High Density Polyethylene: Trends in Flame Retardancy

HDPE FR Evolution

The evolution of flame retardancy for High Density Polyethylene (HDPE) has been marked by significant advancements and shifts in approach over the past decades. Initially, the focus was primarily on halogenated flame retardants, particularly brominated compounds, due to their high efficiency and cost-effectiveness. These additives were widely used in HDPE applications requiring fire resistance, such as electrical enclosures and construction materials.

However, environmental and health concerns led to a paradigm shift in the 1990s and early 2000s. The industry began moving away from halogenated flame retardants, seeking more sustainable alternatives. This transition gave rise to the development and adoption of various non-halogenated flame retardant systems for HDPE. Inorganic compounds like aluminum hydroxide (ATH) and magnesium hydroxide (MDH) gained prominence, offering improved environmental profiles albeit with higher loading requirements.

The mid-2000s saw the emergence of more sophisticated flame retardant solutions. Intumescent systems, combining acid sources, carbonization agents, and blowing agents, became increasingly popular for HDPE applications. These systems offered the advantage of forming a protective char layer upon exposure to heat, effectively insulating the underlying polymer.

Nanotechnology began to play a significant role in HDPE flame retardancy from the late 2000s onwards. The incorporation of nanoparticles, such as nanoclays and carbon nanotubes, demonstrated synergistic effects when combined with conventional flame retardants, allowing for reduced overall additive loadings while maintaining or improving fire performance.

Recent trends have focused on developing more efficient and multifunctional flame retardant systems. Phosphorus-based flame retardants have gained traction, offering good flame retardancy with lower environmental impact. Additionally, the concept of reactive flame retardants, which can be chemically incorporated into the HDPE matrix, has been explored to address issues of additive migration and maintain the polymer's physical properties.

The latest developments in HDPE flame retardancy are centered around bio-based and sustainable solutions. Researchers are investigating naturally derived flame retardants, such as those from plant extracts or modified biomass, aiming to create eco-friendly alternatives that meet stringent fire safety standards while addressing growing environmental concerns.

Market Demand Analysis

The market demand for flame retardant High Density Polyethylene (HDPE) has been steadily increasing due to stringent safety regulations and growing awareness of fire hazards across various industries. The construction sector, particularly in commercial and residential buildings, drives significant demand for flame retardant HDPE in applications such as pipes, insulation, and electrical conduits. This trend is further amplified by the rapid urbanization and infrastructure development in emerging economies.

The automotive industry represents another major market for flame retardant HDPE, with manufacturers seeking lightweight materials that meet strict fire safety standards. As electric vehicles gain popularity, the need for flame retardant materials in battery casings and electrical components has surged, creating new opportunities for HDPE applications.

In the packaging industry, flame retardant HDPE is increasingly used for storage and transportation of flammable materials, addressing safety concerns in logistics and warehousing. The electronics sector also contributes to market growth, utilizing flame retardant HDPE in casings and components to mitigate fire risks in consumer devices and industrial equipment.

The global push towards sustainable and eco-friendly flame retardants has influenced market dynamics. Manufacturers are investing in research and development to create halogen-free flame retardant systems for HDPE, aligning with environmental regulations and consumer preferences. This shift has opened new market segments for "green" flame retardant HDPE products.

Geographically, North America and Europe lead in market demand due to strict fire safety regulations and high adoption rates in construction and automotive sectors. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing safety awareness, and expanding end-use industries.

Market analysts project a compound annual growth rate (CAGR) for the flame retardant HDPE market in the coming years, reflecting the material's expanding applications and the growing emphasis on fire safety across industries. Factors such as technological advancements in flame retardant additives, increasing focus on lightweight and durable materials, and the development of multi-functional flame retardant systems are expected to further stimulate market demand.

The COVID-19 pandemic initially disrupted supply chains and manufacturing processes, temporarily impacting market growth. However, the subsequent focus on health and safety has reinforced the importance of fire-resistant materials, potentially accelerating long-term demand for flame retardant HDPE in healthcare facilities, temporary structures, and personal protective equipment.

FR HDPE Tech Status

The current state of flame retardancy for High Density Polyethylene (HDPE) reflects a dynamic landscape of technological advancements and regulatory challenges. HDPE, known for its versatility and widespread use in various industries, has been the subject of intensive research and development efforts to enhance its flame-retardant properties.

Traditional flame retardants for HDPE, such as halogenated compounds, have faced increasing scrutiny due to environmental and health concerns. This has led to a shift towards more sustainable and eco-friendly alternatives. Phosphorus-based flame retardants have gained significant traction, offering improved fire performance while addressing environmental considerations. These compounds work by promoting char formation and reducing the release of flammable gases during combustion.

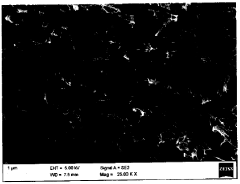

Nanocomposite technology has emerged as a promising approach in flame retardancy for HDPE. The incorporation of nanomaterials, such as clay platelets, carbon nanotubes, and graphene, has shown remarkable improvements in fire resistance without significantly compromising the mechanical properties of HDPE. These nanofillers create a physical barrier that hinders the diffusion of oxygen and volatile combustion products.

Intumescent systems represent another advanced solution in the current flame retardancy landscape for HDPE. These systems typically consist of an acid source, a carbonization agent, and a blowing agent. When exposed to heat, they form an expanded carbonaceous char layer that insulates the underlying polymer and reduces heat transfer.

Recent developments have also focused on synergistic combinations of different flame retardants. By carefully selecting and combining various additives, researchers have achieved enhanced flame-retardant performance at lower overall loading levels, thus maintaining the desirable physical properties of HDPE.

The regulatory environment continues to shape the direction of flame retardancy research for HDPE. Stricter fire safety standards and environmental regulations have driven the development of novel flame-retardant solutions that balance performance, sustainability, and cost-effectiveness. This has led to increased collaboration between material scientists, fire safety experts, and regulatory bodies to develop comprehensive approaches to fire safety in HDPE applications.

In terms of testing and certification, there has been a move towards more realistic fire scenarios and performance-based standards. This shift acknowledges the complex nature of fire behavior and aims to provide a more accurate assessment of a material's fire performance in real-world applications.

Current FR Solutions

01 Incorporation of flame retardant additives

Various flame retardant additives can be incorporated into HDPE to enhance its flame retardancy. These additives may include halogenated compounds, phosphorus-based compounds, or mineral fillers. The additives work by interfering with the combustion process or creating a protective char layer, thereby improving the fire resistance of HDPE materials.- Incorporation of flame retardant additives: Various flame retardant additives can be incorporated into HDPE to enhance its flame retardancy. These additives can include halogenated compounds, phosphorus-based compounds, metal hydroxides, or intumescent systems. The additives work by different mechanisms such as releasing flame-inhibiting gases, forming a protective char layer, or absorbing heat.

- Use of nanocomposites for flame retardancy: Nanocomposites, such as those incorporating nanoclay or carbon nanotubes, can be used to improve the flame retardancy of HDPE. These nanoparticles can create a barrier effect, reducing heat transfer and the release of volatile combustion products. They can also enhance the formation of a protective char layer during combustion.

- Surface treatment and coating techniques: Surface treatments or coatings can be applied to HDPE products to enhance their flame retardancy. These can include flame retardant paints, intumescent coatings, or plasma treatments that modify the surface properties of the HDPE. Such treatments can provide an additional barrier against flame spread and heat transfer.

- Blending with other flame-resistant polymers: HDPE can be blended with other inherently flame-resistant polymers or copolymers to improve its overall flame retardancy. This approach can combine the desirable properties of HDPE with the flame resistance of the added polymer. Examples may include blends with fluoropolymers or engineered thermoplastics.

- Optimization of HDPE molecular structure: The flame retardancy of HDPE can be improved by modifying its molecular structure. This can involve controlling the molecular weight distribution, incorporating comonomers, or introducing branching in the polymer chain. Such modifications can affect the melting behavior, dripping characteristics, and char formation of the HDPE during combustion.

02 Use of nanoparticles for flame retardancy

Nanoparticles, such as nano-sized metal oxides or clay particles, can be dispersed in HDPE to improve its flame retardant properties. These nanoparticles can create a barrier effect, reducing heat transfer and oxygen diffusion during combustion, thus enhancing the overall flame retardancy of the HDPE composite.Expand Specific Solutions03 Synergistic flame retardant systems

Combining multiple flame retardant additives or mechanisms can create synergistic effects, leading to improved flame retardancy in HDPE. These systems may involve the use of intumescent additives, char-forming agents, or combinations of different types of flame retardants to achieve enhanced fire resistance properties.Expand Specific Solutions04 Surface treatment and coatings

Applying flame retardant coatings or surface treatments to HDPE products can improve their fire resistance. These treatments may include the application of intumescent coatings, ceramic-based coatings, or other fire-resistant materials to the surface of HDPE products, providing an additional layer of protection against flame spread.Expand Specific Solutions05 Polymer blending and copolymerization

Blending HDPE with other flame-resistant polymers or copolymerizing HDPE with flame retardant monomers can enhance its flame retardancy. This approach allows for the incorporation of flame retardant properties directly into the polymer structure, potentially reducing the need for additional additives and improving overall material performance.Expand Specific Solutions

Key Industry Players

The flame retardancy market for High Density Polyethylene (HDPE) is in a growth phase, driven by increasing safety regulations and demand across various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is moderately mature but continuously evolving. Companies like SABIC, Borealis AG, and BASF Corp. are leading innovation, focusing on developing more effective and environmentally friendly flame retardants. Emerging players such as Polyrocks Chemical Co., Ltd. and Kingfa Sci. & Tech. Co., Ltd. are also making significant contributions, particularly in eco-friendly solutions. The competitive landscape is characterized by a mix of established chemical giants and specialized flame retardant manufacturers, with ongoing research collaborations between industry and academia driving technological advancements.

SABIC Global Technologies BV

Borealis AG

Core FR Innovations

- A method involving the irradiation of flame retardant polymer resins to achieve a fractional melt index, followed by grinding and sintering to form a porous plastic structure that meets UL flammability standards, using polymers like polyethylene, polyvinyl chloride, or fluoropolymers, and applying electron beam or chemical processes for crosslinking to reduce melt index and enhance molecular weight.

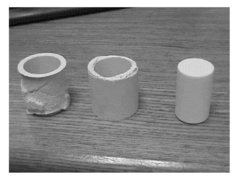

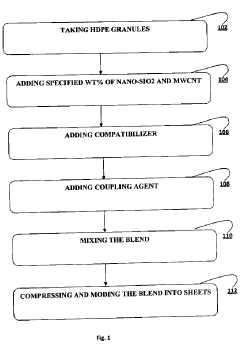

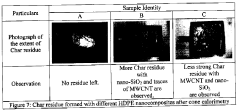

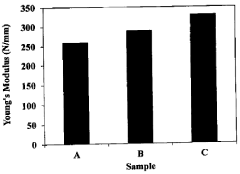

- A high density polyethylene (HDPE) nanocomposite material is developed, incorporating acid functionalized Multi-Walled Carbon Nanotubes (MWCNT) and nano-Silicon dioxide (SiO2) with specific weight percentages, along with a silane coupling agent and blending agents, to enhance dielectric, mechanical, and flame retardant properties, while meeting environmental safety standards.

Environmental Impact

The environmental impact of flame retardants used in High Density Polyethylene (HDPE) has become a significant concern in recent years. Traditional halogenated flame retardants, while effective, have been associated with various environmental and health issues. These compounds can persist in the environment, bioaccumulate in living organisms, and potentially cause adverse effects on ecosystems and human health.

In response to these concerns, there has been a shift towards more environmentally friendly flame retardant solutions for HDPE. One notable trend is the development of halogen-free flame retardants. These alternatives, such as metal hydroxides, phosphorus-based compounds, and nitrogen-based additives, aim to provide effective fire protection while minimizing environmental impact. Metal hydroxides, like aluminum hydroxide and magnesium hydroxide, release water vapor when heated, which helps to cool the material and dilute combustible gases.

Phosphorus-based flame retardants have gained attention due to their lower environmental persistence compared to halogenated compounds. These additives work by promoting char formation, which creates a protective barrier and reduces the release of flammable gases. Nitrogen-based flame retardants, often used in combination with phosphorus compounds, can enhance the efficiency of the flame retardant system while maintaining a lower environmental footprint.

Another emerging trend is the use of nanocomposites as flame retardant additives for HDPE. Nanomaterials such as clay, graphene, and carbon nanotubes can improve fire resistance while requiring lower loading levels, potentially reducing the overall environmental impact of the flame retardant system. These nanocomposites can enhance the formation of a protective char layer and improve the mechanical properties of the polymer.

Biodegradable flame retardants represent a promising avenue for reducing the long-term environmental impact of flame-retardant HDPE. Research is ongoing to develop additives derived from renewable resources, such as plant-based compounds, which can break down more readily in the environment after disposal. This approach aligns with the growing emphasis on circular economy principles and sustainable material design.

The trend towards more sustainable flame retardancy solutions for HDPE also extends to the manufacturing processes. Efforts are being made to develop more energy-efficient production methods and to reduce the use of harmful solvents in the incorporation of flame retardants. Additionally, there is an increased focus on improving the recyclability of flame-retardant HDPE, ensuring that the additives do not hinder the material's ability to be reprocessed at the end of its life cycle.

Regulatory Landscape

The regulatory landscape for flame retardancy in High Density Polyethylene (HDPE) has been evolving rapidly in recent years, driven by increasing concerns over fire safety and environmental impact. Globally, there is a trend towards more stringent regulations and standards governing the use of flame retardants in HDPE products, particularly in sectors such as construction, automotive, and electronics.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has significantly impacted the flame retardant industry. It has led to the phasing out of certain halogenated flame retardants, pushing manufacturers towards more environmentally friendly alternatives. The EU's RoHS (Restriction of Hazardous Substances) directive has further restricted the use of certain flame retardants in electrical and electronic equipment.

The United States has seen similar regulatory shifts. The Environmental Protection Agency (EPA) has been actively reviewing and regulating flame retardants under the Toxic Substances Control Act (TSCA). Several states, including California, have implemented their own regulations, such as the California Proposition 65, which requires warning labels on products containing certain flame retardants.

In Asia, countries like China and Japan have also been tightening their regulations. China's RoHS-like regulation and Japan's Chemical Substances Control Law (CSCL) have both impacted the use of flame retardants in HDPE products.

These regulatory changes have spurred innovation in the flame retardant industry, leading to the development of new, more sustainable flame retardant solutions for HDPE. There is a growing emphasis on halogen-free flame retardants, as well as bio-based and nano-based solutions that can meet both fire safety standards and environmental regulations.

The fire safety standards themselves are also evolving. Organizations such as the International Organization for Standardization (ISO), ASTM International, and Underwriters Laboratories (UL) are continually updating their testing methods and criteria to ensure they reflect real-world fire scenarios and address emerging risks.

Looking ahead, the regulatory landscape is expected to continue evolving, with a likely focus on promoting circular economy principles. This may include regulations that encourage the use of recyclable flame retardants or mandate the recyclability of flame-retardant HDPE products. Additionally, there is growing interest in harmonizing global standards to facilitate international trade and ensure consistent safety levels across different regions.