Exploring Ferrofluid's Potential in Revolutionary System Integrations

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant technological evolution over the past six decades. Initially conceived for controlling fluids in zero gravity, these magnetic liquids have since found applications across various industries, marking key milestones in their development journey.

The 1970s saw the first commercial applications of ferrofluids in sealing technology, particularly in computer hard drives. This breakthrough demonstrated the practical potential of these smart fluids beyond their original space-oriented purpose. The 1980s brought advancements in ferrofluid synthesis techniques, enabling the production of more stable and uniform particles, which expanded their applicability.

In the 1990s, researchers began exploring ferrofluids for biomedical applications, including targeted drug delivery and magnetic hyperthermia for cancer treatment. This period marked a significant shift in the perception of ferrofluids from industrial materials to potential life-saving substances.

The early 2000s witnessed the integration of ferrofluids into microfluidic devices, opening up new possibilities in lab-on-a-chip technologies. This development coincided with the growing interest in nanotechnology, further propelling ferrofluid research and development.

The past decade has seen a surge in ferrofluid applications in energy harvesting and conversion. Researchers have developed ferrofluid-based energy harvesters that can convert low-frequency vibrations into electricity, potentially revolutionizing renewable energy technologies.

Recent years have brought about innovative uses of ferrofluids in soft robotics and adaptive optics. The unique properties of ferrofluids allow for the creation of shape-shifting structures and tunable optical elements, pushing the boundaries of material science and engineering.

Looking towards the future, the evolution of ferrofluid technology is likely to focus on enhancing their stability, improving their responsiveness to external stimuli, and developing new synthesis methods for custom-designed ferrofluids. The integration of ferrofluids with smart materials and AI-driven control systems presents exciting possibilities for revolutionary system integrations across various fields, from advanced manufacturing to next-generation medical devices.

The 1970s saw the first commercial applications of ferrofluids in sealing technology, particularly in computer hard drives. This breakthrough demonstrated the practical potential of these smart fluids beyond their original space-oriented purpose. The 1980s brought advancements in ferrofluid synthesis techniques, enabling the production of more stable and uniform particles, which expanded their applicability.

In the 1990s, researchers began exploring ferrofluids for biomedical applications, including targeted drug delivery and magnetic hyperthermia for cancer treatment. This period marked a significant shift in the perception of ferrofluids from industrial materials to potential life-saving substances.

The early 2000s witnessed the integration of ferrofluids into microfluidic devices, opening up new possibilities in lab-on-a-chip technologies. This development coincided with the growing interest in nanotechnology, further propelling ferrofluid research and development.

The past decade has seen a surge in ferrofluid applications in energy harvesting and conversion. Researchers have developed ferrofluid-based energy harvesters that can convert low-frequency vibrations into electricity, potentially revolutionizing renewable energy technologies.

Recent years have brought about innovative uses of ferrofluids in soft robotics and adaptive optics. The unique properties of ferrofluids allow for the creation of shape-shifting structures and tunable optical elements, pushing the boundaries of material science and engineering.

Looking towards the future, the evolution of ferrofluid technology is likely to focus on enhancing their stability, improving their responsiveness to external stimuli, and developing new synthesis methods for custom-designed ferrofluids. The integration of ferrofluids with smart materials and AI-driven control systems presents exciting possibilities for revolutionary system integrations across various fields, from advanced manufacturing to next-generation medical devices.

Market Demand Analysis

The market demand for ferrofluid-based technologies is experiencing significant growth, driven by the increasing need for innovative solutions in various industries. Ferrofluids, with their unique magnetic properties and ability to respond to external magnetic fields, have captured the attention of researchers and industry professionals alike.

In the electronics sector, there is a growing demand for ferrofluid-based cooling systems in high-performance computing and data centers. These systems offer improved thermal management capabilities, potentially reducing energy consumption and extending the lifespan of electronic components. The miniaturization trend in electronics also creates opportunities for ferrofluid applications in microfluidic devices and sensors.

The automotive industry is exploring ferrofluid technology for advanced suspension systems and vibration damping. As vehicle manufacturers strive to enhance ride comfort and handling, ferrofluid-based solutions offer promising alternatives to traditional mechanical systems. Additionally, the shift towards electric vehicles opens up new possibilities for ferrofluid applications in battery thermal management and motor cooling.

In the medical field, ferrofluids show potential in targeted drug delivery systems and magnetic hyperthermia for cancer treatment. The ability to precisely control ferrofluids using external magnetic fields makes them attractive for minimally invasive medical procedures. This has led to increased research and development efforts in biomedical applications of ferrofluids.

The aerospace and defense sectors are also driving demand for ferrofluid technologies. Applications include advanced sealing systems for aircraft engines, vibration isolation in sensitive equipment, and potential use in space propulsion systems. The unique properties of ferrofluids make them suitable for harsh environments and extreme conditions encountered in these industries.

Environmental applications of ferrofluids are gaining traction, particularly in oil spill cleanup and water treatment processes. The ability of ferrofluids to separate oil from water efficiently has sparked interest from environmental agencies and cleanup organizations. This application addresses the growing global concern for environmental protection and sustainable resource management.

The global market for ferrofluid-based technologies is projected to expand significantly in the coming years. While specific market size figures vary depending on the source and scope of analysis, industry reports consistently indicate double-digit growth rates. Key factors contributing to this growth include increasing research and development activities, rising adoption in emerging applications, and the continuous discovery of new potential uses for ferrofluids across various industries.

In the electronics sector, there is a growing demand for ferrofluid-based cooling systems in high-performance computing and data centers. These systems offer improved thermal management capabilities, potentially reducing energy consumption and extending the lifespan of electronic components. The miniaturization trend in electronics also creates opportunities for ferrofluid applications in microfluidic devices and sensors.

The automotive industry is exploring ferrofluid technology for advanced suspension systems and vibration damping. As vehicle manufacturers strive to enhance ride comfort and handling, ferrofluid-based solutions offer promising alternatives to traditional mechanical systems. Additionally, the shift towards electric vehicles opens up new possibilities for ferrofluid applications in battery thermal management and motor cooling.

In the medical field, ferrofluids show potential in targeted drug delivery systems and magnetic hyperthermia for cancer treatment. The ability to precisely control ferrofluids using external magnetic fields makes them attractive for minimally invasive medical procedures. This has led to increased research and development efforts in biomedical applications of ferrofluids.

The aerospace and defense sectors are also driving demand for ferrofluid technologies. Applications include advanced sealing systems for aircraft engines, vibration isolation in sensitive equipment, and potential use in space propulsion systems. The unique properties of ferrofluids make them suitable for harsh environments and extreme conditions encountered in these industries.

Environmental applications of ferrofluids are gaining traction, particularly in oil spill cleanup and water treatment processes. The ability of ferrofluids to separate oil from water efficiently has sparked interest from environmental agencies and cleanup organizations. This application addresses the growing global concern for environmental protection and sustainable resource management.

The global market for ferrofluid-based technologies is projected to expand significantly in the coming years. While specific market size figures vary depending on the source and scope of analysis, industry reports consistently indicate double-digit growth rates. Key factors contributing to this growth include increasing research and development activities, rising adoption in emerging applications, and the continuous discovery of new potential uses for ferrofluids across various industries.

Current Challenges

Despite the promising potential of ferrofluids in revolutionary system integrations, several significant challenges currently hinder their widespread adoption and implementation. These challenges span across technical, practical, and economic domains, requiring innovative solutions and further research to overcome.

One of the primary technical challenges is the long-term stability of ferrofluids. While these magnetic liquids exhibit remarkable properties in controlled environments, maintaining their stability and performance over extended periods in real-world applications remains problematic. Factors such as temperature fluctuations, exposure to external magnetic fields, and chemical interactions with surrounding materials can lead to degradation of the ferrofluid's properties, potentially compromising the integrity of integrated systems.

Another critical issue is the precise control and manipulation of ferrofluids within complex systems. Although ferrofluids respond to magnetic fields, achieving fine-tuned control for intricate operations or in the presence of multiple magnetic sources presents significant difficulties. This challenge is particularly evident in applications requiring high precision, such as microfluidics or advanced sensing technologies.

The scalability of ferrofluid-based systems also poses a considerable challenge. While many promising applications have been demonstrated at laboratory scales, translating these successes to larger, industrial-scale implementations often encounters unforeseen complications. Issues related to fluid dynamics, magnetic field uniformity, and system integration become more pronounced as the scale increases, necessitating novel engineering approaches.

Compatibility with existing technologies and materials is another hurdle in the integration of ferrofluids. Many current systems are not designed to accommodate the unique properties of ferrofluids, requiring significant modifications or complete redesigns. This compatibility issue extends to the selection of materials that can safely contain and interact with ferrofluids without compromising their magnetic properties or causing unwanted chemical reactions.

From an economic perspective, the cost-effectiveness of ferrofluid-based solutions compared to conventional alternatives remains a significant challenge. The production of high-quality ferrofluids and the development of specialized containment and manipulation systems often involve substantial costs, potentially limiting their adoption in price-sensitive applications or industries.

Environmental and safety concerns also present challenges in the widespread use of ferrofluids. Questions regarding the long-term environmental impact of nanoparticles in ferrofluids, potential health risks associated with their handling, and the development of safe disposal methods need to be thoroughly addressed to ensure regulatory compliance and public acceptance.

Lastly, the interdisciplinary nature of ferrofluid applications presents a challenge in terms of expertise and collaboration. Successful integration of ferrofluids into revolutionary systems often requires a diverse skill set spanning physics, chemistry, materials science, and engineering. Bridging these knowledge gaps and fostering effective collaboration between different scientific and engineering disciplines is crucial for overcoming the current challenges and realizing the full potential of ferrofluid-based innovations.

One of the primary technical challenges is the long-term stability of ferrofluids. While these magnetic liquids exhibit remarkable properties in controlled environments, maintaining their stability and performance over extended periods in real-world applications remains problematic. Factors such as temperature fluctuations, exposure to external magnetic fields, and chemical interactions with surrounding materials can lead to degradation of the ferrofluid's properties, potentially compromising the integrity of integrated systems.

Another critical issue is the precise control and manipulation of ferrofluids within complex systems. Although ferrofluids respond to magnetic fields, achieving fine-tuned control for intricate operations or in the presence of multiple magnetic sources presents significant difficulties. This challenge is particularly evident in applications requiring high precision, such as microfluidics or advanced sensing technologies.

The scalability of ferrofluid-based systems also poses a considerable challenge. While many promising applications have been demonstrated at laboratory scales, translating these successes to larger, industrial-scale implementations often encounters unforeseen complications. Issues related to fluid dynamics, magnetic field uniformity, and system integration become more pronounced as the scale increases, necessitating novel engineering approaches.

Compatibility with existing technologies and materials is another hurdle in the integration of ferrofluids. Many current systems are not designed to accommodate the unique properties of ferrofluids, requiring significant modifications or complete redesigns. This compatibility issue extends to the selection of materials that can safely contain and interact with ferrofluids without compromising their magnetic properties or causing unwanted chemical reactions.

From an economic perspective, the cost-effectiveness of ferrofluid-based solutions compared to conventional alternatives remains a significant challenge. The production of high-quality ferrofluids and the development of specialized containment and manipulation systems often involve substantial costs, potentially limiting their adoption in price-sensitive applications or industries.

Environmental and safety concerns also present challenges in the widespread use of ferrofluids. Questions regarding the long-term environmental impact of nanoparticles in ferrofluids, potential health risks associated with their handling, and the development of safe disposal methods need to be thoroughly addressed to ensure regulatory compliance and public acceptance.

Lastly, the interdisciplinary nature of ferrofluid applications presents a challenge in terms of expertise and collaboration. Successful integration of ferrofluids into revolutionary systems often requires a diverse skill set spanning physics, chemistry, materials science, and engineering. Bridging these knowledge gaps and fostering effective collaboration between different scientific and engineering disciplines is crucial for overcoming the current challenges and realizing the full potential of ferrofluid-based innovations.

Existing Applications

01 Composition and preparation of ferrofluids

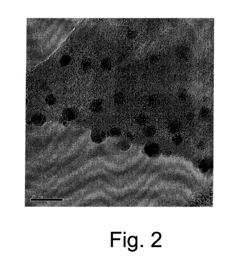

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly for electronic devices. Their unique properties allow for efficient heat transfer and cooling when subjected to magnetic fields, making them valuable in applications such as computer cooling systems and power electronics.

- Damping and vibration control: The viscoelastic properties of ferrofluids make them useful in damping applications. They can be used to control vibrations in mechanical systems, providing adaptive damping that can be tuned by adjusting the applied magnetic field strength.

- Sensing and measurement applications: Ferrofluids are utilized in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position makes them suitable for applications such as accelerometers, inclinometers, and pressure sensors. They can also be used in magnetic field visualization and educational demonstrations.

02 Applications in sealing and lubrication

Ferrofluids are used in various sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, liquid-tight seals that can withstand pressure differentials and prevent contamination. These applications are found in hard disk drives, industrial machinery, and aerospace equipment.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices and power systems. They can be used in heat sinks, liquid cooling systems, and thermomagnetic pumps to enhance heat transfer and improve cooling efficiency. The magnetic properties allow for controlled fluid movement and heat dissipation.Expand Specific Solutions04 Damping and vibration control

Ferrofluids are utilized in damping systems to control vibrations and absorb shocks. Their unique properties allow for adaptive damping in response to magnetic fields, making them suitable for use in automotive suspensions, seismic protection systems, and precision instruments. The controllable viscosity of ferrofluids enables tunable damping characteristics.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids find applications in various sensing and measurement devices. They are used in accelerometers, inclinometers, and position sensors, leveraging their response to magnetic fields and gravity. Additionally, ferrofluids are employed in magnetic resonance imaging (MRI) contrast agents and in specialized optical systems for beam steering and adaptive optics.Expand Specific Solutions

Key Industry Players

The ferrofluid technology integration market is in an early growth stage, with increasing interest across various industries. While the market size remains relatively modest, it shows promising potential for expansion. The technology's maturity is advancing, with key players like Samsung Electronics, Corning, and Philips driving innovation. Academic institutions such as Caltech and Delft University of Technology are contributing significant research. Smaller specialized companies like Ferrotec and S2 Genomics are also making strides in niche applications. As the technology evolves, we can expect to see more diverse and sophisticated integrations across sectors like electronics, healthcare, and energy.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has been exploring the integration of ferrofluids in next-generation display technologies. Their research focuses on using ferrofluids to create dynamic, reconfigurable optical elements in displays, potentially enabling new forms of user interaction and visual effects. The company has also investigated the use of ferrofluids in microfluidic devices for lab-on-a-chip applications, leveraging the fluid's magnetic properties for precise control of liquid movement and mixing[2]. Additionally, Samsung is exploring ferrofluid-based haptic feedback systems for mobile devices, aiming to enhance user experience through tactile sensations controlled by magnetic fields[4].

Strengths: Strong R&D capabilities, diverse product portfolio for potential applications. Weaknesses: May face challenges in scaling ferrofluid technologies for mass production.

California Institute of Technology

Technical Solution: Caltech researchers have been at the forefront of exploring novel applications for ferrofluids in microfluidics and nanoengineering. They have developed techniques for using ferrofluids to create reconfigurable microstructures and self-assembling systems at the microscale. One notable project involves using ferrofluids to create adaptive optical elements, such as tunable lenses and mirrors, which can be controlled with precision using external magnetic fields[5]. The institute has also investigated the potential of ferrofluids in energy harvesting applications, exploring ways to convert mechanical energy into electrical energy using the unique properties of magnetic nanofluids[6].

Strengths: Cutting-edge research in nanotechnology and materials science. Weaknesses: As an academic institution, may face challenges in commercializing research findings.

Core Ferrofluid Patents

Systems containing magnetic nanoparticles and polymers, such as nanocomposites and ferrofluids, and applications thereof

PatentInactiveUS20120141602A1

Innovation

- A system comprising magnetic nanoparticles of metal oxide and a polymer with active functional groups, where the molar [Fe]/[monomer] ratio is controlled to achieve nanoparticles with low size dispersion and biocompatibility, allowing for biological functionalization and immune system avoidance, and can be formulated as either nanocomposites or ferrofluids.

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

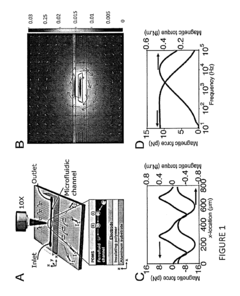

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Environmental Impact

The integration of ferrofluids into various systems presents both opportunities and challenges from an environmental perspective. As these magnetic nanofluids gain traction in revolutionary applications, it is crucial to assess their potential impact on ecosystems and human health.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in diverse fields such as electronics, medicine, and mechanical engineering. However, their widespread use raises concerns about their environmental fate and potential toxicity. The small size of the nanoparticles in ferrofluids allows them to easily penetrate biological barriers, potentially accumulating in living organisms and causing adverse effects.

One of the primary environmental considerations is the potential release of ferrofluids into aquatic ecosystems. Studies have shown that magnetic nanoparticles can interact with aquatic organisms, potentially disrupting their natural behaviors and physiological processes. The long-term effects of such interactions on biodiversity and ecosystem balance remain largely unknown and require further investigation.

The production and disposal of ferrofluid-based systems also present environmental challenges. The manufacturing process of magnetic nanoparticles often involves energy-intensive methods and the use of potentially harmful chemicals. Proper disposal and recycling protocols must be developed to prevent the release of these materials into the environment at the end of their lifecycle.

On the positive side, ferrofluids have shown promise in environmental remediation applications. Their magnetic properties can be harnessed for the removal of pollutants from water and soil, offering a potential solution to certain environmental contamination issues. Additionally, the use of ferrofluids in energy-efficient cooling systems and improved renewable energy technologies could contribute to reducing overall environmental impact in various industries.

As research into ferrofluid applications continues to advance, it is imperative to conduct comprehensive life cycle assessments to fully understand their environmental implications. This includes evaluating the sustainability of raw material sourcing, production processes, use-phase impacts, and end-of-life management. Developing green synthesis methods for ferrofluids and exploring biodegradable carrier fluids could mitigate some of the environmental concerns associated with their use.

Regulatory frameworks and industry standards must evolve to address the unique challenges posed by ferrofluid technologies. This includes establishing guidelines for safe handling, use, and disposal, as well as monitoring protocols to detect and mitigate any potential environmental contamination. Collaboration between researchers, industry stakeholders, and environmental agencies will be crucial in ensuring that the benefits of ferrofluid innovations are realized while minimizing their ecological footprint.

Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have unique properties that make them valuable in diverse fields such as electronics, medicine, and mechanical engineering. However, their widespread use raises concerns about their environmental fate and potential toxicity. The small size of the nanoparticles in ferrofluids allows them to easily penetrate biological barriers, potentially accumulating in living organisms and causing adverse effects.

One of the primary environmental considerations is the potential release of ferrofluids into aquatic ecosystems. Studies have shown that magnetic nanoparticles can interact with aquatic organisms, potentially disrupting their natural behaviors and physiological processes. The long-term effects of such interactions on biodiversity and ecosystem balance remain largely unknown and require further investigation.

The production and disposal of ferrofluid-based systems also present environmental challenges. The manufacturing process of magnetic nanoparticles often involves energy-intensive methods and the use of potentially harmful chemicals. Proper disposal and recycling protocols must be developed to prevent the release of these materials into the environment at the end of their lifecycle.

On the positive side, ferrofluids have shown promise in environmental remediation applications. Their magnetic properties can be harnessed for the removal of pollutants from water and soil, offering a potential solution to certain environmental contamination issues. Additionally, the use of ferrofluids in energy-efficient cooling systems and improved renewable energy technologies could contribute to reducing overall environmental impact in various industries.

As research into ferrofluid applications continues to advance, it is imperative to conduct comprehensive life cycle assessments to fully understand their environmental implications. This includes evaluating the sustainability of raw material sourcing, production processes, use-phase impacts, and end-of-life management. Developing green synthesis methods for ferrofluids and exploring biodegradable carrier fluids could mitigate some of the environmental concerns associated with their use.

Regulatory frameworks and industry standards must evolve to address the unique challenges posed by ferrofluid technologies. This includes establishing guidelines for safe handling, use, and disposal, as well as monitoring protocols to detect and mitigate any potential environmental contamination. Collaboration between researchers, industry stakeholders, and environmental agencies will be crucial in ensuring that the benefits of ferrofluid innovations are realized while minimizing their ecological footprint.

Scalability Assessment

Assessing the scalability of ferrofluid-based systems is crucial for their widespread adoption and integration into various industries. The unique properties of ferrofluids, including their responsiveness to magnetic fields and ability to change shape and viscosity, present both opportunities and challenges in terms of scalability.

One of the primary considerations in scaling ferrofluid applications is the production and quality control of the fluid itself. As demand increases, manufacturers must develop efficient processes to produce large quantities of ferrofluid while maintaining consistent properties across batches. This includes optimizing the synthesis of magnetic nanoparticles and their suspension in carrier fluids, as well as ensuring long-term stability of the colloidal mixture.

The scalability of ferrofluid-based systems also depends on the availability and cost of raw materials. Rare earth elements, often used in high-performance ferrofluids, may face supply chain constraints as demand grows. Researchers are exploring alternative materials and formulations to address this potential bottleneck and ensure sustainable scalability.

In terms of system integration, the scalability of ferrofluid applications varies across different sectors. In microfluidics and lab-on-a-chip devices, scaling up may involve parallel processing or modular designs to increase throughput while maintaining precise control over small fluid volumes. For larger-scale applications, such as in energy harvesting or vibration damping, scaling challenges include maintaining uniform magnetic field distribution and managing heat generation in larger systems.

The adaptability of ferrofluid-based systems to different environmental conditions is another critical factor in assessing scalability. Temperature fluctuations, exposure to contaminants, and long-term stability under various operating conditions must be carefully evaluated to ensure consistent performance across diverse applications and settings.

Scalability also encompasses the integration of ferrofluid systems with existing technologies and infrastructure. This includes developing standardized interfaces, control systems, and maintenance protocols that can be easily implemented across different scales and industries. The ability to seamlessly incorporate ferrofluid-based components into existing manufacturing processes and product lines will significantly impact their scalability and market penetration.

As ferrofluid applications expand, regulatory considerations and safety standards will play a crucial role in scalability assessments. Developing comprehensive guidelines for handling, disposal, and long-term environmental impact will be essential for widespread adoption, particularly in sensitive applications such as biomedical devices or food processing equipment.

One of the primary considerations in scaling ferrofluid applications is the production and quality control of the fluid itself. As demand increases, manufacturers must develop efficient processes to produce large quantities of ferrofluid while maintaining consistent properties across batches. This includes optimizing the synthesis of magnetic nanoparticles and their suspension in carrier fluids, as well as ensuring long-term stability of the colloidal mixture.

The scalability of ferrofluid-based systems also depends on the availability and cost of raw materials. Rare earth elements, often used in high-performance ferrofluids, may face supply chain constraints as demand grows. Researchers are exploring alternative materials and formulations to address this potential bottleneck and ensure sustainable scalability.

In terms of system integration, the scalability of ferrofluid applications varies across different sectors. In microfluidics and lab-on-a-chip devices, scaling up may involve parallel processing or modular designs to increase throughput while maintaining precise control over small fluid volumes. For larger-scale applications, such as in energy harvesting or vibration damping, scaling challenges include maintaining uniform magnetic field distribution and managing heat generation in larger systems.

The adaptability of ferrofluid-based systems to different environmental conditions is another critical factor in assessing scalability. Temperature fluctuations, exposure to contaminants, and long-term stability under various operating conditions must be carefully evaluated to ensure consistent performance across diverse applications and settings.

Scalability also encompasses the integration of ferrofluid systems with existing technologies and infrastructure. This includes developing standardized interfaces, control systems, and maintenance protocols that can be easily implemented across different scales and industries. The ability to seamlessly incorporate ferrofluid-based components into existing manufacturing processes and product lines will significantly impact their scalability and market penetration.

As ferrofluid applications expand, regulatory considerations and safety standards will play a crucial role in scalability assessments. Developing comprehensive guidelines for handling, disposal, and long-term environmental impact will be essential for widespread adoption, particularly in sensitive applications such as biomedical devices or food processing equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!