Exploring Ferrofluid's Role in Advanced Material Engineering

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Background and Objectives

Ferrofluids, first developed in the 1960s by NASA, represent a fascinating intersection of nanotechnology and magnetism. These unique materials consist of nanoscale ferromagnetic particles suspended in a carrier fluid, typically water or an organic solvent. The particles, usually made of magnetite or hematite, are coated with a surfactant to prevent agglomeration and maintain colloidal stability.

The primary objective in exploring ferrofluids' role in advanced material engineering is to harness their distinctive properties for innovative applications. These properties include their ability to change shape and behavior in response to magnetic fields, their high thermal conductivity, and their capacity to form intricate patterns when exposed to external stimuli.

Over the past few decades, ferrofluids have evolved from a scientific curiosity to a versatile material with diverse applications. Their development trajectory has been marked by significant advancements in synthesis methods, particle size control, and surface functionalization techniques. These improvements have led to enhanced stability, magnetic responsiveness, and compatibility with various environments.

Current research in ferrofluid technology focuses on expanding their potential in fields such as biomedicine, energy harvesting, and smart materials. In biomedicine, ferrofluids show promise for targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging. In energy applications, they are being explored for use in novel heat transfer systems and magnetocaloric refrigeration.

The future of ferrofluid technology lies in overcoming existing challenges and pushing the boundaries of their capabilities. Key areas of development include improving long-term stability, enhancing magnetic properties without compromising biocompatibility, and developing ferrofluids with switchable or programmable behaviors. Additionally, there is growing interest in creating multifunctional ferrofluids that combine magnetic properties with other functionalities such as optical or electrical responsiveness.

As we delve deeper into the potential of ferrofluids in advanced material engineering, our goals extend to creating smart, adaptive systems that can respond to multiple stimuli. This includes developing self-healing materials, reconfigurable structures, and dynamic surfaces that can change their properties on demand. The integration of ferrofluids with other advanced materials and technologies, such as 3D printing and microfluidics, opens up new avenues for innovation in fields ranging from soft robotics to advanced manufacturing processes.

The primary objective in exploring ferrofluids' role in advanced material engineering is to harness their distinctive properties for innovative applications. These properties include their ability to change shape and behavior in response to magnetic fields, their high thermal conductivity, and their capacity to form intricate patterns when exposed to external stimuli.

Over the past few decades, ferrofluids have evolved from a scientific curiosity to a versatile material with diverse applications. Their development trajectory has been marked by significant advancements in synthesis methods, particle size control, and surface functionalization techniques. These improvements have led to enhanced stability, magnetic responsiveness, and compatibility with various environments.

Current research in ferrofluid technology focuses on expanding their potential in fields such as biomedicine, energy harvesting, and smart materials. In biomedicine, ferrofluids show promise for targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging. In energy applications, they are being explored for use in novel heat transfer systems and magnetocaloric refrigeration.

The future of ferrofluid technology lies in overcoming existing challenges and pushing the boundaries of their capabilities. Key areas of development include improving long-term stability, enhancing magnetic properties without compromising biocompatibility, and developing ferrofluids with switchable or programmable behaviors. Additionally, there is growing interest in creating multifunctional ferrofluids that combine magnetic properties with other functionalities such as optical or electrical responsiveness.

As we delve deeper into the potential of ferrofluids in advanced material engineering, our goals extend to creating smart, adaptive systems that can respond to multiple stimuli. This includes developing self-healing materials, reconfigurable structures, and dynamic surfaces that can change their properties on demand. The integration of ferrofluids with other advanced materials and technologies, such as 3D printing and microfluidics, opens up new avenues for innovation in fields ranging from soft robotics to advanced manufacturing processes.

Market Demand Analysis for Ferrofluid Applications

The market demand for ferrofluid applications has been steadily growing across various industries, driven by its unique properties and versatile applications in advanced material engineering. The global ferrofluid market is experiencing significant expansion, with projections indicating continued growth in the coming years.

In the electronics and semiconductor industry, ferrofluids are increasingly utilized for cooling and heat dissipation in high-performance devices. As electronic components become more compact and powerful, the need for efficient thermal management solutions has intensified, creating a robust demand for ferrofluid-based cooling systems. This trend is particularly evident in data centers, where the need for energy-efficient cooling solutions is paramount.

The medical sector represents another key market for ferrofluid applications. Magnetic nanoparticles in ferrofluids show promise in targeted drug delivery systems and cancer treatment. The ability to manipulate these particles using external magnetic fields offers precise control in medical procedures, driving research and development efforts in this field. Additionally, ferrofluids are being explored for use in magnetic resonance imaging (MRI) contrast agents, potentially enhancing diagnostic capabilities.

In the automotive industry, ferrofluids are finding applications in adaptive suspension systems and shock absorbers. These smart fluids can rapidly change their viscosity in response to magnetic fields, allowing for real-time adjustments in vehicle dynamics. As the automotive sector moves towards more advanced and responsive suspension systems, the demand for ferrofluid-based solutions is expected to rise.

The aerospace and defense sectors are also showing increased interest in ferrofluid technologies. Applications range from advanced sealing systems in aircraft engines to potential use in stealth technologies. The unique magnetic and fluid properties of ferrofluids make them attractive for solving complex engineering challenges in these high-performance environments.

In the energy sector, ferrofluids are being explored for use in renewable energy technologies. For instance, they show potential in enhancing the efficiency of solar thermal collectors and in developing novel wind turbine designs. As the global focus on sustainable energy solutions intensifies, the demand for innovative materials like ferrofluids in this sector is likely to grow.

The manufacturing industry is another area where ferrofluid applications are gaining traction. They are used in precision polishing processes, particularly in the production of optical components and high-precision instruments. The ability of ferrofluids to conform to complex shapes while maintaining their magnetic properties makes them invaluable in these specialized manufacturing processes.

In the electronics and semiconductor industry, ferrofluids are increasingly utilized for cooling and heat dissipation in high-performance devices. As electronic components become more compact and powerful, the need for efficient thermal management solutions has intensified, creating a robust demand for ferrofluid-based cooling systems. This trend is particularly evident in data centers, where the need for energy-efficient cooling solutions is paramount.

The medical sector represents another key market for ferrofluid applications. Magnetic nanoparticles in ferrofluids show promise in targeted drug delivery systems and cancer treatment. The ability to manipulate these particles using external magnetic fields offers precise control in medical procedures, driving research and development efforts in this field. Additionally, ferrofluids are being explored for use in magnetic resonance imaging (MRI) contrast agents, potentially enhancing diagnostic capabilities.

In the automotive industry, ferrofluids are finding applications in adaptive suspension systems and shock absorbers. These smart fluids can rapidly change their viscosity in response to magnetic fields, allowing for real-time adjustments in vehicle dynamics. As the automotive sector moves towards more advanced and responsive suspension systems, the demand for ferrofluid-based solutions is expected to rise.

The aerospace and defense sectors are also showing increased interest in ferrofluid technologies. Applications range from advanced sealing systems in aircraft engines to potential use in stealth technologies. The unique magnetic and fluid properties of ferrofluids make them attractive for solving complex engineering challenges in these high-performance environments.

In the energy sector, ferrofluids are being explored for use in renewable energy technologies. For instance, they show potential in enhancing the efficiency of solar thermal collectors and in developing novel wind turbine designs. As the global focus on sustainable energy solutions intensifies, the demand for innovative materials like ferrofluids in this sector is likely to grow.

The manufacturing industry is another area where ferrofluid applications are gaining traction. They are used in precision polishing processes, particularly in the production of optical components and high-precision instruments. The ability of ferrofluids to conform to complex shapes while maintaining their magnetic properties makes them invaluable in these specialized manufacturing processes.

Current Challenges in Ferrofluid Engineering

Despite the promising potential of ferrofluids in advanced material engineering, several significant challenges persist in their development and application. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to agglomerate, leading to sedimentation and a loss of their unique properties. This instability limits their practical use in long-term applications and poses difficulties in storage and transportation.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for specific applications, such as in microfluidics or adaptive optics, remains complex. The non-linear response of ferrofluids to magnetic fields complicates their integration into systems requiring precise and predictable behavior.

The synthesis of ferrofluids with tailored properties for specific applications presents another significant hurdle. Current manufacturing processes often struggle to produce ferrofluids with consistent particle size distributions and magnetic properties at scale. This variability can lead to inconsistent performance across batches, hindering their adoption in high-precision industries.

Biocompatibility and environmental concerns also pose challenges, particularly for applications in medicine and environmental sensing. Ensuring that ferrofluids are non-toxic, non-reactive, and safely degradable in biological systems or natural environments is crucial but technically demanding. The potential long-term effects of nanoparticles in ferrofluids on living organisms and ecosystems remain a subject of ongoing research and concern.

The high cost of production, especially for high-quality ferrofluids with specific properties, is another significant barrier to widespread adoption. Current manufacturing processes can be resource-intensive and complex, leading to elevated costs that limit the economic viability of ferrofluids in many potential applications.

Lastly, the integration of ferrofluids into existing systems and manufacturing processes presents engineering challenges. Adapting current technologies and equipment to work effectively with ferrofluids often requires significant redesign and innovation. This integration challenge is particularly evident in fields like electronics cooling, where the magnetic properties of ferrofluids must be carefully managed to avoid interference with sensitive components.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for specific applications, such as in microfluidics or adaptive optics, remains complex. The non-linear response of ferrofluids to magnetic fields complicates their integration into systems requiring precise and predictable behavior.

The synthesis of ferrofluids with tailored properties for specific applications presents another significant hurdle. Current manufacturing processes often struggle to produce ferrofluids with consistent particle size distributions and magnetic properties at scale. This variability can lead to inconsistent performance across batches, hindering their adoption in high-precision industries.

Biocompatibility and environmental concerns also pose challenges, particularly for applications in medicine and environmental sensing. Ensuring that ferrofluids are non-toxic, non-reactive, and safely degradable in biological systems or natural environments is crucial but technically demanding. The potential long-term effects of nanoparticles in ferrofluids on living organisms and ecosystems remain a subject of ongoing research and concern.

The high cost of production, especially for high-quality ferrofluids with specific properties, is another significant barrier to widespread adoption. Current manufacturing processes can be resource-intensive and complex, leading to elevated costs that limit the economic viability of ferrofluids in many potential applications.

Lastly, the integration of ferrofluids into existing systems and manufacturing processes presents engineering challenges. Adapting current technologies and equipment to work effectively with ferrofluids often requires significant redesign and innovation. This integration challenge is particularly evident in fields like electronics cooling, where the magnetic properties of ferrofluids must be carefully managed to avoid interference with sensitive components.

Existing Ferrofluid Engineering Solutions

01 Composition and preparation of ferrofluids

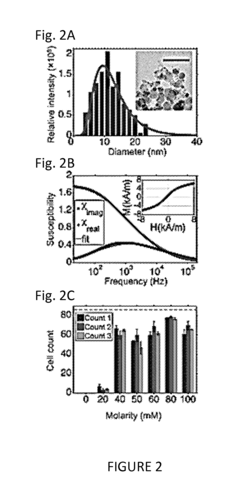

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.

- Thermal management and heat transfer: Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted cooling and improved thermal management in various applications.

- Magnetic field sensing and measurement: Ferrofluids are employed in various sensing and measurement devices that rely on magnetic field detection. Their responsiveness to magnetic fields makes them useful in applications such as accelerometers, inclinometers, and magnetic field sensors. These devices utilize the movement or deformation of ferrofluids in response to magnetic fields to measure physical quantities.

- Biomedical and therapeutic applications: Ferrofluids have emerging applications in biomedicine and therapeutics. They are being investigated for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids with external magnetic fields offers potential for non-invasive medical interventions and improved diagnostic techniques.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials and contaminants while reducing friction. These properties make them valuable in various industries, including electronics, aerospace, and automotive.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to control fluid movement using magnetic fields allows for efficient heat dissipation and temperature regulation.Expand Specific Solutions04 Magnetic field sensing and measurement

Ferrofluids are employed in various sensing and measurement applications, including magnetic field sensors, accelerometers, and inclinometers. Their unique response to magnetic fields allows for precise detection and quantification of magnetic field strength and orientation, making them valuable in scientific instruments and industrial sensors.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have emerging applications in medicine and biotechnology. They are being researched for targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents in magnetic resonance imaging (MRI). The ability to manipulate ferrofluids using external magnetic fields offers potential for minimally invasive medical procedures and diagnostics.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid technology market is in a growth phase, with increasing applications in advanced material engineering. The global market size is projected to expand significantly in the coming years, driven by rising demand in sectors like electronics, automotive, and healthcare. While the technology has matured in some areas, ongoing research by key players indicates potential for further innovation. Companies like Ferrotec and Teledyne Scientific & Imaging are at the forefront of commercial applications, while academic institutions such as Yale University, USC, and Delft University of Technology are advancing fundamental research. The competitive landscape is diverse, with both specialized firms and larger conglomerates like Western Digital and Sony Group exploring ferrofluid applications, suggesting a dynamic and evolving market.

Delft University of Technology

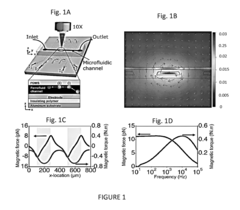

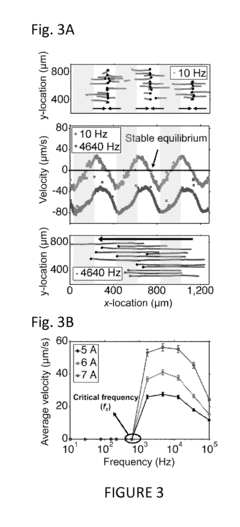

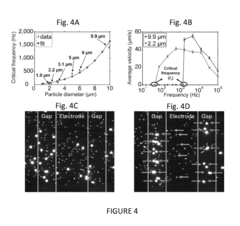

Technical Solution: Researchers at Delft University of Technology have made significant advancements in ferrofluid-based microfluidic devices and lab-on-a-chip systems. They have developed novel techniques for manipulating ferrofluid droplets using external magnetic fields, enabling precise control over fluid movement and mixing in microfluidic channels[12]. This technology has potential applications in point-of-care diagnostics, drug delivery systems, and chemical analysis. The university has also explored the use of ferrofluids in energy harvesting devices, such as vibration-based generators that convert mechanical energy into electricity using the oscillation of ferrofluid droplets in magnetic fields[13]. Additionally, Delft researchers have investigated the use of ferrofluids in self-healing materials and adaptive optical systems[14].

Strengths: Cutting-edge research in microfluidics and energy harvesting applications, potential for breakthrough innovations. Weaknesses: As an academic institution, may face challenges in commercializing research findings, dependent on funding and collaborations for further development.

Ferrotec (USA) Corp.

Technical Solution: Ferrotec has developed advanced ferrofluid-based sealing solutions for rotating equipment in semiconductor manufacturing and other high-tech industries. Their technology utilizes nano-sized magnetic particles suspended in a carrier fluid, which can be precisely controlled by magnetic fields. This allows for the creation of hermetic seals that can withstand high vacuum conditions and prevent contamination in critical processes[1][3]. Ferrotec's ferrofluid seals offer superior performance in terms of longevity, reliability, and minimal maintenance requirements compared to traditional mechanical seals[2].

Strengths: Expertise in ferrofluid applications for industrial sealing, proven track record in semiconductor industry. Weaknesses: Potentially limited to specific industrial applications, may face challenges in expanding to new markets.

Core Innovations in Ferrofluid Research

Comparative study of au-fe2o3 and au-cofe3o4 hybrid ferro fluid over a permeable plate with convective boundaries

PatentPendingIN202311068536A

Innovation

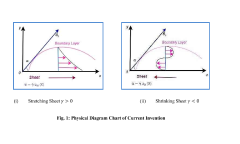

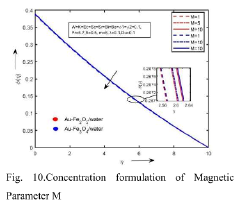

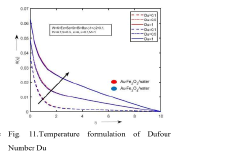

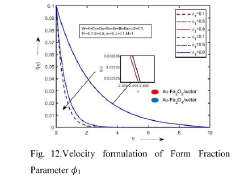

- A comparative study of Au-Fe2O3 and Au-CoFe4 hybrid ferrofluids is conducted using numerical simulations and experimental investigations to assess their heat transfer performance, flow dynamics, and temperature distribution over a permeable plate with convective boundaries, leveraging parameters like Nusselt number, Sherwood number, and skin friction coefficient.

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Environmental Impact of Ferrofluids

The environmental impact of ferrofluids is a critical consideration as these advanced materials gain prominence in various engineering applications. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, possess unique properties that make them valuable in numerous industries. However, their potential environmental consequences must be carefully evaluated.

One primary concern is the potential release of nanoparticles into ecosystems. The magnetic nanoparticles in ferrofluids, typically iron oxides, may pose risks if they enter water bodies or soil. These particles could potentially accumulate in organisms, leading to bioaccumulation and biomagnification through food chains. The long-term effects of such accumulation on ecosystem health and biodiversity are not yet fully understood, necessitating further research.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical reactions and the use of surfactants, which may generate hazardous waste. Proper disposal and treatment of these byproducts are essential to prevent soil and water contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the carbon footprint of ferrofluid manufacturing.

On the positive side, ferrofluids have the potential to contribute to environmental solutions. Their unique properties make them valuable in environmental remediation efforts, such as oil spill cleanup and wastewater treatment. Ferrofluids can be used to separate contaminants from water efficiently, potentially reducing the environmental impact of industrial processes.

The recyclability and reusability of ferrofluids are important factors in assessing their overall environmental impact. While the magnetic properties of these materials allow for easier recovery and potential reuse, the degradation of carrier fluids and surfactants over time may limit their lifespan. Developing more sustainable carrier fluids and improving recycling techniques could significantly enhance the environmental profile of ferrofluids.

As ferrofluids find applications in renewable energy technologies, such as improved solar thermal collectors and more efficient wind turbines, they may indirectly contribute to reducing greenhouse gas emissions. However, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact of these applications.

In conclusion, while ferrofluids offer promising advancements in material engineering, their environmental impact requires careful consideration and ongoing research. Balancing the potential benefits with the risks associated with nanoparticle release and production processes is crucial for the sustainable development and application of these innovative materials.

One primary concern is the potential release of nanoparticles into ecosystems. The magnetic nanoparticles in ferrofluids, typically iron oxides, may pose risks if they enter water bodies or soil. These particles could potentially accumulate in organisms, leading to bioaccumulation and biomagnification through food chains. The long-term effects of such accumulation on ecosystem health and biodiversity are not yet fully understood, necessitating further research.

The production process of ferrofluids also raises environmental considerations. The synthesis of magnetic nanoparticles often involves chemical reactions and the use of surfactants, which may generate hazardous waste. Proper disposal and treatment of these byproducts are essential to prevent soil and water contamination. Additionally, the energy-intensive nature of nanoparticle production contributes to the carbon footprint of ferrofluid manufacturing.

On the positive side, ferrofluids have the potential to contribute to environmental solutions. Their unique properties make them valuable in environmental remediation efforts, such as oil spill cleanup and wastewater treatment. Ferrofluids can be used to separate contaminants from water efficiently, potentially reducing the environmental impact of industrial processes.

The recyclability and reusability of ferrofluids are important factors in assessing their overall environmental impact. While the magnetic properties of these materials allow for easier recovery and potential reuse, the degradation of carrier fluids and surfactants over time may limit their lifespan. Developing more sustainable carrier fluids and improving recycling techniques could significantly enhance the environmental profile of ferrofluids.

As ferrofluids find applications in renewable energy technologies, such as improved solar thermal collectors and more efficient wind turbines, they may indirectly contribute to reducing greenhouse gas emissions. However, a comprehensive life cycle assessment is necessary to fully understand the net environmental impact of these applications.

In conclusion, while ferrofluids offer promising advancements in material engineering, their environmental impact requires careful consideration and ongoing research. Balancing the potential benefits with the risks associated with nanoparticle release and production processes is crucial for the sustainable development and application of these innovative materials.

Ferrofluid Safety and Regulations

As ferrofluids gain prominence in advanced material engineering, ensuring their safe handling and compliance with regulations becomes paramount. The unique properties of ferrofluids, particularly their responsiveness to magnetic fields, necessitate specific safety protocols and regulatory considerations.

Occupational safety is a primary concern when working with ferrofluids. Proper personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, and lab coats. Inhalation risks associated with ferrofluid nanoparticles require adequate ventilation systems in laboratories and manufacturing facilities. Spill containment measures should be in place, as ferrofluids can be challenging to clean up due to their magnetic properties.

Environmental regulations play a crucial role in ferrofluid management. Proper disposal methods must be implemented to prevent contamination of water sources and soil. Many jurisdictions classify ferrofluids as hazardous materials, requiring specialized handling and disposal procedures. Companies working with ferrofluids must adhere to local and national environmental protection guidelines, which may include obtaining permits for storage and transportation.

The regulatory landscape for ferrofluids is evolving as their applications expand. In the medical field, ferrofluids used in diagnostic imaging or drug delivery systems must comply with stringent FDA regulations in the United States or equivalent bodies in other countries. For industrial applications, such as in electronic devices or mechanical seals, adherence to industry-specific standards is necessary.

Material safety data sheets (MSDS) for ferrofluids must be comprehensive, detailing composition, potential hazards, and emergency procedures. Regular safety training for personnel handling ferrofluids is essential to maintain compliance and minimize risks. As research continues, regulatory bodies may update guidelines, requiring companies to stay informed and adapt their practices accordingly.

International transportation of ferrofluids is subject to strict regulations. The International Air Transport Association (IATA) and maritime shipping organizations have specific guidelines for the packaging and labeling of magnetic materials. Compliance with these regulations is crucial for companies engaged in global trade of ferrofluid-based products or research materials.

As the field of ferrofluid technology advances, proactive engagement with regulatory bodies and industry standards organizations is vital. This collaboration can help shape future regulations that balance innovation with safety concerns, ensuring the responsible development and application of ferrofluid technology in advanced material engineering.

Occupational safety is a primary concern when working with ferrofluids. Proper personal protective equipment (PPE) is essential, including chemical-resistant gloves, safety goggles, and lab coats. Inhalation risks associated with ferrofluid nanoparticles require adequate ventilation systems in laboratories and manufacturing facilities. Spill containment measures should be in place, as ferrofluids can be challenging to clean up due to their magnetic properties.

Environmental regulations play a crucial role in ferrofluid management. Proper disposal methods must be implemented to prevent contamination of water sources and soil. Many jurisdictions classify ferrofluids as hazardous materials, requiring specialized handling and disposal procedures. Companies working with ferrofluids must adhere to local and national environmental protection guidelines, which may include obtaining permits for storage and transportation.

The regulatory landscape for ferrofluids is evolving as their applications expand. In the medical field, ferrofluids used in diagnostic imaging or drug delivery systems must comply with stringent FDA regulations in the United States or equivalent bodies in other countries. For industrial applications, such as in electronic devices or mechanical seals, adherence to industry-specific standards is necessary.

Material safety data sheets (MSDS) for ferrofluids must be comprehensive, detailing composition, potential hazards, and emergency procedures. Regular safety training for personnel handling ferrofluids is essential to maintain compliance and minimize risks. As research continues, regulatory bodies may update guidelines, requiring companies to stay informed and adapt their practices accordingly.

International transportation of ferrofluids is subject to strict regulations. The International Air Transport Association (IATA) and maritime shipping organizations have specific guidelines for the packaging and labeling of magnetic materials. Compliance with these regulations is crucial for companies engaged in global trade of ferrofluid-based products or research materials.

As the field of ferrofluid technology advances, proactive engagement with regulatory bodies and industry standards organizations is vital. This collaboration can help shape future regulations that balance innovation with safety concerns, ensuring the responsible development and application of ferrofluid technology in advanced material engineering.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!