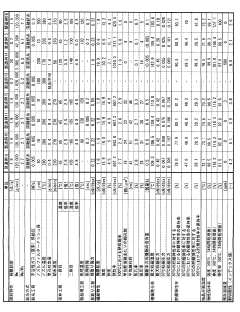

Key Players in HDPE Sports Equipment Market

The research on High Density Polyethylene (HDPE) in sports equipment manufacturing is in a mature stage, with a growing market driven by increasing demand for lightweight, durable, and high-performance sports gear. The global HDPE market size is substantial, with key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV leading the field. These companies, along with others such as DSM IP Assets BV and LG Chem Ltd., are continuously innovating to improve HDPE properties for sports applications. The technology's maturity is evident in the diverse range of companies involved, from petrochemical giants like China Petroleum & Chemical Corp. to specialized manufacturers like Toyobo Co., Ltd., indicating a well-established but still evolving technological landscape.

Dow Global Technologies LLC

DSM IP Assets BV

Innovations in HDPE Material Science for Sports Applications

- A solvent-free melt-spinning and drawing process is employed, with precise control over heat treatment and winding conditions to produce high-performance polyethylene fibers with specific intrinsic viscosity, shrinkage stress, and pore structure, enhancing mechanical properties and dyeability.

- A novel method involving the use of ultra-high molecular weight polyethylene with specific processing conditions, such as controlled solvent evaporation, inert gas feeding, and rapid uniform cooling, to produce multifilaments with monoclinic crystal sizes less than 9 nm, orthorhombic crystal size ratios between 0.8 and 1.2, and high tensile strengths above 20 cN/dTex, achieving uniformity and high knot strength retention.

Environmental Impact and Sustainability of HDPE in Sports

The environmental impact and sustainability of High Density Polyethylene (HDPE) in sports equipment manufacturing have become increasingly important considerations in recent years. HDPE, a versatile and durable plastic, has found widespread use in various sports equipment due to its excellent properties. However, its production and disposal pose significant environmental challenges that need to be addressed.

The production of HDPE involves the use of non-renewable fossil fuels, primarily natural gas and petroleum. This process contributes to greenhouse gas emissions and energy consumption. Additionally, the extraction of these raw materials can lead to habitat destruction and pollution. As the demand for sports equipment continues to grow, the environmental footprint of HDPE production becomes more pronounced.

One of the primary concerns surrounding HDPE in sports equipment is its end-of-life management. HDPE is not biodegradable, meaning it can persist in the environment for hundreds of years if not properly disposed of. This has led to growing concerns about plastic pollution in oceans and landfills. However, HDPE is recyclable, which offers a potential solution to mitigate its environmental impact.

Recycling HDPE from sports equipment presents both opportunities and challenges. On the positive side, recycled HDPE can be used to manufacture new products, reducing the need for virgin materials and lowering the overall environmental impact. Many sports equipment manufacturers have implemented take-back programs and are incorporating recycled HDPE into their production processes. However, the recycling process itself requires energy and resources, and not all HDPE products are easily recyclable due to additives or composite materials used in their construction.

To address these sustainability concerns, the sports equipment industry is exploring various strategies. One approach is the development of bio-based HDPE, which uses renewable resources such as sugarcane or corn as feedstock. While this reduces reliance on fossil fuels, it raises questions about land use and food security. Another avenue is the improvement of HDPE recycling technologies to increase efficiency and reduce the environmental impact of the recycling process itself.

The durability of HDPE in sports equipment also contributes to its sustainability profile. HDPE products often have a longer lifespan compared to alternatives, which can reduce the frequency of replacement and, consequently, the overall resource consumption. However, this durability becomes a double-edged sword when considering end-of-life disposal.

As environmental awareness grows, consumers and regulatory bodies are placing increasing pressure on manufacturers to adopt more sustainable practices. This has led to innovations in product design, such as modular construction that allows for easier repair and recycling. Some companies are also exploring alternative materials that offer similar performance to HDPE but with a lower environmental impact.

In conclusion, while HDPE has proven to be a valuable material in sports equipment manufacturing, its environmental impact and sustainability remain significant challenges. The industry's future will likely involve a balance between leveraging HDPE's beneficial properties and mitigating its environmental drawbacks through improved production methods, recycling technologies, and innovative material alternatives.

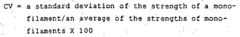

Performance Testing and Quality Control for HDPE Sports Equipment

Performance testing and quality control are critical aspects of HDPE sports equipment manufacturing, ensuring that products meet rigorous standards for safety, durability, and performance. The testing process typically begins with material characterization, where the physical and chemical properties of the HDPE are analyzed to confirm its suitability for the intended application.

One of the primary performance tests for HDPE sports equipment is impact resistance. This involves subjecting the equipment to controlled impact forces that simulate real-world usage conditions. For instance, HDPE helmets undergo drop tests from various heights and angles to assess their ability to absorb and distribute impact energy. Similarly, HDPE protective gear like shin guards or elbow pads are tested for their shock-absorbing capabilities.

Tensile strength testing is another crucial aspect of quality control. This test measures the maximum stress that HDPE can withstand while being stretched before failure. For sports equipment like goal posts or training barriers, high tensile strength is essential to ensure they can withstand repeated stress without deforming or breaking.

Weathering resistance is particularly important for outdoor sports equipment made from HDPE. Accelerated weathering tests expose the material to simulated environmental conditions, including UV radiation, moisture, and temperature fluctuations. These tests help predict how the equipment will perform over time when exposed to outdoor elements.

Fatigue testing is employed to evaluate the long-term durability of HDPE sports equipment. This involves subjecting the material to repeated cycles of stress to determine its resistance to failure under prolonged use. For example, HDPE kayaks or canoes undergo cyclic loading tests to ensure they can withstand the repeated stresses of paddling and water impact.

Chemical resistance testing is crucial for HDPE sports equipment that may come into contact with various substances. This includes exposure to sweat, cleaning agents, and in some cases, chlorinated water for swimming equipment. The material's ability to maintain its integrity and performance characteristics after exposure to these substances is carefully evaluated.

Quality control in HDPE sports equipment manufacturing also involves dimensional accuracy testing. Precision measurements are taken to ensure that each piece of equipment meets the specified dimensions, which is critical for both performance and safety. This is particularly important for items like protective gear, where a proper fit is essential for effective protection.

Finally, non-destructive testing methods, such as ultrasonic inspection or X-ray analysis, may be employed to detect any internal defects or inconsistencies in the HDPE structure that could compromise the equipment's performance or safety. These advanced techniques allow manufacturers to identify and address potential issues before the product reaches the end-user.