Evaluating Ferrofluid's Influence on Competitive Engineering Strategies

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel manipulation in zero gravity, ferrofluids have since found applications across various industries, showcasing their versatility and potential.

The early stages of ferrofluid development focused primarily on improving stability and magnetic responsiveness. Scientists worked on refining the composition of ferrofluids, experimenting with different carrier liquids and magnetic nanoparticles to enhance their properties. This period saw the emergence of oil-based and water-based ferrofluids, each with unique characteristics suited for specific applications.

In the 1970s and 1980s, ferrofluid technology expanded into industrial applications. The development of ferrofluid seals for hard disk drives marked a significant milestone, demonstrating the practical use of these smart materials in consumer electronics. This period also saw the exploration of ferrofluids in loudspeaker design, where they were used to improve heat dissipation and damping.

The 1990s and early 2000s witnessed a surge in biomedical applications of ferrofluids. Researchers began investigating their potential in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). This shift towards biomedical applications necessitated the development of biocompatible ferrofluids, spurring innovation in nanoparticle synthesis and surface functionalization.

Concurrent with biomedical advancements, the field of microfluidics embraced ferrofluid technology. Scientists developed novel methods for manipulating small volumes of fluids using magnetic fields, leading to innovations in lab-on-a-chip devices and microfluidic pumps. This integration of ferrofluids with microfluidics opened up new possibilities in chemical analysis and biomedical diagnostics.

Recent years have seen a focus on enhancing the magnetic and rheological properties of ferrofluids. Advanced synthesis techniques have enabled the production of ferrofluids with higher magnetic saturation and improved stability. These developments have paved the way for applications in energy harvesting, where ferrofluids are being explored for use in novel generators and damping systems.

The evolution of ferrofluid technology has also been marked by advancements in computational modeling and simulation. Improved understanding of ferrofluid behavior at the nanoscale has allowed for more accurate predictions of their macroscopic properties, facilitating the design of optimized ferrofluid-based systems.

Looking forward, the trajectory of ferrofluid technology points towards increased integration with smart materials and systems. Researchers are exploring the potential of ferrofluids in soft robotics, adaptive optics, and responsive surfaces. The ongoing miniaturization of devices and the growing interest in nanotechnology are likely to drive further innovations in ferrofluid applications, potentially revolutionizing fields such as wearable technology and environmental sensing.

The early stages of ferrofluid development focused primarily on improving stability and magnetic responsiveness. Scientists worked on refining the composition of ferrofluids, experimenting with different carrier liquids and magnetic nanoparticles to enhance their properties. This period saw the emergence of oil-based and water-based ferrofluids, each with unique characteristics suited for specific applications.

In the 1970s and 1980s, ferrofluid technology expanded into industrial applications. The development of ferrofluid seals for hard disk drives marked a significant milestone, demonstrating the practical use of these smart materials in consumer electronics. This period also saw the exploration of ferrofluids in loudspeaker design, where they were used to improve heat dissipation and damping.

The 1990s and early 2000s witnessed a surge in biomedical applications of ferrofluids. Researchers began investigating their potential in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). This shift towards biomedical applications necessitated the development of biocompatible ferrofluids, spurring innovation in nanoparticle synthesis and surface functionalization.

Concurrent with biomedical advancements, the field of microfluidics embraced ferrofluid technology. Scientists developed novel methods for manipulating small volumes of fluids using magnetic fields, leading to innovations in lab-on-a-chip devices and microfluidic pumps. This integration of ferrofluids with microfluidics opened up new possibilities in chemical analysis and biomedical diagnostics.

Recent years have seen a focus on enhancing the magnetic and rheological properties of ferrofluids. Advanced synthesis techniques have enabled the production of ferrofluids with higher magnetic saturation and improved stability. These developments have paved the way for applications in energy harvesting, where ferrofluids are being explored for use in novel generators and damping systems.

The evolution of ferrofluid technology has also been marked by advancements in computational modeling and simulation. Improved understanding of ferrofluid behavior at the nanoscale has allowed for more accurate predictions of their macroscopic properties, facilitating the design of optimized ferrofluid-based systems.

Looking forward, the trajectory of ferrofluid technology points towards increased integration with smart materials and systems. Researchers are exploring the potential of ferrofluids in soft robotics, adaptive optics, and responsive surfaces. The ongoing miniaturization of devices and the growing interest in nanotechnology are likely to drive further innovations in ferrofluid applications, potentially revolutionizing fields such as wearable technology and environmental sensing.

Market Demand Analysis

The market demand for ferrofluid technology has been steadily growing across various industries, driven by its unique properties and potential applications. In the automotive sector, ferrofluids are increasingly sought after for their ability to enhance shock absorbers and improve vehicle suspension systems. This demand is particularly strong in high-performance and luxury vehicle segments, where manufacturers are constantly seeking innovative solutions to enhance ride quality and handling.

The aerospace industry has also shown significant interest in ferrofluid technology. Its potential applications in fuel systems, vibration damping, and thermal management have led to increased research and development efforts. Major aerospace companies are exploring ways to incorporate ferrofluids into their designs to improve efficiency and performance of aircraft systems.

In the medical field, ferrofluids are gaining traction for their potential use in targeted drug delivery systems and magnetic hyperthermia treatments for cancer. The growing emphasis on personalized medicine and non-invasive therapies has fueled the demand for ferrofluid-based solutions. Research institutions and pharmaceutical companies are investing heavily in developing ferrofluid applications for diagnostic and therapeutic purposes.

The electronics industry has identified ferrofluids as a promising material for cooling systems in high-performance computing and data centers. As the demand for more powerful and compact electronic devices continues to rise, the need for efficient cooling solutions becomes critical. Ferrofluid-based cooling systems offer the potential for improved heat dissipation in confined spaces, addressing a key challenge in electronic device design.

Energy sector applications, particularly in renewable energy, have also contributed to the growing market demand for ferrofluids. Wind turbine manufacturers are exploring the use of ferrofluids in sealing and lubrication systems to enhance efficiency and reduce maintenance requirements. Similarly, solar energy companies are investigating ferrofluid applications in thermal energy storage and heat transfer systems.

The global ferrofluid market is expected to experience substantial growth in the coming years. Factors such as increasing research and development activities, expanding applications across diverse industries, and the push for more efficient and sustainable technologies are driving this growth. However, challenges such as high production costs and limited awareness of ferrofluid capabilities in some sectors may impact market expansion.

As competitive engineering strategies evolve, companies across various industries are recognizing the potential of ferrofluids to provide a technological edge. The unique properties of ferrofluids offer opportunities for product differentiation and performance enhancement, making them an attractive focus for innovation-driven organizations. This growing recognition is likely to further stimulate market demand and accelerate the development of new ferrofluid-based solutions across multiple sectors.

The aerospace industry has also shown significant interest in ferrofluid technology. Its potential applications in fuel systems, vibration damping, and thermal management have led to increased research and development efforts. Major aerospace companies are exploring ways to incorporate ferrofluids into their designs to improve efficiency and performance of aircraft systems.

In the medical field, ferrofluids are gaining traction for their potential use in targeted drug delivery systems and magnetic hyperthermia treatments for cancer. The growing emphasis on personalized medicine and non-invasive therapies has fueled the demand for ferrofluid-based solutions. Research institutions and pharmaceutical companies are investing heavily in developing ferrofluid applications for diagnostic and therapeutic purposes.

The electronics industry has identified ferrofluids as a promising material for cooling systems in high-performance computing and data centers. As the demand for more powerful and compact electronic devices continues to rise, the need for efficient cooling solutions becomes critical. Ferrofluid-based cooling systems offer the potential for improved heat dissipation in confined spaces, addressing a key challenge in electronic device design.

Energy sector applications, particularly in renewable energy, have also contributed to the growing market demand for ferrofluids. Wind turbine manufacturers are exploring the use of ferrofluids in sealing and lubrication systems to enhance efficiency and reduce maintenance requirements. Similarly, solar energy companies are investigating ferrofluid applications in thermal energy storage and heat transfer systems.

The global ferrofluid market is expected to experience substantial growth in the coming years. Factors such as increasing research and development activities, expanding applications across diverse industries, and the push for more efficient and sustainable technologies are driving this growth. However, challenges such as high production costs and limited awareness of ferrofluid capabilities in some sectors may impact market expansion.

As competitive engineering strategies evolve, companies across various industries are recognizing the potential of ferrofluids to provide a technological edge. The unique properties of ferrofluids offer opportunities for product differentiation and performance enhancement, making them an attractive focus for innovation-driven organizations. This growing recognition is likely to further stimulate market demand and accelerate the development of new ferrofluid-based solutions across multiple sectors.

Current Challenges

The current challenges in evaluating ferrofluid's influence on competitive engineering strategies are multifaceted and complex. One of the primary obstacles is the limited understanding of ferrofluid behavior under diverse environmental conditions. While ferrofluids exhibit unique properties in controlled laboratory settings, their performance in real-world applications can be unpredictable, particularly when subjected to varying temperatures, pressures, and electromagnetic fields.

Another significant challenge lies in the scalability of ferrofluid-based technologies. Many promising applications have been demonstrated at small scales, but translating these successes to industrial-scale operations presents numerous engineering hurdles. Issues such as maintaining uniform particle distribution, preventing agglomeration, and ensuring long-term stability of ferrofluids in large-scale systems remain unresolved.

The interdisciplinary nature of ferrofluid research also poses a challenge. Effective evaluation and implementation of ferrofluid technologies require expertise from various fields, including materials science, fluid dynamics, electromagnetics, and mechanical engineering. Bridging these diverse disciplines and fostering collaborative research efforts is crucial for advancing ferrofluid applications but remains a significant challenge in many organizations.

Cost considerations present another obstacle in the widespread adoption of ferrofluid technologies. The production of high-quality ferrofluids with consistent properties can be expensive, limiting their commercial viability in certain applications. Additionally, the specialized equipment and infrastructure required for handling and manipulating ferrofluids add to the overall cost of implementation.

Regulatory and safety concerns also pose challenges in evaluating ferrofluid applications. The potential environmental and health impacts of nanoparticles used in ferrofluids are not fully understood, leading to uncertainties in regulatory approval processes. This uncertainty can hinder investment and slow down the development of ferrofluid-based technologies in competitive engineering strategies.

Furthermore, the lack of standardized testing and characterization methods for ferrofluids complicates the evaluation process. Different research groups and companies often use varying methodologies to assess ferrofluid properties and performance, making it difficult to compare results and establish industry-wide benchmarks. This inconsistency hampers the ability to make informed decisions about the potential of ferrofluid technologies in competitive engineering applications.

Lastly, the rapid pace of technological advancement in related fields, such as smart materials and nanotechnology, presents a challenge in maintaining the relevance of ferrofluid research. Staying at the forefront of these developments while simultaneously advancing ferrofluid technology requires significant resources and strategic planning, which can be challenging for many organizations in competitive engineering environments.

Another significant challenge lies in the scalability of ferrofluid-based technologies. Many promising applications have been demonstrated at small scales, but translating these successes to industrial-scale operations presents numerous engineering hurdles. Issues such as maintaining uniform particle distribution, preventing agglomeration, and ensuring long-term stability of ferrofluids in large-scale systems remain unresolved.

The interdisciplinary nature of ferrofluid research also poses a challenge. Effective evaluation and implementation of ferrofluid technologies require expertise from various fields, including materials science, fluid dynamics, electromagnetics, and mechanical engineering. Bridging these diverse disciplines and fostering collaborative research efforts is crucial for advancing ferrofluid applications but remains a significant challenge in many organizations.

Cost considerations present another obstacle in the widespread adoption of ferrofluid technologies. The production of high-quality ferrofluids with consistent properties can be expensive, limiting their commercial viability in certain applications. Additionally, the specialized equipment and infrastructure required for handling and manipulating ferrofluids add to the overall cost of implementation.

Regulatory and safety concerns also pose challenges in evaluating ferrofluid applications. The potential environmental and health impacts of nanoparticles used in ferrofluids are not fully understood, leading to uncertainties in regulatory approval processes. This uncertainty can hinder investment and slow down the development of ferrofluid-based technologies in competitive engineering strategies.

Furthermore, the lack of standardized testing and characterization methods for ferrofluids complicates the evaluation process. Different research groups and companies often use varying methodologies to assess ferrofluid properties and performance, making it difficult to compare results and establish industry-wide benchmarks. This inconsistency hampers the ability to make informed decisions about the potential of ferrofluid technologies in competitive engineering applications.

Lastly, the rapid pace of technological advancement in related fields, such as smart materials and nanotechnology, presents a challenge in maintaining the relevance of ferrofluid research. Staying at the forefront of these developments while simultaneously advancing ferrofluid technology requires significant resources and strategic planning, which can be challenging for many organizations in competitive engineering environments.

Existing Applications

01 Magnetic field control of ferrofluids

Ferrofluids can be manipulated and controlled using magnetic fields. This property allows for various applications in mechanical systems, such as seals, dampers, and bearings. The magnetic field can be used to alter the viscosity and shape of the ferrofluid, enabling precise control and adaptability in different environments.- Ferrofluid applications in sealing and lubrication: Ferrofluids are utilized in various sealing and lubrication applications, particularly in rotating shaft seals and bearings. These magnetic fluids provide effective sealing against contaminants and reduce friction in mechanical systems, improving overall performance and longevity of equipment.

- Ferrofluid-based damping and vibration control: Ferrofluids are employed in damping systems and vibration control mechanisms. Their unique properties allow for adaptive damping in response to magnetic fields, making them useful in applications such as automotive suspensions, aerospace systems, and precision instruments.

- Ferrofluid influence on heat transfer and cooling: Ferrofluids play a significant role in enhancing heat transfer and cooling processes. Their magnetic properties allow for controlled fluid movement and improved thermal conductivity, making them valuable in applications such as electronic cooling systems and thermal management of industrial equipment.

- Ferrofluid-based sensors and measurement devices: Ferrofluids are utilized in various sensing and measurement applications. Their responsiveness to magnetic fields and unique fluid properties enable the development of innovative sensors for pressure, acceleration, and position measurement, as well as in fluid level indicators and flow meters.

- Ferrofluid influence on magnetic field manipulation: Ferrofluids are employed in applications involving magnetic field manipulation and control. Their ability to interact with and modify magnetic fields makes them useful in magnetic separators, magnetic field shaping devices, and electromagnetic shielding applications.

02 Heat transfer and cooling applications

Ferrofluids have unique thermal properties that make them useful in heat transfer and cooling systems. They can be used to enhance heat dissipation in electronic devices, improve thermal management in industrial processes, and create novel cooling solutions. The magnetic properties of ferrofluids allow for controlled movement and distribution of heat.Expand Specific Solutions03 Optical and display technologies

Ferrofluids have applications in optical and display technologies due to their unique visual properties when subjected to magnetic fields. They can be used to create dynamic displays, light modulators, and optical switches. The ability to control the arrangement and movement of ferrofluid particles allows for the creation of novel visual effects and optical devices.Expand Specific Solutions04 Sensing and measurement applications

Ferrofluids can be utilized in various sensing and measurement applications. Their magnetic properties make them suitable for use in accelerometers, tilt sensors, and fluid level sensors. The behavior of ferrofluids in response to magnetic fields and gravitational forces enables precise measurements and detection of changes in orientation or position.Expand Specific Solutions05 Sealing and lubrication in mechanical systems

Ferrofluids are employed in sealing and lubrication applications for mechanical systems. They can create effective seals in rotating shafts, bearings, and other moving parts. The magnetic properties of ferrofluids allow for adaptive sealing and lubrication, improving the performance and longevity of mechanical components in various industrial and technological applications.Expand Specific Solutions

Key Industry Players

The competitive landscape for ferrofluid technology is evolving rapidly, with the market currently in a growth phase. The global ferrofluid market size is expanding, driven by increasing applications in electronics, medical devices, and aerospace industries. While the technology is maturing, there is still significant room for innovation and development. Key players like Ferrotec (USA) Corp. and LORD Corp. are leading in commercial applications, while research institutions such as Delft University of Technology and Beijing University of Technology are advancing the fundamental science. Companies like Mazda Motor Corp. and The Boeing Co. are exploring ferrofluid applications in automotive and aerospace sectors, respectively, indicating the technology's broad potential across industries.

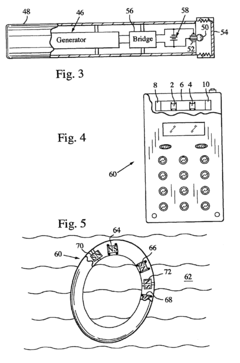

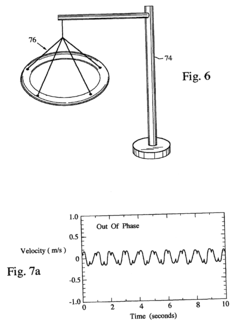

Delft University of Technology

Technical Solution: Delft University of Technology has conducted extensive research on ferrofluids and their applications in various engineering fields. Their approach focuses on understanding the fundamental physics of ferrofluids and developing novel applications. Researchers at Delft have explored the use of ferrofluids in microfluidic devices, developing techniques for precise control of fluid flow using magnetic fields[7]. They have also investigated the potential of ferrofluids in energy harvesting applications, such as wave energy converters that utilize the oscillation of ferrofluids in magnetic fields to generate electricity[8]. Additionally, Delft has made significant contributions to the field of ferrohydrodynamics, developing models to predict and optimize ferrofluid behavior in various engineering systems.

Strengths: Strong fundamental research capabilities, interdisciplinary approach combining physics and engineering, and potential for breakthrough applications. Weaknesses: Challenges in translating academic research into commercial applications and limited industrial partnerships.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid-based technologies for various engineering applications. Their approach involves synthesizing custom ferrofluids with tailored magnetic and rheological properties. They utilize nanoparticle engineering to create stable suspensions of magnetic particles in carrier fluids, optimizing the balance between magnetic responsiveness and fluid stability[1]. Ferrotec's ferrofluids are designed to maintain their magnetic properties over a wide temperature range, making them suitable for diverse industrial environments. The company has also developed innovative sealing solutions using ferrofluids, which provide near-zero leakage in rotating shaft applications[2]. Their ferrofluid-based heat transfer systems offer enhanced thermal management capabilities in electronics and industrial processes.

Strengths: Extensive experience in ferrofluid development, diverse application portfolio, and custom formulation capabilities. Weaknesses: Potential high costs associated with specialized ferrofluid production and limited scalability for certain applications.

Core Ferrofluid Patents

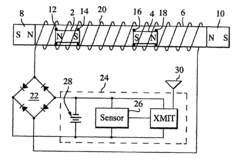

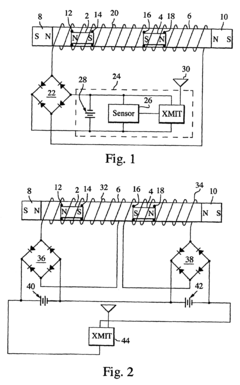

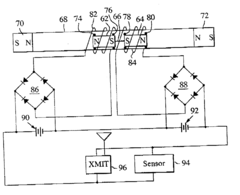

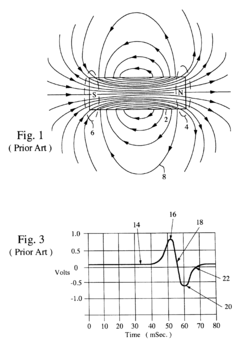

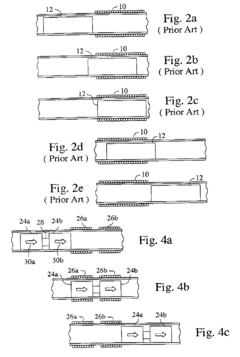

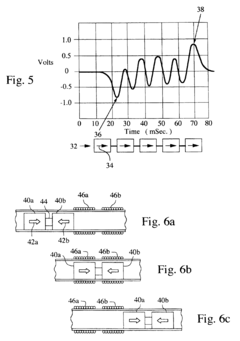

Multiple magnet transducer

PatentInactiveUS6768230B2

Innovation

- The implementation of ultra-low friction ferrofluid bearings between magnets and a support structure, allowing for horizontal orientation and enabling multiple oscillation modes that respond to various types of motion, including gentle and random movements, by using multiple magnets in polar opposition with a common axis.

Electrical power generation by coupled magnets

PatentInactiveUS6798090B2

Innovation

- Constraining multiple magnets to move together in tandem relative to multiple coils, with alternating magnetic fields generated by equal numbers of magnets and coils, and orienting them in magnetic opposition to enhance magnetic field differentials and voltage output.

Competitive Advantages

Ferrofluids offer several competitive advantages that can significantly impact engineering strategies across various industries. One of the primary advantages is their unique ability to change properties in response to magnetic fields, allowing for precise control and manipulation in applications such as sealing, damping, and heat transfer. This adaptability enables the development of more efficient and responsive systems, giving companies a technological edge in their respective markets.

The use of ferrofluids can lead to substantial cost reductions in manufacturing and maintenance processes. For instance, in rotating shaft seals, ferrofluid-based seals provide superior performance compared to traditional mechanical seals, reducing friction, wear, and the need for frequent replacements. This translates to lower operational costs and increased equipment lifespan, enhancing a company's competitive position through improved cost-effectiveness.

Ferrofluids also offer opportunities for miniaturization and improved performance in various devices. In the field of electronics and computing, ferrofluid-based cooling systems can significantly enhance heat dissipation in compact devices, allowing for more powerful and efficient designs. This advantage is particularly crucial in the rapidly evolving markets of mobile devices, data centers, and high-performance computing, where thermal management is a critical factor in product differentiation.

The versatility of ferrofluids opens up new avenues for product innovation and diversification. Companies that effectively integrate ferrofluid technology into their product lines can expand their market reach and create unique selling propositions. For example, in the automotive industry, ferrofluid-based shock absorbers can provide superior ride quality and handling, offering a competitive edge in both performance and comfort aspects of vehicle design.

Furthermore, ferrofluids present opportunities for developing environmentally friendly solutions. Their ability to be precisely controlled and recycled makes them an attractive option for sustainable engineering practices. Companies leveraging this aspect can align with growing consumer demand for eco-friendly products, potentially capturing market share from competitors who rely on less sustainable technologies.

In the medical and biotechnology sectors, ferrofluids offer unique advantages in targeted drug delivery, magnetic separation processes, and diagnostic imaging. Firms that successfully harness these capabilities can establish themselves as leaders in emerging medical technologies, gaining a significant competitive advantage in the lucrative healthcare market.

Lastly, the ongoing research and development in ferrofluid technology continually unveil new properties and applications. Companies that invest in ferrofluid R&D and maintain close collaborations with research institutions can stay at the forefront of technological advancements. This proactive approach to innovation can lead to the development of proprietary technologies and patents, further strengthening their competitive position in the market.

The use of ferrofluids can lead to substantial cost reductions in manufacturing and maintenance processes. For instance, in rotating shaft seals, ferrofluid-based seals provide superior performance compared to traditional mechanical seals, reducing friction, wear, and the need for frequent replacements. This translates to lower operational costs and increased equipment lifespan, enhancing a company's competitive position through improved cost-effectiveness.

Ferrofluids also offer opportunities for miniaturization and improved performance in various devices. In the field of electronics and computing, ferrofluid-based cooling systems can significantly enhance heat dissipation in compact devices, allowing for more powerful and efficient designs. This advantage is particularly crucial in the rapidly evolving markets of mobile devices, data centers, and high-performance computing, where thermal management is a critical factor in product differentiation.

The versatility of ferrofluids opens up new avenues for product innovation and diversification. Companies that effectively integrate ferrofluid technology into their product lines can expand their market reach and create unique selling propositions. For example, in the automotive industry, ferrofluid-based shock absorbers can provide superior ride quality and handling, offering a competitive edge in both performance and comfort aspects of vehicle design.

Furthermore, ferrofluids present opportunities for developing environmentally friendly solutions. Their ability to be precisely controlled and recycled makes them an attractive option for sustainable engineering practices. Companies leveraging this aspect can align with growing consumer demand for eco-friendly products, potentially capturing market share from competitors who rely on less sustainable technologies.

In the medical and biotechnology sectors, ferrofluids offer unique advantages in targeted drug delivery, magnetic separation processes, and diagnostic imaging. Firms that successfully harness these capabilities can establish themselves as leaders in emerging medical technologies, gaining a significant competitive advantage in the lucrative healthcare market.

Lastly, the ongoing research and development in ferrofluid technology continually unveil new properties and applications. Companies that invest in ferrofluid R&D and maintain close collaborations with research institutions can stay at the forefront of technological advancements. This proactive approach to innovation can lead to the development of proprietary technologies and patents, further strengthening their competitive position in the market.

Environmental Impact

The environmental impact of ferrofluids in competitive engineering strategies is a crucial consideration that demands thorough evaluation. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have gained significant attention in various engineering applications due to their unique properties. However, their widespread use raises concerns about potential environmental consequences.

One primary environmental consideration is the production process of ferrofluids. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. These byproducts, if not properly managed, can lead to air and water pollution. Additionally, the energy-intensive nature of nanoparticle production contributes to increased carbon emissions, potentially exacerbating climate change issues.

The disposal of ferrofluid-containing products presents another environmental challenge. As these materials reach the end of their lifecycle, improper disposal methods may result in the release of nanoparticles into ecosystems. The long-term effects of these particles on soil, water bodies, and living organisms are not yet fully understood, necessitating further research and careful waste management practices.

Ferrofluids' potential for environmental remediation offers a positive aspect. Their magnetic properties can be harnessed for the removal of oil spills and other contaminants from water bodies. This application demonstrates the dual nature of ferrofluids in environmental contexts, highlighting the importance of balanced utilization.

The use of ferrofluids in various engineering applications may indirectly impact the environment. For instance, their implementation in energy-efficient cooling systems for electronic devices could lead to reduced energy consumption and, consequently, lower greenhouse gas emissions. However, the increased demand for rare earth elements used in ferrofluid production may intensify mining activities, potentially causing habitat destruction and biodiversity loss.

Regulatory frameworks play a crucial role in mitigating the environmental risks associated with ferrofluids. As competitive engineering strategies increasingly incorporate these materials, it becomes imperative to establish and enforce stringent guidelines for their production, use, and disposal. This approach ensures that the benefits of ferrofluid technology are realized while minimizing negative environmental impacts.

In conclusion, the environmental impact of ferrofluids in competitive engineering strategies is multifaceted. While they offer promising solutions for various technological challenges, their potential environmental risks cannot be overlooked. Striking a balance between innovation and environmental stewardship is essential for the sustainable development and implementation of ferrofluid-based technologies in competitive engineering landscapes.

One primary environmental consideration is the production process of ferrofluids. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. These byproducts, if not properly managed, can lead to air and water pollution. Additionally, the energy-intensive nature of nanoparticle production contributes to increased carbon emissions, potentially exacerbating climate change issues.

The disposal of ferrofluid-containing products presents another environmental challenge. As these materials reach the end of their lifecycle, improper disposal methods may result in the release of nanoparticles into ecosystems. The long-term effects of these particles on soil, water bodies, and living organisms are not yet fully understood, necessitating further research and careful waste management practices.

Ferrofluids' potential for environmental remediation offers a positive aspect. Their magnetic properties can be harnessed for the removal of oil spills and other contaminants from water bodies. This application demonstrates the dual nature of ferrofluids in environmental contexts, highlighting the importance of balanced utilization.

The use of ferrofluids in various engineering applications may indirectly impact the environment. For instance, their implementation in energy-efficient cooling systems for electronic devices could lead to reduced energy consumption and, consequently, lower greenhouse gas emissions. However, the increased demand for rare earth elements used in ferrofluid production may intensify mining activities, potentially causing habitat destruction and biodiversity loss.

Regulatory frameworks play a crucial role in mitigating the environmental risks associated with ferrofluids. As competitive engineering strategies increasingly incorporate these materials, it becomes imperative to establish and enforce stringent guidelines for their production, use, and disposal. This approach ensures that the benefits of ferrofluid technology are realized while minimizing negative environmental impacts.

In conclusion, the environmental impact of ferrofluids in competitive engineering strategies is multifaceted. While they offer promising solutions for various technological challenges, their potential environmental risks cannot be overlooked. Striking a balance between innovation and environmental stewardship is essential for the sustainable development and implementation of ferrofluid-based technologies in competitive engineering landscapes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!