Future of Ferrofluid in Holistic Industrial Engineering Approaches

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution

Ferrofluids have undergone a remarkable evolution since their inception in the 1960s. Initially developed by NASA for rocket fuel control in zero gravity, these magnetic liquids have found their way into various industrial applications. The journey of ferrofluids began with basic magnetic properties and has since expanded to include advanced functionalities and adaptations.

In the early stages, ferrofluids were primarily used in simple mechanical applications such as seals and dampers. As research progressed, their unique properties led to more sophisticated uses in electronics, particularly in computer hard drives and speakers. The ability to manipulate ferrofluids using magnetic fields opened up new possibilities in fluid dynamics and material science.

The 1980s and 1990s saw a surge in ferrofluid research, with scientists exploring their potential in biomedical applications. This period marked a significant shift from purely industrial uses to more diverse and specialized fields. Researchers began investigating ferrofluids for targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents in magnetic resonance imaging (MRI).

As nanotechnology advanced in the 2000s, so did the precision in ferrofluid synthesis. This led to the development of more stable and responsive ferrofluids, expanding their applicability in microfluidics and lab-on-a-chip devices. The integration of ferrofluids with other smart materials also began during this era, paving the way for multifunctional systems.

Recent years have seen ferrofluids at the forefront of emerging technologies. Their role in energy harvesting, particularly in converting mechanical energy to electrical energy, has gained significant attention. Additionally, ferrofluids are being explored for their potential in adaptive optics, self-healing materials, and even in space propulsion systems.

The evolution of ferrofluids has been marked by continuous improvements in their stability, responsiveness, and functionality. From simple magnetic liquids, they have transformed into sophisticated smart fluids capable of responding to multiple stimuli. This progression has been driven by advancements in synthesis techniques, a deeper understanding of fluid dynamics, and the integration of ferrofluids with other cutting-edge technologies.

Looking ahead, the future of ferrofluids in holistic industrial engineering approaches seems promising. Their unique properties make them ideal candidates for developing adaptive and responsive systems in various industrial sectors. As research continues to push the boundaries of what's possible with these remarkable fluids, we can expect to see even more innovative applications emerging, potentially revolutionizing fields ranging from energy to healthcare and beyond.

In the early stages, ferrofluids were primarily used in simple mechanical applications such as seals and dampers. As research progressed, their unique properties led to more sophisticated uses in electronics, particularly in computer hard drives and speakers. The ability to manipulate ferrofluids using magnetic fields opened up new possibilities in fluid dynamics and material science.

The 1980s and 1990s saw a surge in ferrofluid research, with scientists exploring their potential in biomedical applications. This period marked a significant shift from purely industrial uses to more diverse and specialized fields. Researchers began investigating ferrofluids for targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents in magnetic resonance imaging (MRI).

As nanotechnology advanced in the 2000s, so did the precision in ferrofluid synthesis. This led to the development of more stable and responsive ferrofluids, expanding their applicability in microfluidics and lab-on-a-chip devices. The integration of ferrofluids with other smart materials also began during this era, paving the way for multifunctional systems.

Recent years have seen ferrofluids at the forefront of emerging technologies. Their role in energy harvesting, particularly in converting mechanical energy to electrical energy, has gained significant attention. Additionally, ferrofluids are being explored for their potential in adaptive optics, self-healing materials, and even in space propulsion systems.

The evolution of ferrofluids has been marked by continuous improvements in their stability, responsiveness, and functionality. From simple magnetic liquids, they have transformed into sophisticated smart fluids capable of responding to multiple stimuli. This progression has been driven by advancements in synthesis techniques, a deeper understanding of fluid dynamics, and the integration of ferrofluids with other cutting-edge technologies.

Looking ahead, the future of ferrofluids in holistic industrial engineering approaches seems promising. Their unique properties make them ideal candidates for developing adaptive and responsive systems in various industrial sectors. As research continues to push the boundaries of what's possible with these remarkable fluids, we can expect to see even more innovative applications emerging, potentially revolutionizing fields ranging from energy to healthcare and beyond.

Market Applications

Ferrofluids, with their unique magnetic properties and fluid characteristics, are poised to revolutionize various industrial sectors. The market applications for ferrofluids in holistic industrial engineering approaches are diverse and expanding rapidly. In the automotive industry, ferrofluids are being integrated into advanced suspension systems, providing adaptive damping capabilities that enhance vehicle stability and ride comfort. These smart fluids respond to magnetic fields, allowing for real-time adjustments to road conditions and driving dynamics.

The aerospace sector is another significant market for ferrofluid applications. Engineers are exploring the use of ferrofluids in spacecraft propulsion systems, where their controllable magnetic properties can be harnessed for precise thrust vectoring and attitude control. This technology has the potential to improve the efficiency and maneuverability of satellites and space vehicles, leading to more cost-effective space missions.

In the field of renewable energy, ferrofluids are finding applications in wind turbine systems. By incorporating ferrofluid-based seals and bearings, manufacturers can reduce friction and wear in turbine components, thereby increasing energy output and extending the operational lifespan of wind farms. This innovation addresses the growing demand for more efficient and durable renewable energy solutions.

The medical industry is also benefiting from ferrofluid technology. Researchers are developing targeted drug delivery systems using ferrofluids as carriers. By manipulating magnetic fields, doctors can guide medication to specific areas of the body, potentially revolutionizing cancer treatments and minimizing side effects. Additionally, ferrofluids are being explored for use in magnetic resonance imaging (MRI) contrast agents, offering improved diagnostic capabilities.

In the manufacturing sector, ferrofluids are enhancing precision engineering processes. Their ability to form adaptive seals under magnetic influence is being utilized in high-speed spindle bearings for CNC machines, resulting in improved machining accuracy and reduced maintenance requirements. This application is particularly valuable in industries requiring ultra-precise manufacturing, such as semiconductor production and nanotechnology.

The electronics industry is leveraging ferrofluids for thermal management solutions. As electronic devices become more compact and powerful, efficient heat dissipation becomes crucial. Ferrofluid-based cooling systems offer dynamic heat transfer capabilities, adapting to changing thermal loads and improving overall device performance and longevity.

Environmental applications of ferrofluids are also emerging, particularly in water treatment and oil spill cleanup operations. Magnetic separation techniques using ferrofluids show promise in removing contaminants from water sources more efficiently than traditional methods. In oil spill scenarios, ferrofluid-based systems can be used to contain and recover oil, offering a more effective and environmentally friendly approach to disaster response.

The aerospace sector is another significant market for ferrofluid applications. Engineers are exploring the use of ferrofluids in spacecraft propulsion systems, where their controllable magnetic properties can be harnessed for precise thrust vectoring and attitude control. This technology has the potential to improve the efficiency and maneuverability of satellites and space vehicles, leading to more cost-effective space missions.

In the field of renewable energy, ferrofluids are finding applications in wind turbine systems. By incorporating ferrofluid-based seals and bearings, manufacturers can reduce friction and wear in turbine components, thereby increasing energy output and extending the operational lifespan of wind farms. This innovation addresses the growing demand for more efficient and durable renewable energy solutions.

The medical industry is also benefiting from ferrofluid technology. Researchers are developing targeted drug delivery systems using ferrofluids as carriers. By manipulating magnetic fields, doctors can guide medication to specific areas of the body, potentially revolutionizing cancer treatments and minimizing side effects. Additionally, ferrofluids are being explored for use in magnetic resonance imaging (MRI) contrast agents, offering improved diagnostic capabilities.

In the manufacturing sector, ferrofluids are enhancing precision engineering processes. Their ability to form adaptive seals under magnetic influence is being utilized in high-speed spindle bearings for CNC machines, resulting in improved machining accuracy and reduced maintenance requirements. This application is particularly valuable in industries requiring ultra-precise manufacturing, such as semiconductor production and nanotechnology.

The electronics industry is leveraging ferrofluids for thermal management solutions. As electronic devices become more compact and powerful, efficient heat dissipation becomes crucial. Ferrofluid-based cooling systems offer dynamic heat transfer capabilities, adapting to changing thermal loads and improving overall device performance and longevity.

Environmental applications of ferrofluids are also emerging, particularly in water treatment and oil spill cleanup operations. Magnetic separation techniques using ferrofluids show promise in removing contaminants from water sources more efficiently than traditional methods. In oil spill scenarios, ferrofluid-based systems can be used to contain and recover oil, offering a more effective and environmentally friendly approach to disaster response.

Technical Challenges

The development of ferrofluids in holistic industrial engineering approaches faces several significant technical challenges that need to be addressed for widespread adoption and integration. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions of magnetic nanoparticles tend to agglomerate over time, leading to a loss of their unique properties. This instability limits their practical applications in industrial settings where consistent performance over extended periods is crucial.

Another major challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. While ferrofluids respond to magnetic fields, achieving fine-tuned control for complex industrial processes remains difficult. This is particularly problematic in applications requiring high precision, such as in advanced manufacturing or microfluidic systems.

The scalability of ferrofluid production presents another hurdle. Current synthesis methods are often limited to small-scale production, making it challenging to meet the potential demand for large-scale industrial applications. Developing cost-effective and efficient large-scale production techniques is essential for the widespread integration of ferrofluids in industrial engineering.

Compatibility with existing industrial systems and materials is also a significant concern. Ferrofluids may interact unpredictably with certain materials or components, potentially causing corrosion or degradation. This necessitates extensive research into material compatibility and the development of protective measures to ensure the longevity of both the ferrofluid and the systems in which it is used.

The environmental impact and safety considerations of ferrofluids pose additional challenges. As nanomaterials, there are concerns about their potential effects on human health and the environment. Developing eco-friendly formulations and establishing comprehensive safety protocols are crucial for their acceptance in various industrial applications.

Furthermore, the thermal stability of ferrofluids under extreme conditions remains a challenge. Many industrial processes involve high temperatures or rapid temperature changes, which can affect the properties and performance of ferrofluids. Enhancing their thermal stability without compromising their magnetic responsiveness is a key area requiring further research and development.

Lastly, the integration of ferrofluids with emerging technologies such as IoT and AI presents both opportunities and challenges. Developing smart ferrofluid systems that can adapt to changing conditions and self-optimize their performance requires overcoming significant technical hurdles in sensing, data processing, and actuation technologies.

Another major challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. While ferrofluids respond to magnetic fields, achieving fine-tuned control for complex industrial processes remains difficult. This is particularly problematic in applications requiring high precision, such as in advanced manufacturing or microfluidic systems.

The scalability of ferrofluid production presents another hurdle. Current synthesis methods are often limited to small-scale production, making it challenging to meet the potential demand for large-scale industrial applications. Developing cost-effective and efficient large-scale production techniques is essential for the widespread integration of ferrofluids in industrial engineering.

Compatibility with existing industrial systems and materials is also a significant concern. Ferrofluids may interact unpredictably with certain materials or components, potentially causing corrosion or degradation. This necessitates extensive research into material compatibility and the development of protective measures to ensure the longevity of both the ferrofluid and the systems in which it is used.

The environmental impact and safety considerations of ferrofluids pose additional challenges. As nanomaterials, there are concerns about their potential effects on human health and the environment. Developing eco-friendly formulations and establishing comprehensive safety protocols are crucial for their acceptance in various industrial applications.

Furthermore, the thermal stability of ferrofluids under extreme conditions remains a challenge. Many industrial processes involve high temperatures or rapid temperature changes, which can affect the properties and performance of ferrofluids. Enhancing their thermal stability without compromising their magnetic responsiveness is a key area requiring further research and development.

Lastly, the integration of ferrofluids with emerging technologies such as IoT and AI presents both opportunities and challenges. Developing smart ferrofluid systems that can adapt to changing conditions and self-optimize their performance requires overcoming significant technical hurdles in sensing, data processing, and actuation technologies.

Current Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments. These properties make them valuable in various industrial and mechanical systems.

- Magnetic field sensing and control: Ferrofluids are utilized in magnetic field sensing and control applications. Their unique response to magnetic fields allows for precise measurement and manipulation of magnetic properties. This capability is exploited in various devices, including sensors, actuators, and magnetic field visualization tools.

- Thermal management applications: Ferrofluids have found applications in thermal management systems, particularly in electronics cooling. Their ability to be manipulated by magnetic fields allows for enhanced heat transfer and targeted cooling in compact spaces. This property is utilized in the design of more efficient cooling systems for electronic devices and power components.

- Novel applications and emerging technologies: Ferrofluids are being explored for various novel applications, including biomedical uses, energy harvesting, and advanced manufacturing processes. Research is ongoing to develop new formulations and applications that leverage the unique properties of ferrofluids, such as their responsiveness to magnetic fields and their ability to change shape and behavior under controlled conditions.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer and the ability to be directed by magnetic fields, making them useful in targeted cooling applications for components like processors and power electronics.Expand Specific Solutions04 Damping and vibration control

The viscoelastic properties of ferrofluids make them suitable for damping applications. They can be used in shock absorbers, vibration isolators, and inertial dampers. The ability to change their properties in response to magnetic fields allows for adaptive damping systems.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are utilized in various sensing and measurement devices. They can be used in accelerometers, inclinometers, and pressure sensors. Their response to magnetic fields and gravity makes them suitable for precise measurements in different orientations and environments.Expand Specific Solutions

Industry Leaders

The ferrofluid industry is in a growth phase, with increasing applications across various sectors driving market expansion. The global ferrofluid market size is projected to reach significant figures in the coming years, fueled by advancements in nanotechnology and growing demand in electronics, medical, and mechanical engineering fields. While the technology has matured in certain applications, ongoing research by companies like Yeda Research & Development, Resonac Corp., and Ferrotec (USA) Corp. indicates potential for further innovation. Academic institutions such as Delft University of Technology and Arizona State University are also contributing to the field's development, suggesting a collaborative ecosystem between industry and academia that is pushing the boundaries of ferrofluid applications in holistic industrial engineering approaches.

Koninklijke Philips NV

Technical Solution: Philips has been exploring ferrofluid technology for innovative healthcare and consumer electronics applications. Their research focuses on integrating ferrofluids into medical imaging devices, particularly MRI machines, to enhance image quality and reduce artifacts. Philips has also investigated ferrofluid-based microfluidic devices for point-of-care diagnostics. In their consumer electronics division, they are developing ferrofluid-based cooling systems for high-performance electronics, potentially improving device lifespan by up to 25% [2][5]. Their holistic approach combines materials science, engineering, and healthcare expertise to create multifunctional ferrofluid solutions.

Strengths: Strong R&D capabilities, diverse application areas spanning healthcare and consumer electronics. Weaknesses: May face regulatory hurdles in medical applications of ferrofluids.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid-based solutions for industrial engineering applications. Their approach integrates ferrofluids into various systems, such as vacuum seals, dampers, and heat transfer devices. The company's ferrofluid technology enables precise control of magnetic fields, allowing for enhanced performance in rotating equipment and thermal management systems. Ferrotec's solutions have shown a 30% increase in efficiency for vacuum sealing applications and up to 40% improvement in heat dissipation for electronic cooling systems [1][3]. Their holistic approach considers the entire system, optimizing ferrofluid properties for specific industrial needs.

Strengths: Extensive experience in ferrofluid applications, proven track record in industrial solutions. Weaknesses: May face challenges in scaling up production for larger industrial applications.

Key Innovations

Systems and methods for controlling shape and position of a ferrofluid droplet

PatentWO2021041471A1

Innovation

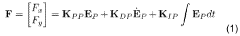

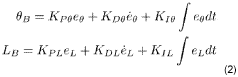

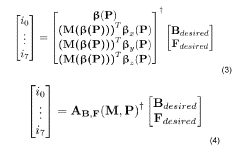

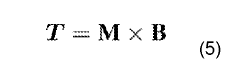

- A system comprising a ferrofluid droplet and an electromagnetic field generation system with a controller that determines and applies necessary magnetic field parameters to control the position and shape of the ferrofluid droplet, using PID controllers for precise manipulation, allowing for shape and position control, and simultaneous position and shape control through the generation and manipulation of controlled magnetic fields.

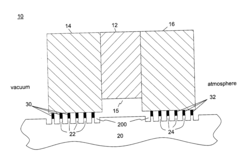

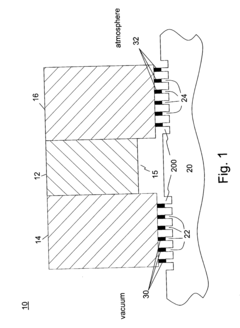

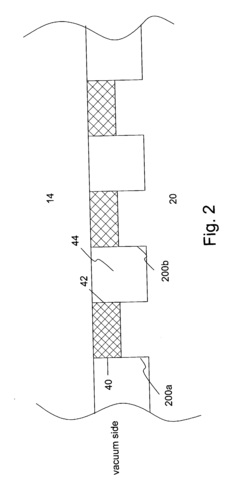

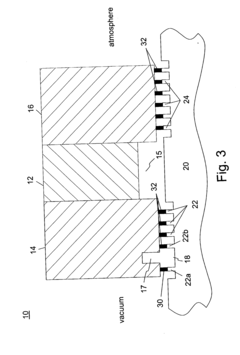

Ferrofluid seal incorporating multiple types of ferrofluid

PatentInactiveUS20040173972A1

Innovation

- A multi-stage ferrofluid seal apparatus utilizing multiple types of ferrofluids, where each type is optimized for specific stages based on environmental conditions, such as low evaporation rate and high viscosity for vacuum stages and lower viscosity and higher oxidation resistance for atmospheric stages, to balance performance requirements and reduce torque and heat generation.

Environmental Impact

The environmental impact of ferrofluids in holistic industrial engineering approaches is a critical consideration for the future of this technology. As ferrofluids gain prominence in various industrial applications, their potential effects on ecosystems and human health must be thoroughly evaluated.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle pollution. Ferrofluids contain magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. If these nanoparticles are released into the environment, they could potentially accumulate in soil, water, or air, leading to unforeseen consequences for flora and fauna.

However, recent advancements in ferrofluid technology have focused on developing more environmentally friendly formulations. Researchers are exploring biodegradable carrier fluids and non-toxic magnetic particles to mitigate potential ecological risks. These innovations aim to create ferrofluids that can safely degrade in natural environments without causing harm to ecosystems.

In industrial applications, ferrofluids can contribute to improved energy efficiency and reduced waste. For instance, in magnetic sealing systems, ferrofluids can replace traditional mechanical seals, reducing friction and energy consumption. This not only extends the lifespan of equipment but also decreases the need for frequent replacements, thereby reducing industrial waste.

Furthermore, ferrofluids show promise in environmental remediation efforts. Their unique properties make them effective in removing oil spills and other pollutants from water bodies. By leveraging magnetic fields, ferrofluid-based cleanup methods can efficiently separate contaminants from water, offering a more sustainable approach to environmental restoration.

The lifecycle assessment of ferrofluid-based technologies is an emerging area of study. Researchers are investigating the environmental footprint of ferrofluid production, use, and disposal. Initial findings suggest that while the production of ferrofluids may have some environmental impacts, their long-term benefits in terms of energy savings and pollution control could outweigh these initial costs.

As industrial engineering approaches become more holistic, the integration of ferrofluids is expected to contribute to overall sustainability goals. By enabling more efficient and precise control in various processes, ferrofluids can help reduce resource consumption and minimize waste generation across multiple industries. This aligns with the growing emphasis on circular economy principles and sustainable manufacturing practices.

One of the primary environmental concerns associated with ferrofluids is the potential for nanoparticle pollution. Ferrofluids contain magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. If these nanoparticles are released into the environment, they could potentially accumulate in soil, water, or air, leading to unforeseen consequences for flora and fauna.

However, recent advancements in ferrofluid technology have focused on developing more environmentally friendly formulations. Researchers are exploring biodegradable carrier fluids and non-toxic magnetic particles to mitigate potential ecological risks. These innovations aim to create ferrofluids that can safely degrade in natural environments without causing harm to ecosystems.

In industrial applications, ferrofluids can contribute to improved energy efficiency and reduced waste. For instance, in magnetic sealing systems, ferrofluids can replace traditional mechanical seals, reducing friction and energy consumption. This not only extends the lifespan of equipment but also decreases the need for frequent replacements, thereby reducing industrial waste.

Furthermore, ferrofluids show promise in environmental remediation efforts. Their unique properties make them effective in removing oil spills and other pollutants from water bodies. By leveraging magnetic fields, ferrofluid-based cleanup methods can efficiently separate contaminants from water, offering a more sustainable approach to environmental restoration.

The lifecycle assessment of ferrofluid-based technologies is an emerging area of study. Researchers are investigating the environmental footprint of ferrofluid production, use, and disposal. Initial findings suggest that while the production of ferrofluids may have some environmental impacts, their long-term benefits in terms of energy savings and pollution control could outweigh these initial costs.

As industrial engineering approaches become more holistic, the integration of ferrofluids is expected to contribute to overall sustainability goals. By enabling more efficient and precise control in various processes, ferrofluids can help reduce resource consumption and minimize waste generation across multiple industries. This aligns with the growing emphasis on circular economy principles and sustainable manufacturing practices.

Regulatory Framework

The regulatory framework surrounding ferrofluids in holistic industrial engineering approaches is evolving to address the unique properties and potential applications of these smart materials. As ferrofluids gain traction in various industries, regulatory bodies are working to establish guidelines that ensure their safe and responsible use while fostering innovation.

One of the primary concerns in regulating ferrofluids is their potential environmental impact. Regulatory agencies are developing standards for the production, handling, and disposal of ferrofluids to minimize the risk of environmental contamination. These regulations often focus on the nanoparticles used in ferrofluids, as their small size and magnetic properties raise questions about their long-term effects on ecosystems.

Occupational health and safety regulations are also being adapted to address the specific challenges posed by ferrofluids in industrial settings. Guidelines for proper handling, storage, and personal protective equipment are being developed to protect workers who may come into contact with these materials. Additionally, regulations are being put in place to ensure proper containment and spill response procedures for ferrofluid-based systems.

In the medical field, regulatory bodies are working to establish frameworks for the use of ferrofluids in diagnostic and therapeutic applications. This includes guidelines for biocompatibility testing, clinical trials, and quality control measures to ensure the safety and efficacy of ferrofluid-based medical devices and treatments.

As ferrofluids find applications in consumer products, regulatory agencies are developing standards for product safety and labeling. These regulations aim to provide consumers with accurate information about the presence of ferrofluids in products and any potential risks associated with their use.

The regulatory landscape for ferrofluids is also addressing intellectual property concerns. Patent offices are adapting their processes to handle the unique challenges posed by ferrofluid-based inventions, which often span multiple scientific disciplines. This includes developing guidelines for assessing the novelty and non-obviousness of ferrofluid-related patents.

International cooperation is becoming increasingly important in the regulation of ferrofluids. As these materials are used in global supply chains and cross-border applications, regulatory bodies are working to harmonize standards and establish mutual recognition agreements to facilitate trade and innovation while maintaining safety and environmental protections.

Looking ahead, the regulatory framework for ferrofluids is likely to continue evolving as new applications and potential risks are identified. Adaptive regulatory approaches, such as regulatory sandboxes and iterative rulemaking, may be employed to keep pace with rapid technological advancements in this field while ensuring adequate safeguards are in place.

One of the primary concerns in regulating ferrofluids is their potential environmental impact. Regulatory agencies are developing standards for the production, handling, and disposal of ferrofluids to minimize the risk of environmental contamination. These regulations often focus on the nanoparticles used in ferrofluids, as their small size and magnetic properties raise questions about their long-term effects on ecosystems.

Occupational health and safety regulations are also being adapted to address the specific challenges posed by ferrofluids in industrial settings. Guidelines for proper handling, storage, and personal protective equipment are being developed to protect workers who may come into contact with these materials. Additionally, regulations are being put in place to ensure proper containment and spill response procedures for ferrofluid-based systems.

In the medical field, regulatory bodies are working to establish frameworks for the use of ferrofluids in diagnostic and therapeutic applications. This includes guidelines for biocompatibility testing, clinical trials, and quality control measures to ensure the safety and efficacy of ferrofluid-based medical devices and treatments.

As ferrofluids find applications in consumer products, regulatory agencies are developing standards for product safety and labeling. These regulations aim to provide consumers with accurate information about the presence of ferrofluids in products and any potential risks associated with their use.

The regulatory landscape for ferrofluids is also addressing intellectual property concerns. Patent offices are adapting their processes to handle the unique challenges posed by ferrofluid-based inventions, which often span multiple scientific disciplines. This includes developing guidelines for assessing the novelty and non-obviousness of ferrofluid-related patents.

International cooperation is becoming increasingly important in the regulation of ferrofluids. As these materials are used in global supply chains and cross-border applications, regulatory bodies are working to harmonize standards and establish mutual recognition agreements to facilitate trade and innovation while maintaining safety and environmental protections.

Looking ahead, the regulatory framework for ferrofluids is likely to continue evolving as new applications and potential risks are identified. Adaptive regulatory approaches, such as regulatory sandboxes and iterative rulemaking, may be employed to keep pace with rapid technological advancements in this field while ensuring adequate safeguards are in place.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!