The Role of Polymers in Bioelectronic Interface Technology

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioelectronic Interface Polymers Background and Objectives

Bioelectronic interfaces represent a revolutionary frontier where electronics meet biology, enabling direct communication between electronic devices and biological systems. Polymers have emerged as critical materials in this field due to their unique properties that bridge the gap between rigid electronic components and soft biological tissues. The evolution of polymer-based bioelectronic interfaces can be traced back to the 1970s with the discovery of conductive polymers, which opened new possibilities for creating flexible, biocompatible electronic systems.

Over the past decades, the field has witnessed significant advancements, transitioning from simple conductive polymer films to sophisticated architectures incorporating multiple functionalities. The development trajectory has been driven by the increasing demand for minimally invasive medical devices, neural interfaces, biosensors, and drug delivery systems that can seamlessly integrate with living tissues.

Current polymer technologies in bioelectronics encompass a wide range of materials, including conductive polymers like PEDOT:PSS, biodegradable polymers such as PLGA, and responsive hydrogels that can change properties in response to biological stimuli. These materials have enabled unprecedented progress in applications ranging from neural recording electrodes to artificial skin and organ-on-chip platforms.

The technical objectives in this field are multifaceted and ambitious. Primary goals include enhancing the biocompatibility of electronic interfaces to minimize foreign body responses, improving long-term stability in physiological environments, and increasing the spatial resolution of sensing and stimulation capabilities. Additionally, researchers aim to develop polymers with tunable mechanical properties that can match the elasticity of target tissues, reducing mechanical mismatch and associated inflammation.

Another critical objective is the development of biodegradable electronic systems that can perform their function for a predetermined period before safely dissolving in the body, eliminating the need for removal surgeries. Simultaneously, there is a push toward creating self-healing polymers that can extend device lifespan by autonomously repairing damage caused by mechanical stress or biochemical degradation.

The field is also moving toward multifunctional polymer interfaces that can simultaneously record electrical signals, deliver drugs, and monitor biochemical markers. This integration of multiple capabilities within a single polymer platform represents the next frontier in bioelectronic interface technology, potentially enabling closed-loop therapeutic systems that can adapt to changing physiological conditions in real-time.

As we look toward future developments, the convergence of polymer science, electronics, and biotechnology promises to yield increasingly sophisticated bioelectronic interfaces with transformative implications for healthcare, neuroscience, and human-machine interaction.

Over the past decades, the field has witnessed significant advancements, transitioning from simple conductive polymer films to sophisticated architectures incorporating multiple functionalities. The development trajectory has been driven by the increasing demand for minimally invasive medical devices, neural interfaces, biosensors, and drug delivery systems that can seamlessly integrate with living tissues.

Current polymer technologies in bioelectronics encompass a wide range of materials, including conductive polymers like PEDOT:PSS, biodegradable polymers such as PLGA, and responsive hydrogels that can change properties in response to biological stimuli. These materials have enabled unprecedented progress in applications ranging from neural recording electrodes to artificial skin and organ-on-chip platforms.

The technical objectives in this field are multifaceted and ambitious. Primary goals include enhancing the biocompatibility of electronic interfaces to minimize foreign body responses, improving long-term stability in physiological environments, and increasing the spatial resolution of sensing and stimulation capabilities. Additionally, researchers aim to develop polymers with tunable mechanical properties that can match the elasticity of target tissues, reducing mechanical mismatch and associated inflammation.

Another critical objective is the development of biodegradable electronic systems that can perform their function for a predetermined period before safely dissolving in the body, eliminating the need for removal surgeries. Simultaneously, there is a push toward creating self-healing polymers that can extend device lifespan by autonomously repairing damage caused by mechanical stress or biochemical degradation.

The field is also moving toward multifunctional polymer interfaces that can simultaneously record electrical signals, deliver drugs, and monitor biochemical markers. This integration of multiple capabilities within a single polymer platform represents the next frontier in bioelectronic interface technology, potentially enabling closed-loop therapeutic systems that can adapt to changing physiological conditions in real-time.

As we look toward future developments, the convergence of polymer science, electronics, and biotechnology promises to yield increasingly sophisticated bioelectronic interfaces with transformative implications for healthcare, neuroscience, and human-machine interaction.

Market Analysis for Polymer-Based Bioelectronic Interfaces

The global market for polymer-based bioelectronic interfaces is experiencing robust growth, projected to reach $7.5 billion by 2027, with a compound annual growth rate (CAGR) of 14.3% from 2022 to 2027. This growth is primarily driven by increasing applications in neural interfaces, biosensors, drug delivery systems, and implantable medical devices.

Healthcare applications currently dominate the market landscape, accounting for approximately 65% of the total market share. Within healthcare, neural interfaces for treating neurological disorders represent the fastest-growing segment, expanding at 17.8% annually. The aging global population and rising prevalence of chronic diseases are significant market drivers, creating sustained demand for advanced bioelectronic solutions.

Regionally, North America leads the market with 42% share, followed by Europe (28%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to witness the highest growth rate of 16.5% during the forecast period, primarily due to increasing healthcare investments in China, Japan, and South Korea, along with the expansion of medical device manufacturing capabilities.

Consumer demand trends indicate a strong preference for minimally invasive, biocompatible solutions with extended operational lifespans. End-users are increasingly prioritizing devices that offer improved signal-to-noise ratios, reduced foreign body responses, and enhanced long-term stability at the tissue-electrode interface.

The market is characterized by significant investment activity, with venture capital funding for polymer-based bioelectronic startups reaching $1.2 billion in 2022, a 35% increase from the previous year. This investment surge reflects growing confidence in the commercial potential of these technologies.

Regulatory considerations remain a critical market factor, with approval processes for implantable bioelectronic devices typically taking 3-5 years in major markets. Recent regulatory frameworks have begun adapting to accommodate novel polymer-based technologies, potentially accelerating time-to-market for innovative products.

Pricing analysis reveals that while initial development costs for polymer-based interfaces are high, economies of scale and manufacturing innovations are gradually reducing unit costs, making these technologies increasingly accessible for broader applications. Current premium pricing strategies reflect the significant value proposition these interfaces offer in clinical settings.

Market challenges include competition from alternative technologies, reimbursement uncertainties in healthcare systems, and the need for extensive clinical validation. However, these are counterbalanced by strong growth drivers including technological advancements, increasing prevalence of target conditions, and expanding application areas beyond traditional medical uses.

Healthcare applications currently dominate the market landscape, accounting for approximately 65% of the total market share. Within healthcare, neural interfaces for treating neurological disorders represent the fastest-growing segment, expanding at 17.8% annually. The aging global population and rising prevalence of chronic diseases are significant market drivers, creating sustained demand for advanced bioelectronic solutions.

Regionally, North America leads the market with 42% share, followed by Europe (28%) and Asia-Pacific (23%). However, the Asia-Pacific region is expected to witness the highest growth rate of 16.5% during the forecast period, primarily due to increasing healthcare investments in China, Japan, and South Korea, along with the expansion of medical device manufacturing capabilities.

Consumer demand trends indicate a strong preference for minimally invasive, biocompatible solutions with extended operational lifespans. End-users are increasingly prioritizing devices that offer improved signal-to-noise ratios, reduced foreign body responses, and enhanced long-term stability at the tissue-electrode interface.

The market is characterized by significant investment activity, with venture capital funding for polymer-based bioelectronic startups reaching $1.2 billion in 2022, a 35% increase from the previous year. This investment surge reflects growing confidence in the commercial potential of these technologies.

Regulatory considerations remain a critical market factor, with approval processes for implantable bioelectronic devices typically taking 3-5 years in major markets. Recent regulatory frameworks have begun adapting to accommodate novel polymer-based technologies, potentially accelerating time-to-market for innovative products.

Pricing analysis reveals that while initial development costs for polymer-based interfaces are high, economies of scale and manufacturing innovations are gradually reducing unit costs, making these technologies increasingly accessible for broader applications. Current premium pricing strategies reflect the significant value proposition these interfaces offer in clinical settings.

Market challenges include competition from alternative technologies, reimbursement uncertainties in healthcare systems, and the need for extensive clinical validation. However, these are counterbalanced by strong growth drivers including technological advancements, increasing prevalence of target conditions, and expanding application areas beyond traditional medical uses.

Current Polymer Technologies and Challenges in Bioelectronics

Polymer materials have emerged as critical components in bioelectronic interfaces due to their unique properties that bridge the gap between rigid electronic devices and soft biological tissues. Currently, conductive polymers like poly(3,4-ethylenedioxythiophene) (PEDOT), polypyrrole (PPy), and polyaniline (PANI) dominate the field, offering excellent electrical conductivity while maintaining biocompatibility. These materials have revolutionized neural interfaces, biosensors, and implantable devices by reducing mechanical mismatch with tissue and improving signal transduction.

Hydrogel-based polymers represent another significant category, providing high water content environments that mimic extracellular matrices. These materials excel in applications requiring ion transport and tissue integration, with examples including polyacrylamide, poly(vinyl alcohol), and alginate-based systems. Their ability to swell and maintain hydration creates favorable conditions for cell adhesion and growth at the bioelectronic interface.

Biodegradable polymers such as poly(lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL), and silk fibroin have gained attention for temporary implantable devices. These materials offer controlled degradation profiles that eliminate the need for secondary removal surgeries while maintaining functional electronic performance during their operational lifetime.

Despite these advances, significant challenges persist in polymer-based bioelectronics. Long-term stability remains problematic, with many conductive polymers experiencing performance degradation in physiological environments due to oxidation, delamination, or ion exchange processes. This instability limits the clinical translation of otherwise promising technologies, particularly for chronic applications requiring years of reliable operation.

Mechanical property optimization presents another major challenge. While polymers are inherently more flexible than traditional electronic materials, achieving the perfect balance between mechanical compliance and electronic functionality remains difficult. Too soft, and the material loses structural integrity; too rigid, and it causes tissue damage or immune responses.

Manufacturability and scalability issues also hinder widespread adoption. Many laboratory-developed polymer systems rely on complex synthesis procedures or processing techniques that are difficult to standardize for industrial production. This creates barriers to commercialization and increases costs, limiting accessibility of these technologies.

Biocompatibility concerns persist despite improvements. Some conductive polymers require dopants or processing agents that may leach into surrounding tissue, potentially causing inflammatory responses or toxicity. Additionally, the long-term effects of degradation products from biodegradable electronic polymers remain incompletely characterized.

Signal-to-noise ratio optimization represents a fundamental electronic challenge, as polymer interfaces typically exhibit higher impedance than metallic alternatives. This can result in reduced signal quality, particularly in applications requiring detection of subtle biological signals such as neural recordings.

Hydrogel-based polymers represent another significant category, providing high water content environments that mimic extracellular matrices. These materials excel in applications requiring ion transport and tissue integration, with examples including polyacrylamide, poly(vinyl alcohol), and alginate-based systems. Their ability to swell and maintain hydration creates favorable conditions for cell adhesion and growth at the bioelectronic interface.

Biodegradable polymers such as poly(lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL), and silk fibroin have gained attention for temporary implantable devices. These materials offer controlled degradation profiles that eliminate the need for secondary removal surgeries while maintaining functional electronic performance during their operational lifetime.

Despite these advances, significant challenges persist in polymer-based bioelectronics. Long-term stability remains problematic, with many conductive polymers experiencing performance degradation in physiological environments due to oxidation, delamination, or ion exchange processes. This instability limits the clinical translation of otherwise promising technologies, particularly for chronic applications requiring years of reliable operation.

Mechanical property optimization presents another major challenge. While polymers are inherently more flexible than traditional electronic materials, achieving the perfect balance between mechanical compliance and electronic functionality remains difficult. Too soft, and the material loses structural integrity; too rigid, and it causes tissue damage or immune responses.

Manufacturability and scalability issues also hinder widespread adoption. Many laboratory-developed polymer systems rely on complex synthesis procedures or processing techniques that are difficult to standardize for industrial production. This creates barriers to commercialization and increases costs, limiting accessibility of these technologies.

Biocompatibility concerns persist despite improvements. Some conductive polymers require dopants or processing agents that may leach into surrounding tissue, potentially causing inflammatory responses or toxicity. Additionally, the long-term effects of degradation products from biodegradable electronic polymers remain incompletely characterized.

Signal-to-noise ratio optimization represents a fundamental electronic challenge, as polymer interfaces typically exhibit higher impedance than metallic alternatives. This can result in reduced signal quality, particularly in applications requiring detection of subtle biological signals such as neural recordings.

Existing Polymer Solutions for Bioelectronic Interfaces

01 Polymer synthesis and polymerization methods

Various methods for synthesizing polymers and controlling polymerization processes are disclosed. These include techniques for creating polymers with specific properties, controlling molecular weight distribution, and developing novel polymerization catalysts. The methods cover different types of polymerization reactions such as addition polymerization, condensation polymerization, and controlled radical polymerization to produce polymers with tailored characteristics for specific applications.- Polymer synthesis and polymerization methods: Various methods for synthesizing polymers including different polymerization techniques such as addition polymerization, condensation polymerization, and controlled radical polymerization. These methods allow for the creation of polymers with specific properties and characteristics by controlling the polymerization conditions, catalysts, and monomers used in the process.

- Modified polymer compositions and blends: Development of modified polymer compositions and polymer blends to enhance specific properties such as mechanical strength, thermal stability, or chemical resistance. These modifications can involve combining different types of polymers, adding fillers, or chemically modifying the polymer structure to achieve desired characteristics for various applications.

- Biodegradable and sustainable polymers: Formulation of biodegradable and environmentally sustainable polymers derived from renewable resources. These polymers are designed to break down naturally in the environment, reducing waste and environmental impact. Research focuses on improving the performance of these materials while maintaining their biodegradability and sustainability credentials.

- Specialty polymers for industrial applications: Development of specialty polymers designed for specific industrial applications such as coatings, adhesives, electronics, and medical devices. These polymers possess unique properties tailored to meet the requirements of their intended use, including heat resistance, electrical conductivity, biocompatibility, or chemical stability.

- Historical polymer development and processing techniques: Historical developments in polymer science and processing techniques that have shaped the field. This includes early discoveries of polymer structures, pioneering processing methods, and fundamental research that established the foundation for modern polymer science and engineering practices.

02 Modified polymer compositions with enhanced properties

Polymer compositions that have been modified to enhance specific properties such as thermal stability, mechanical strength, or chemical resistance. These modifications may involve the incorporation of additives, crosslinking agents, or functional groups into the polymer structure. The resulting materials exhibit improved performance characteristics for applications in various industries including automotive, construction, and consumer products.Expand Specific Solutions03 Biodegradable and sustainable polymers

Development of environmentally friendly polymers that are biodegradable or derived from renewable resources. These polymers are designed to reduce environmental impact while maintaining performance comparable to conventional petroleum-based polymers. The technologies include bio-based monomers, degradable polymer structures, and composting-friendly additives that facilitate breakdown after the product's useful life.Expand Specific Solutions04 Polymer processing and manufacturing techniques

Methods and equipment for processing polymers into usable forms such as films, fibers, molded parts, or coatings. These techniques include extrusion, injection molding, blow molding, and other forming processes that transform raw polymer materials into finished products. The innovations focus on improving efficiency, reducing energy consumption, and enhancing the quality of the final polymer products.Expand Specific Solutions05 Specialty polymers for specific applications

Polymers designed for specialized applications such as medical devices, electronics, water treatment, or high-performance industrial uses. These materials have unique properties tailored to specific requirements, such as biocompatibility, electrical conductivity, selective permeability, or extreme durability. The formulations often involve complex polymer architectures, blends, or composites to achieve the desired performance characteristics.Expand Specific Solutions

Leading Organizations in Bioelectronic Polymer Development

The bioelectronic interface technology market is currently in a growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is expanding rapidly, projected to reach significant value as healthcare systems adopt more bioelectronic solutions. From a technological maturity perspective, the field shows varied development stages across applications. Leading academic institutions like University of Michigan, Rutgers, and University of California are pioneering fundamental research, while companies including Medtronic, LG Chem, and Infineon Technologies are advancing commercial applications. Specialized firms such as Biotectix and Interface Biologics are developing polymer-specific innovations for bioelectronic interfaces. The competitive landscape reveals a collaborative ecosystem where academic-industrial partnerships are accelerating technology transfer and commercialization of polymer-based bioelectronic interfaces.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered advanced conducting polymer technologies for bioelectronic interfaces, focusing on PEDOT (poly(3,4-ethylenedioxythiophene)) derivatives with enhanced biocompatibility. Their research team has developed novel polymer composites that combine electrical conductivity with mechanical flexibility, creating neural interfaces that more closely match the mechanical properties of biological tissues. Their proprietary processing techniques allow for the creation of ultra-thin (sub-micron) polymer films that can conform to neural tissues while maintaining excellent charge transfer capabilities. Michigan researchers have demonstrated long-term stability of these interfaces in vivo, with reduced foreign body responses compared to traditional metal electrodes. Their recent innovations include biodegradable conducting polymer scaffolds that can be gradually replaced by native tissue, addressing the critical challenge of long-term biocompatibility in implantable devices.

Strengths: Superior mechanical compatibility with neural tissue, reducing inflammatory responses and improving long-term stability. Their polymer interfaces demonstrate excellent charge injection capacity while maintaining flexibility. Weaknesses: Some formulations still face challenges with degradation in biological environments over extended periods, and manufacturing scalability remains a concern for commercial applications.

Merck Patent GmbH

Technical Solution: Merck has developed an extensive portfolio of specialized conductive polymers for bioelectronic interfaces under their Clevios™ brand. Their technology centers on highly refined PEDOT:PSS (poly(3,4-ethylenedioxythiophene):polystyrene sulfonate) formulations with tailored properties for different biomedical applications. Merck's innovations include water-dispersible conductive polymer systems with controlled viscosity, particle size, and conductivity, enabling various deposition methods including inkjet printing, screen printing, and spray coating for flexible bioelectronic devices. Their advanced polymer formulations achieve conductivities exceeding 1000 S/cm while maintaining biocompatibility, representing a significant improvement over earlier generations of conductive polymers. Merck has developed specialized additives that enhance the mechanical properties and stability of these polymers in biological environments, addressing the historical limitations of conductive polymers for long-term implantable applications. Their materials have been successfully implemented in biosensors, neural interfaces, and drug delivery systems, demonstrating reliable performance in both in vitro and in vivo settings.

Strengths: Unparalleled control over material properties through precise chemical engineering, allowing customization for specific applications. Their industrial-scale production capabilities ensure consistent quality and supply chain reliability. Weaknesses: Some formulations still require encapsulation for long-term stability in vivo, and the proprietary nature of their additives can make academic research and optimization challenging.

Key Polymer Innovations for Tissue-Electronics Integration

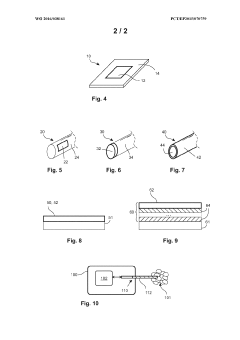

Biologically integrated electrode devices

PatentInactiveUS8005526B2

Innovation

- Development of biologically integrated bioelectrodes with a conductive polymer matrix polymerized in the presence of live tissue, cells, and artificial scaffolds, enhancing surface area and stability while reducing impedance and immune rejection.

Implantable electrode

PatentWO2016038161A1

Innovation

- An implantable electrode made of Indium nitride (InN) is used, which is electrically conductive, inhibits cell adhesion, and exhibits low toxicity, reducing bio-fouling and enhancing signal quality by preventing cell growth on its surface, thus improving the signal-to-noise ratio and extending the electrode's longevity.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations represent critical factors in the development and implementation of polymer-based bioelectronic interfaces. The intimate contact between these devices and biological tissues necessitates rigorous evaluation of potential adverse reactions and long-term effects on host organisms.

Polymers used in bioelectronic interfaces must demonstrate minimal cytotoxicity when in contact with cells and tissues. Recent studies have shown that conducting polymers such as PEDOT:PSS and PPy exhibit acceptable biocompatibility profiles, though their degradation products require careful characterization. The surface properties of polymers, including topography, hydrophilicity, and charge distribution, significantly influence cell adhesion, proliferation, and differentiation at the interface.

Inflammatory responses present a major challenge for implantable bioelectronic devices. The foreign body reaction can lead to fibrous encapsulation, effectively isolating the device from target tissues and compromising functionality. Advanced polymer designs incorporating anti-inflammatory agents or mimicking extracellular matrix components have shown promise in mitigating these responses. For instance, zwitterionic polymer coatings have demonstrated remarkable resistance to protein adsorption and subsequent inflammatory cascades.

Sterilization compatibility represents another crucial consideration, as polymeric materials must withstand standard sterilization procedures without compromising their electrical, mechanical, or biological properties. Techniques such as ethylene oxide treatment and gamma irradiation can potentially alter polymer structures, necessitating careful selection of both materials and sterilization methods.

Long-term stability in physiological environments poses significant challenges, as hydrolytic degradation, oxidative stress, and enzymatic activity can compromise device performance over time. Strategies to enhance stability include crosslinking, incorporation of antioxidants, and development of core-shell structures that protect sensitive electronic components while maintaining biocompatibility at the tissue interface.

Regulatory frameworks for bioelectronic interfaces continue to evolve, with ISO 10993 standards providing guidelines for biological evaluation. However, the unique nature of these devices, combining electrical activity with biological interfaces, often requires customized testing protocols beyond standard biocompatibility assessments. Emerging considerations include potential neurotoxicity for neural interfaces and immunogenicity of degradation products.

Future directions in biocompatibility research focus on developing predictive in vitro models that better recapitulate in vivo conditions, reducing reliance on animal testing while improving translation to clinical applications. Additionally, "smart" polymers capable of adapting to changing physiological conditions or responding to early signs of adverse reactions represent a promising frontier in bioelectronic interface technology.

Polymers used in bioelectronic interfaces must demonstrate minimal cytotoxicity when in contact with cells and tissues. Recent studies have shown that conducting polymers such as PEDOT:PSS and PPy exhibit acceptable biocompatibility profiles, though their degradation products require careful characterization. The surface properties of polymers, including topography, hydrophilicity, and charge distribution, significantly influence cell adhesion, proliferation, and differentiation at the interface.

Inflammatory responses present a major challenge for implantable bioelectronic devices. The foreign body reaction can lead to fibrous encapsulation, effectively isolating the device from target tissues and compromising functionality. Advanced polymer designs incorporating anti-inflammatory agents or mimicking extracellular matrix components have shown promise in mitigating these responses. For instance, zwitterionic polymer coatings have demonstrated remarkable resistance to protein adsorption and subsequent inflammatory cascades.

Sterilization compatibility represents another crucial consideration, as polymeric materials must withstand standard sterilization procedures without compromising their electrical, mechanical, or biological properties. Techniques such as ethylene oxide treatment and gamma irradiation can potentially alter polymer structures, necessitating careful selection of both materials and sterilization methods.

Long-term stability in physiological environments poses significant challenges, as hydrolytic degradation, oxidative stress, and enzymatic activity can compromise device performance over time. Strategies to enhance stability include crosslinking, incorporation of antioxidants, and development of core-shell structures that protect sensitive electronic components while maintaining biocompatibility at the tissue interface.

Regulatory frameworks for bioelectronic interfaces continue to evolve, with ISO 10993 standards providing guidelines for biological evaluation. However, the unique nature of these devices, combining electrical activity with biological interfaces, often requires customized testing protocols beyond standard biocompatibility assessments. Emerging considerations include potential neurotoxicity for neural interfaces and immunogenicity of degradation products.

Future directions in biocompatibility research focus on developing predictive in vitro models that better recapitulate in vivo conditions, reducing reliance on animal testing while improving translation to clinical applications. Additionally, "smart" polymers capable of adapting to changing physiological conditions or responding to early signs of adverse reactions represent a promising frontier in bioelectronic interface technology.

Scalability and Manufacturing Challenges

The scaling of polymer-based bioelectronic interfaces from laboratory prototypes to mass-produced devices presents significant manufacturing challenges. Current fabrication methods often rely on complex, multi-step processes that are difficult to standardize across large production volumes. Techniques such as photolithography, screen printing, and inkjet printing each offer certain advantages for polymer processing, but maintaining consistent electrical and mechanical properties across batches remains problematic.

Material stability during manufacturing represents another critical hurdle. Many conductive polymers exhibit sensitivity to environmental conditions including temperature, humidity, and oxygen exposure. These sensitivities can lead to performance variations during production processes, resulting in yield inconsistencies that impact commercial viability. Furthermore, sterilization requirements for biomedical applications often degrade polymer properties, necessitating specialized post-processing techniques.

Integration challenges emerge when combining polymers with rigid electronic components and microfluidic systems. The interface between soft polymeric materials and hard substrates frequently develops mechanical stress points that compromise long-term device reliability. This integration complexity increases exponentially with device miniaturization, particularly for implantable or wearable bioelectronic systems where space constraints are significant.

Cost-effectiveness represents a substantial barrier to widespread adoption. Current manufacturing approaches for high-performance bioelectronic polymers involve expensive precursors and complex synthesis procedures. The specialized equipment required for precise deposition and patterning further increases capital investment requirements. Without economies of scale, these factors contribute to prohibitively high unit costs that limit commercial applications beyond high-value medical devices.

Quality control methodologies for polymer-based bioelectronics remain underdeveloped compared to traditional semiconductor manufacturing. The heterogeneous nature of polymer interfaces makes standardized testing protocols difficult to establish. Non-destructive evaluation techniques capable of detecting microscopic defects in polymer layers are still emerging, creating uncertainty in reliability predictions for mass-produced devices.

Regulatory considerations add another layer of complexity to manufacturing scale-up. Biocompatibility testing must be performed on materials processed under production conditions, which may differ significantly from laboratory preparations. Documentation requirements for consistent manufacturing processes are particularly challenging for polymer systems with inherent batch-to-batch variations, potentially extending regulatory approval timelines and increasing development costs.

Material stability during manufacturing represents another critical hurdle. Many conductive polymers exhibit sensitivity to environmental conditions including temperature, humidity, and oxygen exposure. These sensitivities can lead to performance variations during production processes, resulting in yield inconsistencies that impact commercial viability. Furthermore, sterilization requirements for biomedical applications often degrade polymer properties, necessitating specialized post-processing techniques.

Integration challenges emerge when combining polymers with rigid electronic components and microfluidic systems. The interface between soft polymeric materials and hard substrates frequently develops mechanical stress points that compromise long-term device reliability. This integration complexity increases exponentially with device miniaturization, particularly for implantable or wearable bioelectronic systems where space constraints are significant.

Cost-effectiveness represents a substantial barrier to widespread adoption. Current manufacturing approaches for high-performance bioelectronic polymers involve expensive precursors and complex synthesis procedures. The specialized equipment required for precise deposition and patterning further increases capital investment requirements. Without economies of scale, these factors contribute to prohibitively high unit costs that limit commercial applications beyond high-value medical devices.

Quality control methodologies for polymer-based bioelectronics remain underdeveloped compared to traditional semiconductor manufacturing. The heterogeneous nature of polymer interfaces makes standardized testing protocols difficult to establish. Non-destructive evaluation techniques capable of detecting microscopic defects in polymer layers are still emerging, creating uncertainty in reliability predictions for mass-produced devices.

Regulatory considerations add another layer of complexity to manufacturing scale-up. Biocompatibility testing must be performed on materials processed under production conditions, which may differ significantly from laboratory preparations. Documentation requirements for consistent manufacturing processes are particularly challenging for polymer systems with inherent batch-to-batch variations, potentially extending regulatory approval timelines and increasing development costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!