Analyzing Ferrofluid's Contribution to Enhanced Scientific Exploration

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have since found applications across various scientific and industrial domains. The journey of ferrofluid technology can be traced through several key developmental stages, each marked by notable advancements and expanding applications.

In the 1970s and 1980s, research focused on understanding the fundamental properties of ferrofluids, including their magnetic behavior, rheological characteristics, and stability. This period saw the refinement of ferrofluid synthesis techniques, leading to improved quality and consistency of the colloidal suspensions. The development of surfactant-coated magnetic nanoparticles was a crucial breakthrough, enhancing the stability and preventing agglomeration of the magnetic particles in the carrier fluid.

The 1990s witnessed a surge in ferrofluid applications, particularly in the electronics industry. Ferrofluids found use in computer hard drive seals and speakers, leveraging their unique ability to form hermetic seals while maintaining low friction. This decade also saw increased exploration of ferrofluids in biomedical applications, with early research into targeted drug delivery and magnetic hyperthermia for cancer treatment.

The turn of the millennium brought about a new era of nanoscale engineering, significantly impacting ferrofluid technology. Advanced synthesis methods, such as thermal decomposition and co-precipitation, enabled greater control over nanoparticle size, shape, and magnetic properties. This period also saw the development of biocompatible ferrofluids, opening up new possibilities in medical imaging and therapeutics.

In recent years, ferrofluid technology has experienced a renaissance in scientific exploration. The advent of microfluidics has led to novel applications in lab-on-a-chip devices, where ferrofluids are used for fluid manipulation and sensing. Additionally, the field of magneto-optics has benefited from ferrofluid innovations, with applications in adaptive optics and tunable photonic devices.

The latest frontier in ferrofluid evolution involves smart materials and responsive systems. Researchers are developing ferrofluids that can change properties in response to external stimuli, paving the way for adaptive and self-regulating systems. This includes work on magnetorheological fluids, which can rapidly change viscosity in response to magnetic fields, finding applications in advanced damping systems and haptic interfaces.

As we look to the future, the evolution of ferrofluid technology continues to accelerate. Emerging areas of research include the development of multi-functional ferrofluids, combining magnetic properties with other functionalities such as electrical conductivity or optical activity. These advancements promise to further expand the role of ferrofluids in scientific exploration, from nanoscale manipulation to macroscale engineering applications.

In the 1970s and 1980s, research focused on understanding the fundamental properties of ferrofluids, including their magnetic behavior, rheological characteristics, and stability. This period saw the refinement of ferrofluid synthesis techniques, leading to improved quality and consistency of the colloidal suspensions. The development of surfactant-coated magnetic nanoparticles was a crucial breakthrough, enhancing the stability and preventing agglomeration of the magnetic particles in the carrier fluid.

The 1990s witnessed a surge in ferrofluid applications, particularly in the electronics industry. Ferrofluids found use in computer hard drive seals and speakers, leveraging their unique ability to form hermetic seals while maintaining low friction. This decade also saw increased exploration of ferrofluids in biomedical applications, with early research into targeted drug delivery and magnetic hyperthermia for cancer treatment.

The turn of the millennium brought about a new era of nanoscale engineering, significantly impacting ferrofluid technology. Advanced synthesis methods, such as thermal decomposition and co-precipitation, enabled greater control over nanoparticle size, shape, and magnetic properties. This period also saw the development of biocompatible ferrofluids, opening up new possibilities in medical imaging and therapeutics.

In recent years, ferrofluid technology has experienced a renaissance in scientific exploration. The advent of microfluidics has led to novel applications in lab-on-a-chip devices, where ferrofluids are used for fluid manipulation and sensing. Additionally, the field of magneto-optics has benefited from ferrofluid innovations, with applications in adaptive optics and tunable photonic devices.

The latest frontier in ferrofluid evolution involves smart materials and responsive systems. Researchers are developing ferrofluids that can change properties in response to external stimuli, paving the way for adaptive and self-regulating systems. This includes work on magnetorheological fluids, which can rapidly change viscosity in response to magnetic fields, finding applications in advanced damping systems and haptic interfaces.

As we look to the future, the evolution of ferrofluid technology continues to accelerate. Emerging areas of research include the development of multi-functional ferrofluids, combining magnetic properties with other functionalities such as electrical conductivity or optical activity. These advancements promise to further expand the role of ferrofluids in scientific exploration, from nanoscale manipulation to macroscale engineering applications.

Scientific Exploration Needs

Scientific exploration is continuously evolving, driven by the need for more precise, efficient, and versatile tools and techniques. Ferrofluids, with their unique properties, have emerged as a promising solution to address several challenges in scientific research across various disciplines. The demand for advanced materials that can enhance experimental setups, improve measurement accuracy, and enable novel approaches to data collection is growing rapidly in the scientific community.

In the field of physics, researchers require materials that can respond dynamically to magnetic fields while maintaining fluid properties. This need is particularly acute in studies of magnetohydrodynamics, where ferrofluids can serve as an ideal medium for visualizing and manipulating magnetic field lines. Additionally, the development of more sensitive sensors and actuators for precision instruments calls for materials that can provide both magnetic responsiveness and fluid adaptability.

Biological and medical sciences are seeking innovative methods for targeted drug delivery, cell separation, and imaging techniques. Ferrofluids offer potential solutions in these areas, as they can be manipulated externally using magnetic fields, allowing for non-invasive control within biological systems. The ability to guide and concentrate ferrofluids in specific locations could revolutionize cancer treatments and diagnostic procedures.

Environmental scientists and geologists are in need of advanced tracers and probes that can navigate through complex geological formations or aquatic environments. Ferrofluids, with their ability to flow through porous media while being detectable and controllable via magnetic fields, present an opportunity to study fluid dynamics in underground reservoirs or track pollutants in water systems with unprecedented accuracy.

In space exploration, the unique behavior of ferrofluids in microgravity conditions opens up new possibilities for fluid management systems, thermal regulation, and even propulsion technologies. As space agencies and private companies push the boundaries of human presence in space, materials that can adapt to extreme conditions while providing multiple functionalities are in high demand.

The field of nanotechnology and materials science is constantly seeking novel compounds that exhibit controllable properties at the nanoscale. Ferrofluids, being a colloidal suspension of magnetic nanoparticles, serve as an excellent platform for studying nanoscale phenomena and developing new composite materials with tailored magnetic, optical, and rheological properties.

As scientific instruments become more sophisticated, there is a growing need for calibration and reference materials that can provide consistent and reliable results across different experimental setups. Ferrofluids, with their reproducible response to magnetic fields, could serve as standard reference materials in magnetometry and other magnetic measurement techniques.

In the field of physics, researchers require materials that can respond dynamically to magnetic fields while maintaining fluid properties. This need is particularly acute in studies of magnetohydrodynamics, where ferrofluids can serve as an ideal medium for visualizing and manipulating magnetic field lines. Additionally, the development of more sensitive sensors and actuators for precision instruments calls for materials that can provide both magnetic responsiveness and fluid adaptability.

Biological and medical sciences are seeking innovative methods for targeted drug delivery, cell separation, and imaging techniques. Ferrofluids offer potential solutions in these areas, as they can be manipulated externally using magnetic fields, allowing for non-invasive control within biological systems. The ability to guide and concentrate ferrofluids in specific locations could revolutionize cancer treatments and diagnostic procedures.

Environmental scientists and geologists are in need of advanced tracers and probes that can navigate through complex geological formations or aquatic environments. Ferrofluids, with their ability to flow through porous media while being detectable and controllable via magnetic fields, present an opportunity to study fluid dynamics in underground reservoirs or track pollutants in water systems with unprecedented accuracy.

In space exploration, the unique behavior of ferrofluids in microgravity conditions opens up new possibilities for fluid management systems, thermal regulation, and even propulsion technologies. As space agencies and private companies push the boundaries of human presence in space, materials that can adapt to extreme conditions while providing multiple functionalities are in high demand.

The field of nanotechnology and materials science is constantly seeking novel compounds that exhibit controllable properties at the nanoscale. Ferrofluids, being a colloidal suspension of magnetic nanoparticles, serve as an excellent platform for studying nanoscale phenomena and developing new composite materials with tailored magnetic, optical, and rheological properties.

As scientific instruments become more sophisticated, there is a growing need for calibration and reference materials that can provide consistent and reliable results across different experimental setups. Ferrofluids, with their reproducible response to magnetic fields, could serve as standard reference materials in magnetometry and other magnetic measurement techniques.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in scientific exploration, several significant challenges hinder their widespread adoption and application. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to agglomerate, leading to a loss of their unique properties. This instability can result in reduced performance and limited shelf life, making it difficult to maintain consistent results in long-term experiments or applications.

Another critical challenge is the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond to magnetic fields, achieving fine-tuned control for specific scientific applications remains complex. This limitation affects the accuracy and reproducibility of experiments, particularly in sensitive scientific instruments or microfluidic devices.

The biocompatibility of ferrofluids presents a significant hurdle in biomedical applications. Many ferrofluids contain materials that may be toxic or cause adverse reactions in living organisms. Developing ferrofluids that are both functionally effective and safe for use in biological systems is an ongoing challenge that requires extensive research and testing.

Temperature sensitivity is another factor that complicates the use of ferrofluids in certain scientific contexts. The magnetic and rheological properties of ferrofluids can change significantly with temperature fluctuations, potentially affecting experimental outcomes or the performance of devices utilizing these fluids. This sensitivity necessitates careful environmental control in many applications.

The production of high-quality, consistent ferrofluids at scale remains a technical challenge. Variations in nanoparticle size, distribution, and coating can lead to inconsistencies in ferrofluid properties, making it difficult to achieve reproducible results across different batches or laboratories. This variability can impede scientific progress and limit the commercial viability of ferrofluid-based technologies.

Furthermore, the integration of ferrofluids with existing scientific equipment and methodologies poses engineering challenges. Adapting current technologies to incorporate ferrofluids often requires significant modifications or the development of entirely new systems, which can be both time-consuming and costly.

Lastly, the environmental impact and disposal of ferrofluids are concerns that need addressing. As nanomaterials, ferrofluids may have unforeseen effects on ecosystems if released into the environment. Developing safe disposal methods and understanding the long-term environmental implications of ferrofluid use are crucial challenges that must be overcome for responsible scientific exploration.

Another critical challenge is the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond to magnetic fields, achieving fine-tuned control for specific scientific applications remains complex. This limitation affects the accuracy and reproducibility of experiments, particularly in sensitive scientific instruments or microfluidic devices.

The biocompatibility of ferrofluids presents a significant hurdle in biomedical applications. Many ferrofluids contain materials that may be toxic or cause adverse reactions in living organisms. Developing ferrofluids that are both functionally effective and safe for use in biological systems is an ongoing challenge that requires extensive research and testing.

Temperature sensitivity is another factor that complicates the use of ferrofluids in certain scientific contexts. The magnetic and rheological properties of ferrofluids can change significantly with temperature fluctuations, potentially affecting experimental outcomes or the performance of devices utilizing these fluids. This sensitivity necessitates careful environmental control in many applications.

The production of high-quality, consistent ferrofluids at scale remains a technical challenge. Variations in nanoparticle size, distribution, and coating can lead to inconsistencies in ferrofluid properties, making it difficult to achieve reproducible results across different batches or laboratories. This variability can impede scientific progress and limit the commercial viability of ferrofluid-based technologies.

Furthermore, the integration of ferrofluids with existing scientific equipment and methodologies poses engineering challenges. Adapting current technologies to incorporate ferrofluids often requires significant modifications or the development of entirely new systems, which can be both time-consuming and costly.

Lastly, the environmental impact and disposal of ferrofluids are concerns that need addressing. As nanomaterials, ferrofluids may have unforeseen effects on ecosystems if released into the environment. Developing safe disposal methods and understanding the long-term environmental implications of ferrofluid use are crucial challenges that must be overcome for responsible scientific exploration.

Current Ferrofluid Apps

01 Magnetic fluid sealing applications

Ferrofluids are used in various sealing applications, particularly in rotating shaft seals. These magnetic fluids provide effective sealing against pressure differentials and contaminants while allowing for low friction movement. The unique properties of ferrofluids enable their use in dynamic sealing systems for diverse industrial and scientific applications.- Magnetic fluid sealing applications: Ferrofluids are used in various sealing applications, particularly in rotating shaft seals. These magnetic fluids provide effective sealing against pressure differentials and contaminants while allowing for low friction movement. The unique properties of ferrofluids enable their use in diverse fields such as aerospace, automotive, and industrial machinery.

- Ferrofluid-based heat transfer systems: Ferrofluids are explored for their potential in heat transfer applications. Their magnetic properties allow for controlled movement and positioning within systems, enhancing heat dissipation and thermal management. This technology is particularly useful in electronic cooling, energy systems, and space applications where efficient heat transfer is crucial.

- Magnetic field sensing and measurement: Ferrofluids are utilized in the development of sensitive magnetic field sensors and measurement devices. Their unique response to magnetic fields enables precise detection and quantification of magnetic field strengths and orientations. These applications extend to geomagnetic studies, navigation systems, and scientific instrumentation.

- Ferrofluid-based actuators and control systems: The controllable nature of ferrofluids under magnetic fields is exploited in the design of novel actuators and control systems. These systems offer advantages such as precise movement, variable stiffness, and adaptive damping. Applications include robotics, haptic devices, and vibration control in various mechanical systems.

- Optical and display technologies: Ferrofluids are investigated for their potential in optical and display technologies. Their ability to form complex patterns and structures under magnetic fields is utilized in creating dynamic displays, light modulators, and adaptive optical elements. This research explores applications in areas such as information displays, art installations, and tunable optical devices.

02 Ferrofluid-based heat transfer and cooling systems

Ferrofluids are explored for their potential in heat transfer and cooling applications. Their magnetic properties allow for controlled movement and heat dissipation, making them suitable for use in electronic cooling systems, thermal management devices, and other heat transfer applications where conventional fluids may be less effective.Expand Specific Solutions03 Magnetic field sensing and measurement

Ferrofluids are utilized in the development of sensitive magnetic field sensors and measurement devices. Their unique response to magnetic fields enables the creation of innovative instruments for detecting and quantifying magnetic field strengths and distributions in various scientific and industrial applications.Expand Specific Solutions04 Ferrofluid-based optical devices

The optical properties of ferrofluids are explored for use in various optical devices and systems. These applications include tunable optical filters, displays, and adaptive optics, where the magnetic control of ferrofluid properties can be used to manipulate light transmission, reflection, or diffraction.Expand Specific Solutions05 Ferrofluid synthesis and characterization

Research focuses on developing new methods for synthesizing ferrofluids with improved properties and characterizing their behavior. This includes exploring different nanoparticle compositions, surfactants, and carrier fluids to enhance stability, magnetic response, and other key properties for various scientific and industrial applications.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid technology market is in a growth phase, with increasing applications in scientific exploration driving expansion. The global market size is projected to reach several hundred million dollars by 2025, indicating significant potential. Technologically, ferrofluids are advancing rapidly, with key players like Yale University, Tata Steel, and China National Petroleum Corp leading research and development efforts. These organizations are exploring novel applications in areas such as magnetic separation, sensors, and biomedical devices. While the technology is maturing, there is still room for innovation, particularly in enhancing stability and tailoring properties for specific scientific applications. Collaboration between academic institutions and industry leaders is accelerating progress and commercialization of ferrofluid-based solutions for scientific exploration.

Yale University

Technical Solution: Yale University has made significant contributions to ferrofluid research, particularly in the field of scientific exploration. Their approach involves developing novel ferrofluid compositions with enhanced magnetic properties and stability. These advanced ferrofluids are utilized in microfluidic devices for precise control of fluid flow and particle manipulation[1]. Yale researchers have also explored the use of ferrofluids in magnetic resonance imaging (MRI) contrast agents, improving image resolution and sensitivity[3]. Additionally, they have investigated the potential of ferrofluids in environmental remediation, using magnetically-guided nanoparticles for contaminant removal from water and soil[5].

Strengths: Cutting-edge research in ferrofluid applications, interdisciplinary approach combining physics, chemistry, and engineering. Weaknesses: Potential challenges in scaling up laboratory discoveries for practical, large-scale applications.

The Regents of the University of California

Technical Solution: The University of California system has contributed significantly to ferrofluid research and its applications in scientific exploration. Their approach includes developing biocompatible ferrofluids for medical imaging and drug delivery. These ferrofluids are designed to enhance contrast in MRI scans and enable targeted drug delivery to specific tissues[8]. UC researchers have also explored the use of ferrofluids in microfluidic devices for cell sorting and analysis, improving the efficiency and accuracy of biological assays[10]. Furthermore, they have investigated the potential of ferrofluids in space exploration, developing magnetic shielding systems to protect spacecraft and astronauts from cosmic radiation[12].

Strengths: Broad range of research areas, from biomedical applications to space technology. Weaknesses: Potential challenges in translating academic research into commercial products.

Ferrofluid Breakthroughs

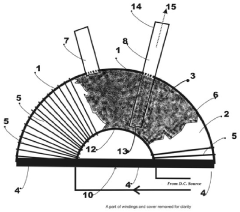

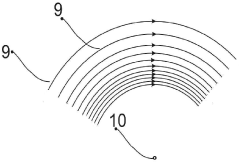

Non varying magnetic field pump

PatentInactiveIN338DEL2012A

Innovation

- A pump design utilizing a Ferrofluid with Fe3O4 solid nanoparticles as the core material, generating a gradient magnetic field with enameled wire windings and a channel structure that focuses magnetic flux for unidirectional force application, minimizing friction and achieving self-generated pressure for pumping.

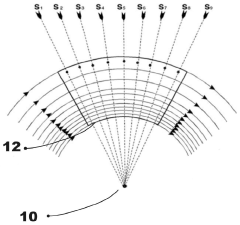

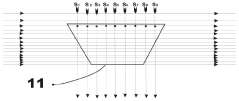

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

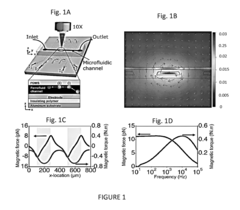

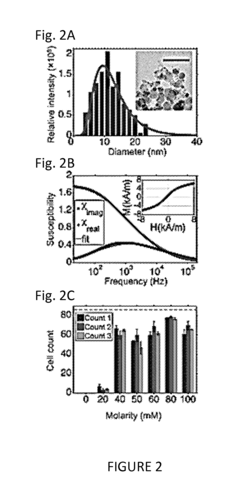

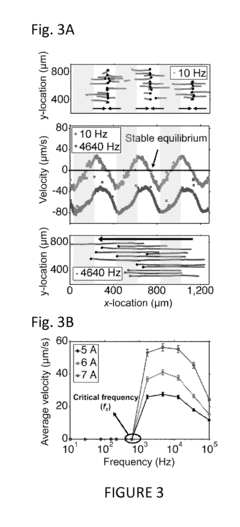

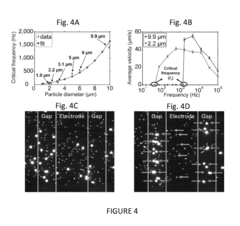

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Ferrofluid Safety Standards

Ferrofluid safety standards are crucial for ensuring the responsible use and handling of these unique magnetic liquids in scientific exploration and various applications. The development of comprehensive safety guidelines is essential to mitigate potential risks associated with ferrofluid exposure and manipulation.

One of the primary safety concerns with ferrofluids is their potential toxicity. While the base carrier fluid is typically non-toxic, the suspended magnetic nanoparticles may pose health risks if ingested or inhaled. Consequently, safety standards must address proper containment, storage, and disposal procedures to prevent accidental exposure. Guidelines should include recommendations for personal protective equipment (PPE), such as gloves, goggles, and respiratory protection when working with ferrofluids in open systems.

Environmental considerations are also paramount in ferrofluid safety standards. The potential impact of ferrofluids on ecosystems, particularly aquatic environments, necessitates strict protocols for handling and disposal. Standards should outline proper containment methods to prevent spills and leaks, as well as appropriate cleanup procedures in case of accidental release.

The magnetic properties of ferrofluids introduce unique safety challenges. Safety standards must address the potential interactions between ferrofluids and strong magnetic fields, including guidelines for safe distances from MRI machines, powerful electromagnets, and other magnetic equipment. Additionally, standards should cover the proper shielding and containment of ferrofluids to prevent interference with sensitive electronic devices or medical implants.

Thermal stability is another critical aspect of ferrofluid safety. Standards should specify safe operating temperature ranges and provide guidelines for proper cooling and temperature control during experiments or applications involving heat. This is particularly important in high-temperature environments or when ferrofluids are used in heat transfer applications.

As ferrofluids find increasing use in various industries, safety standards must also address sector-specific concerns. For instance, in biomedical applications, guidelines should cover biocompatibility testing, sterilization procedures, and potential long-term effects of ferrofluid exposure on living tissues. In aerospace or automotive applications, standards should address the behavior of ferrofluids under extreme conditions, such as rapid acceleration or microgravity environments.

Standardized testing protocols are essential components of ferrofluid safety standards. These should include methods for assessing the purity, stability, and magnetic properties of ferrofluids, as well as procedures for evaluating their potential environmental and health impacts. Regular quality control and batch testing guidelines should be established to ensure consistency and safety across different production lots.

One of the primary safety concerns with ferrofluids is their potential toxicity. While the base carrier fluid is typically non-toxic, the suspended magnetic nanoparticles may pose health risks if ingested or inhaled. Consequently, safety standards must address proper containment, storage, and disposal procedures to prevent accidental exposure. Guidelines should include recommendations for personal protective equipment (PPE), such as gloves, goggles, and respiratory protection when working with ferrofluids in open systems.

Environmental considerations are also paramount in ferrofluid safety standards. The potential impact of ferrofluids on ecosystems, particularly aquatic environments, necessitates strict protocols for handling and disposal. Standards should outline proper containment methods to prevent spills and leaks, as well as appropriate cleanup procedures in case of accidental release.

The magnetic properties of ferrofluids introduce unique safety challenges. Safety standards must address the potential interactions between ferrofluids and strong magnetic fields, including guidelines for safe distances from MRI machines, powerful electromagnets, and other magnetic equipment. Additionally, standards should cover the proper shielding and containment of ferrofluids to prevent interference with sensitive electronic devices or medical implants.

Thermal stability is another critical aspect of ferrofluid safety. Standards should specify safe operating temperature ranges and provide guidelines for proper cooling and temperature control during experiments or applications involving heat. This is particularly important in high-temperature environments or when ferrofluids are used in heat transfer applications.

As ferrofluids find increasing use in various industries, safety standards must also address sector-specific concerns. For instance, in biomedical applications, guidelines should cover biocompatibility testing, sterilization procedures, and potential long-term effects of ferrofluid exposure on living tissues. In aerospace or automotive applications, standards should address the behavior of ferrofluids under extreme conditions, such as rapid acceleration or microgravity environments.

Standardized testing protocols are essential components of ferrofluid safety standards. These should include methods for assessing the purity, stability, and magnetic properties of ferrofluids, as well as procedures for evaluating their potential environmental and health impacts. Regular quality control and batch testing guidelines should be established to ensure consistency and safety across different production lots.

Ferrofluid Eco-Impact

The environmental impact of ferrofluids is a critical consideration as their use in scientific exploration and various applications continues to expand. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in numerous fields. However, their potential ecological consequences must be carefully evaluated.

One of the primary environmental concerns associated with ferrofluids is the potential release of nanoparticles into ecosystems. These particles, typically made of iron oxides, could accumulate in soil and water systems if not properly contained or disposed of. The long-term effects of such accumulation on flora and fauna are not yet fully understood, necessitating further research to assess potential bioaccumulation and toxicity risks.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical reactions and the use of surfactants, which may generate waste products. Ensuring proper waste management and developing more environmentally friendly production methods are crucial steps in mitigating the ecological footprint of ferrofluid manufacturing.

On a positive note, ferrofluids have shown promise in environmental remediation applications. Their magnetic properties make them potentially useful for removing contaminants from water and soil. For instance, ferrofluids can be used to extract heavy metals or oil spills from water bodies, offering a novel approach to environmental cleanup efforts.

The recyclability and reusability of ferrofluids are important factors in assessing their overall environmental impact. While the magnetic properties of these fluids allow for their recovery and potential reuse in some applications, the degradation of the carrier fluid over time may limit their lifespan. Developing more durable formulations and efficient recycling processes could significantly reduce the environmental burden associated with ferrofluid disposal.

As ferrofluids find increasing use in renewable energy technologies, such as improved solar thermal collectors and more efficient wind turbines, their indirect positive environmental impact should also be considered. By enhancing the performance of clean energy systems, ferrofluids could contribute to reducing reliance on fossil fuels and lowering overall carbon emissions.

In conclusion, while ferrofluids offer significant benefits for scientific exploration and technological advancement, their environmental impact requires careful consideration and ongoing research. Balancing their potential ecological risks with their benefits in environmental remediation and clean energy applications will be crucial for their sustainable use in the future.

One of the primary environmental concerns associated with ferrofluids is the potential release of nanoparticles into ecosystems. These particles, typically made of iron oxides, could accumulate in soil and water systems if not properly contained or disposed of. The long-term effects of such accumulation on flora and fauna are not yet fully understood, necessitating further research to assess potential bioaccumulation and toxicity risks.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical reactions and the use of surfactants, which may generate waste products. Ensuring proper waste management and developing more environmentally friendly production methods are crucial steps in mitigating the ecological footprint of ferrofluid manufacturing.

On a positive note, ferrofluids have shown promise in environmental remediation applications. Their magnetic properties make them potentially useful for removing contaminants from water and soil. For instance, ferrofluids can be used to extract heavy metals or oil spills from water bodies, offering a novel approach to environmental cleanup efforts.

The recyclability and reusability of ferrofluids are important factors in assessing their overall environmental impact. While the magnetic properties of these fluids allow for their recovery and potential reuse in some applications, the degradation of the carrier fluid over time may limit their lifespan. Developing more durable formulations and efficient recycling processes could significantly reduce the environmental burden associated with ferrofluid disposal.

As ferrofluids find increasing use in renewable energy technologies, such as improved solar thermal collectors and more efficient wind turbines, their indirect positive environmental impact should also be considered. By enhancing the performance of clean energy systems, ferrofluids could contribute to reducing reliance on fossil fuels and lowering overall carbon emissions.

In conclusion, while ferrofluids offer significant benefits for scientific exploration and technological advancement, their environmental impact requires careful consideration and ongoing research. Balancing their potential ecological risks with their benefits in environmental remediation and clean energy applications will be crucial for their sustainable use in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!