The Role of Ferrofluid in Efficient Resource Management Systems

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel management in zero gravity, ferrofluids have found diverse applications across various industries. The technology's progression has been marked by advancements in synthesis methods, particle size control, and stability enhancement, leading to improved performance and broader applicability.

In the early stages, ferrofluids were primarily composed of magnetite particles suspended in carrier fluids. Over time, researchers have explored different magnetic materials and carrier liquids to optimize properties for specific applications. The development of surfactant technologies has played a crucial role in preventing particle agglomeration and enhancing long-term stability, a key factor in the practical use of ferrofluids.

The miniaturization of magnetic particles has been a significant focus area, with advancements in nanotechnology enabling the production of ferrofluids with increasingly smaller particle sizes. This has led to improved fluid properties, including magnetic responsiveness and overall stability. Concurrently, efforts to enhance the magnetic properties of the particles have resulted in ferrofluids with stronger magnetic responses and greater control capabilities.

In the context of resource management systems, ferrofluid technology has evolved to address specific challenges in areas such as environmental remediation, energy harvesting, and waste management. The ability of ferrofluids to selectively target and separate materials based on magnetic properties has opened new avenues for efficient resource recovery and purification processes.

The objectives of ferrofluid technology in resource management systems are multifaceted. Primarily, there is a focus on developing ferrofluids with enhanced selectivity and efficiency in material separation processes. This includes improving the magnetic response of ferrofluids to enable the extraction of valuable resources from complex mixtures with minimal energy input.

Another key objective is to increase the scalability and cost-effectiveness of ferrofluid-based systems for industrial applications. This involves optimizing production methods to reduce costs while maintaining or improving performance characteristics. Additionally, there is a push towards developing environmentally friendly ferrofluids that minimize potential ecological impacts, aligning with broader sustainability goals in resource management.

Research efforts are also directed towards expanding the range of materials that can be effectively managed using ferrofluid technology. This includes exploring novel applications in water treatment, rare earth element recovery, and oil spill cleanup. The integration of ferrofluid technology with other emerging fields, such as microfluidics and smart materials, represents another important objective, aiming to create more sophisticated and responsive resource management systems.

In the early stages, ferrofluids were primarily composed of magnetite particles suspended in carrier fluids. Over time, researchers have explored different magnetic materials and carrier liquids to optimize properties for specific applications. The development of surfactant technologies has played a crucial role in preventing particle agglomeration and enhancing long-term stability, a key factor in the practical use of ferrofluids.

The miniaturization of magnetic particles has been a significant focus area, with advancements in nanotechnology enabling the production of ferrofluids with increasingly smaller particle sizes. This has led to improved fluid properties, including magnetic responsiveness and overall stability. Concurrently, efforts to enhance the magnetic properties of the particles have resulted in ferrofluids with stronger magnetic responses and greater control capabilities.

In the context of resource management systems, ferrofluid technology has evolved to address specific challenges in areas such as environmental remediation, energy harvesting, and waste management. The ability of ferrofluids to selectively target and separate materials based on magnetic properties has opened new avenues for efficient resource recovery and purification processes.

The objectives of ferrofluid technology in resource management systems are multifaceted. Primarily, there is a focus on developing ferrofluids with enhanced selectivity and efficiency in material separation processes. This includes improving the magnetic response of ferrofluids to enable the extraction of valuable resources from complex mixtures with minimal energy input.

Another key objective is to increase the scalability and cost-effectiveness of ferrofluid-based systems for industrial applications. This involves optimizing production methods to reduce costs while maintaining or improving performance characteristics. Additionally, there is a push towards developing environmentally friendly ferrofluids that minimize potential ecological impacts, aligning with broader sustainability goals in resource management.

Research efforts are also directed towards expanding the range of materials that can be effectively managed using ferrofluid technology. This includes exploring novel applications in water treatment, rare earth element recovery, and oil spill cleanup. The integration of ferrofluid technology with other emerging fields, such as microfluidics and smart materials, represents another important objective, aiming to create more sophisticated and responsive resource management systems.

Market Demand for Ferrofluid-based Resource Management

The market demand for ferrofluid-based resource management systems has been steadily growing in recent years, driven by the increasing need for efficient and sustainable resource utilization across various industries. Ferrofluids, with their unique magnetic properties and ability to respond to external magnetic fields, have opened up new possibilities in resource management applications.

In the energy sector, ferrofluid-based systems have shown promising potential for enhancing oil recovery processes. The global enhanced oil recovery market, which includes ferrofluid applications, is projected to reach significant market value in the coming years. This growth is fueled by the rising demand for energy and the need to maximize extraction from existing oil fields.

The water treatment industry has also recognized the potential of ferrofluid-based systems for efficient contaminant removal and water purification. As water scarcity becomes a pressing global issue, the demand for innovative water treatment technologies continues to rise. Ferrofluid-based solutions offer a novel approach to addressing this challenge, attracting interest from both municipal and industrial water treatment facilities.

In the manufacturing sector, ferrofluid-based systems are gaining traction for their ability to improve process efficiency and reduce waste. Industries such as automotive, aerospace, and electronics are exploring ferrofluid applications in areas like precision machining, thermal management, and vibration damping. The growing emphasis on sustainable manufacturing practices is expected to further drive the adoption of ferrofluid-based resource management systems in these sectors.

The environmental remediation market presents another significant opportunity for ferrofluid-based technologies. As governments and industries worldwide focus on cleaning up contaminated sites and reducing environmental impact, there is a growing demand for innovative remediation solutions. Ferrofluid-based systems offer potential advantages in soil and groundwater decontamination, creating a niche market within the broader environmental services industry.

In the renewable energy sector, ferrofluid-based systems are being explored for applications in solar thermal power plants and wind turbines. These systems can potentially enhance energy conversion efficiency and improve overall system performance. As the renewable energy market continues to expand globally, the demand for advanced technologies like ferrofluid-based solutions is expected to grow in tandem.

The healthcare industry is another emerging market for ferrofluid-based resource management systems. Applications in drug delivery, medical imaging, and biosensors are being researched and developed. While still in early stages, the potential for ferrofluid-based technologies in healthcare is significant, driven by the need for more precise and efficient medical treatments.

In the energy sector, ferrofluid-based systems have shown promising potential for enhancing oil recovery processes. The global enhanced oil recovery market, which includes ferrofluid applications, is projected to reach significant market value in the coming years. This growth is fueled by the rising demand for energy and the need to maximize extraction from existing oil fields.

The water treatment industry has also recognized the potential of ferrofluid-based systems for efficient contaminant removal and water purification. As water scarcity becomes a pressing global issue, the demand for innovative water treatment technologies continues to rise. Ferrofluid-based solutions offer a novel approach to addressing this challenge, attracting interest from both municipal and industrial water treatment facilities.

In the manufacturing sector, ferrofluid-based systems are gaining traction for their ability to improve process efficiency and reduce waste. Industries such as automotive, aerospace, and electronics are exploring ferrofluid applications in areas like precision machining, thermal management, and vibration damping. The growing emphasis on sustainable manufacturing practices is expected to further drive the adoption of ferrofluid-based resource management systems in these sectors.

The environmental remediation market presents another significant opportunity for ferrofluid-based technologies. As governments and industries worldwide focus on cleaning up contaminated sites and reducing environmental impact, there is a growing demand for innovative remediation solutions. Ferrofluid-based systems offer potential advantages in soil and groundwater decontamination, creating a niche market within the broader environmental services industry.

In the renewable energy sector, ferrofluid-based systems are being explored for applications in solar thermal power plants and wind turbines. These systems can potentially enhance energy conversion efficiency and improve overall system performance. As the renewable energy market continues to expand globally, the demand for advanced technologies like ferrofluid-based solutions is expected to grow in tandem.

The healthcare industry is another emerging market for ferrofluid-based resource management systems. Applications in drug delivery, medical imaging, and biosensors are being researched and developed. While still in early stages, the potential for ferrofluid-based technologies in healthcare is significant, driven by the need for more precise and efficient medical treatments.

Current Challenges in Ferrofluid Applications

Despite the promising potential of ferrofluids in resource management systems, several challenges currently hinder their widespread adoption and optimal utilization. These challenges span across technical, economic, and practical domains, necessitating innovative solutions and further research.

One of the primary technical challenges is the long-term stability of ferrofluids. Over time, these magnetic liquids tend to experience particle agglomeration and sedimentation, which can significantly impact their performance and reliability in resource management applications. This instability can lead to reduced efficiency and increased maintenance requirements, potentially offsetting the benefits of ferrofluid implementation.

Another critical issue is the limited temperature range in which ferrofluids maintain their desired properties. Many industrial applications require materials that can withstand extreme temperatures, but current ferrofluid formulations often struggle to maintain their magnetic responsiveness and fluid characteristics under such conditions. This limitation restricts their use in high-temperature environments, such as certain energy production or waste management systems.

The scalability of ferrofluid production presents an economic challenge. While ferrofluids show great promise in laboratory settings and small-scale applications, scaling up production for large-scale industrial use remains costly and complex. The intricate process of synthesizing stable ferrofluids with consistent properties across large batches poses significant manufacturing hurdles.

Environmental concerns also pose challenges to ferrofluid adoption. The potential ecological impact of nanoparticles in ferrofluids, should they be released into the environment, is not yet fully understood. This uncertainty raises questions about the long-term sustainability and safety of ferrofluid-based resource management systems, particularly in sensitive ecological areas.

Furthermore, the integration of ferrofluids into existing resource management infrastructure presents practical challenges. Many current systems are not designed to accommodate the unique properties of ferrofluids, requiring significant modifications or complete overhauls. This integration complexity can deter potential adopters, especially when considering the associated costs and operational disruptions.

Lastly, there is a notable knowledge gap in the broader engineering and resource management communities regarding the potential applications and benefits of ferrofluids. This lack of awareness and expertise can slow down innovation and adoption rates, as decision-makers may be hesitant to invest in unfamiliar technologies.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, engineering, and environmental studies. Overcoming these hurdles will be crucial for unlocking the full potential of ferrofluids in creating more efficient and sustainable resource management systems.

One of the primary technical challenges is the long-term stability of ferrofluids. Over time, these magnetic liquids tend to experience particle agglomeration and sedimentation, which can significantly impact their performance and reliability in resource management applications. This instability can lead to reduced efficiency and increased maintenance requirements, potentially offsetting the benefits of ferrofluid implementation.

Another critical issue is the limited temperature range in which ferrofluids maintain their desired properties. Many industrial applications require materials that can withstand extreme temperatures, but current ferrofluid formulations often struggle to maintain their magnetic responsiveness and fluid characteristics under such conditions. This limitation restricts their use in high-temperature environments, such as certain energy production or waste management systems.

The scalability of ferrofluid production presents an economic challenge. While ferrofluids show great promise in laboratory settings and small-scale applications, scaling up production for large-scale industrial use remains costly and complex. The intricate process of synthesizing stable ferrofluids with consistent properties across large batches poses significant manufacturing hurdles.

Environmental concerns also pose challenges to ferrofluid adoption. The potential ecological impact of nanoparticles in ferrofluids, should they be released into the environment, is not yet fully understood. This uncertainty raises questions about the long-term sustainability and safety of ferrofluid-based resource management systems, particularly in sensitive ecological areas.

Furthermore, the integration of ferrofluids into existing resource management infrastructure presents practical challenges. Many current systems are not designed to accommodate the unique properties of ferrofluids, requiring significant modifications or complete overhauls. This integration complexity can deter potential adopters, especially when considering the associated costs and operational disruptions.

Lastly, there is a notable knowledge gap in the broader engineering and resource management communities regarding the potential applications and benefits of ferrofluids. This lack of awareness and expertise can slow down innovation and adoption rates, as decision-makers may be hesitant to invest in unfamiliar technologies.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, engineering, and environmental studies. Overcoming these hurdles will be crucial for unlocking the full potential of ferrofluids in creating more efficient and sustainable resource management systems.

Existing Ferrofluid Resource Management Solutions

01 Magnetic field optimization for ferrofluid efficiency

Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based devices and systems.- Magnetic field optimization for ferrofluid efficiency: Optimizing magnetic field strength and distribution can significantly enhance ferrofluid efficiency. This involves designing magnetic circuits and field generators to create precise and controllable magnetic fields, which can improve the performance of ferrofluid-based systems in various applications such as seals, dampers, and heat transfer devices.

- Ferrofluid composition and particle size control: The efficiency of ferrofluids can be improved by carefully controlling their composition and magnetic particle size distribution. This includes selecting appropriate carrier fluids, surfactants, and magnetic nanoparticles to optimize stability, magnetic response, and overall performance in specific applications.

- Thermal management and heat transfer applications: Ferrofluids can be utilized for efficient thermal management and heat transfer in various systems. By leveraging their unique properties, such as thermomagnetic convection and enhanced thermal conductivity, ferrofluids can improve cooling efficiency in electronic devices, transformers, and other heat-generating equipment.

- Sealing and lubrication applications: Ferrofluids can be employed to create efficient seals and lubricants in mechanical systems. By utilizing their magnetic properties and low friction characteristics, ferrofluids can enhance the performance of rotary seals, bearings, and other moving parts, reducing wear and improving overall system efficiency.

- Sensing and measurement applications: Ferrofluids can be used to develop highly sensitive and efficient sensing and measurement devices. By exploiting their magnetic and fluid properties, ferrofluids can be incorporated into accelerometers, inclinometers, and other instruments to improve accuracy and response time in various industrial and scientific applications.

02 Ferrofluid composition and particle size control

The efficiency of ferrofluids can be improved by carefully controlling their composition and the size of magnetic particles. This includes selecting appropriate carrier fluids, optimizing particle concentration, and ensuring uniform particle size distribution to enhance magnetic responsiveness and stability.Expand Specific Solutions03 Sealing and lubrication applications

Ferrofluids can be used to create efficient seals and lubricants in various mechanical systems. By leveraging their unique properties, ferrofluids can reduce friction, improve heat dissipation, and enhance overall system performance in applications such as bearings and rotary seals.Expand Specific Solutions04 Thermal management and heat transfer

Ferrofluids can be utilized to improve thermal management and heat transfer in various systems. Their ability to respond to magnetic fields allows for controlled heat dissipation and targeted cooling, enhancing the efficiency of electronic devices and other heat-sensitive applications.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids can be employed in various sensing and measurement devices to improve efficiency and accuracy. Their unique magnetic properties allow for precise detection of motion, position, and other physical parameters, enhancing the performance of instruments such as accelerometers and gyroscopes.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid technology market is in a growth phase, with increasing applications in resource management systems driving expansion. The global market size is projected to reach several hundred million dollars by 2025, indicating significant potential. Technologically, ferrofluids are advancing rapidly, with key players like IBM, Philips, and Ericsson pushing innovations in areas such as heat transfer, sealing, and sensing. While established companies lead in commercialization, research institutions like Arizona State University and Delft University of Technology are making important contributions to fundamental science. The involvement of diverse players across industry and academia suggests ferrofluid technology is maturing but still has room for breakthrough developments.

International Business Machines Corp.

Technical Solution: IBM has developed advanced ferrofluid-based cooling systems for efficient resource management in data centers. Their technology utilizes the unique properties of ferrofluids to enhance heat transfer in electronic components. The system employs a closed-loop ferrofluid circulation mechanism that responds to magnetic fields, allowing precise control of coolant flow[1]. This enables targeted cooling of high-heat areas, reducing overall energy consumption. IBM's ferrofluid cooling solution integrates with their AI-driven data center management platform, optimizing cooling efficiency based on real-time workload and environmental factors[3].

Strengths: Highly efficient cooling, reduced energy consumption, and integration with AI-driven management. Weaknesses: Potential for magnetic interference with sensitive equipment and higher initial implementation costs.

Koninklijke Philips NV

Technical Solution: Philips has innovated in the application of ferrofluids for medical imaging and diagnostic equipment. Their technology utilizes ferrofluids as contrast agents in MRI scans, enhancing image quality and diagnostic accuracy[2]. Additionally, Philips has developed ferrofluid-based microfluidic devices for point-of-care diagnostics, enabling rapid and efficient resource management in healthcare settings. The company's ferrofluid solutions also extend to smart drug delivery systems, where magnetically controlled ferrofluids can target specific areas in the body, optimizing medication efficacy and resource utilization[4].

Strengths: Enhanced medical imaging, improved diagnostic accuracy, and targeted drug delivery. Weaknesses: Regulatory challenges in medical applications and potential biocompatibility issues.

Core Innovations in Ferrofluid Technology

Electronically-controlled digital ferrofluidic device and method for scalable and addressable bioanalytical operations

PatentWO2021081103A1

Innovation

- An electronically-controlled digital ferrofluidic device using an electromagnetic induction-coil matrix and moveable permanent magnets to create addressable magnetic fields for manipulating nanoliter or microliter volumes of magnetic droplets, enabling advanced tasks like droplet generation, dispensing, and sorting.

Stock solution

PatentActiveUS20220351886A1

Innovation

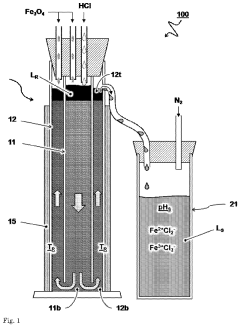

- A method involving an acidic solution reacting with an excess of mineral bulk material to form a stock solution with a desired Fe(II)/Fe(III) ratio, eliminating the need for separate ion sources and allowing for scalable production by minimizing gas entrainment and optimizing reaction conditions, such as using a continuous process with specific reactor configurations and acid concentrations.

Environmental Impact of Ferrofluid Systems

The integration of ferrofluid systems in resource management has raised significant environmental considerations. These systems, while offering innovative solutions for efficient resource handling, also present potential ecological impacts that require careful assessment. The environmental footprint of ferrofluid-based technologies spans various aspects, from production and implementation to long-term ecosystem effects.

During the manufacturing process of ferrofluids, the synthesis of nanoparticles and their suspension in carrier fluids may involve the use of chemicals and energy-intensive procedures. This initial phase carries implications for resource consumption and potential emissions. However, advancements in green chemistry and sustainable manufacturing practices are progressively mitigating these concerns, leading to more environmentally friendly production methods.

In operational contexts, ferrofluid systems demonstrate promising environmental benefits. Their ability to enhance the efficiency of resource extraction and processing can lead to reduced energy consumption and minimized waste generation. For instance, in oil recovery applications, ferrofluids can improve the precision of extraction, potentially decreasing the environmental impact associated with conventional drilling techniques.

Water treatment represents another area where ferrofluid systems show positive environmental potential. Their capacity to selectively remove contaminants from water sources could contribute to more effective and less chemically intensive purification processes. This application not only conserves water resources but also reduces the reliance on harsh chemical treatments that may have detrimental ecological effects.

However, the release of ferrofluids into natural environments, whether through accidental spills or improper disposal, poses ecological risks that demand attention. The behavior of magnetic nanoparticles in ecosystems is an area of ongoing research, with concerns about their potential bioaccumulation and long-term effects on flora and fauna. Stringent containment measures and disposal protocols are essential to mitigate these risks.

The recyclability and end-of-life management of ferrofluid systems also factor into their overall environmental impact. While the magnetic properties of these fluids facilitate their recovery and potential reuse, the development of comprehensive recycling strategies remains a critical area for improvement to ensure closed-loop resource management.

As ferrofluid technologies continue to evolve, ongoing environmental monitoring and impact assessments are crucial. These efforts should focus on understanding the long-term ecological consequences of ferrofluid applications, particularly in sensitive ecosystems. By proactively addressing environmental concerns and leveraging the efficiency gains offered by ferrofluid systems, it is possible to harness their potential for resource management while minimizing negative ecological impacts.

During the manufacturing process of ferrofluids, the synthesis of nanoparticles and their suspension in carrier fluids may involve the use of chemicals and energy-intensive procedures. This initial phase carries implications for resource consumption and potential emissions. However, advancements in green chemistry and sustainable manufacturing practices are progressively mitigating these concerns, leading to more environmentally friendly production methods.

In operational contexts, ferrofluid systems demonstrate promising environmental benefits. Their ability to enhance the efficiency of resource extraction and processing can lead to reduced energy consumption and minimized waste generation. For instance, in oil recovery applications, ferrofluids can improve the precision of extraction, potentially decreasing the environmental impact associated with conventional drilling techniques.

Water treatment represents another area where ferrofluid systems show positive environmental potential. Their capacity to selectively remove contaminants from water sources could contribute to more effective and less chemically intensive purification processes. This application not only conserves water resources but also reduces the reliance on harsh chemical treatments that may have detrimental ecological effects.

However, the release of ferrofluids into natural environments, whether through accidental spills or improper disposal, poses ecological risks that demand attention. The behavior of magnetic nanoparticles in ecosystems is an area of ongoing research, with concerns about their potential bioaccumulation and long-term effects on flora and fauna. Stringent containment measures and disposal protocols are essential to mitigate these risks.

The recyclability and end-of-life management of ferrofluid systems also factor into their overall environmental impact. While the magnetic properties of these fluids facilitate their recovery and potential reuse, the development of comprehensive recycling strategies remains a critical area for improvement to ensure closed-loop resource management.

As ferrofluid technologies continue to evolve, ongoing environmental monitoring and impact assessments are crucial. These efforts should focus on understanding the long-term ecological consequences of ferrofluid applications, particularly in sensitive ecosystems. By proactively addressing environmental concerns and leveraging the efficiency gains offered by ferrofluid systems, it is possible to harness their potential for resource management while minimizing negative ecological impacts.

Scalability and Integration Considerations

The scalability and integration of ferrofluid-based resource management systems present both challenges and opportunities for widespread adoption. As these systems grow in complexity and scale, careful consideration must be given to their expandability and seamless incorporation into existing infrastructure.

One key aspect of scalability is the ability to increase the volume of ferrofluid used in a system without compromising its efficiency or functionality. This requires advanced engineering solutions to maintain uniform magnetic field distribution and fluid dynamics across larger scales. Additionally, the development of modular designs allows for easier expansion and adaptation to varying resource management needs.

Integration considerations involve the compatibility of ferrofluid systems with current resource management infrastructure. This includes developing standardized interfaces and protocols for communication between ferrofluid-based components and conventional systems. Ensuring interoperability is crucial for the gradual adoption of this technology without necessitating complete overhauls of existing setups.

The scalability of ferrofluid production itself is another critical factor. As demand for these systems grows, manufacturing processes must be optimized to produce large quantities of high-quality ferrofluid consistently. This may involve innovations in nanoparticle synthesis and suspension techniques to maintain the desired magnetic properties at scale.

Energy efficiency is a paramount concern when scaling up ferrofluid systems. Optimizing the power consumption of electromagnetic components and developing more efficient cooling mechanisms are essential for maintaining the economic viability of large-scale implementations. This may involve the integration of smart power management systems and the use of renewable energy sources to offset operational costs.

Data management and analysis capabilities must also scale proportionally with system size. This requires robust software architectures capable of processing and analyzing vast amounts of sensor data in real-time. Machine learning algorithms can be employed to optimize system performance and predict maintenance needs as the complexity of the system increases.

Lastly, the integration of ferrofluid technology into diverse resource management applications necessitates a flexible and adaptable approach. This may involve developing customizable modules that can be tailored to specific industries or environmental conditions, ensuring that the technology can be effectively deployed across a wide range of scenarios.

One key aspect of scalability is the ability to increase the volume of ferrofluid used in a system without compromising its efficiency or functionality. This requires advanced engineering solutions to maintain uniform magnetic field distribution and fluid dynamics across larger scales. Additionally, the development of modular designs allows for easier expansion and adaptation to varying resource management needs.

Integration considerations involve the compatibility of ferrofluid systems with current resource management infrastructure. This includes developing standardized interfaces and protocols for communication between ferrofluid-based components and conventional systems. Ensuring interoperability is crucial for the gradual adoption of this technology without necessitating complete overhauls of existing setups.

The scalability of ferrofluid production itself is another critical factor. As demand for these systems grows, manufacturing processes must be optimized to produce large quantities of high-quality ferrofluid consistently. This may involve innovations in nanoparticle synthesis and suspension techniques to maintain the desired magnetic properties at scale.

Energy efficiency is a paramount concern when scaling up ferrofluid systems. Optimizing the power consumption of electromagnetic components and developing more efficient cooling mechanisms are essential for maintaining the economic viability of large-scale implementations. This may involve the integration of smart power management systems and the use of renewable energy sources to offset operational costs.

Data management and analysis capabilities must also scale proportionally with system size. This requires robust software architectures capable of processing and analyzing vast amounts of sensor data in real-time. Machine learning algorithms can be employed to optimize system performance and predict maintenance needs as the complexity of the system increases.

Lastly, the integration of ferrofluid technology into diverse resource management applications necessitates a flexible and adaptable approach. This may involve developing customizable modules that can be tailored to specific industries or environmental conditions, ensuring that the technology can be effectively deployed across a wide range of scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!