Analysis of Electrolyte Choices in Bioelectronic Interface Design

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioelectronic Interface Electrolyte Background and Objectives

Bioelectronic interfaces represent a critical intersection between electronic devices and biological systems, enabling bidirectional communication through electrical signals. The evolution of these interfaces has progressed significantly since the pioneering work in the 1970s, when early neural recording electrodes were first developed. Over subsequent decades, advancements in materials science, microfabrication techniques, and understanding of biological systems have dramatically enhanced the capabilities and applications of bioelectronic interfaces.

Electrolytes play a fundamental role in these interfaces, serving as the conductive medium that facilitates ion transport between electronic devices and biological tissues. The historical trajectory shows a shift from simple saline solutions to increasingly sophisticated electrolyte formulations designed to address specific challenges in bioelectronic communication. This evolution reflects the growing recognition that electrolyte composition significantly impacts interface performance, biocompatibility, and long-term stability.

Current technological trends indicate a move toward biomimetic electrolytes that more closely resemble the native biological environment, as well as stimuli-responsive electrolytes capable of adapting to changing physiological conditions. Additionally, there is increasing interest in solid and gel electrolytes that offer improved mechanical stability while maintaining excellent ionic conductivity, addressing the limitations of traditional liquid electrolytes in implantable and wearable applications.

The primary technical objectives in bioelectronic interface electrolyte development include enhancing charge transfer efficiency across the electronic-biological interface, minimizing electrochemical reactions that can damage tissues or degrade device performance, and ensuring long-term biocompatibility. Researchers aim to develop electrolytes that maintain stable performance under physiological conditions while supporting high-fidelity signal transduction.

Another critical objective is the development of electrolytes that can mitigate the foreign body response, which often leads to encapsulation of implanted devices and degradation of interface performance over time. This includes designing electrolytes with anti-inflammatory properties or incorporating bioactive molecules that promote favorable tissue integration.

The field is also moving toward multifunctional electrolytes that can simultaneously conduct ions, deliver therapeutic agents, and respond to biological signals. These advanced electrolytes represent a promising approach to creating more integrated and responsive bioelectronic systems capable of adapting to the dynamic nature of biological environments.

Achieving these objectives requires interdisciplinary collaboration between materials scientists, electrochemists, bioengineers, and clinicians to develop electrolyte solutions that balance electrical performance, biocompatibility, and practical implementation considerations for specific bioelectronic applications ranging from neural interfaces to wearable health monitoring systems.

Electrolytes play a fundamental role in these interfaces, serving as the conductive medium that facilitates ion transport between electronic devices and biological tissues. The historical trajectory shows a shift from simple saline solutions to increasingly sophisticated electrolyte formulations designed to address specific challenges in bioelectronic communication. This evolution reflects the growing recognition that electrolyte composition significantly impacts interface performance, biocompatibility, and long-term stability.

Current technological trends indicate a move toward biomimetic electrolytes that more closely resemble the native biological environment, as well as stimuli-responsive electrolytes capable of adapting to changing physiological conditions. Additionally, there is increasing interest in solid and gel electrolytes that offer improved mechanical stability while maintaining excellent ionic conductivity, addressing the limitations of traditional liquid electrolytes in implantable and wearable applications.

The primary technical objectives in bioelectronic interface electrolyte development include enhancing charge transfer efficiency across the electronic-biological interface, minimizing electrochemical reactions that can damage tissues or degrade device performance, and ensuring long-term biocompatibility. Researchers aim to develop electrolytes that maintain stable performance under physiological conditions while supporting high-fidelity signal transduction.

Another critical objective is the development of electrolytes that can mitigate the foreign body response, which often leads to encapsulation of implanted devices and degradation of interface performance over time. This includes designing electrolytes with anti-inflammatory properties or incorporating bioactive molecules that promote favorable tissue integration.

The field is also moving toward multifunctional electrolytes that can simultaneously conduct ions, deliver therapeutic agents, and respond to biological signals. These advanced electrolytes represent a promising approach to creating more integrated and responsive bioelectronic systems capable of adapting to the dynamic nature of biological environments.

Achieving these objectives requires interdisciplinary collaboration between materials scientists, electrochemists, bioengineers, and clinicians to develop electrolyte solutions that balance electrical performance, biocompatibility, and practical implementation considerations for specific bioelectronic applications ranging from neural interfaces to wearable health monitoring systems.

Market Analysis of Bioelectronic Interface Applications

The bioelectronic interface market is experiencing robust growth, driven by increasing applications in healthcare, neuroscience, and consumer electronics. Current market valuations place the global bioelectronic medicine sector at approximately 25 billion USD, with projected annual growth rates of 7-9% through 2030. This expansion is particularly evident in neural interfaces, implantable devices, and non-invasive monitoring systems where electrolyte technology plays a crucial role.

Healthcare applications represent the largest market segment, with significant investments in electrolyte-based interfaces for neural recording, stimulation, and drug delivery systems. The aging global population and rising prevalence of neurological disorders have created substantial demand for advanced bioelectronic interfaces with optimized electrolyte compositions that enhance signal quality while minimizing tissue damage.

Consumer electronics represents an emerging high-growth sector, with companies developing wearable bioelectronic interfaces for health monitoring and human-computer interaction. These applications require specialized electrolyte formulations that maintain performance under variable environmental conditions while ensuring user comfort and safety.

Regional analysis reveals North America currently dominates the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in China, Japan, and South Korea, where government initiatives are actively promoting bioelectronics research and commercialization.

Market segmentation by electrolyte type shows liquid electrolytes currently hold the largest market share due to their established performance characteristics and manufacturing processes. However, gel-based and solid-state electrolytes are gaining significant traction, with annual growth rates exceeding the overall market average by 3-4 percentage points.

Key market drivers include increasing demand for minimally invasive medical procedures, growing adoption of personalized medicine approaches, and expanding applications in neural prosthetics. The push toward miniaturization and improved biocompatibility is creating specific requirements for next-generation electrolyte formulations that balance ionic conductivity, stability, and tissue compatibility.

Market barriers include stringent regulatory requirements, particularly for implantable devices, which extend development timelines and increase costs. Additionally, concerns regarding long-term biocompatibility and stability of electrolyte materials in physiological environments remain significant challenges for widespread commercial adoption.

Customer demand analysis indicates growing preference for bioelectronic interfaces with extended operational lifetimes, reduced inflammatory responses, and improved signal-to-noise ratios – all factors directly influenced by electrolyte composition and design.

Healthcare applications represent the largest market segment, with significant investments in electrolyte-based interfaces for neural recording, stimulation, and drug delivery systems. The aging global population and rising prevalence of neurological disorders have created substantial demand for advanced bioelectronic interfaces with optimized electrolyte compositions that enhance signal quality while minimizing tissue damage.

Consumer electronics represents an emerging high-growth sector, with companies developing wearable bioelectronic interfaces for health monitoring and human-computer interaction. These applications require specialized electrolyte formulations that maintain performance under variable environmental conditions while ensuring user comfort and safety.

Regional analysis reveals North America currently dominates the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in China, Japan, and South Korea, where government initiatives are actively promoting bioelectronics research and commercialization.

Market segmentation by electrolyte type shows liquid electrolytes currently hold the largest market share due to their established performance characteristics and manufacturing processes. However, gel-based and solid-state electrolytes are gaining significant traction, with annual growth rates exceeding the overall market average by 3-4 percentage points.

Key market drivers include increasing demand for minimally invasive medical procedures, growing adoption of personalized medicine approaches, and expanding applications in neural prosthetics. The push toward miniaturization and improved biocompatibility is creating specific requirements for next-generation electrolyte formulations that balance ionic conductivity, stability, and tissue compatibility.

Market barriers include stringent regulatory requirements, particularly for implantable devices, which extend development timelines and increase costs. Additionally, concerns regarding long-term biocompatibility and stability of electrolyte materials in physiological environments remain significant challenges for widespread commercial adoption.

Customer demand analysis indicates growing preference for bioelectronic interfaces with extended operational lifetimes, reduced inflammatory responses, and improved signal-to-noise ratios – all factors directly influenced by electrolyte composition and design.

Current Electrolyte Technologies and Limitations

The current landscape of electrolyte technologies for bioelectronic interfaces presents a complex array of options, each with distinct advantages and limitations. Traditional liquid electrolytes, primarily composed of saline solutions or ionic liquids, offer excellent ionic conductivity and interface formation with biological tissues. However, they suffer from evaporation issues, potential leakage, and limited long-term stability, making them suboptimal for implantable or wearable bioelectronic devices requiring extended operational lifetimes.

Gel electrolytes, including hydrogels and ionogels, represent a significant advancement by combining the high ionic conductivity of liquids with improved mechanical stability. Polyethylene oxide (PEO), polyvinyl alcohol (PVA), and polyacrylamide-based hydrogels have demonstrated promising biocompatibility profiles. Nevertheless, these materials often experience performance degradation over time due to dehydration and mechanical stress, particularly at the tissue-electrode interface.

Solid polymer electrolytes have emerged as alternatives that address the stability limitations of liquid and gel systems. These materials, typically consisting of polymer matrices doped with ionic compounds, offer enhanced mechanical robustness and reduced leakage risk. However, they generally exhibit lower ionic conductivity at physiological temperatures compared to their liquid counterparts, creating a fundamental trade-off between stability and performance.

Recent innovations in composite electrolytes combine multiple material classes to optimize performance characteristics. For instance, polymer matrices embedded with ionic liquid components or nanoparticle-enhanced polymer electrolytes show promising improvements in both conductivity and stability. Despite these advances, achieving the ideal balance of ionic conductivity, mechanical properties, biocompatibility, and long-term stability remains challenging.

A critical limitation across all electrolyte technologies is the biofouling phenomenon, where protein adsorption and cellular encapsulation progressively degrade the electrode-tissue interface. This process increases impedance and reduces signal quality over time, presenting a significant hurdle for chronic bioelectronic applications. Current anti-fouling strategies, including surface modifications and drug-eluting coatings, offer only partial solutions with limited durability.

The integration of electrolytes with flexible and stretchable substrates presents another technological challenge. While considerable progress has been made in developing mechanically compliant electrode materials, creating electrolytes that maintain consistent performance under deformation while preserving the biological interface integrity remains problematic, particularly for applications requiring conformability to dynamic tissue surfaces.

Gel electrolytes, including hydrogels and ionogels, represent a significant advancement by combining the high ionic conductivity of liquids with improved mechanical stability. Polyethylene oxide (PEO), polyvinyl alcohol (PVA), and polyacrylamide-based hydrogels have demonstrated promising biocompatibility profiles. Nevertheless, these materials often experience performance degradation over time due to dehydration and mechanical stress, particularly at the tissue-electrode interface.

Solid polymer electrolytes have emerged as alternatives that address the stability limitations of liquid and gel systems. These materials, typically consisting of polymer matrices doped with ionic compounds, offer enhanced mechanical robustness and reduced leakage risk. However, they generally exhibit lower ionic conductivity at physiological temperatures compared to their liquid counterparts, creating a fundamental trade-off between stability and performance.

Recent innovations in composite electrolytes combine multiple material classes to optimize performance characteristics. For instance, polymer matrices embedded with ionic liquid components or nanoparticle-enhanced polymer electrolytes show promising improvements in both conductivity and stability. Despite these advances, achieving the ideal balance of ionic conductivity, mechanical properties, biocompatibility, and long-term stability remains challenging.

A critical limitation across all electrolyte technologies is the biofouling phenomenon, where protein adsorption and cellular encapsulation progressively degrade the electrode-tissue interface. This process increases impedance and reduces signal quality over time, presenting a significant hurdle for chronic bioelectronic applications. Current anti-fouling strategies, including surface modifications and drug-eluting coatings, offer only partial solutions with limited durability.

The integration of electrolytes with flexible and stretchable substrates presents another technological challenge. While considerable progress has been made in developing mechanically compliant electrode materials, creating electrolytes that maintain consistent performance under deformation while preserving the biological interface integrity remains problematic, particularly for applications requiring conformability to dynamic tissue surfaces.

Existing Electrolyte Solutions for Bioelectronic Interfaces

01 Electrolyte compositions for batteries

Various electrolyte compositions are developed for use in batteries to improve performance, stability, and safety. These compositions may include specific salts, solvents, and additives designed to enhance ionic conductivity and electrochemical stability. Advanced electrolyte formulations can lead to longer battery life, faster charging capabilities, and reduced risk of thermal runaway in lithium-ion and other battery technologies.- Electrolyte compositions for batteries: Various electrolyte compositions are developed for use in battery systems to improve performance, stability, and safety. These compositions include specific salts, solvents, and additives that enhance ionic conductivity and electrochemical stability. Advanced electrolyte formulations can extend battery life, increase energy density, and operate across wider temperature ranges while reducing risks of thermal runaway.

- Electrolyte systems for water treatment and purification: Electrolyte solutions are utilized in water treatment processes such as electrodialysis, electrodeionization, and electrolytic purification. These systems employ specific electrolyte compositions to facilitate ion exchange, membrane separation, and contaminant removal. The technology enables efficient desalination, heavy metal removal, and purification of drinking water through electrochemical processes.

- Medical and physiological electrolyte formulations: Specialized electrolyte formulations are developed for medical applications including intravenous fluids, dialysis solutions, and rehydration products. These formulations contain precise balances of sodium, potassium, calcium, magnesium, and other ions to maintain physiological homeostasis. The compositions are designed to address specific clinical needs such as dehydration, electrolyte imbalances, and support during medical procedures.

- Industrial electrolyte applications in electrochemical processes: Electrolyte solutions are formulated for various industrial electrochemical processes including electroplating, electrolysis, and electrowinning. These specialized compositions facilitate controlled metal deposition, surface treatment, and material extraction. The electrolytes contain specific conductivity enhancers, buffering agents, and additives that optimize process efficiency, product quality, and reduce energy consumption in manufacturing operations.

- Advanced electrolyte technologies for energy storage systems: Novel electrolyte technologies are being developed for next-generation energy storage systems including solid-state batteries, flow batteries, and supercapacitors. These include polymer electrolytes, ionic liquids, and composite electrolyte materials that offer improved safety, higher energy density, and better cycling stability. The innovations focus on overcoming limitations of conventional liquid electrolytes while enabling new device architectures and applications in renewable energy storage.

02 Electrolyte solutions for water treatment and purification

Electrolyte solutions play a crucial role in water treatment processes such as electrodialysis, electrodeionization, and electrolytic purification. These solutions facilitate the removal of contaminants, desalination, and disinfection of water. The specific composition of electrolytes can be tailored to target particular pollutants or to optimize energy efficiency in water treatment systems.Expand Specific Solutions03 Medical and physiological electrolyte formulations

Specialized electrolyte formulations are designed for medical applications including intravenous fluids, dialysis solutions, and sports drinks. These formulations carefully balance ions such as sodium, potassium, calcium, and magnesium to maintain proper hydration, support cellular function, and replace electrolytes lost through physical activity or medical conditions. The precise composition is critical for maintaining physiological homeostasis.Expand Specific Solutions04 Solid electrolyte materials for advanced devices

Solid electrolyte materials are developed for use in solid-state batteries, fuel cells, and other electrochemical devices. These materials conduct ions while maintaining a solid structure, offering advantages in safety, stability, and form factor compared to liquid electrolytes. Research focuses on improving ionic conductivity, mechanical properties, and interfacial compatibility with electrodes to enable next-generation energy storage and conversion technologies.Expand Specific Solutions05 Electrolyte systems for electrochemical processes

Specialized electrolyte systems are designed for industrial electrochemical processes such as electroplating, electrolysis, and electrowinning. These systems facilitate controlled ion transport and electron transfer at electrode surfaces, enabling precise metal deposition, chemical synthesis, or material extraction. The composition and concentration of electrolytes are optimized for specific applications to enhance efficiency, product quality, and process economics.Expand Specific Solutions

Key Industry Players in Bioelectronic Interface Development

The bioelectronic interface electrolyte market is in its growth phase, characterized by rapid technological advancement and expanding applications in medical devices and neural interfaces. The global market is projected to reach significant scale as healthcare technology integration accelerates. In terms of technical maturity, established players like Medtronic and Johnson & Johnson Vision Care lead with commercialized solutions, while research institutions including Massachusetts Institute of Technology, Kyushu University, and Arizona State University drive fundamental innovation. Chemical companies such as Sinopec, NGK Insulators, and 3M Innovative Properties contribute specialized materials expertise. The competitive landscape features strategic collaborations between academic institutions and industry players, with increasing focus on biocompatible, long-lasting electrolyte formulations that enhance signal transduction while minimizing tissue response.

Medtronic, Inc.

Technical Solution: Medtronic has developed advanced biocompatible electrolyte systems for implantable bioelectronic interfaces, focusing on long-term stability in physiological environments. Their proprietary electrolyte formulations incorporate ionic liquids and polymer-based gel electrolytes that maintain stable electrode-tissue interfaces while minimizing foreign body responses. These systems feature controlled ion transport mechanisms that optimize signal transduction between electronic devices and biological tissues. Medtronic's electrolyte technology includes specialized coatings that prevent protein adsorption and biofouling, extending device longevity in vivo. Their research has demonstrated significant improvements in charge transfer efficiency and reduced impedance at the electrode-tissue interface compared to conventional electrolyte systems, enabling more sensitive neural recording and stimulation capabilities for their neurostimulation platforms.

Strengths: Extensive clinical validation of electrolyte formulations in FDA-approved implantable devices; proprietary manufacturing processes ensuring consistent quality and performance. Weaknesses: Higher production costs compared to standard electrolytes; some formulations may require specific storage conditions to maintain stability.

Abbott Diabetes Care, Inc.

Technical Solution: Abbott Diabetes Care has pioneered specialized electrolyte systems for continuous glucose monitoring (CGM) bioelectronic interfaces. Their technology employs enzyme-optimized electrolyte formulations that enhance glucose oxidase stability and electron transfer efficiency at the sensing interface. The company has developed multi-component electrolyte systems containing carefully balanced redox mediators that facilitate electron shuttling between the glucose oxidation reaction and the electrode surface. These formulations incorporate biocompatible polymers that create semi-permeable membranes, allowing selective diffusion of glucose while excluding interfering substances. Abbott's electrolyte technology also features anti-inflammatory components that reduce tissue reaction at the insertion site, improving sensor accuracy and longevity. Their continuous research has led to electrolyte systems that maintain sensor performance across varying physiological conditions including temperature fluctuations and pH changes.

Strengths: Highly optimized for glucose sensing applications with demonstrated long-term stability in subcutaneous environments; excellent signal-to-noise ratio in complex biological fluids. Weaknesses: Specialized formulations may be less versatile for other bioelectronic applications; performance can be affected by extreme physiological conditions.

Critical Innovations in Electrolyte Material Science

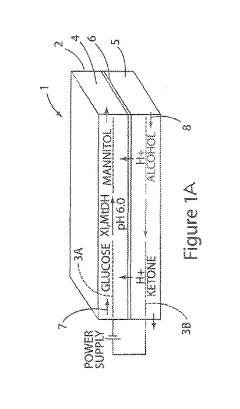

Renewable bioelectronic interface for electrobiocatalytic reactor

PatentInactiveUS10246786B2

Innovation

- A bioelectronic device with a conductive carbon electrode and a bioelectronic interface where the catalytically active material is electrostatically bound, allowing for easy removal and replacement by changing the pH, and a process for reconstituting the interface using aqueous media with specific pH levels to facilitate bonding and regeneration of the interface.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the design of bioelectronic interfaces, particularly when selecting appropriate electrolytes. The interaction between artificial electronic systems and biological tissues necessitates careful evaluation of potential adverse reactions, toxicity profiles, and long-term stability of electrolyte materials.

The primary biocompatibility concern for electrolytes in bioelectronic interfaces involves their potential cytotoxicity. Conventional electrolytes often contain components that may induce cell death or tissue inflammation when leaching occurs. Studies have demonstrated that certain ionic liquids and organic electrolytes can disrupt cell membranes, leading to cellular dysfunction and eventual necrosis. Therefore, comprehensive cytotoxicity testing using both in vitro cell cultures and in vivo animal models is essential before clinical implementation.

Immunogenicity represents another critical safety consideration, as foreign materials can trigger immune responses ranging from mild inflammation to severe rejection. Electrolytes containing novel polymers or nanoparticles may be recognized as foreign entities by the immune system, potentially leading to encapsulation of the device or systemic inflammatory responses. Recent research has focused on developing immunologically inert electrolyte formulations that minimize protein adsorption and subsequent immune cell recruitment.

The electrochemical stability of electrolytes directly impacts safety profiles, as degradation products may possess different toxicity characteristics than the original compounds. Redox reactions at the electrode-electrolyte interface can generate reactive oxygen species or other harmful byproducts that damage surrounding tissues. Advanced electrolyte systems incorporating antioxidant properties or self-healing capabilities have shown promise in mitigating these concerns.

Regulatory frameworks governing bioelectronic interfaces require rigorous safety assessment protocols for electrolyte materials. The FDA and equivalent international bodies mandate extensive biocompatibility testing according to ISO 10993 standards, including genotoxicity, sensitization, and systemic toxicity evaluations. Electrolyte developers must navigate these regulatory pathways early in the design process to avoid costly reformulations later.

Long-term stability presents unique challenges for implantable bioelectronic systems. Electrolytes must maintain their performance characteristics while resisting degradation from enzymatic activity, pH variations, and mechanical stresses in the biological environment. Encapsulation strategies using biocompatible polymers or hydrogels have emerged as effective approaches to isolate potentially harmful electrolyte components while maintaining necessary ionic conductivity.

The future of biocompatible electrolytes lies in biomimetic approaches that leverage naturally occurring ionic transport systems. Electrolyte formulations incorporating components found in extracellular matrices or utilizing biological ion channels show exceptional promise for seamless integration with living tissues while minimizing foreign body responses.

The primary biocompatibility concern for electrolytes in bioelectronic interfaces involves their potential cytotoxicity. Conventional electrolytes often contain components that may induce cell death or tissue inflammation when leaching occurs. Studies have demonstrated that certain ionic liquids and organic electrolytes can disrupt cell membranes, leading to cellular dysfunction and eventual necrosis. Therefore, comprehensive cytotoxicity testing using both in vitro cell cultures and in vivo animal models is essential before clinical implementation.

Immunogenicity represents another critical safety consideration, as foreign materials can trigger immune responses ranging from mild inflammation to severe rejection. Electrolytes containing novel polymers or nanoparticles may be recognized as foreign entities by the immune system, potentially leading to encapsulation of the device or systemic inflammatory responses. Recent research has focused on developing immunologically inert electrolyte formulations that minimize protein adsorption and subsequent immune cell recruitment.

The electrochemical stability of electrolytes directly impacts safety profiles, as degradation products may possess different toxicity characteristics than the original compounds. Redox reactions at the electrode-electrolyte interface can generate reactive oxygen species or other harmful byproducts that damage surrounding tissues. Advanced electrolyte systems incorporating antioxidant properties or self-healing capabilities have shown promise in mitigating these concerns.

Regulatory frameworks governing bioelectronic interfaces require rigorous safety assessment protocols for electrolyte materials. The FDA and equivalent international bodies mandate extensive biocompatibility testing according to ISO 10993 standards, including genotoxicity, sensitization, and systemic toxicity evaluations. Electrolyte developers must navigate these regulatory pathways early in the design process to avoid costly reformulations later.

Long-term stability presents unique challenges for implantable bioelectronic systems. Electrolytes must maintain their performance characteristics while resisting degradation from enzymatic activity, pH variations, and mechanical stresses in the biological environment. Encapsulation strategies using biocompatible polymers or hydrogels have emerged as effective approaches to isolate potentially harmful electrolyte components while maintaining necessary ionic conductivity.

The future of biocompatible electrolytes lies in biomimetic approaches that leverage naturally occurring ionic transport systems. Electrolyte formulations incorporating components found in extracellular matrices or utilizing biological ion channels show exceptional promise for seamless integration with living tissues while minimizing foreign body responses.

Scalability and Manufacturing Challenges

The scalability and manufacturing of bioelectronic interfaces with appropriate electrolyte systems present significant challenges that must be addressed for widespread commercial adoption. Current laboratory-scale production methods for electrolyte-based bioelectronic interfaces often involve manual processes that are difficult to translate to industrial-scale manufacturing. The transition from bench to production requires standardization of electrolyte formulations, which is complicated by the sensitivity of many ionic solutions to environmental factors such as temperature, humidity, and exposure to air.

Mass production of devices incorporating liquid or gel electrolytes faces particular hurdles related to encapsulation and shelf stability. Hermetic sealing technologies must prevent electrolyte leakage or evaporation while maintaining biocompatibility and flexibility. The development of automated dispensing systems capable of precisely depositing controlled volumes of electrolyte solutions represents another manufacturing bottleneck, especially for miniaturized or microfluidic bioelectronic platforms.

Supply chain considerations also impact scalability, as high-purity electrolyte components often come from limited sources and may be subject to batch-to-batch variations. This variability can significantly affect device performance and reliability, necessitating robust quality control protocols. Furthermore, the cost of specialty electrolyte materials can become prohibitive at scale, driving research toward more economical alternatives that maintain essential electrochemical properties.

Regulatory frameworks present additional complexity for manufacturing scale-up. Electrolyte formulations must meet stringent safety and biocompatibility standards, particularly for implantable devices. Documentation requirements for composition, purity, and stability add layers of validation testing that extend development timelines and increase costs.

Emerging approaches to address these challenges include the development of solid-state or quasi-solid electrolytes that offer improved manufacturing compatibility. These materials can potentially be integrated using established electronic manufacturing processes such as screen printing or roll-to-roll fabrication. Additionally, advances in microencapsulation technologies are enabling pre-packaged electrolyte systems that can be activated in situ, simplifying handling during device assembly.

Cross-disciplinary collaboration between materials scientists, chemical engineers, and manufacturing specialists is essential to overcome these scalability hurdles. The establishment of industry standards for electrolyte characterization and performance metrics would further facilitate the transition from research prototypes to commercially viable bioelectronic interfaces with optimized electrolyte systems.

Mass production of devices incorporating liquid or gel electrolytes faces particular hurdles related to encapsulation and shelf stability. Hermetic sealing technologies must prevent electrolyte leakage or evaporation while maintaining biocompatibility and flexibility. The development of automated dispensing systems capable of precisely depositing controlled volumes of electrolyte solutions represents another manufacturing bottleneck, especially for miniaturized or microfluidic bioelectronic platforms.

Supply chain considerations also impact scalability, as high-purity electrolyte components often come from limited sources and may be subject to batch-to-batch variations. This variability can significantly affect device performance and reliability, necessitating robust quality control protocols. Furthermore, the cost of specialty electrolyte materials can become prohibitive at scale, driving research toward more economical alternatives that maintain essential electrochemical properties.

Regulatory frameworks present additional complexity for manufacturing scale-up. Electrolyte formulations must meet stringent safety and biocompatibility standards, particularly for implantable devices. Documentation requirements for composition, purity, and stability add layers of validation testing that extend development timelines and increase costs.

Emerging approaches to address these challenges include the development of solid-state or quasi-solid electrolytes that offer improved manufacturing compatibility. These materials can potentially be integrated using established electronic manufacturing processes such as screen printing or roll-to-roll fabrication. Additionally, advances in microencapsulation technologies are enabling pre-packaged electrolyte systems that can be activated in situ, simplifying handling during device assembly.

Cross-disciplinary collaboration between materials scientists, chemical engineers, and manufacturing specialists is essential to overcome these scalability hurdles. The establishment of industry standards for electrolyte characterization and performance metrics would further facilitate the transition from research prototypes to commercially viable bioelectronic interfaces with optimized electrolyte systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!