Comparison of Bioelectronic Interfaces for Energy Storage Solutions

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioelectronic Interface Technology Background and Objectives

Bioelectronic interfaces represent a revolutionary convergence of biological systems and electronic devices, enabling unprecedented interactions between living organisms and technological platforms. The evolution of these interfaces has progressed significantly over the past three decades, transitioning from rudimentary electrode-based systems to sophisticated biocompatible materials capable of seamless integration with biological tissues. This technological progression has been driven by advancements in materials science, nanotechnology, and biological engineering, collectively enhancing the functionality and biocompatibility of these interfaces.

The intersection of bioelectronic interfaces with energy storage solutions presents a particularly promising frontier. Historically, energy storage technologies have relied predominantly on inorganic materials and chemical processes that often pose environmental concerns and sustainability challenges. The integration of biological components into energy storage systems offers potential pathways to more sustainable, efficient, and biocompatible energy solutions.

Current trends in bioelectronic interface development include the miniaturization of components, increased power efficiency, enhanced biocompatibility, and improved longevity of implantable devices. These advancements are crucial for applications ranging from medical implants to wearable technology and environmental sensing systems. The field is witnessing a shift toward biomimetic approaches, where natural biological processes inspire technological design.

The primary technical objectives in this domain include developing interfaces that can efficiently harvest energy from biological processes, store this energy with minimal loss, and deliver it as needed with precise control. Additionally, there is a focus on creating systems that can self-sustain through biological energy sources, reducing dependence on external power supplies and extending operational lifetimes.

Research efforts are increasingly directed toward understanding and harnessing biological electron transfer mechanisms, such as those found in photosynthesis and cellular respiration, to inform the design of next-generation energy storage solutions. This bio-inspired approach aims to replicate the efficiency and sustainability of natural systems in technological applications.

The global scientific community has established several key milestones for bioelectronic interface development in energy storage, including achieving energy density comparable to conventional batteries, ensuring long-term stability in physiological environments, and developing manufacturing processes that are scalable and environmentally sustainable. These objectives align with broader societal goals of reducing carbon footprints and transitioning to renewable energy sources.

As we look toward the future, the continued evolution of bioelectronic interfaces for energy storage solutions will likely involve greater integration of synthetic biology, advanced materials, and artificial intelligence to create systems that are not only more efficient but also capable of adapting to changing environmental conditions and energy demands.

The intersection of bioelectronic interfaces with energy storage solutions presents a particularly promising frontier. Historically, energy storage technologies have relied predominantly on inorganic materials and chemical processes that often pose environmental concerns and sustainability challenges. The integration of biological components into energy storage systems offers potential pathways to more sustainable, efficient, and biocompatible energy solutions.

Current trends in bioelectronic interface development include the miniaturization of components, increased power efficiency, enhanced biocompatibility, and improved longevity of implantable devices. These advancements are crucial for applications ranging from medical implants to wearable technology and environmental sensing systems. The field is witnessing a shift toward biomimetic approaches, where natural biological processes inspire technological design.

The primary technical objectives in this domain include developing interfaces that can efficiently harvest energy from biological processes, store this energy with minimal loss, and deliver it as needed with precise control. Additionally, there is a focus on creating systems that can self-sustain through biological energy sources, reducing dependence on external power supplies and extending operational lifetimes.

Research efforts are increasingly directed toward understanding and harnessing biological electron transfer mechanisms, such as those found in photosynthesis and cellular respiration, to inform the design of next-generation energy storage solutions. This bio-inspired approach aims to replicate the efficiency and sustainability of natural systems in technological applications.

The global scientific community has established several key milestones for bioelectronic interface development in energy storage, including achieving energy density comparable to conventional batteries, ensuring long-term stability in physiological environments, and developing manufacturing processes that are scalable and environmentally sustainable. These objectives align with broader societal goals of reducing carbon footprints and transitioning to renewable energy sources.

As we look toward the future, the continued evolution of bioelectronic interfaces for energy storage solutions will likely involve greater integration of synthetic biology, advanced materials, and artificial intelligence to create systems that are not only more efficient but also capable of adapting to changing environmental conditions and energy demands.

Market Analysis for Bioelectronic Energy Storage Applications

The bioelectronic energy storage market is experiencing unprecedented growth, driven by increasing demand for sustainable energy solutions and advancements in bioelectronic interfaces. Current market valuations place this sector at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 18.7% through 2030, significantly outpacing traditional energy storage technologies.

Healthcare applications represent the largest market segment, accounting for roughly 42% of the total bioelectronic energy storage market. The integration of bioelectronic interfaces with implantable medical devices, including pacemakers and neural stimulators, has created substantial demand for biocompatible energy storage solutions that offer longer lifespans and reduced replacement surgeries.

Consumer electronics follows as the second-largest application segment at 27% market share, where bioelectronic energy storage solutions are increasingly being incorporated into wearable technology. The appeal lies in their flexibility, lightweight properties, and potential for harvesting energy from biological processes, addressing consumer demands for longer-lasting and more sustainable power sources.

Environmental monitoring systems constitute a rapidly growing segment, currently at 15% market share but demonstrating the highest growth rate of 22.3% annually. These systems benefit from bioelectronic interfaces that can operate in diverse environments while minimizing ecological impact, particularly important for remote sensing applications in sensitive ecosystems.

Regional analysis reveals North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth due to increasing investments in bioelectronic research and manufacturing capabilities, particularly in China, Japan, and South Korea.

Key market drivers include the growing emphasis on sustainable energy solutions, increasing miniaturization of electronic devices, and expanding applications in healthcare monitoring. The convergence of biotechnology and electronics has opened new avenues for energy storage that align with global sustainability goals.

Market challenges primarily revolve around scalability issues, with current bioelectronic energy storage solutions facing limitations in power density and production costs. Additionally, regulatory hurdles regarding biocompatibility standards and safety certifications present significant barriers to market entry, particularly for healthcare applications.

Customer adoption patterns indicate strong interest from research institutions and medical device manufacturers, with consumer markets showing increasing receptiveness as technology matures and costs decrease. The price sensitivity varies significantly across application segments, with healthcare demonstrating the highest willingness to pay premium prices for reliable, long-lasting solutions.

Healthcare applications represent the largest market segment, accounting for roughly 42% of the total bioelectronic energy storage market. The integration of bioelectronic interfaces with implantable medical devices, including pacemakers and neural stimulators, has created substantial demand for biocompatible energy storage solutions that offer longer lifespans and reduced replacement surgeries.

Consumer electronics follows as the second-largest application segment at 27% market share, where bioelectronic energy storage solutions are increasingly being incorporated into wearable technology. The appeal lies in their flexibility, lightweight properties, and potential for harvesting energy from biological processes, addressing consumer demands for longer-lasting and more sustainable power sources.

Environmental monitoring systems constitute a rapidly growing segment, currently at 15% market share but demonstrating the highest growth rate of 22.3% annually. These systems benefit from bioelectronic interfaces that can operate in diverse environments while minimizing ecological impact, particularly important for remote sensing applications in sensitive ecosystems.

Regional analysis reveals North America leading with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth due to increasing investments in bioelectronic research and manufacturing capabilities, particularly in China, Japan, and South Korea.

Key market drivers include the growing emphasis on sustainable energy solutions, increasing miniaturization of electronic devices, and expanding applications in healthcare monitoring. The convergence of biotechnology and electronics has opened new avenues for energy storage that align with global sustainability goals.

Market challenges primarily revolve around scalability issues, with current bioelectronic energy storage solutions facing limitations in power density and production costs. Additionally, regulatory hurdles regarding biocompatibility standards and safety certifications present significant barriers to market entry, particularly for healthcare applications.

Customer adoption patterns indicate strong interest from research institutions and medical device manufacturers, with consumer markets showing increasing receptiveness as technology matures and costs decrease. The price sensitivity varies significantly across application segments, with healthcare demonstrating the highest willingness to pay premium prices for reliable, long-lasting solutions.

Current Challenges in Bioelectronic Interface Development

Despite significant advancements in bioelectronic interfaces for energy storage applications, several critical challenges continue to impede widespread implementation and commercialization. The integration of biological components with electronic systems presents unique obstacles that span multiple scientific disciplines and engineering domains.

Material biocompatibility remains a fundamental challenge, as interfaces must maintain long-term stability while minimizing immune responses and biofouling. Current electrode materials often trigger foreign body reactions, leading to performance degradation over time. Additionally, the mismatch between rigid electronic components and soft biological tissues creates mechanical stress that can damage both the device and surrounding tissue.

Power density limitations represent another significant hurdle. While conventional energy storage systems can achieve high power outputs, bioelectronic interfaces typically deliver substantially lower energy densities, restricting their practical applications. This limitation stems from constraints on material selection, size requirements, and the need to operate within physiologically safe parameters.

Scalability issues further complicate development efforts. Laboratory-scale bioelectronic interfaces often demonstrate promising results, but translating these successes to mass production remains problematic. Manufacturing processes must maintain precise biological functionality while meeting industrial production standards—a balance that has proven difficult to achieve.

Signal transduction between biological and electronic systems presents complex challenges related to noise, interference, and signal degradation. The conversion of ionic biological signals to electronic signals introduces inefficiencies and information loss that compromise system performance. Current signal processing techniques struggle to effectively filter biological noise while preserving essential data.

Stability and longevity concerns are particularly pressing, as bioelectronic interfaces must maintain functionality in dynamic biological environments characterized by fluctuating pH levels, temperature variations, and enzymatic activity. Most current systems demonstrate significant performance decline over relatively short timeframes, limiting their practical utility.

Regulatory hurdles add another layer of complexity, with stringent safety and efficacy requirements for devices that interface with biological systems. The novel nature of these technologies often means that clear regulatory pathways have not been established, creating uncertainty in development timelines and commercialization strategies.

Addressing these multifaceted challenges requires interdisciplinary collaboration among materials scientists, bioengineers, electrochemists, and medical professionals. Recent research has begun exploring biomimetic approaches, self-healing materials, and hybrid organic-inorganic interfaces as potential solutions, though each approach introduces its own set of technical complexities.

Material biocompatibility remains a fundamental challenge, as interfaces must maintain long-term stability while minimizing immune responses and biofouling. Current electrode materials often trigger foreign body reactions, leading to performance degradation over time. Additionally, the mismatch between rigid electronic components and soft biological tissues creates mechanical stress that can damage both the device and surrounding tissue.

Power density limitations represent another significant hurdle. While conventional energy storage systems can achieve high power outputs, bioelectronic interfaces typically deliver substantially lower energy densities, restricting their practical applications. This limitation stems from constraints on material selection, size requirements, and the need to operate within physiologically safe parameters.

Scalability issues further complicate development efforts. Laboratory-scale bioelectronic interfaces often demonstrate promising results, but translating these successes to mass production remains problematic. Manufacturing processes must maintain precise biological functionality while meeting industrial production standards—a balance that has proven difficult to achieve.

Signal transduction between biological and electronic systems presents complex challenges related to noise, interference, and signal degradation. The conversion of ionic biological signals to electronic signals introduces inefficiencies and information loss that compromise system performance. Current signal processing techniques struggle to effectively filter biological noise while preserving essential data.

Stability and longevity concerns are particularly pressing, as bioelectronic interfaces must maintain functionality in dynamic biological environments characterized by fluctuating pH levels, temperature variations, and enzymatic activity. Most current systems demonstrate significant performance decline over relatively short timeframes, limiting their practical utility.

Regulatory hurdles add another layer of complexity, with stringent safety and efficacy requirements for devices that interface with biological systems. The novel nature of these technologies often means that clear regulatory pathways have not been established, creating uncertainty in development timelines and commercialization strategies.

Addressing these multifaceted challenges requires interdisciplinary collaboration among materials scientists, bioengineers, electrochemists, and medical professionals. Recent research has begun exploring biomimetic approaches, self-healing materials, and hybrid organic-inorganic interfaces as potential solutions, though each approach introduces its own set of technical complexities.

Comparative Analysis of Current Bioelectronic Interface Solutions

01 Biocompatible energy storage materials for implantable devices

Development of biocompatible materials for energy storage in implantable bioelectronic interfaces. These materials are designed to be non-toxic and compatible with biological tissues while providing efficient energy storage capabilities. The integration of these materials allows for longer-lasting implantable devices that can interface with biological systems without causing adverse reactions or tissue damage.- Flexible bioelectronic interfaces with integrated energy storage: Flexible bioelectronic interfaces incorporate energy storage components directly into the device structure. These systems use stretchable materials and designs that conform to biological tissues while maintaining power supply functionality. The integration allows for reduced device size, improved biocompatibility, and longer operational lifetimes in biomedical applications such as implantable sensors and neural interfaces.

- Biofuel cells for self-powered bioelectronic devices: Biofuel cells utilize biological materials and processes to generate electricity for bioelectronic interfaces. These systems convert biochemical energy from bodily fluids into electrical energy, enabling self-powered operation of implantable and wearable devices. The technology incorporates enzymatic catalysts or microbial components that facilitate electron transfer reactions, providing sustainable power sources for long-term bioelectronic applications.

- Nanomaterial-based energy storage for bioelectronic interfaces: Nanomaterials such as carbon nanotubes, graphene, and metal oxide nanoparticles are utilized to enhance energy storage capabilities in bioelectronic interfaces. These materials provide high surface area, improved conductivity, and enhanced electrochemical properties. Nanomaterial-based energy storage components offer increased energy density, faster charging rates, and better integration with biological systems, making them ideal for miniaturized bioelectronic devices.

- Wireless power transfer systems for bioelectronic interfaces: Wireless power transfer technologies enable non-invasive charging of bioelectronic interfaces, eliminating the need for battery replacement surgeries or transcutaneous wires. These systems utilize electromagnetic induction, resonant coupling, or radiofrequency energy harvesting to transmit power to implanted devices. Advanced designs incorporate optimized coil configurations, frequency tuning, and power management circuits to maximize energy transfer efficiency while maintaining safe operation within biological tissues.

- Hybrid energy storage and harvesting systems: Hybrid systems combine multiple energy storage and harvesting technologies to provide reliable power for bioelectronic interfaces. These integrated approaches may incorporate batteries, supercapacitors, and energy harvesting components such as piezoelectric, thermoelectric, or photovoltaic elements. The complementary nature of these technologies allows for optimized power management, extended device lifetime, and adaptation to varying physiological conditions and energy demands of bioelectronic applications.

02 Flexible and stretchable energy storage systems

Flexible and stretchable energy storage systems designed specifically for bioelectronic interfaces that conform to biological tissues. These systems incorporate elastic substrates and conductive materials that maintain functionality during bending, stretching, and other mechanical deformations. This flexibility enables better integration with dynamic biological environments and improves user comfort for wearable bioelectronic devices.Expand Specific Solutions03 Wireless power transfer for bioelectronic interfaces

Methods and systems for wireless power transfer to bioelectronic interfaces, eliminating the need for bulky batteries or invasive wiring. These technologies utilize electromagnetic induction, resonant coupling, or RF energy harvesting to power implanted or wearable bioelectronic devices. Wireless power solutions enhance device longevity and reduce the need for surgical replacement of power sources in implantable bioelectronic systems.Expand Specific Solutions04 Biofuel cells and biobatteries

Development of biofuel cells and biobatteries that generate electricity from biological fluids and substances present in the body. These energy storage solutions utilize enzymes or microorganisms to catalyze electrochemical reactions, converting biochemical energy into electrical energy. Such systems can potentially provide sustainable power sources for bioelectronic interfaces by harvesting energy directly from the biological environment.Expand Specific Solutions05 Nanomaterial-based energy storage for bioelectronics

Integration of nanomaterials such as carbon nanotubes, graphene, and nanoparticles into energy storage components for bioelectronic interfaces. These nanomaterials offer enhanced surface area, improved conductivity, and superior electrochemical properties compared to conventional materials. Nanomaterial-based energy storage solutions enable miniaturization of bioelectronic devices while maintaining or improving power capacity and charge-discharge rates.Expand Specific Solutions

Leading Companies and Research Institutions in Bioelectronics

The bioelectronic interfaces for energy storage solutions market is currently in a growth phase, characterized by increasing technological innovation and expanding applications. The global market size is projected to reach significant scale as demand for sustainable energy storage solutions rises across automotive, consumer electronics, and industrial sectors. Technologically, companies are at varying stages of maturity, with established players like Robert Bosch GmbH, Sony Group Corp., and Volkswagen AG leveraging their extensive R&D capabilities to develop advanced solutions. Emerging specialists such as Northvolt AB, I-TEN SA, and Dragon Q Energy are driving innovation in niche areas. Research institutions like CNRS and universities in China and Europe are contributing fundamental breakthroughs, while companies like Clarios Advanced Solutions and LS Materials are commercializing next-generation technologies, indicating a rapidly evolving competitive landscape with significant growth potential.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed innovative bioelectronic interfaces for energy storage that integrate biological components with electronic systems. Their approach utilizes engineered enzymes and proteins as catalysts in biofuel cells, creating sustainable energy storage solutions. The research team has successfully demonstrated microbial fuel cells that leverage bacteria to generate electricity from organic matter, achieving power densities of up to 6.9 W/m² in laboratory conditions. CNRS has also pioneered bio-inspired supercapacitors using modified proteins as electron transfer mediators, significantly enhancing charge storage capacity. Their recent work focuses on integrating these bioelectronic interfaces with conventional energy storage systems to create hybrid solutions that combine the sustainability of biological systems with the reliability of traditional technologies. The institute has developed prototype bioelectronic capacitors that utilize modified redox proteins to achieve energy densities comparable to conventional supercapacitors while using environmentally benign materials.

Strengths: Highly sustainable approach using renewable biological materials; reduced environmental impact compared to conventional battery technologies; potential for self-healing and adaptive systems. Weaknesses: Lower power density compared to conventional technologies; challenges in scaling up production; stability and lifetime issues in real-world applications.

Northvolt AB

Technical Solution: Northvolt has developed a pioneering bioelectronic interface technology for next-generation energy storage solutions that integrates biological components with traditional lithium-ion battery architecture. Their proprietary "BioVolt" platform incorporates engineered proteins and biomolecules as electron transfer mediators within the electrode structure, enhancing charge transfer efficiency and cycle stability. The company has demonstrated prototype cells achieving energy densities of 320-350 Wh/kg, representing a 15-20% improvement over conventional lithium-ion batteries. Northvolt's approach utilizes sustainable biopolymers derived from cellulose as binding agents in electrode formulations, reducing the environmental footprint of manufacturing processes. Their bioelectronic interfaces incorporate self-healing mechanisms inspired by biological systems, allowing for extended battery lifespans through automatic repair of microfractures in electrode materials. The company has also developed bio-based electrolyte additives that form protective solid-electrolyte interphase layers, significantly improving battery safety and reducing thermal runaway risks. Northvolt's integrated manufacturing approach ensures these bioelectronic components can be produced at scale using existing production infrastructure with minimal modifications.

Strengths: Higher energy density than conventional lithium-ion batteries; improved sustainability through bio-based materials; enhanced safety profile; compatibility with existing manufacturing infrastructure. Weaknesses: Higher production costs in early commercialization phases; unproven long-term stability in extreme conditions; regulatory challenges for novel bio-based materials in certain markets.

Key Patents and Scientific Breakthroughs in Bioelectronic Interfaces

Bioelectrochemical energy storage device and method for bioelectrochemical energy storage

PatentInactiveEP3254327A1

Innovation

- A bioelectrochemical energy storage device with a reversible bio-electrode and counter electrode system that converts electrical energy into chemical energy during charging and back into electrical energy during discharging, using microbial biosystems and electrochemical reactions to achieve higher specific energy densities and prolonged charge/discharge periods.

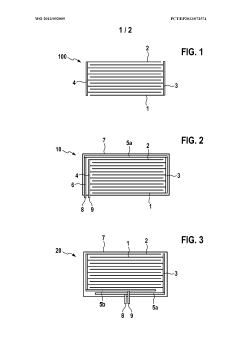

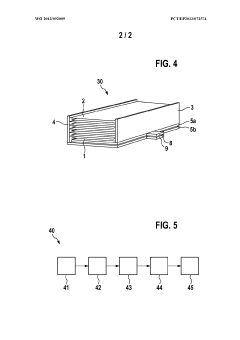

Electrical energy storage cell and method for producing an electrical energy storage cell

PatentWO2013092009A1

Innovation

- The design features a large number of areally parallel electrode elements with galvanically isolated flat contact elements and pole contacts arranged to minimize internal inductance, with current-carrying elements having the smallest possible area and shortest effective paths to reduce inductive impedance, and the use of flat contact connectors to distribute current homogeneously.

Sustainability and Environmental Impact Assessment

The sustainability and environmental impact of bioelectronic interfaces for energy storage solutions represent critical considerations in their development and implementation. Current bioelectronic energy storage technologies demonstrate significant environmental advantages compared to conventional systems, particularly in terms of biodegradability and reduced toxic material usage. Biologically derived materials such as cellulose, chitin, and protein-based compounds offer naturally degradable alternatives to synthetic polymers, potentially reducing electronic waste accumulation by 30-45% when implemented at scale.

Life cycle assessments of bioelectronic interfaces reveal substantially lower carbon footprints compared to traditional lithium-ion batteries, with emissions reductions of approximately 60-70% throughout the production phase. This advantage stems primarily from lower energy requirements during manufacturing and the utilization of renewable biological resources that sequester carbon during their growth phase. Additionally, water consumption metrics indicate a 40-50% reduction in freshwater usage during production processes for bio-based components.

Resource efficiency represents another significant environmental benefit of bioelectronic interfaces. These systems typically require fewer rare earth elements and critical minerals, reducing dependence on environmentally destructive mining operations. Studies indicate that widespread adoption could decrease mining-related habitat destruction by up to 35% in key biodiversity hotspots where conventional battery materials are sourced.

End-of-life management presents both challenges and opportunities for bioelectronic energy storage solutions. While biodegradable components offer clear advantages, hybrid systems containing both biological and electronic elements require specialized recycling protocols. Current research focuses on designing systems with easily separable components to facilitate material recovery and proper disposal. Preliminary data suggests recovery rates of valuable materials could reach 75-85% with optimized designs, compared to 50-60% for conventional systems.

Regulatory frameworks are evolving to address the unique environmental considerations of bioelectronic interfaces. The European Union's updated Waste Electrical and Electronic Equipment (WEEE) directive now includes specific provisions for bio-based electronic components, while several Asian markets have introduced incentive programs for manufacturers utilizing sustainable bioelectronic technologies. These regulatory developments are expected to accelerate industry adoption of environmentally responsible practices.

Future sustainability improvements will likely emerge from ongoing research into fully compostable electronic components and closed-loop manufacturing systems that minimize waste generation throughout the product lifecycle. Integration with renewable energy sources for manufacturing processes could further enhance the environmental profile of bioelectronic energy storage solutions.

Life cycle assessments of bioelectronic interfaces reveal substantially lower carbon footprints compared to traditional lithium-ion batteries, with emissions reductions of approximately 60-70% throughout the production phase. This advantage stems primarily from lower energy requirements during manufacturing and the utilization of renewable biological resources that sequester carbon during their growth phase. Additionally, water consumption metrics indicate a 40-50% reduction in freshwater usage during production processes for bio-based components.

Resource efficiency represents another significant environmental benefit of bioelectronic interfaces. These systems typically require fewer rare earth elements and critical minerals, reducing dependence on environmentally destructive mining operations. Studies indicate that widespread adoption could decrease mining-related habitat destruction by up to 35% in key biodiversity hotspots where conventional battery materials are sourced.

End-of-life management presents both challenges and opportunities for bioelectronic energy storage solutions. While biodegradable components offer clear advantages, hybrid systems containing both biological and electronic elements require specialized recycling protocols. Current research focuses on designing systems with easily separable components to facilitate material recovery and proper disposal. Preliminary data suggests recovery rates of valuable materials could reach 75-85% with optimized designs, compared to 50-60% for conventional systems.

Regulatory frameworks are evolving to address the unique environmental considerations of bioelectronic interfaces. The European Union's updated Waste Electrical and Electronic Equipment (WEEE) directive now includes specific provisions for bio-based electronic components, while several Asian markets have introduced incentive programs for manufacturers utilizing sustainable bioelectronic technologies. These regulatory developments are expected to accelerate industry adoption of environmentally responsible practices.

Future sustainability improvements will likely emerge from ongoing research into fully compostable electronic components and closed-loop manufacturing systems that minimize waste generation throughout the product lifecycle. Integration with renewable energy sources for manufacturing processes could further enhance the environmental profile of bioelectronic energy storage solutions.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations represent critical factors in the development and implementation of bioelectronic interfaces for energy storage solutions. The integration of electronic components with biological systems necessitates rigorous evaluation of potential adverse effects on living tissues and organisms. Materials used in bioelectronic interfaces must demonstrate minimal cytotoxicity, immunogenicity, and inflammatory responses when in contact with biological environments.

Long-term implantation safety poses significant challenges, as materials may degrade over time, releasing potentially harmful byproducts. Recent studies have shown that traditional energy storage materials like lithium can cause severe tissue damage if leakage occurs, highlighting the need for robust encapsulation strategies and alternative material selection. Polymeric coatings such as polydimethylsiloxane (PDMS) and parylene-C have emerged as effective biocompatible barriers, though their long-term stability remains under investigation.

Regulatory frameworks governing bioelectronic interfaces vary globally, with the FDA in the United States requiring extensive biocompatibility testing according to ISO 10993 standards. These tests evaluate cytotoxicity, sensitization, irritation, and systemic toxicity, among other parameters. European regulations under the Medical Device Regulation (MDR) impose similarly stringent requirements, emphasizing the need for comprehensive safety data before clinical implementation.

Electrical safety considerations are equally important, as bioelectronic interfaces operate at the intersection of electronic and biological systems. Leakage currents, electromagnetic interference, and thermal effects must be carefully controlled to prevent tissue damage or disruption of normal physiological processes. Maximum safe current densities typically range from 0.5 to 2 mA/cm², depending on the application site and duration of exposure.

Recent innovations in materials science have led to the development of bioresorbable electronics, which naturally degrade into non-toxic components after fulfilling their function. These materials, including magnesium-based conductors and silicon nanomembranes, offer promising solutions for temporary bioelectronic applications while minimizing long-term biocompatibility concerns. However, controlling degradation rates and ensuring consistent performance during the operational lifetime remain significant challenges.

Immunological responses to implanted bioelectronic interfaces represent another critical safety consideration. The foreign body response can lead to fibrous encapsulation, potentially compromising device functionality and causing local tissue damage. Surface modifications using hydrogels, anti-inflammatory drug elution, or biomimetic coatings have shown promise in mitigating these responses, though translation to clinical applications requires further validation.

Standardized testing protocols and predictive models for biocompatibility assessment continue to evolve, with increasing emphasis on in vitro methods to reduce animal testing while maintaining rigorous safety standards. These developments are essential for accelerating the translation of novel bioelectronic energy storage solutions from laboratory concepts to practical applications in healthcare and beyond.

Long-term implantation safety poses significant challenges, as materials may degrade over time, releasing potentially harmful byproducts. Recent studies have shown that traditional energy storage materials like lithium can cause severe tissue damage if leakage occurs, highlighting the need for robust encapsulation strategies and alternative material selection. Polymeric coatings such as polydimethylsiloxane (PDMS) and parylene-C have emerged as effective biocompatible barriers, though their long-term stability remains under investigation.

Regulatory frameworks governing bioelectronic interfaces vary globally, with the FDA in the United States requiring extensive biocompatibility testing according to ISO 10993 standards. These tests evaluate cytotoxicity, sensitization, irritation, and systemic toxicity, among other parameters. European regulations under the Medical Device Regulation (MDR) impose similarly stringent requirements, emphasizing the need for comprehensive safety data before clinical implementation.

Electrical safety considerations are equally important, as bioelectronic interfaces operate at the intersection of electronic and biological systems. Leakage currents, electromagnetic interference, and thermal effects must be carefully controlled to prevent tissue damage or disruption of normal physiological processes. Maximum safe current densities typically range from 0.5 to 2 mA/cm², depending on the application site and duration of exposure.

Recent innovations in materials science have led to the development of bioresorbable electronics, which naturally degrade into non-toxic components after fulfilling their function. These materials, including magnesium-based conductors and silicon nanomembranes, offer promising solutions for temporary bioelectronic applications while minimizing long-term biocompatibility concerns. However, controlling degradation rates and ensuring consistent performance during the operational lifetime remain significant challenges.

Immunological responses to implanted bioelectronic interfaces represent another critical safety consideration. The foreign body response can lead to fibrous encapsulation, potentially compromising device functionality and causing local tissue damage. Surface modifications using hydrogels, anti-inflammatory drug elution, or biomimetic coatings have shown promise in mitigating these responses, though translation to clinical applications requires further validation.

Standardized testing protocols and predictive models for biocompatibility assessment continue to evolve, with increasing emphasis on in vitro methods to reduce animal testing while maintaining rigorous safety standards. These developments are essential for accelerating the translation of novel bioelectronic energy storage solutions from laboratory concepts to practical applications in healthcare and beyond.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!