High Density Polyethylene: Reducing Industrial Waste

HDPE Waste Reduction Background and Objectives

High Density Polyethylene (HDPE) has become a ubiquitous material in modern industry, valued for its durability, versatility, and cost-effectiveness. However, the widespread use of HDPE has led to significant environmental challenges, particularly in the realm of industrial waste management. The accumulation of HDPE waste in landfills and oceans has raised global concerns, prompting a critical need for innovative solutions to reduce and manage this persistent form of industrial waste.

The evolution of HDPE waste reduction technologies has been driven by increasing environmental awareness and stringent regulations. Initially, efforts focused on improving recycling processes, but as the scale of the problem grew, more comprehensive approaches became necessary. The industry has witnessed a shift from simple mechanical recycling to advanced chemical recycling methods, aiming to break down HDPE into its constituent monomers for reuse in new products.

Current technological trends in HDPE waste reduction encompass a wide range of strategies, including enhanced sorting and separation techniques, innovative recycling processes, and the development of biodegradable alternatives. Emerging technologies such as artificial intelligence-driven waste sorting systems and catalytic depolymerization are showing promise in addressing the complexities of HDPE waste management.

The primary objective of research in this field is to develop efficient, cost-effective, and scalable solutions for reducing HDPE industrial waste. This involves not only improving end-of-life management but also rethinking the entire lifecycle of HDPE products. Key goals include increasing the recyclability of HDPE products, enhancing the quality of recycled HDPE to match virgin material properties, and exploring novel applications for recycled HDPE in high-value products.

Furthermore, there is a growing emphasis on circular economy principles, aiming to create closed-loop systems where HDPE waste is minimized or eliminated entirely. This approach requires collaboration across the value chain, from product designers and manufacturers to waste management companies and recyclers. The ultimate aim is to transform HDPE from a source of industrial waste into a valuable resource within a sustainable industrial ecosystem.

As research progresses, it is anticipated that breakthroughs in HDPE waste reduction will not only address environmental concerns but also create new economic opportunities. The development of innovative technologies and processes in this field has the potential to spawn new industries, create jobs, and drive sustainable economic growth while significantly reducing the environmental footprint of HDPE usage in industrial applications.

Market Analysis for HDPE Recycling Solutions

The global market for High Density Polyethylene (HDPE) recycling solutions is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures to reduce industrial waste. The demand for HDPE recycling technologies is expected to rise steadily over the next decade, as industries seek sustainable alternatives to traditional waste management practices.

In the industrial sector, HDPE waste is generated from various sources, including packaging materials, containers, and manufacturing byproducts. The market for HDPE recycling solutions in this sector is particularly robust, with a growing number of companies investing in recycling infrastructure to meet sustainability goals and comply with waste reduction regulations.

The automotive industry represents a significant market segment for HDPE recycling solutions. As vehicle manufacturers strive to increase the use of recycled materials in their products, the demand for high-quality recycled HDPE is rising. This trend is expected to continue, driven by both consumer preferences for eco-friendly vehicles and stringent environmental regulations in major automotive markets.

The construction industry is another key market for HDPE recycling solutions. Recycled HDPE is increasingly used in the production of construction materials such as pipes, fittings, and insulation. The durability and cost-effectiveness of recycled HDPE make it an attractive option for builders and contractors looking to improve their environmental footprint.

In the packaging industry, there is a growing trend towards circular economy principles, with many companies committing to using recycled materials in their packaging. This shift is creating new opportunities for HDPE recycling solution providers, as manufacturers seek reliable sources of high-quality recycled HDPE for their products.

The market for HDPE recycling solutions is also being shaped by technological advancements. Innovations in sorting, cleaning, and processing technologies are improving the quality and efficiency of HDPE recycling, making it more economically viable for a wider range of industries. These technological improvements are expected to further drive market growth in the coming years.

Geographically, North America and Europe currently lead the market for HDPE recycling solutions, due to well-established recycling infrastructure and stringent waste management regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and government initiatives to promote recycling.

Current HDPE Waste Management Challenges

High Density Polyethylene (HDPE) waste management faces several significant challenges in the current industrial landscape. One of the primary issues is the sheer volume of HDPE waste generated globally. As HDPE is widely used in packaging, consumer products, and industrial applications, the amount of waste produced annually is substantial and continues to grow.

The recycling rate for HDPE remains suboptimal, with a significant portion of waste still ending up in landfills or incineration facilities. This is partly due to the lack of efficient collection and sorting systems in many regions. Mixed plastic waste streams often contain various types of plastics, making it difficult to isolate HDPE for recycling without costly sorting processes.

Contamination of HDPE waste poses another major challenge. Many HDPE products contain additives, labels, or residual contents that can interfere with the recycling process. These contaminants can degrade the quality of recycled HDPE, limiting its potential applications and reducing its market value.

The economic viability of HDPE recycling is also a concern. Fluctuations in oil prices directly impact the cost-competitiveness of recycled HDPE compared to virgin material. When oil prices are low, it becomes more challenging for recycled HDPE to compete in the market, potentially discouraging investment in recycling infrastructure.

Technological limitations in recycling processes present additional hurdles. While mechanical recycling is widely used, it can lead to a degradation of material properties over multiple recycling cycles. Advanced recycling technologies, such as chemical recycling, are still in the early stages of development and face scalability challenges.

The lack of standardization in HDPE product design and composition further complicates recycling efforts. Different additives, colorants, and multi-layer structures can make it difficult to develop universal recycling solutions. This variability also impacts the quality and consistency of recycled HDPE, potentially limiting its use in high-value applications.

Regulatory frameworks and policy incentives for HDPE recycling vary significantly across regions, creating an uneven playing field for waste management practices. In some areas, insufficient regulations or enforcement mechanisms fail to encourage proper HDPE waste management, while in others, complex regulations may inadvertently hinder recycling efforts.

Consumer awareness and behavior also play a crucial role in HDPE waste management challenges. Improper disposal practices and low participation in recycling programs contribute to the overall problem. Educating consumers about the importance of HDPE recycling and implementing effective collection systems remain ongoing challenges in many communities.

Existing HDPE Waste Reduction Methods

01 Recycling and processing of HDPE industrial waste

Various methods and systems are developed for recycling and processing HDPE industrial waste. These include sorting, cleaning, shredding, and reprocessing techniques to convert waste HDPE into reusable materials or new products. The recycling process often involves melting and extruding the waste HDPE to create pellets or other forms suitable for manufacturing.- Recycling and processing of HDPE industrial waste: Various methods are employed to recycle and process HDPE industrial waste, including sorting, cleaning, and reprocessing techniques. These processes aim to convert waste HDPE into reusable materials for manufacturing new products, reducing environmental impact and conserving resources.

- Modification and enhancement of recycled HDPE: Techniques for modifying and enhancing recycled HDPE are developed to improve its properties and expand its applications. These may include adding compatibilizers, reinforcing agents, or other additives to enhance mechanical, thermal, or chemical properties of the recycled material.

- HDPE waste-based composite materials: HDPE industrial waste is utilized in the development of composite materials by combining it with other materials such as natural fibers, inorganic fillers, or other polymers. These composites often exhibit improved properties and find applications in various industries.

- Equipment and systems for HDPE waste processing: Specialized equipment and systems are designed for efficient processing of HDPE industrial waste. These may include sorting machines, granulators, extruders, and other machinery optimized for handling and recycling HDPE waste materials.

- Chemical recycling of HDPE waste: Chemical recycling methods are developed to break down HDPE waste into its chemical components or convert it into valuable chemicals. These processes may involve depolymerization, pyrolysis, or other chemical treatments to recover raw materials or produce fuels from HDPE waste.

02 Modification and enhancement of recycled HDPE

Techniques are developed to modify and enhance the properties of recycled HDPE from industrial waste. This includes adding additives, blending with other materials, or applying specific treatments to improve mechanical, thermal, or chemical properties. The goal is to create high-quality recycled HDPE suitable for various applications.Expand Specific Solutions03 HDPE waste-based composite materials

Research focuses on developing composite materials using HDPE industrial waste as a base component. These composites often incorporate other materials such as natural fibers, inorganic fillers, or other polymers to create products with enhanced properties for specific applications in construction, automotive, or packaging industries.Expand Specific Solutions04 Energy recovery from HDPE waste

Methods are developed for energy recovery from HDPE industrial waste that cannot be recycled effectively. This includes pyrolysis, gasification, or incineration processes to convert waste HDPE into fuel or energy, providing an alternative to landfill disposal while recovering value from the waste material.Expand Specific Solutions05 Innovative applications for recycled HDPE

New and innovative applications are explored for recycled HDPE from industrial waste. This includes using the recycled material in 3D printing, creating eco-friendly products, or developing novel materials with unique properties. The aim is to find high-value applications for recycled HDPE, promoting circular economy principles.Expand Specific Solutions

Key Players in HDPE Recycling Industry

The research on reducing industrial waste through High Density Polyethylene (HDPE) is in a mature stage of development, with significant market potential due to increasing environmental concerns. The global HDPE market size is substantial, driven by demand in packaging, construction, and automotive industries. Technologically, the field is well-established but continues to evolve, with major players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV leading innovation. These companies, along with others such as Borealis AG and LG Chem Ltd., are focusing on developing more efficient recycling processes and enhancing HDPE properties to reduce waste and improve sustainability. The competitive landscape is characterized by ongoing R&D efforts to create more eco-friendly HDPE solutions and circular economy initiatives.

Dow Global Technologies LLC

Borealis AG

Innovative HDPE Recycling Techniques

- A process involving the collection, separation, cleaning, and grinding of non-black high-density polyethylene detergent packaging waste, followed by blending with virgin polyethylene to produce a polyethylene blend with enhanced mechanical properties and environmental stress crack resistance, suitable for high-value applications.

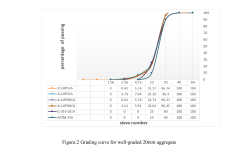

- A composite material is created by blending HDPE plastic with sand and rock dust, which is crushed, mixed, and processed to form a durable aggregate suitable for construction and flexible pavement applications, leveraging the properties of HDPE, sand, and rock dust to produce a valuable resource from discarded plastics.

Environmental Impact Assessment

The environmental impact assessment of reducing industrial waste through High Density Polyethylene (HDPE) reveals both positive and negative effects on the ecosystem and human health. This analysis is crucial for understanding the overall sustainability of HDPE recycling and waste reduction initiatives.

Positive impacts include a significant reduction in landfill waste, as HDPE is a major component of industrial plastic waste. By recycling and reusing HDPE, the volume of plastic entering landfills decreases, thereby reducing soil and groundwater contamination risks. Additionally, the reduction in HDPE waste production leads to lower greenhouse gas emissions associated with the degradation of plastics in landfills.

The recycling process of HDPE consumes less energy compared to the production of virgin HDPE, resulting in reduced carbon emissions. This energy efficiency contributes to the mitigation of climate change impacts. Furthermore, the decreased demand for raw materials in HDPE production helps conserve natural resources and reduces the environmental footprint associated with extraction and processing activities.

However, the recycling process itself is not without environmental concerns. The cleaning and processing of recycled HDPE can generate wastewater containing contaminants, which requires proper treatment to prevent water pollution. Additionally, the transportation of HDPE waste to recycling facilities may contribute to air pollution and increased carbon emissions if not managed efficiently.

The production of recycled HDPE products may also release volatile organic compounds (VOCs) and other air pollutants, albeit at lower levels compared to virgin HDPE production. Proper emission control measures are essential to minimize these impacts on air quality and worker health.

Long-term environmental benefits include reduced plastic pollution in marine ecosystems, as less HDPE waste enters waterways and oceans. This contributes to the protection of marine biodiversity and reduces the risk of microplastic contamination in the food chain.

The assessment also considers the potential for improved resource efficiency through the development of closed-loop recycling systems for HDPE. Such systems can significantly reduce the need for virgin materials and minimize waste generation throughout the product lifecycle.

In conclusion, while the reduction of industrial waste through HDPE recycling offers substantial environmental benefits, it is crucial to address and mitigate the potential negative impacts associated with the recycling process. Implementing best practices in waste collection, transportation, and processing can maximize the positive environmental outcomes while minimizing adverse effects on ecosystems and human health.

Circular Economy Integration Strategies

Integrating High Density Polyethylene (HDPE) waste reduction strategies into a circular economy framework requires a multifaceted approach that addresses the entire lifecycle of HDPE products. This integration can significantly reduce industrial waste while creating economic opportunities and environmental benefits.

One key strategy is to implement design for recyclability principles in HDPE product development. This involves creating products that are easily disassembled, use minimal mixed materials, and incorporate recycled HDPE content. By considering end-of-life scenarios during the design phase, manufacturers can ensure that their products are more readily recyclable, thus reducing waste and promoting circular material flows.

Establishing efficient collection and sorting systems is crucial for maximizing HDPE recycling rates. This can be achieved through improved waste management infrastructure, including advanced sorting technologies such as near-infrared spectroscopy and artificial intelligence-driven robotic sorting. These systems can effectively separate HDPE from other plastics and contaminants, increasing the quality and quantity of recyclable material.

Developing and scaling up advanced recycling technologies is another vital component of circular economy integration. Mechanical recycling processes can be optimized to handle a wider range of HDPE waste streams, while chemical recycling methods, such as pyrolysis and depolymerization, offer the potential to break down contaminated or low-quality HDPE into its chemical building blocks for reuse in new products.

Creating market demand for recycled HDPE is essential for closing the loop in the circular economy. This can be achieved through policy measures such as minimum recycled content requirements, tax incentives for using recycled materials, and green public procurement policies. Additionally, industry collaborations and partnerships can help develop new applications for recycled HDPE, expanding its market potential.

Implementing industrial symbiosis networks can further reduce HDPE waste by facilitating the exchange of materials between different industries. For example, HDPE waste from one sector can become a valuable input for another, creating a closed-loop system that minimizes overall waste generation.

Education and awareness campaigns play a crucial role in promoting circular economy principles for HDPE. These initiatives can target both consumers and industry stakeholders, highlighting the importance of proper disposal, recycling practices, and the benefits of using recycled HDPE products.

Lastly, developing standardized metrics and reporting frameworks for HDPE circularity can help track progress and identify areas for improvement. This data-driven approach enables companies to set meaningful targets, measure their circular economy performance, and communicate their achievements to stakeholders, fostering transparency and accountability in waste reduction efforts.