How to Advance Ferrofluid Technologies for Superb Data Accuracy?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel control in zero gravity, ferrofluids have found diverse applications across various industries. The technology's progression can be traced through several key phases, each marked by breakthroughs in synthesis, characterization, and application.

In the early stages, research focused on improving the stability and magnetic properties of ferrofluids. Scientists worked on refining the synthesis process to create uniform nanoparticles and develop suitable surfactants to prevent agglomeration. This period saw the emergence of ferrofluids with enhanced magnetic susceptibility and colloidal stability, laying the foundation for more advanced applications.

The 1980s and 1990s witnessed a surge in ferrofluid research for industrial applications. Innovations in magnetic sealing and damping technologies leveraged the unique properties of ferrofluids, leading to their adoption in hard disk drives and loudspeakers. Concurrently, advancements in characterization techniques, such as dynamic light scattering and magnetometry, enabled a deeper understanding of ferrofluid behavior under various conditions.

The turn of the millennium marked a new era in ferrofluid technology, with a focus on biomedical applications. Researchers explored the potential of ferrofluids in targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging. This phase saw the development of biocompatible ferrofluids with tailored surface properties to enhance their efficacy in biological systems.

Recent years have witnessed a shift towards nanoscale precision and control in ferrofluid technology. The advent of advanced fabrication techniques, such as microfluidics and 3D printing, has enabled the creation of complex ferrofluid-based structures and devices. This has opened up new possibilities in fields like microfluidics, soft robotics, and adaptive optics.

In the context of data accuracy, ferrofluid technology has evolved to address challenges in sensing and measurement applications. Researchers have developed highly sensitive magnetometers and accelerometers utilizing ferrofluids, capable of detecting minute changes in magnetic fields or motion. These advancements have significantly improved the precision and reliability of data collection in various scientific and industrial settings.

The ongoing evolution of ferrofluid technology is driven by interdisciplinary collaborations and the integration of cutting-edge materials science, nanotechnology, and data analytics. Current research focuses on developing smart ferrofluids with programmable properties, enabling real-time response to external stimuli. This direction holds promise for creating adaptive systems with unprecedented accuracy in data sensing and processing, paving the way for next-generation technologies in fields ranging from environmental monitoring to advanced computing.

In the early stages, research focused on improving the stability and magnetic properties of ferrofluids. Scientists worked on refining the synthesis process to create uniform nanoparticles and develop suitable surfactants to prevent agglomeration. This period saw the emergence of ferrofluids with enhanced magnetic susceptibility and colloidal stability, laying the foundation for more advanced applications.

The 1980s and 1990s witnessed a surge in ferrofluid research for industrial applications. Innovations in magnetic sealing and damping technologies leveraged the unique properties of ferrofluids, leading to their adoption in hard disk drives and loudspeakers. Concurrently, advancements in characterization techniques, such as dynamic light scattering and magnetometry, enabled a deeper understanding of ferrofluid behavior under various conditions.

The turn of the millennium marked a new era in ferrofluid technology, with a focus on biomedical applications. Researchers explored the potential of ferrofluids in targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging. This phase saw the development of biocompatible ferrofluids with tailored surface properties to enhance their efficacy in biological systems.

Recent years have witnessed a shift towards nanoscale precision and control in ferrofluid technology. The advent of advanced fabrication techniques, such as microfluidics and 3D printing, has enabled the creation of complex ferrofluid-based structures and devices. This has opened up new possibilities in fields like microfluidics, soft robotics, and adaptive optics.

In the context of data accuracy, ferrofluid technology has evolved to address challenges in sensing and measurement applications. Researchers have developed highly sensitive magnetometers and accelerometers utilizing ferrofluids, capable of detecting minute changes in magnetic fields or motion. These advancements have significantly improved the precision and reliability of data collection in various scientific and industrial settings.

The ongoing evolution of ferrofluid technology is driven by interdisciplinary collaborations and the integration of cutting-edge materials science, nanotechnology, and data analytics. Current research focuses on developing smart ferrofluids with programmable properties, enabling real-time response to external stimuli. This direction holds promise for creating adaptive systems with unprecedented accuracy in data sensing and processing, paving the way for next-generation technologies in fields ranging from environmental monitoring to advanced computing.

Market Demand Analysis

The market demand for advanced ferrofluid technologies in data accuracy applications has been steadily growing across various industries. This surge is primarily driven by the increasing need for precise and reliable data in sectors such as healthcare, aerospace, and advanced manufacturing. Ferrofluids, with their unique magnetic properties and ability to respond to external magnetic fields, offer significant potential for enhancing data accuracy in a wide range of sensing and measurement applications.

In the healthcare sector, there is a rising demand for ferrofluid-based technologies in medical imaging and diagnostics. Magnetic Resonance Imaging (MRI) systems, in particular, can benefit from improved contrast agents based on ferrofluids, leading to more accurate and detailed scans. This advancement is crucial for early disease detection and treatment planning, driving the market growth in this segment.

The aerospace industry is another key driver of market demand for ferrofluid technologies. With the increasing complexity of aircraft systems and the need for precise navigation and control, there is a growing interest in ferrofluid-based sensors and actuators. These technologies can provide more accurate data for flight control systems, enhancing overall safety and performance.

In the field of advanced manufacturing, the demand for high-precision measurement and control systems is fueling the adoption of ferrofluid technologies. Industries such as semiconductor manufacturing and nanotechnology require extremely accurate positioning and vibration control, which can be achieved through ferrofluid-based systems. This trend is expected to continue as manufacturing processes become increasingly sophisticated and demand higher levels of precision.

The automotive industry is also showing increased interest in ferrofluid technologies for improving data accuracy in various applications. From enhancing the performance of suspension systems to developing more precise sensors for autonomous vehicles, ferrofluids offer promising solutions to meet the industry's evolving needs.

Environmental monitoring and research represent another growing market for ferrofluid technologies. The ability to detect and measure minute changes in magnetic fields can be applied to geophysical surveys, climate research, and pollution monitoring, driving demand in these sectors.

As the Internet of Things (IoT) and smart devices continue to proliferate, there is an emerging market for miniaturized, high-accuracy sensors based on ferrofluid technology. These sensors can provide more precise data for a wide range of applications, from wearable health monitors to smart home devices.

The global market for ferrofluid technologies in data accuracy applications is expected to experience significant growth in the coming years. This growth is supported by ongoing research and development efforts aimed at expanding the capabilities and applications of ferrofluids, as well as increasing awareness of their potential benefits across various industries.

In the healthcare sector, there is a rising demand for ferrofluid-based technologies in medical imaging and diagnostics. Magnetic Resonance Imaging (MRI) systems, in particular, can benefit from improved contrast agents based on ferrofluids, leading to more accurate and detailed scans. This advancement is crucial for early disease detection and treatment planning, driving the market growth in this segment.

The aerospace industry is another key driver of market demand for ferrofluid technologies. With the increasing complexity of aircraft systems and the need for precise navigation and control, there is a growing interest in ferrofluid-based sensors and actuators. These technologies can provide more accurate data for flight control systems, enhancing overall safety and performance.

In the field of advanced manufacturing, the demand for high-precision measurement and control systems is fueling the adoption of ferrofluid technologies. Industries such as semiconductor manufacturing and nanotechnology require extremely accurate positioning and vibration control, which can be achieved through ferrofluid-based systems. This trend is expected to continue as manufacturing processes become increasingly sophisticated and demand higher levels of precision.

The automotive industry is also showing increased interest in ferrofluid technologies for improving data accuracy in various applications. From enhancing the performance of suspension systems to developing more precise sensors for autonomous vehicles, ferrofluids offer promising solutions to meet the industry's evolving needs.

Environmental monitoring and research represent another growing market for ferrofluid technologies. The ability to detect and measure minute changes in magnetic fields can be applied to geophysical surveys, climate research, and pollution monitoring, driving demand in these sectors.

As the Internet of Things (IoT) and smart devices continue to proliferate, there is an emerging market for miniaturized, high-accuracy sensors based on ferrofluid technology. These sensors can provide more precise data for a wide range of applications, from wearable health monitors to smart home devices.

The global market for ferrofluid technologies in data accuracy applications is expected to experience significant growth in the coming years. This growth is supported by ongoing research and development efforts aimed at expanding the capabilities and applications of ferrofluids, as well as increasing awareness of their potential benefits across various industries.

Current Challenges

Ferrofluid technologies, while promising for enhancing data accuracy, face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is the stability of ferrofluids over extended periods. These colloidal suspensions of magnetic nanoparticles tend to aggregate or settle over time, compromising their uniform distribution and, consequently, their effectiveness in data-related applications. This instability can lead to inconsistent magnetic responses and reduced precision in data recording or sensing processes.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. While ferrofluids respond readily to external magnetic fields, achieving fine-tuned control over their movement, shape, and properties remains complex. This limitation impacts the accuracy and reliability of ferrofluid-based data systems, particularly in scenarios requiring high-resolution measurements or rapid response times.

The thermal sensitivity of ferrofluids presents an additional hurdle. Temperature fluctuations can significantly affect the viscosity and magnetic properties of these fluids, potentially leading to data inconsistencies or errors in applications where thermal stability is crucial. This sensitivity necessitates sophisticated temperature control mechanisms, adding complexity and cost to ferrofluid-based systems.

Compatibility issues with existing data storage and processing technologies also pose a significant challenge. Integrating ferrofluid technologies into established data infrastructure requires substantial modifications to hardware and software systems. This integration complexity often results in resistance from industry stakeholders and slows down the adoption of ferrofluid-based solutions.

Furthermore, the production of high-quality ferrofluids with consistent properties at scale remains a technical challenge. Variations in nanoparticle size, distribution, and magnetic properties can lead to inconsistencies in ferrofluid performance, impacting data accuracy and reliability. Achieving uniformity in large-scale production is essential for the widespread implementation of ferrofluid technologies in data-centric applications.

Lastly, the environmental and health implications of ferrofluids, particularly in the context of data centers or consumer electronics, are not yet fully understood. Concerns about the potential long-term effects of exposure to nanoparticles and magnetic fields need to be addressed to ensure the safe and sustainable use of ferrofluid technologies in data-related applications.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. While ferrofluids respond readily to external magnetic fields, achieving fine-tuned control over their movement, shape, and properties remains complex. This limitation impacts the accuracy and reliability of ferrofluid-based data systems, particularly in scenarios requiring high-resolution measurements or rapid response times.

The thermal sensitivity of ferrofluids presents an additional hurdle. Temperature fluctuations can significantly affect the viscosity and magnetic properties of these fluids, potentially leading to data inconsistencies or errors in applications where thermal stability is crucial. This sensitivity necessitates sophisticated temperature control mechanisms, adding complexity and cost to ferrofluid-based systems.

Compatibility issues with existing data storage and processing technologies also pose a significant challenge. Integrating ferrofluid technologies into established data infrastructure requires substantial modifications to hardware and software systems. This integration complexity often results in resistance from industry stakeholders and slows down the adoption of ferrofluid-based solutions.

Furthermore, the production of high-quality ferrofluids with consistent properties at scale remains a technical challenge. Variations in nanoparticle size, distribution, and magnetic properties can lead to inconsistencies in ferrofluid performance, impacting data accuracy and reliability. Achieving uniformity in large-scale production is essential for the widespread implementation of ferrofluid technologies in data-centric applications.

Lastly, the environmental and health implications of ferrofluids, particularly in the context of data centers or consumer electronics, are not yet fully understood. Concerns about the potential long-term effects of exposure to nanoparticles and magnetic fields need to be addressed to ensure the safe and sustainable use of ferrofluid technologies in data-related applications.

Existing Solutions

01 Ferrofluid sealing technologies

Ferrofluid sealing technologies are used to improve data accuracy in various applications. These seals provide effective containment of fluids and gases, reducing contamination and enhancing the precision of measurements. The technology is particularly useful in rotating shaft seals, where it can maintain a clean environment for sensitive components.- Ferrofluid sealing technologies: Ferrofluid sealing technologies are used to improve data accuracy in various applications. These seals provide effective containment of fluids and gases, reducing contamination and enhancing the precision of measurements. The technology is particularly useful in rotating shaft seals, where it can maintain a clean environment for sensitive components.

- Magnetic field sensing and measurement: Ferrofluids are utilized in magnetic field sensing and measurement applications to enhance data accuracy. The unique properties of ferrofluids allow for precise detection and quantification of magnetic fields, enabling improved sensor performance and reliability in various devices and systems.

- Thermal management systems: Ferrofluids are employed in thermal management systems to improve data accuracy by maintaining stable operating temperatures. These systems utilize the heat transfer properties of ferrofluids to efficiently dissipate heat from electronic components, ensuring consistent performance and reducing temperature-related errors in data processing and storage devices.

- Vibration damping and isolation: Ferrofluid-based vibration damping and isolation systems are used to enhance data accuracy in sensitive equipment. By reducing mechanical vibrations and disturbances, these systems improve the stability and precision of measurements, particularly in applications such as high-precision manufacturing and scientific instruments.

- Optical systems and imaging: Ferrofluids are utilized in optical systems and imaging applications to improve data accuracy. The unique properties of ferrofluids allow for precise control of optical elements, such as lenses and mirrors, enabling enhanced focusing, stabilization, and image quality in various imaging devices and systems.

02 Magnetic field sensing and measurement

Ferrofluids are utilized in magnetic field sensing and measurement applications to enhance data accuracy. The responsive nature of ferrofluids to magnetic fields allows for precise detection and quantification of magnetic field strengths. This technology is applied in various sensors and measurement devices to improve sensitivity and reliability.Expand Specific Solutions03 Thermal management systems

Ferrofluids are employed in thermal management systems to improve data accuracy by maintaining stable operating temperatures. These systems utilize the unique properties of ferrofluids to efficiently transfer heat, ensuring consistent performance of sensitive equipment. This technology is particularly beneficial in electronic devices and industrial machinery.Expand Specific Solutions04 Vibration damping and control

Ferrofluid technologies are used in vibration damping and control systems to enhance data accuracy. By leveraging the magnetic properties of ferrofluids, these systems can effectively reduce unwanted vibrations in precision instruments and measurement devices. This results in more stable and accurate data collection across various applications.Expand Specific Solutions05 Nanoparticle synthesis and characterization

Ferrofluid technologies play a crucial role in nanoparticle synthesis and characterization, contributing to improved data accuracy in nanoscale measurements. The magnetic properties of ferrofluids enable precise control and manipulation of nanoparticles, allowing for more accurate analysis and characterization of their properties and behavior.Expand Specific Solutions

Key Industry Players

The ferrofluid technology market is in a growth phase, with increasing applications across various industries driving market expansion. The global ferrofluid market size is projected to reach significant figures in the coming years, indicating substantial potential. Technologically, ferrofluids are advancing rapidly, with key players like IBM, Philips, and Rolls-Royce investing in research and development to enhance data accuracy and performance. Academic institutions such as Chongqing University, ETH Zurich, and MIT are also contributing to technological advancements. While the technology is maturing, there's still room for innovation, particularly in improving stability, magnetic properties, and application-specific formulations to meet the growing demand for high-precision data in various sectors.

International Business Machines Corp.

Technical Solution: IBM has made significant advancements in ferrofluid technologies for data storage and processing applications. They have developed a novel approach using ferrofluids to create self-assembling magnetic nanoparticle arrays, which can be used for high-density data storage[4]. This technology allows for the precise positioning of magnetic nanoparticles, enabling the creation of ultra-high-density storage media with improved data accuracy and stability. IBM's research also extends to using ferrofluids in cooling systems for data centers, where the magnetic properties of the fluid are harnessed to enhance heat transfer efficiency[5]. Additionally, they have explored the use of ferrofluids in microfluidic devices for lab-on-a-chip applications, leveraging the fluid's unique properties to achieve precise control over sample manipulation and analysis[6].

Strengths: Cutting-edge research in data storage and processing applications, potential for significant improvements in data density and accuracy. Weaknesses: Some technologies may still be in the research phase, requiring further development for commercial viability.

Koninklijke Philips NV

Technical Solution: Philips has incorporated ferrofluid technology into their audio systems, particularly in loudspeaker design, to enhance sound quality and accuracy. Their approach uses ferrofluids as a damping medium in the voice coil gap of speakers, which helps to dissipate heat and reduce distortion[7]. This results in improved audio fidelity and more accurate sound reproduction. Beyond audio applications, Philips has also explored the use of ferrofluids in medical imaging technologies. They have developed contrast agents based on superparamagnetic iron oxide nanoparticles, which can be used to enhance the accuracy and resolution of MRI scans[8]. These ferrofluid-based contrast agents allow for better visualization of specific tissues or organs, potentially improving diagnostic accuracy in various medical conditions[9].

Strengths: Practical applications in audio and medical imaging, improving both sound and diagnostic accuracy. Weaknesses: Limited to specific application areas, may face competition from alternative technologies in these fields.

Core Innovations

Method for diagnosing disease by preprocessing biologically-extracted data and device therefor

PatentWO2021075826A1

Innovation

- A method and device that preprocess FCS data by converting it into a hypercube format, using machine learning to extract feature values and classify them, enabling accurate disease diagnosis and understanding of clinical situations through automated analysis.

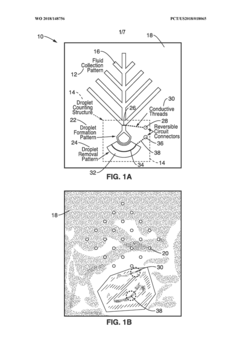

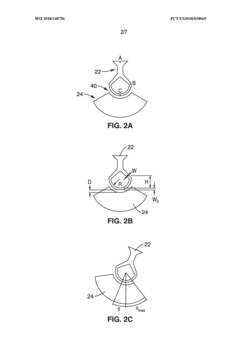

Apparatus and methods for digital droplet flowmetry

PatentWO2018148756A1

Innovation

- A wearable digital droplet flowmetry platform using conventional fabric materials and laser micromachining, which employs interfacial microfluidics to discretize continuous flow into droplets, allowing for real-time, continuous measurement of perspiration rates with high precision through a digital microfluidic flowmeter that utilizes interfacial bursting events and impedance detection.

Regulatory Considerations

The regulatory landscape surrounding ferrofluid technologies is complex and multifaceted, requiring careful consideration as these technologies advance towards enhanced data accuracy applications. Regulatory bodies across various jurisdictions are increasingly focusing on the potential environmental and health impacts of nanomaterials, including ferrofluids. As such, manufacturers and researchers must navigate a web of regulations governing the production, use, and disposal of these materials.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating nanomaterials under the Toxic Substances Control Act (TSCA). Ferrofluid developers must comply with reporting and testing requirements, particularly when introducing new formulations or applications. The Food and Drug Administration (FDA) also maintains oversight on ferrofluids used in medical devices or diagnostic tools, ensuring their safety and efficacy through rigorous approval processes.

European regulations, notably the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), impose stringent requirements on the registration and safety assessment of nanomaterials. Ferrofluid manufacturers targeting the European market must provide detailed information on the physicochemical properties, toxicological profiles, and potential environmental impacts of their products.

As ferrofluid technologies advance towards data accuracy applications, regulatory considerations extend beyond material safety to data protection and privacy. The General Data Protection Regulation (GDPR) in the EU and similar laws worldwide may impact the development and deployment of ferrofluid-based sensing and data collection systems, particularly in scenarios involving personal or sensitive information.

Occupational health and safety regulations also play a significant role in the advancement of ferrofluid technologies. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for handling nanomaterials in workplace settings. Compliance with these regulations is essential for research laboratories and manufacturing facilities working with ferrofluids.

As the field progresses, it is likely that regulatory frameworks will evolve to address the specific challenges posed by advanced ferrofluid technologies. Developers and researchers must stay abreast of these changes and actively engage with regulatory bodies to ensure compliance and foster innovation. Proactive approaches, such as participating in voluntary reporting schemes and contributing to the development of industry standards, can help shape a regulatory environment that balances technological advancement with safety and ethical considerations.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating nanomaterials under the Toxic Substances Control Act (TSCA). Ferrofluid developers must comply with reporting and testing requirements, particularly when introducing new formulations or applications. The Food and Drug Administration (FDA) also maintains oversight on ferrofluids used in medical devices or diagnostic tools, ensuring their safety and efficacy through rigorous approval processes.

European regulations, notably the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), impose stringent requirements on the registration and safety assessment of nanomaterials. Ferrofluid manufacturers targeting the European market must provide detailed information on the physicochemical properties, toxicological profiles, and potential environmental impacts of their products.

As ferrofluid technologies advance towards data accuracy applications, regulatory considerations extend beyond material safety to data protection and privacy. The General Data Protection Regulation (GDPR) in the EU and similar laws worldwide may impact the development and deployment of ferrofluid-based sensing and data collection systems, particularly in scenarios involving personal or sensitive information.

Occupational health and safety regulations also play a significant role in the advancement of ferrofluid technologies. Organizations such as the Occupational Safety and Health Administration (OSHA) in the US and the European Agency for Safety and Health at Work (EU-OSHA) provide guidelines for handling nanomaterials in workplace settings. Compliance with these regulations is essential for research laboratories and manufacturing facilities working with ferrofluids.

As the field progresses, it is likely that regulatory frameworks will evolve to address the specific challenges posed by advanced ferrofluid technologies. Developers and researchers must stay abreast of these changes and actively engage with regulatory bodies to ensure compliance and foster innovation. Proactive approaches, such as participating in voluntary reporting schemes and contributing to the development of industry standards, can help shape a regulatory environment that balances technological advancement with safety and ethical considerations.

Environmental Impact

The environmental impact of ferrofluid technologies is a critical consideration as these materials gain prominence in various applications, particularly in data accuracy enhancement. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, present both potential benefits and challenges from an environmental perspective.

One of the primary environmental advantages of ferrofluid technologies lies in their potential to improve energy efficiency in various systems. By enhancing data accuracy and precision in sensors and measurement devices, ferrofluids can contribute to more efficient resource utilization and reduced energy consumption across industries. This improved efficiency can lead to a decrease in overall carbon footprint and resource depletion associated with data-driven processes.

However, the production and disposal of ferrofluids raise important environmental concerns. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. The long-term environmental fate of these nanoparticles, if released into ecosystems, remains a subject of ongoing research and debate. There are concerns about their potential bioaccumulation and impacts on aquatic and terrestrial organisms.

The stability and degradation of ferrofluids in various environmental conditions also warrant attention. While many ferrofluids are designed to be chemically stable, their breakdown over time could release constituent materials into the environment. The carrier fluids used in ferrofluid formulations, which may be organic solvents or synthetic oils, pose additional environmental risks if not properly managed or contained.

From a lifecycle perspective, the environmental impact of ferrofluid technologies extends beyond their immediate use. The extraction and processing of raw materials for nanoparticle production, such as iron oxides, can have significant environmental implications, including habitat disruption and energy consumption. Additionally, the eventual disposal or recycling of devices and systems containing ferrofluids presents challenges in terms of material recovery and waste management.

As ferrofluid technologies advance, there is a growing emphasis on developing more environmentally friendly formulations. Research is being conducted on bio-based carrier fluids and less toxic synthesis methods for magnetic nanoparticles. These efforts aim to mitigate the potential negative environmental impacts while preserving the beneficial properties of ferrofluids for data accuracy applications.

The regulatory landscape surrounding ferrofluid technologies and their environmental impact is still evolving. As these materials find wider application, it is likely that more stringent environmental guidelines and disposal protocols will be established to ensure responsible use and minimize ecological risks.

One of the primary environmental advantages of ferrofluid technologies lies in their potential to improve energy efficiency in various systems. By enhancing data accuracy and precision in sensors and measurement devices, ferrofluids can contribute to more efficient resource utilization and reduced energy consumption across industries. This improved efficiency can lead to a decrease in overall carbon footprint and resource depletion associated with data-driven processes.

However, the production and disposal of ferrofluids raise important environmental concerns. The synthesis of magnetic nanoparticles often involves energy-intensive processes and the use of potentially harmful chemicals. The long-term environmental fate of these nanoparticles, if released into ecosystems, remains a subject of ongoing research and debate. There are concerns about their potential bioaccumulation and impacts on aquatic and terrestrial organisms.

The stability and degradation of ferrofluids in various environmental conditions also warrant attention. While many ferrofluids are designed to be chemically stable, their breakdown over time could release constituent materials into the environment. The carrier fluids used in ferrofluid formulations, which may be organic solvents or synthetic oils, pose additional environmental risks if not properly managed or contained.

From a lifecycle perspective, the environmental impact of ferrofluid technologies extends beyond their immediate use. The extraction and processing of raw materials for nanoparticle production, such as iron oxides, can have significant environmental implications, including habitat disruption and energy consumption. Additionally, the eventual disposal or recycling of devices and systems containing ferrofluids presents challenges in terms of material recovery and waste management.

As ferrofluid technologies advance, there is a growing emphasis on developing more environmentally friendly formulations. Research is being conducted on bio-based carrier fluids and less toxic synthesis methods for magnetic nanoparticles. These efforts aim to mitigate the potential negative environmental impacts while preserving the beneficial properties of ferrofluids for data accuracy applications.

The regulatory landscape surrounding ferrofluid technologies and their environmental impact is still evolving. As these materials find wider application, it is likely that more stringent environmental guidelines and disposal protocols will be established to ensure responsible use and minimize ecological risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!