The Role of Cellophane in Next-Gen Medical Products

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane in Medicine: Background and Objectives

Cellophane, a thin transparent sheet made from regenerated cellulose, has a rich history in the medical field dating back to the early 20th century. Initially developed as a packaging material, its unique properties quickly caught the attention of medical professionals. The evolution of cellophane in medicine has been marked by continuous innovation and adaptation to meet the ever-changing demands of healthcare.

The primary objective of incorporating cellophane in next-generation medical products is to leverage its inherent characteristics for enhanced patient care and improved medical outcomes. These properties include its transparency, flexibility, and barrier properties against moisture and bacteria. As the medical industry progresses, there is a growing need for materials that can meet the stringent requirements of modern healthcare while remaining cost-effective and environmentally friendly.

One of the key goals in utilizing cellophane in medical applications is to develop advanced wound dressings. The material's ability to maintain a moist wound environment while allowing for gas exchange makes it an ideal candidate for promoting faster healing and reducing the risk of infection. Additionally, researchers aim to explore cellophane's potential in drug delivery systems, where its controlled permeability can be harnessed to regulate the release of medications over time.

Another significant objective is to investigate cellophane's role in medical packaging and sterilization processes. As healthcare facilities strive to minimize the risk of contamination, cellophane's barrier properties against microorganisms become increasingly valuable. The material's compatibility with various sterilization methods, including ethylene oxide and gamma radiation, further enhances its appeal in this context.

The integration of cellophane into biosensors and diagnostic devices represents another frontier in medical technology. By exploiting its optical clarity and potential for surface modification, researchers aim to create more sensitive and accurate diagnostic tools. This could lead to the development of point-of-care devices that offer rapid and reliable results, potentially revolutionizing disease detection and monitoring.

As environmental concerns gain prominence, the biodegradability of cellophane aligns with the growing demand for sustainable medical products. The objective is to reduce the environmental impact of healthcare waste while maintaining the highest standards of patient safety and care. This aspect of cellophane makes it an attractive option for developing eco-friendly alternatives to traditional plastic-based medical supplies.

In conclusion, the background and objectives of cellophane in medicine reflect a multifaceted approach to addressing current healthcare challenges. By harnessing the material's unique properties and exploring novel applications, researchers and medical professionals aim to push the boundaries of what is possible in patient care, diagnostics, and sustainable healthcare practices.

The primary objective of incorporating cellophane in next-generation medical products is to leverage its inherent characteristics for enhanced patient care and improved medical outcomes. These properties include its transparency, flexibility, and barrier properties against moisture and bacteria. As the medical industry progresses, there is a growing need for materials that can meet the stringent requirements of modern healthcare while remaining cost-effective and environmentally friendly.

One of the key goals in utilizing cellophane in medical applications is to develop advanced wound dressings. The material's ability to maintain a moist wound environment while allowing for gas exchange makes it an ideal candidate for promoting faster healing and reducing the risk of infection. Additionally, researchers aim to explore cellophane's potential in drug delivery systems, where its controlled permeability can be harnessed to regulate the release of medications over time.

Another significant objective is to investigate cellophane's role in medical packaging and sterilization processes. As healthcare facilities strive to minimize the risk of contamination, cellophane's barrier properties against microorganisms become increasingly valuable. The material's compatibility with various sterilization methods, including ethylene oxide and gamma radiation, further enhances its appeal in this context.

The integration of cellophane into biosensors and diagnostic devices represents another frontier in medical technology. By exploiting its optical clarity and potential for surface modification, researchers aim to create more sensitive and accurate diagnostic tools. This could lead to the development of point-of-care devices that offer rapid and reliable results, potentially revolutionizing disease detection and monitoring.

As environmental concerns gain prominence, the biodegradability of cellophane aligns with the growing demand for sustainable medical products. The objective is to reduce the environmental impact of healthcare waste while maintaining the highest standards of patient safety and care. This aspect of cellophane makes it an attractive option for developing eco-friendly alternatives to traditional plastic-based medical supplies.

In conclusion, the background and objectives of cellophane in medicine reflect a multifaceted approach to addressing current healthcare challenges. By harnessing the material's unique properties and exploring novel applications, researchers and medical professionals aim to push the boundaries of what is possible in patient care, diagnostics, and sustainable healthcare practices.

Market Analysis for Cellophane-Based Medical Products

The global market for cellophane-based medical products is experiencing significant growth, driven by the increasing demand for innovative and sustainable healthcare solutions. Cellophane, a thin, transparent sheet made from regenerated cellulose, has found its way into various medical applications due to its unique properties such as biocompatibility, flexibility, and barrier characteristics.

In the pharmaceutical sector, cellophane is widely used in drug packaging, particularly for blister packs and sachets. The market for cellophane in this segment is expected to grow steadily as pharmaceutical companies seek packaging materials that can protect sensitive medications while meeting sustainability goals. The rise in chronic diseases and the aging population in many countries are contributing factors to this growth.

The wound care segment represents another substantial market for cellophane-based products. Advanced wound dressings incorporating cellophane layers are gaining traction due to their ability to maintain a moist wound environment while allowing for gas exchange. This sector is particularly promising in regions with a high prevalence of chronic wounds, such as diabetic ulcers and pressure sores.

Surgical applications of cellophane are also on the rise. Surgeons are increasingly using cellophane-based products for tissue separation and as protective barriers during procedures. The market for these products is expanding, especially in countries with growing healthcare infrastructure and increasing rates of surgical interventions.

The disposable medical supplies sector is another area where cellophane is making inroads. Products such as disposable gloves, face masks, and protective gowns often incorporate cellophane components. The COVID-19 pandemic has significantly boosted demand in this segment, and the trend is likely to continue as healthcare facilities maintain higher hygiene standards.

Geographically, North America and Europe currently dominate the market for cellophane-based medical products, owing to their advanced healthcare systems and stringent regulatory environments. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by improving healthcare infrastructure, rising disposable incomes, and increasing awareness of advanced medical technologies.

Market analysts predict that the global cellophane-based medical products market will continue to expand at a compound annual growth rate (CAGR) in the mid-single digits over the next five years. This growth is attributed to ongoing research and development efforts to enhance cellophane's properties for specific medical applications, as well as the material's alignment with the growing focus on eco-friendly and biodegradable products in the healthcare industry.

In the pharmaceutical sector, cellophane is widely used in drug packaging, particularly for blister packs and sachets. The market for cellophane in this segment is expected to grow steadily as pharmaceutical companies seek packaging materials that can protect sensitive medications while meeting sustainability goals. The rise in chronic diseases and the aging population in many countries are contributing factors to this growth.

The wound care segment represents another substantial market for cellophane-based products. Advanced wound dressings incorporating cellophane layers are gaining traction due to their ability to maintain a moist wound environment while allowing for gas exchange. This sector is particularly promising in regions with a high prevalence of chronic wounds, such as diabetic ulcers and pressure sores.

Surgical applications of cellophane are also on the rise. Surgeons are increasingly using cellophane-based products for tissue separation and as protective barriers during procedures. The market for these products is expanding, especially in countries with growing healthcare infrastructure and increasing rates of surgical interventions.

The disposable medical supplies sector is another area where cellophane is making inroads. Products such as disposable gloves, face masks, and protective gowns often incorporate cellophane components. The COVID-19 pandemic has significantly boosted demand in this segment, and the trend is likely to continue as healthcare facilities maintain higher hygiene standards.

Geographically, North America and Europe currently dominate the market for cellophane-based medical products, owing to their advanced healthcare systems and stringent regulatory environments. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by improving healthcare infrastructure, rising disposable incomes, and increasing awareness of advanced medical technologies.

Market analysts predict that the global cellophane-based medical products market will continue to expand at a compound annual growth rate (CAGR) in the mid-single digits over the next five years. This growth is attributed to ongoing research and development efforts to enhance cellophane's properties for specific medical applications, as well as the material's alignment with the growing focus on eco-friendly and biodegradable products in the healthcare industry.

Current Challenges in Cellophane Medical Applications

Despite the widespread use of cellophane in medical applications, several challenges persist in its implementation for next-generation medical products. One of the primary concerns is the limited barrier properties of cellophane against certain gases and moisture. While cellophane provides excellent transparency and flexibility, its permeability to oxygen and water vapor can compromise the shelf life and efficacy of sensitive medical products, particularly in pharmaceutical packaging.

Another significant challenge lies in the mechanical properties of cellophane. Although it offers good tensile strength, its tear resistance and puncture resistance are relatively low compared to some synthetic polymers. This limitation can be problematic in applications where the integrity of the packaging is crucial, such as in sterile medical device packaging or for products that require protection from physical damage during handling and transportation.

The biodegradability of cellophane, while generally considered an environmental advantage, presents challenges in certain medical applications. The material's susceptibility to degradation in moist environments can lead to concerns about long-term stability and sterility maintenance, especially for products with extended shelf lives or those used in high-humidity settings.

Furthermore, the surface properties of cellophane pose challenges in some medical applications. Its relatively high surface energy can lead to issues with printability and adhesion, which are critical factors in medical packaging for proper labeling and sealing. This can necessitate additional surface treatments or coatings, potentially increasing production costs and complexity.

The limited heat-sealing capabilities of cellophane compared to thermoplastic materials present another hurdle. This limitation can complicate packaging processes and may require the use of adhesives or additional layers of heat-sealable materials, potentially impacting the overall cost and environmental footprint of the packaging.

Regulatory compliance and standardization pose ongoing challenges for cellophane in medical applications. As regulations evolve, particularly concerning materials in contact with drugs or medical devices, ensuring consistent quality and meeting stringent regulatory requirements can be complex and resource-intensive for manufacturers.

Lastly, the scalability and cost-effectiveness of cellophane production for specialized medical applications remain challenging. While cellophane is widely available, producing variants with enhanced properties specific to medical needs often involves complex modifications or treatments, which can impact production efficiency and overall cost-competitiveness compared to synthetic alternatives.

Another significant challenge lies in the mechanical properties of cellophane. Although it offers good tensile strength, its tear resistance and puncture resistance are relatively low compared to some synthetic polymers. This limitation can be problematic in applications where the integrity of the packaging is crucial, such as in sterile medical device packaging or for products that require protection from physical damage during handling and transportation.

The biodegradability of cellophane, while generally considered an environmental advantage, presents challenges in certain medical applications. The material's susceptibility to degradation in moist environments can lead to concerns about long-term stability and sterility maintenance, especially for products with extended shelf lives or those used in high-humidity settings.

Furthermore, the surface properties of cellophane pose challenges in some medical applications. Its relatively high surface energy can lead to issues with printability and adhesion, which are critical factors in medical packaging for proper labeling and sealing. This can necessitate additional surface treatments or coatings, potentially increasing production costs and complexity.

The limited heat-sealing capabilities of cellophane compared to thermoplastic materials present another hurdle. This limitation can complicate packaging processes and may require the use of adhesives or additional layers of heat-sealable materials, potentially impacting the overall cost and environmental footprint of the packaging.

Regulatory compliance and standardization pose ongoing challenges for cellophane in medical applications. As regulations evolve, particularly concerning materials in contact with drugs or medical devices, ensuring consistent quality and meeting stringent regulatory requirements can be complex and resource-intensive for manufacturers.

Lastly, the scalability and cost-effectiveness of cellophane production for specialized medical applications remain challenging. While cellophane is widely available, producing variants with enhanced properties specific to medical needs often involves complex modifications or treatments, which can impact production efficiency and overall cost-competitiveness compared to synthetic alternatives.

Existing Cellophane-Based Medical Solutions

01 Cellophane production and modification

Various methods and processes for producing and modifying cellophane are described. These include techniques for improving the properties of cellophane, such as its strength, flexibility, and barrier characteristics. The production processes may involve chemical treatments, physical modifications, or the incorporation of additives to enhance the material's performance.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, providing protection against moisture and gases while allowing visibility of the product. Cellophane can be used alone or in combination with other materials to create various packaging solutions.

- Cellophane production and processing: The production and processing of cellophane involve various techniques to improve its properties and performance. This includes methods for manufacturing, treating, and modifying cellophane to enhance its strength, flexibility, and barrier characteristics. Innovations in this area focus on optimizing the production process and developing new formulations.

- Cellophane in biotechnology and medical applications: Cellophane finds applications in biotechnology and medical fields due to its biocompatibility and unique properties. It can be used in cell culture, tissue engineering, and as a membrane for various medical devices. Research in this area focuses on modifying cellophane to enhance its performance in specific biological applications.

- Cellophane-based composites and laminates: Cellophane can be combined with other materials to create composites and laminates with enhanced properties. These combinations can improve strength, barrier properties, and functionality for various applications. Research in this area focuses on developing new composite materials and lamination techniques using cellophane as a key component.

- Cellophane in sustainable and biodegradable products: As a biodegradable material derived from renewable resources, cellophane is being explored for use in sustainable and eco-friendly products. Research in this area focuses on developing new applications for cellophane as an alternative to synthetic plastics, as well as improving its biodegradability and environmental impact.

02 Packaging applications of cellophane

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. The material is employed in food packaging, consumer goods packaging, and industrial applications. Innovations in this area focus on improving the sealing properties, printability, and compatibility with various products.Expand Specific Solutions03 Biodegradable and eco-friendly cellophane

Development of biodegradable and environmentally friendly cellophane alternatives is a growing area of research. These materials aim to maintain the desirable properties of traditional cellophane while offering improved sustainability and reduced environmental impact. Innovations in this field often involve the use of renewable resources and modifications to enhance biodegradability.Expand Specific Solutions04 Cellophane in medical and pharmaceutical applications

Cellophane finds applications in the medical and pharmaceutical industries due to its unique properties. It is used in various medical devices, drug delivery systems, and packaging for medical supplies. Research in this area focuses on improving the material's biocompatibility, sterilization resistance, and controlled release capabilities.Expand Specific Solutions05 Cellophane-based composite materials

The development of composite materials incorporating cellophane is an emerging field of research. These composites aim to combine the advantageous properties of cellophane with other materials to create novel products with enhanced characteristics. Applications include reinforced materials, smart packaging, and functional films with improved mechanical or barrier properties.Expand Specific Solutions

Key Players in Cellophane Medical Product Development

The cellophane market for next-generation medical products is in a growth phase, driven by increasing demand for advanced wound care and drug delivery systems. The global market size is projected to expand significantly, with a compound annual growth rate exceeding 5% over the next five years. Technologically, cellophane is evolving from traditional applications to more sophisticated uses in medical devices. Companies like UPM-Kymmene Oyj, SCHOTT AG, and Becton, Dickinson & Co. are at the forefront of innovation, developing novel cellophane-based products for medical applications. These industry leaders are investing heavily in R&D to enhance cellophane's properties, such as biocompatibility and controlled permeability, to meet the stringent requirements of next-generation medical products.

UPM-Kymmene Oyj

Technical Solution: UPM-Kymmene Oyj has developed advanced cellophane-based materials for next-generation medical products. Their technology focuses on creating bio-based, renewable cellophane films with enhanced barrier properties and controlled permeability. These films are engineered to provide optimal protection for sensitive medical devices and pharmaceuticals while allowing for controlled release of active ingredients. UPM's cellophane technology incorporates nanocellulose reinforcement, which significantly improves the mechanical strength and flexibility of the material[1]. The company has also developed a proprietary surface treatment process that enhances the film's antimicrobial properties, making it suitable for wound dressings and sterile packaging applications[3].

Strengths: Sustainable and bio-based material, excellent barrier properties, controlled permeability, and antimicrobial features. Weaknesses: Higher production costs compared to traditional synthetic materials, limited high-temperature applications.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered the integration of cellophane in pharmaceutical packaging and drug delivery systems. Their innovative approach combines cellophane with glass to create hybrid packaging solutions that offer the best of both materials. SCHOTT's technology utilizes a multi-layer structure where a thin cellophane film is sandwiched between glass layers, providing enhanced barrier properties against moisture and oxygen[2]. This composite material maintains the transparency and inertness of glass while benefiting from cellophane's flexibility and lightweight nature. SCHOTT has also developed a cellophane-based, dissolvable drug delivery system for controlled release applications, where the cellophane matrix is engineered to dissolve at specific rates in the body, allowing for precise dosing of medications[4].

Strengths: Combines benefits of glass and cellophane, excellent barrier properties, suitable for controlled drug release. Weaknesses: Complex manufacturing process, potentially higher costs than single-material solutions.

Innovative Cellophane Technologies for Healthcare

A novel collagen scaffold for delivery of multi-therapeutics and a process for the preparation thereof

PatentInactiveIN672DEL2011A

Innovation

- A multi-layered collagen scaffold is developed, impregnated with therapeutic-loaded microparticles made from different polymers, allowing for controlled and phase-wise delivery of multiple pharmaceuticals through a process involving collagen modification, microparticle preparation, and layering techniques, ensuring homogenous distribution and mechanical strength.

Cell culture material based on microbial cellulose

PatentWO2012056110A2

Innovation

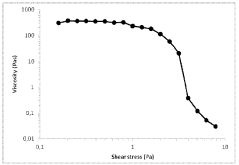

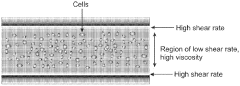

- A cell culture composition using cellulose nanofibers and derivatives based on microbial cellulose, forming a hydrogel or membrane that mimics the extracellular matrix, providing a non-animal based, biocompatible scaffold for 3D cell growth and allowing for the transfer of cells without damage.

Regulatory Framework for Cellophane in Medical Devices

The regulatory framework for cellophane in medical devices is a complex and evolving landscape that plays a crucial role in ensuring the safety and efficacy of next-generation medical products. As cellophane continues to find new applications in the medical field, regulatory bodies worldwide have been adapting their guidelines to address the unique properties and potential risks associated with this material.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices containing cellophane. These devices are typically classified based on their intended use and level of risk. Class I devices, which pose the lowest risk, may include simple cellophane-based products like wound dressings. Class II devices, such as certain diagnostic tools incorporating cellophane, require more stringent controls. Class III devices, which present the highest risk, undergo the most rigorous regulatory scrutiny.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations have introduced more stringent requirements for medical devices, including those utilizing cellophane. Manufacturers must now provide more comprehensive clinical data and post-market surveillance to demonstrate the safety and performance of their products.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates medical devices, including those containing cellophane. The Japanese regulatory framework emphasizes the importance of quality management systems and post-market surveillance, aligning with global trends in medical device regulation.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to cellophane in medical devices. ISO 10993, for instance, provides guidelines for the biological evaluation of medical devices, which is crucial for assessing the biocompatibility of cellophane-based products.

As the use of cellophane in medical devices continues to expand, regulatory bodies are increasingly focusing on specific aspects such as biocompatibility, sterilization processes, and long-term stability. Manufacturers are required to conduct thorough risk assessments and provide robust scientific evidence to support the safety and efficacy of their cellophane-based medical products.

The regulatory landscape also addresses the environmental impact of cellophane in medical devices. With growing concerns about sustainability, regulations are evolving to encourage the development of biodegradable or recyclable cellophane formulations for medical applications. This shift aligns with broader initiatives to reduce the environmental footprint of healthcare products.

Looking ahead, the regulatory framework for cellophane in medical devices is likely to become more harmonized globally, as regulatory bodies collaborate to streamline approval processes and ensure consistent safety standards across different markets. This harmonization will be crucial in facilitating the development and adoption of innovative cellophane-based medical technologies worldwide.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices containing cellophane. These devices are typically classified based on their intended use and level of risk. Class I devices, which pose the lowest risk, may include simple cellophane-based products like wound dressings. Class II devices, such as certain diagnostic tools incorporating cellophane, require more stringent controls. Class III devices, which present the highest risk, undergo the most rigorous regulatory scrutiny.

The European Union has implemented the Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR), which came into full effect in 2021 and 2022, respectively. These regulations have introduced more stringent requirements for medical devices, including those utilizing cellophane. Manufacturers must now provide more comprehensive clinical data and post-market surveillance to demonstrate the safety and performance of their products.

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) regulates medical devices, including those containing cellophane. The Japanese regulatory framework emphasizes the importance of quality management systems and post-market surveillance, aligning with global trends in medical device regulation.

Internationally, the International Organization for Standardization (ISO) has developed several standards relevant to cellophane in medical devices. ISO 10993, for instance, provides guidelines for the biological evaluation of medical devices, which is crucial for assessing the biocompatibility of cellophane-based products.

As the use of cellophane in medical devices continues to expand, regulatory bodies are increasingly focusing on specific aspects such as biocompatibility, sterilization processes, and long-term stability. Manufacturers are required to conduct thorough risk assessments and provide robust scientific evidence to support the safety and efficacy of their cellophane-based medical products.

The regulatory landscape also addresses the environmental impact of cellophane in medical devices. With growing concerns about sustainability, regulations are evolving to encourage the development of biodegradable or recyclable cellophane formulations for medical applications. This shift aligns with broader initiatives to reduce the environmental footprint of healthcare products.

Looking ahead, the regulatory framework for cellophane in medical devices is likely to become more harmonized globally, as regulatory bodies collaborate to streamline approval processes and ensure consistent safety standards across different markets. This harmonization will be crucial in facilitating the development and adoption of innovative cellophane-based medical technologies worldwide.

Environmental Impact of Cellophane in Healthcare

The environmental impact of cellophane in healthcare is a critical consideration as the medical industry increasingly adopts this material in next-generation products. Cellophane, a thin, transparent film made from regenerated cellulose, offers unique properties that make it attractive for medical applications. However, its widespread use raises concerns about its ecological footprint throughout its lifecycle.

In the production phase, cellophane manufacturing requires significant energy inputs and chemical processes. The raw material, wood pulp, is treated with alkali and carbon disulfide to create viscose, which is then extruded into an acid bath to form the film. This process involves potentially harmful chemicals and generates wastewater that must be carefully managed to prevent environmental contamination.

During its use in healthcare settings, cellophane contributes to reducing waste by extending the shelf life of medical products and minimizing contamination risks. Its barrier properties help maintain sterility and protect against moisture and gases, potentially reducing the need for additional packaging materials. This can lead to a decrease in overall waste generation within healthcare facilities.

However, the disposal of cellophane-based medical products presents significant challenges. While cellophane is biodegradable under certain conditions, the rate of decomposition in landfills can be slow due to the lack of oxygen and proper microbial activity. In medical applications, cellophane is often combined with other materials or contaminated with biological waste, complicating recycling efforts and potentially increasing the volume of non-recyclable medical waste.

Incineration is a common disposal method for medical waste, including cellophane products. While this process reduces waste volume and can generate energy, it also releases greenhouse gases and potentially harmful emissions if not properly controlled. The incomplete combustion of cellophane can produce toxic substances, necessitating advanced emission control systems in medical waste incinerators.

The increasing use of cellophane in healthcare also raises concerns about microplastic pollution. As cellophane products break down, they may release small particles into the environment, contributing to the growing problem of microplastic contamination in water systems and ecosystems. The long-term effects of these particles on wildlife and human health are still being studied but are a cause for concern.

To mitigate the environmental impact of cellophane in healthcare, the industry is exploring several strategies. These include developing more sustainable production methods, improving waste management practices, and researching alternative materials with similar properties but lower environmental footprints. Additionally, there is a growing focus on designing medical products for easier recycling and implementing closed-loop systems to recover and reuse materials where possible.

In the production phase, cellophane manufacturing requires significant energy inputs and chemical processes. The raw material, wood pulp, is treated with alkali and carbon disulfide to create viscose, which is then extruded into an acid bath to form the film. This process involves potentially harmful chemicals and generates wastewater that must be carefully managed to prevent environmental contamination.

During its use in healthcare settings, cellophane contributes to reducing waste by extending the shelf life of medical products and minimizing contamination risks. Its barrier properties help maintain sterility and protect against moisture and gases, potentially reducing the need for additional packaging materials. This can lead to a decrease in overall waste generation within healthcare facilities.

However, the disposal of cellophane-based medical products presents significant challenges. While cellophane is biodegradable under certain conditions, the rate of decomposition in landfills can be slow due to the lack of oxygen and proper microbial activity. In medical applications, cellophane is often combined with other materials or contaminated with biological waste, complicating recycling efforts and potentially increasing the volume of non-recyclable medical waste.

Incineration is a common disposal method for medical waste, including cellophane products. While this process reduces waste volume and can generate energy, it also releases greenhouse gases and potentially harmful emissions if not properly controlled. The incomplete combustion of cellophane can produce toxic substances, necessitating advanced emission control systems in medical waste incinerators.

The increasing use of cellophane in healthcare also raises concerns about microplastic pollution. As cellophane products break down, they may release small particles into the environment, contributing to the growing problem of microplastic contamination in water systems and ecosystems. The long-term effects of these particles on wildlife and human health are still being studied but are a cause for concern.

To mitigate the environmental impact of cellophane in healthcare, the industry is exploring several strategies. These include developing more sustainable production methods, improving waste management practices, and researching alternative materials with similar properties but lower environmental footprints. Additionally, there is a growing focus on designing medical products for easier recycling and implementing closed-loop systems to recover and reuse materials where possible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!