Ferrofluid Dynamics in Modern Engineering Applications

Ferrofluid Tech Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant technological evolution over the past six decades. Initially conceived for controlling liquids in zero gravity, these magnetic nanofluids have found diverse applications across various engineering fields. The evolution of ferrofluid technology can be traced through several key stages, each marked by advancements in synthesis, characterization, and application methodologies.

In the 1970s and 1980s, research focused primarily on understanding the fundamental properties of ferrofluids and developing improved synthesis techniques. Scientists explored various methods to create stable colloidal suspensions of magnetic nanoparticles, leading to the development of surfactant-coated ferrofluids with enhanced stability and performance.

The 1990s saw a surge in ferrofluid applications, particularly in the electronics industry. Ferrofluids found use in computer hard drive seals and loudspeaker cooling systems, demonstrating their potential in thermal management and sealing technologies. This period also witnessed advancements in theoretical modeling of ferrofluid behavior, enabling more accurate predictions of their response to magnetic fields.

The early 2000s marked a significant leap in ferrofluid technology with the advent of biomedical applications. Researchers began exploring the use of ferrofluids in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). This period also saw improvements in nanoparticle synthesis techniques, allowing for greater control over particle size and magnetic properties.

From 2010 onwards, ferrofluid technology has experienced rapid advancement in both materials science and application domains. The development of novel magnetic nanoparticles, such as iron carbide and cobalt ferrite, has expanded the range of ferrofluid properties and applications. Concurrently, progress in surface functionalization techniques has led to ferrofluids with enhanced biocompatibility and stability in various environments.

Recent years have witnessed the emergence of smart ferrofluids, capable of responding to multiple stimuli beyond magnetic fields. These advanced materials show promise in areas such as adaptive optics, microfluidics, and energy harvesting. The integration of ferrofluids with other emerging technologies, such as 3D printing and soft robotics, has opened new avenues for innovative engineering solutions.

Looking ahead, the evolution of ferrofluid technology is expected to continue its trajectory towards more sophisticated, multifunctional materials. Research trends indicate a growing interest in developing environmentally friendly ferrofluids and exploring their potential in sustainable energy applications. As our understanding of nanofluid dynamics deepens and fabrication techniques improve, ferrofluids are poised to play an increasingly important role in addressing complex engineering challenges across various sectors.

Market Demand Analysis

The market demand for ferrofluid dynamics in modern engineering applications has been steadily growing, driven by advancements in various industries and the unique properties of ferrofluids. These magnetic liquids, composed of nanoscale ferromagnetic particles suspended in a carrier fluid, offer a wide range of potential applications across multiple sectors.

In the medical field, ferrofluids are gaining traction for targeted drug delivery systems and magnetic hyperthermia treatments for cancer. The ability to precisely control and manipulate ferrofluids using external magnetic fields has opened up new possibilities for minimally invasive medical procedures. This has led to increased research and development investments from pharmaceutical companies and medical device manufacturers.

The automotive industry has shown significant interest in ferrofluid-based shock absorbers and damping systems. These applications promise improved vehicle stability, reduced vibration, and enhanced overall performance. Major automotive manufacturers are exploring the integration of ferrofluid technology into their next-generation vehicle designs, potentially creating a substantial market for ferrofluid-based components.

In the energy sector, ferrofluids are being investigated for their potential in improving the efficiency of renewable energy systems. Solar thermal power plants and wind turbines can benefit from ferrofluid-based heat transfer and cooling systems, leading to increased energy output and reduced maintenance costs. As the global push for sustainable energy solutions continues, the demand for ferrofluid applications in this sector is expected to grow significantly.

The electronics industry has also recognized the potential of ferrofluids in thermal management solutions for high-performance computing systems and data centers. With the increasing power density of electronic devices, efficient cooling mechanisms are crucial, and ferrofluid-based systems offer promising solutions. This has created a niche market with high growth potential as the demand for more powerful and compact electronic devices continues to rise.

Aerospace and defense sectors are exploring ferrofluid applications in advanced guidance systems, vibration damping, and radar-absorbing materials. The unique properties of ferrofluids make them suitable for use in extreme environments, opening up new possibilities for space exploration and military technologies.

While the market for ferrofluid dynamics is still relatively nascent, industry analysts project substantial growth in the coming years. The versatility of ferrofluids across multiple industries, coupled with ongoing research and development efforts, suggests a promising future for this technology. However, challenges such as scalability, long-term stability, and cost-effectiveness need to be addressed to fully realize the market potential of ferrofluid-based applications.

Current Challenges

Ferrofluid dynamics in modern engineering applications face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions tend to degrade over time due to particle agglomeration and sedimentation, which can lead to a loss of magnetic responsiveness and altered fluid properties. This instability poses a major hurdle for applications requiring prolonged operational lifetimes, such as in mechanical seals or biomedical devices.

Another critical challenge lies in the precise control of ferrofluid behavior under complex magnetic fields and flow conditions. While the basic principles of ferrohydrodynamics are well understood, predicting and manipulating ferrofluid responses in intricate geometries or under dynamic field conditions remains difficult. This limitation impacts the development of advanced microfluidic devices and adaptive optical systems that rely on precise ferrofluid manipulation.

The thermal management of ferrofluids presents yet another significant challenge. As these fluids are often used in heat transfer applications, their performance under extreme temperature conditions is crucial. However, the magnetic properties of ferrofluids can be significantly affected by temperature changes, leading to reduced efficiency and potential system failures. Developing ferrofluids with enhanced thermal stability and consistent magnetic properties across a wide temperature range is an ongoing area of research.

Biocompatibility remains a major hurdle for ferrofluid applications in the medical field. While ferrofluids show great promise for targeted drug delivery and hyperthermia treatment, ensuring their long-term safety and compatibility with biological systems is challenging. The potential toxicity of nanoparticles and the body's immune response to these foreign materials are concerns that require extensive research and rigorous testing protocols.

Scaling up ferrofluid production for industrial applications also presents significant challenges. Current synthesis methods often result in inconsistent particle size distributions and magnetic properties, which can lead to unpredictable behavior in large-scale systems. Developing cost-effective and reliable manufacturing processes that can produce high-quality ferrofluids in large quantities is essential for their widespread industrial adoption.

Lastly, the environmental impact of ferrofluids is an emerging concern. As these materials find increasing use in various applications, questions arise about their long-term effects on ecosystems and potential for environmental contamination. Developing environmentally friendly ferrofluids and establishing proper disposal and recycling methods are becoming critical challenges that need to be addressed to ensure sustainable use of this technology.

Existing Solutions

01 Ferrofluid sealing and lubrication systems

Ferrofluids are used in sealing and lubrication systems to improve performance and efficiency. These systems utilize the unique properties of ferrofluids to create dynamic seals and reduce friction in various mechanical applications, such as bearings and rotary shafts.- Ferrofluid sealing and lubrication systems: Ferrofluids are used in sealing and lubrication systems to improve performance and reduce friction. These systems utilize the unique properties of ferrofluids to create dynamic seals and provide efficient lubrication in various mechanical applications, such as bearings and rotary shafts.

- Ferrofluid-based damping and vibration control: Ferrofluids are employed in damping systems and vibration control mechanisms. The magnetic properties of ferrofluids allow for adaptive damping and precise control of vibrations in various applications, including automotive suspensions and structural engineering.

- Ferrofluid heat transfer and cooling systems: Ferrofluids are utilized in heat transfer and cooling systems due to their unique thermal properties. These systems leverage the magnetic control of ferrofluids to enhance heat dissipation and improve thermal management in electronic devices and industrial equipment.

- Ferrofluid-based sensors and actuators: Ferrofluids are incorporated into sensors and actuators to enhance their performance and functionality. These devices utilize the magnetic responsiveness of ferrofluids to detect changes in magnetic fields, measure acceleration, or provide precise actuation in various applications.

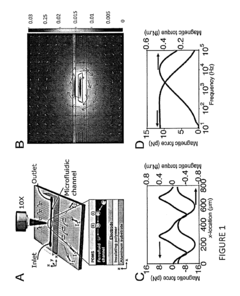

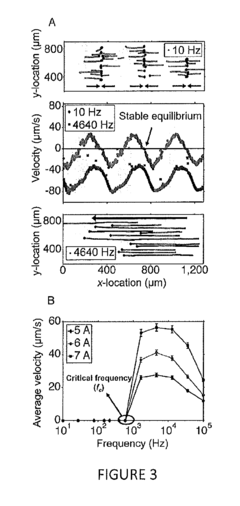

- Ferrofluid manipulation and control techniques: Various techniques are developed to manipulate and control ferrofluids for different applications. These methods involve the use of magnetic fields, electromagnetic forces, and specialized equipment to shape, move, and precisely control ferrofluid behavior in diverse fields such as microfluidics and material science.

02 Ferrofluid-based damping and vibration control

Ferrofluids are employed in damping systems to control vibrations and absorb shocks. The magnetic properties of ferrofluids allow for adaptive damping characteristics, making them suitable for use in various applications, including vehicle suspensions and structural vibration control.Expand Specific Solutions03 Ferrofluid heat transfer and cooling systems

Ferrofluids are utilized in heat transfer and cooling systems due to their ability to be controlled by magnetic fields. These systems can enhance heat dissipation in electronic devices and other applications where efficient thermal management is crucial.Expand Specific Solutions04 Ferrofluid-based sensors and actuators

Ferrofluids are employed in the development of sensors and actuators that leverage their magnetic properties. These devices can be used for various applications, including position sensing, force measurement, and precise fluid control in microfluidic systems.Expand Specific Solutions05 Ferrofluid separation and filtration techniques

Ferrofluids are used in separation and filtration processes, taking advantage of their magnetic properties to selectively remove particles or separate materials. These techniques can be applied in various fields, including environmental remediation and biomedical applications.Expand Specific Solutions

Key Industry Players

The ferrofluid dynamics field in modern engineering applications is in a growth phase, with increasing market size and technological advancements. The global market for ferrofluids is expanding, driven by diverse applications in electronics, medical devices, and mechanical engineering. While the technology is maturing, there is still significant room for innovation. Key players like Ferrotec, Chongqing University, and ANSYS are advancing research and development in this area. Academic institutions such as Yale University and Delft University of Technology are contributing to fundamental research, while companies like Robert Bosch GmbH and Siemens Industry Software are exploring practical applications. The competitive landscape is characterized by a mix of specialized ferrofluid companies, large industrial conglomerates, and research-focused academic institutions, indicating a dynamic and evolving field.

Ferrotec (USA) Corp.

Honeywell International Technologies Ltd.

Core Innovations

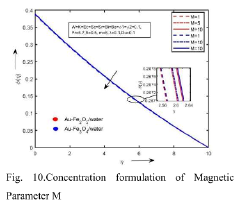

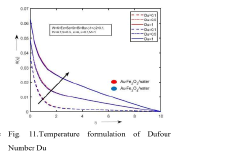

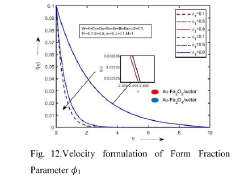

- A comparative study of Au-Fe2O3 and Au-CoFe4 hybrid ferrofluids is conducted using numerical simulations and experimental investigations to assess their heat transfer performance, flow dynamics, and temperature distribution over a permeable plate with convective boundaries, leveraging parameters like Nusselt number, Sherwood number, and skin friction coefficient.

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Environmental Impact

The environmental impact of ferrofluid dynamics in modern engineering applications is a critical consideration as these innovative materials find increasing use across various industries. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that enable novel solutions in fields such as electronics cooling, mechanical sealing, and biomedical applications. However, their widespread adoption necessitates a thorough examination of potential environmental consequences.

One primary environmental concern is the potential release of nanoparticles into ecosystems. The magnetic nanoparticles in ferrofluids, typically iron oxides, may pose risks if they enter water systems or soil. While these particles are generally considered to have low toxicity, their long-term effects on aquatic and terrestrial organisms remain under investigation. Studies have shown that some nanoparticles can accumulate in living tissues, potentially disrupting biological processes or entering food chains.

The production of ferrofluids also raises environmental questions. The synthesis of magnetic nanoparticles often involves chemical processes that may generate hazardous waste or consume significant energy. As demand for ferrofluids grows, scaling up production could lead to increased industrial emissions and resource consumption. However, advancements in green chemistry and sustainable manufacturing practices offer promising avenues for mitigating these impacts.

On the positive side, ferrofluid applications can contribute to environmental protection in several ways. In the field of renewable energy, ferrofluids enhance the efficiency of wind turbine seals and improve heat dissipation in solar panels, supporting the transition to cleaner energy sources. In wastewater treatment, magnetically functionalized ferrofluids show potential for removing pollutants and heavy metals from water, offering a more efficient and less chemically intensive purification method.

The recyclability and reusability of ferrofluids present both challenges and opportunities. While the magnetic properties of these fluids facilitate their recovery in many applications, separating nanoparticles from carrier fluids for recycling can be energy-intensive. Developing efficient recycling processes is crucial to minimize waste and reduce the need for new raw materials.

As ferrofluid technology advances, ongoing research focuses on creating more environmentally friendly formulations. Bio-based carrier fluids and naturally derived surfactants are being explored to replace synthetic components, potentially reducing the environmental footprint of ferrofluid production and disposal. Additionally, efforts to enhance the stability and longevity of ferrofluids aim to extend their useful life, thereby decreasing replacement frequency and associated waste.

Safety Regulations

Safety regulations play a crucial role in the development and application of ferrofluid technology in modern engineering. As the use of ferrofluids expands across various industries, it is essential to establish and adhere to comprehensive safety guidelines to protect workers, consumers, and the environment.

Ferrofluids, being a unique combination of magnetic nanoparticles suspended in a carrier fluid, present specific safety concerns that must be addressed. One primary consideration is the potential health risks associated with exposure to nanoparticles. Inhalation or skin contact with these particles may lead to adverse health effects, necessitating strict handling protocols and personal protective equipment requirements for workers in manufacturing and research settings.

Environmental safety is another critical aspect of ferrofluid regulations. Proper disposal and containment methods must be implemented to prevent the release of ferrofluids into ecosystems, where they could potentially impact wildlife and water sources. This includes guidelines for storage, transportation, and waste management of ferrofluid-containing products and materials.

Electromagnetic compatibility is a key safety concern in ferrofluid applications, particularly in electronic and medical devices. Regulations must ensure that ferrofluid-based components do not interfere with other electronic systems or pose risks to patients with implanted medical devices. This requires thorough testing and certification processes for products incorporating ferrofluid technology.

In the automotive and aerospace industries, where ferrofluids are increasingly used in damping systems and seals, safety regulations focus on reliability and performance under extreme conditions. Standards must be established to guarantee the stability and effectiveness of ferrofluid-based components throughout the operational life of vehicles and aircraft, ensuring passenger safety.

As ferrofluids find applications in biomedical fields, such as targeted drug delivery and magnetic hyperthermia, stringent safety protocols are essential. Regulations must address biocompatibility, toxicity, and long-term effects of ferrofluids in the human body. Clinical trials and extensive testing are required to validate the safety of these medical applications before approval for human use.

The development of international safety standards for ferrofluid technology is an ongoing process, involving collaboration between regulatory bodies, industry experts, and research institutions. These standards must evolve alongside technological advancements to address new applications and potential risks as they emerge. Regular review and updating of safety regulations ensure that they remain relevant and effective in protecting all stakeholders involved in the production, use, and disposal of ferrofluid-based products and systems.