Ferrofluid's Role in Enabling High-Stakes Research Initiatives

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids have undergone a remarkable evolution since their inception in the 1960s, driven by continuous research and technological advancements. Initially developed by NASA for fuel control in zero-gravity environments, these magnetic liquids have found their way into various high-stakes research initiatives across multiple disciplines.

The early stages of ferrofluid development focused primarily on understanding their unique properties and basic applications. Scientists explored the fundamental physics behind the behavior of magnetic nanoparticles suspended in carrier fluids, leading to improved stability and magnetic responsiveness. This foundational research paved the way for more sophisticated applications in subsequent decades.

In the 1980s and 1990s, ferrofluid technology saw significant advancements in synthesis methods and particle engineering. Researchers developed techniques to produce more uniform and stable nanoparticles, enhancing the overall performance and reliability of ferrofluids. This period also marked the beginning of ferrofluids' integration into industrial applications, such as seals for computer hard drives and damping systems in high-end audio speakers.

The turn of the millennium brought about a new era for ferrofluid technology, characterized by interdisciplinary collaborations and novel applications in cutting-edge research fields. Biomedical researchers began exploring ferrofluids for targeted drug delivery and magnetic hyperthermia in cancer treatment. Meanwhile, materials scientists investigated their potential in smart materials and adaptive structures.

Recent years have witnessed an explosion of interest in ferrofluids for high-stakes research initiatives. In the field of microfluidics, ferrofluids have enabled precise control of fluid flow at the microscale, opening new possibilities for lab-on-a-chip devices and advanced diagnostic tools. Environmental scientists have leveraged ferrofluids for oil spill cleanup and water purification, showcasing their potential in addressing critical global challenges.

The evolution of ferrofluid technology has also been marked by advancements in computational modeling and simulation. These tools have allowed researchers to predict and optimize ferrofluid behavior in complex systems, accelerating the development of novel applications and improving existing ones. This synergy between experimental and computational approaches has been crucial in pushing the boundaries of ferrofluid capabilities.

Looking ahead, the trajectory of ferrofluid technology points towards even more sophisticated and transformative applications. Researchers are exploring their potential in next-generation energy systems, such as magnetocaloric refrigeration and enhanced heat transfer in nuclear reactors. The integration of ferrofluids with nanotechnology and smart materials promises to revolutionize fields like robotics, aerospace engineering, and advanced manufacturing.

The early stages of ferrofluid development focused primarily on understanding their unique properties and basic applications. Scientists explored the fundamental physics behind the behavior of magnetic nanoparticles suspended in carrier fluids, leading to improved stability and magnetic responsiveness. This foundational research paved the way for more sophisticated applications in subsequent decades.

In the 1980s and 1990s, ferrofluid technology saw significant advancements in synthesis methods and particle engineering. Researchers developed techniques to produce more uniform and stable nanoparticles, enhancing the overall performance and reliability of ferrofluids. This period also marked the beginning of ferrofluids' integration into industrial applications, such as seals for computer hard drives and damping systems in high-end audio speakers.

The turn of the millennium brought about a new era for ferrofluid technology, characterized by interdisciplinary collaborations and novel applications in cutting-edge research fields. Biomedical researchers began exploring ferrofluids for targeted drug delivery and magnetic hyperthermia in cancer treatment. Meanwhile, materials scientists investigated their potential in smart materials and adaptive structures.

Recent years have witnessed an explosion of interest in ferrofluids for high-stakes research initiatives. In the field of microfluidics, ferrofluids have enabled precise control of fluid flow at the microscale, opening new possibilities for lab-on-a-chip devices and advanced diagnostic tools. Environmental scientists have leveraged ferrofluids for oil spill cleanup and water purification, showcasing their potential in addressing critical global challenges.

The evolution of ferrofluid technology has also been marked by advancements in computational modeling and simulation. These tools have allowed researchers to predict and optimize ferrofluid behavior in complex systems, accelerating the development of novel applications and improving existing ones. This synergy between experimental and computational approaches has been crucial in pushing the boundaries of ferrofluid capabilities.

Looking ahead, the trajectory of ferrofluid technology points towards even more sophisticated and transformative applications. Researchers are exploring their potential in next-generation energy systems, such as magnetocaloric refrigeration and enhanced heat transfer in nuclear reactors. The integration of ferrofluids with nanotechnology and smart materials promises to revolutionize fields like robotics, aerospace engineering, and advanced manufacturing.

High-Stakes Research Demand

Ferrofluids have emerged as a critical component in enabling high-stakes research initiatives across various scientific disciplines. The demand for these unique magnetic liquids has grown significantly in recent years, driven by their exceptional properties and versatile applications in cutting-edge research fields.

In the realm of space exploration, ferrofluids play a crucial role in developing advanced propulsion systems and spacecraft components. NASA and other space agencies have invested heavily in ferrofluid research to improve the efficiency of satellite attitude control systems and develop novel microgravity experiments. The ability of ferrofluids to respond to magnetic fields in zero-gravity environments makes them invaluable for space-based research initiatives.

The medical field has also witnessed a surge in ferrofluid applications, particularly in targeted drug delivery and cancer treatment research. Leading pharmaceutical companies and research institutions are exploring the use of ferrofluids as carriers for precision medicine, aiming to revolutionize the treatment of complex diseases. The demand for ferrofluids in this sector is driven by their potential to enhance the efficacy of treatments while minimizing side effects.

In the realm of advanced materials research, ferrofluids are being investigated for their potential in developing smart materials and adaptive structures. Major aerospace and defense contractors are investing in ferrofluid-based technologies to create self-healing materials and dynamic camouflage systems. This research has significant implications for next-generation military equipment and infrastructure resilience.

The energy sector has also recognized the potential of ferrofluids in high-stakes research initiatives. Renewable energy companies and national laboratories are exploring ferrofluid applications in improving the efficiency of solar thermal power plants and developing novel energy harvesting technologies. The unique thermal and magnetic properties of ferrofluids make them attractive for addressing critical challenges in sustainable energy production.

Nanotechnology research has further fueled the demand for ferrofluids, as they serve as an ideal platform for studying nanoscale phenomena and developing new nanodevices. Leading technology companies and academic institutions are leveraging ferrofluids to advance research in quantum computing, spintronics, and nanofluidics. The ability to manipulate ferrofluids at the nanoscale opens up new possibilities for breakthrough discoveries in these fields.

As high-stakes research initiatives continue to push the boundaries of science and technology, the demand for ferrofluids is expected to grow exponentially. Their unique properties and wide-ranging applications make them indispensable in addressing complex challenges across multiple disciplines, from space exploration to advanced medicine and beyond.

In the realm of space exploration, ferrofluids play a crucial role in developing advanced propulsion systems and spacecraft components. NASA and other space agencies have invested heavily in ferrofluid research to improve the efficiency of satellite attitude control systems and develop novel microgravity experiments. The ability of ferrofluids to respond to magnetic fields in zero-gravity environments makes them invaluable for space-based research initiatives.

The medical field has also witnessed a surge in ferrofluid applications, particularly in targeted drug delivery and cancer treatment research. Leading pharmaceutical companies and research institutions are exploring the use of ferrofluids as carriers for precision medicine, aiming to revolutionize the treatment of complex diseases. The demand for ferrofluids in this sector is driven by their potential to enhance the efficacy of treatments while minimizing side effects.

In the realm of advanced materials research, ferrofluids are being investigated for their potential in developing smart materials and adaptive structures. Major aerospace and defense contractors are investing in ferrofluid-based technologies to create self-healing materials and dynamic camouflage systems. This research has significant implications for next-generation military equipment and infrastructure resilience.

The energy sector has also recognized the potential of ferrofluids in high-stakes research initiatives. Renewable energy companies and national laboratories are exploring ferrofluid applications in improving the efficiency of solar thermal power plants and developing novel energy harvesting technologies. The unique thermal and magnetic properties of ferrofluids make them attractive for addressing critical challenges in sustainable energy production.

Nanotechnology research has further fueled the demand for ferrofluids, as they serve as an ideal platform for studying nanoscale phenomena and developing new nanodevices. Leading technology companies and academic institutions are leveraging ferrofluids to advance research in quantum computing, spintronics, and nanofluidics. The ability to manipulate ferrofluids at the nanoscale opens up new possibilities for breakthrough discoveries in these fields.

As high-stakes research initiatives continue to push the boundaries of science and technology, the demand for ferrofluids is expected to grow exponentially. Their unique properties and wide-ranging applications make them indispensable in addressing complex challenges across multiple disciplines, from space exploration to advanced medicine and beyond.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in high-stakes research initiatives, several significant challenges hinder their widespread adoption and application. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions tend to aggregate over time, leading to a loss of their unique magnetic properties. This instability poses a significant hurdle in applications requiring prolonged use or storage, such as in space exploration or long-term medical implants.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for specific research applications remains difficult. This limitation impacts the accuracy and reliability of experiments and devices utilizing ferrofluids, particularly in sensitive research areas like microfluidics or targeted drug delivery.

The biocompatibility of ferrofluids presents a substantial challenge in medical and biological research applications. Although progress has been made in developing biocompatible ferrofluids, concerns persist regarding their long-term effects on living tissues and potential toxicity. This issue is particularly crucial for in vivo applications, where the safety and biocompatibility of ferrofluids must be rigorously established before they can be widely adopted in clinical settings.

Scalability and cost-effectiveness pose additional challenges in the broader implementation of ferrofluid technology. The production of high-quality, stable ferrofluids often involves complex processes and expensive materials, limiting their accessibility for large-scale or budget-constrained research initiatives. This economic barrier restricts the potential for widespread adoption and experimentation across various scientific disciplines.

Environmental concerns also present a significant challenge. The potential ecological impact of ferrofluids, particularly in the event of accidental release or disposal, remains a topic of ongoing research and debate. Addressing these environmental considerations is crucial for the responsible development and application of ferrofluid technology in high-stakes research scenarios.

Lastly, the interdisciplinary nature of ferrofluid research poses a challenge in terms of knowledge integration and collaboration. Effective utilization of ferrofluids in advanced research initiatives requires expertise from diverse fields such as physics, chemistry, materials science, and engineering. Bridging these disciplinary gaps and fostering effective collaboration remains a significant hurdle in fully leveraging the potential of ferrofluids in cutting-edge research applications.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control for specific research applications remains difficult. This limitation impacts the accuracy and reliability of experiments and devices utilizing ferrofluids, particularly in sensitive research areas like microfluidics or targeted drug delivery.

The biocompatibility of ferrofluids presents a substantial challenge in medical and biological research applications. Although progress has been made in developing biocompatible ferrofluids, concerns persist regarding their long-term effects on living tissues and potential toxicity. This issue is particularly crucial for in vivo applications, where the safety and biocompatibility of ferrofluids must be rigorously established before they can be widely adopted in clinical settings.

Scalability and cost-effectiveness pose additional challenges in the broader implementation of ferrofluid technology. The production of high-quality, stable ferrofluids often involves complex processes and expensive materials, limiting their accessibility for large-scale or budget-constrained research initiatives. This economic barrier restricts the potential for widespread adoption and experimentation across various scientific disciplines.

Environmental concerns also present a significant challenge. The potential ecological impact of ferrofluids, particularly in the event of accidental release or disposal, remains a topic of ongoing research and debate. Addressing these environmental considerations is crucial for the responsible development and application of ferrofluid technology in high-stakes research scenarios.

Lastly, the interdisciplinary nature of ferrofluid research poses a challenge in terms of knowledge integration and collaboration. Effective utilization of ferrofluids in advanced research initiatives requires expertise from diverse fields such as physics, chemistry, materials science, and engineering. Bridging these disciplinary gaps and fostering effective collaboration remains a significant hurdle in fully leveraging the potential of ferrofluids in cutting-edge research applications.

Current Ferrofluid Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly for electronic devices. They can be used in cooling systems where their magnetic properties allow for enhanced heat transfer and precise control of fluid flow, improving overall cooling efficiency.

- Magnetic field sensing and measurement: Ferrofluids are utilized in various sensing and measurement applications involving magnetic fields. Their unique response to magnetic fields allows for the development of sensitive instruments for detecting and measuring magnetic field strength and direction.

- Dynamic control and actuation systems: Ferrofluids are employed in dynamic control and actuation systems where their properties can be manipulated by external magnetic fields. This allows for the development of adaptive damping systems, variable stiffness mechanisms, and other smart fluid applications in various industries.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. They provide low-friction, zero-leakage seals that can operate under high pressure differentials and in vacuum environments. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining liquid properties.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, speakers, and transformers. When subjected to a magnetic field, the fluid's thermal conductivity can be controlled, allowing for adaptive thermal management in various applications.Expand Specific Solutions04 Damping and vibration control

The unique properties of ferrofluids make them excellent for damping and vibration control applications. They can be used in shock absorbers, inertial dampers, and acoustic devices. The fluid's viscosity can be dynamically altered by applying magnetic fields, allowing for adaptive damping in response to varying conditions.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are employed in various sensing and measurement devices. They are used in accelerometers, inclinometers, and pressure sensors. The fluid's response to magnetic fields and gravity allows for precise measurements of position, orientation, and force. These applications often involve innovative designs that leverage the fluid's unique behavior under different conditions.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid technology landscape is in a growth phase, with increasing applications across high-stakes research initiatives. The market size is expanding as more industries recognize the potential of ferrofluids in advanced applications. While the technology is maturing, there's still significant room for innovation and development. Key players like Yale University, TDK Corp., and Ferrotec (USA) Corp. are driving advancements in ferrofluid research and applications. Academic institutions such as École Polytechnique Fédérale de Lausanne and Arizona State University are contributing to fundamental research, while companies like Proterial Ltd. and LORD Corp. are focusing on industrial applications. The competitive landscape is diverse, with a mix of established corporations, research institutions, and specialized firms collaborating and competing to unlock ferrofluid's full potential in high-stakes research initiatives.

Yale University

Technical Solution: Yale University has been at the forefront of ferrofluid research, developing novel applications in high-stakes initiatives. Their approach involves using ferrofluids for advanced magnetic drug targeting systems, which allow for precise control and delivery of therapeutic agents in the body[1]. The university has also explored ferrofluid-based microfluidic devices for lab-on-a-chip applications, enabling miniaturized and highly efficient analytical processes[2]. Additionally, Yale researchers have investigated the use of ferrofluids in energy harvesting systems, particularly in converting low-grade waste heat into electricity through thermomagnetic cycles[3].

Strengths: Strong interdisciplinary research capabilities, access to advanced laboratory facilities, and collaborations with medical institutions. Weaknesses: Potential challenges in scaling up laboratory discoveries for industrial applications.

TDK Corp.

Technical Solution: TDK Corporation has leveraged its expertise in magnetic materials to develop cutting-edge ferrofluid technologies for various high-stakes applications. The company has focused on creating advanced ferrofluid-based sealing systems for critical industrial equipment, particularly in semiconductor manufacturing and aerospace industries[1]. TDK has also pioneered the use of ferrofluids in next-generation cooling systems for high-performance electronics, utilizing the unique thermal and magnetic properties of ferrofluids to enhance heat dissipation in compact devices[2]. Furthermore, the company has explored ferrofluid applications in precision sensors and actuators, enabling highly responsive and accurate control systems in robotics and automation[3].

Strengths: Extensive experience in magnetic materials, strong manufacturing capabilities, and global market presence. Weaknesses: Potential limitations in adapting to rapidly evolving research fields outside their core expertise.

Ferrofluid Innovations

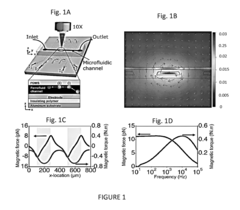

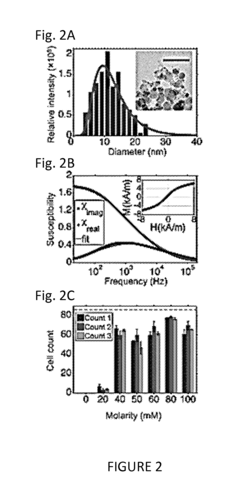

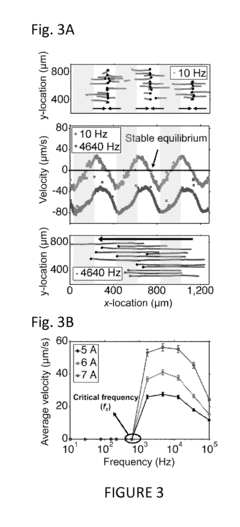

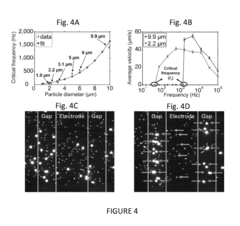

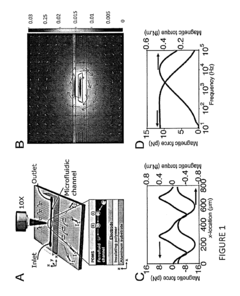

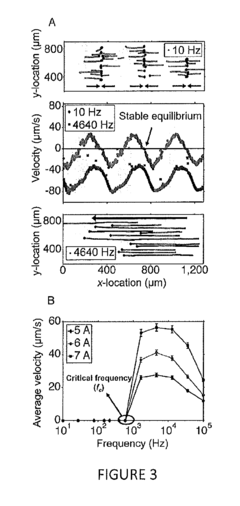

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Ferrofluid Safety Protocols

Ferrofluid safety protocols are paramount in high-stakes research initiatives due to the unique properties and potential hazards associated with these magnetic nanofluids. Proper handling and containment of ferrofluids are essential to ensure the safety of researchers and the integrity of experiments.

Firstly, personal protective equipment (PPE) is crucial when working with ferrofluids. Researchers must wear appropriate gloves, lab coats, and safety goggles to prevent skin contact and eye exposure. Ferrofluids can cause skin irritation and staining, and their nanoparticles may pose inhalation risks if aerosolized.

Containment measures are vital to prevent spills and environmental contamination. Ferrofluids should be stored in sealed, non-magnetic containers to maintain their stability and prevent leakage. Work areas must be equipped with spill kits and absorbent materials specifically designed for magnetic fluids.

Proper disposal protocols are essential to mitigate environmental risks. Ferrofluids should never be disposed of in regular waste streams or sinks. Instead, they must be collected in designated containers and disposed of as hazardous waste according to local regulations and institutional guidelines.

Electromagnetic field management is another critical aspect of ferrofluid safety. Strong magnetic fields can cause unexpected behavior in ferrofluids, potentially leading to spills or equipment damage. Research facilities must implement strict controls on magnetic field exposure and ensure proper shielding of sensitive equipment.

Training and education play a crucial role in maintaining safety standards. All personnel working with ferrofluids must undergo comprehensive safety training, covering handling procedures, emergency response, and the specific risks associated with these materials. Regular refresher courses and safety audits should be conducted to ensure ongoing compliance.

Emergency response plans must be in place to address potential accidents or exposures. These plans should include procedures for containing spills, decontamination protocols, and guidelines for seeking medical attention in case of exposure. Clear signage and easily accessible safety information should be prominently displayed in all areas where ferrofluids are used or stored.

Lastly, ongoing risk assessment and protocol updates are necessary to address emerging safety concerns. As research applications for ferrofluids expand, safety protocols must evolve to encompass new potential hazards and best practices. Regular review and revision of safety guidelines, in collaboration with safety experts and regulatory bodies, ensure that high-stakes research initiatives maintain the highest standards of safety and responsibility in ferrofluid handling and use.

Firstly, personal protective equipment (PPE) is crucial when working with ferrofluids. Researchers must wear appropriate gloves, lab coats, and safety goggles to prevent skin contact and eye exposure. Ferrofluids can cause skin irritation and staining, and their nanoparticles may pose inhalation risks if aerosolized.

Containment measures are vital to prevent spills and environmental contamination. Ferrofluids should be stored in sealed, non-magnetic containers to maintain their stability and prevent leakage. Work areas must be equipped with spill kits and absorbent materials specifically designed for magnetic fluids.

Proper disposal protocols are essential to mitigate environmental risks. Ferrofluids should never be disposed of in regular waste streams or sinks. Instead, they must be collected in designated containers and disposed of as hazardous waste according to local regulations and institutional guidelines.

Electromagnetic field management is another critical aspect of ferrofluid safety. Strong magnetic fields can cause unexpected behavior in ferrofluids, potentially leading to spills or equipment damage. Research facilities must implement strict controls on magnetic field exposure and ensure proper shielding of sensitive equipment.

Training and education play a crucial role in maintaining safety standards. All personnel working with ferrofluids must undergo comprehensive safety training, covering handling procedures, emergency response, and the specific risks associated with these materials. Regular refresher courses and safety audits should be conducted to ensure ongoing compliance.

Emergency response plans must be in place to address potential accidents or exposures. These plans should include procedures for containing spills, decontamination protocols, and guidelines for seeking medical attention in case of exposure. Clear signage and easily accessible safety information should be prominently displayed in all areas where ferrofluids are used or stored.

Lastly, ongoing risk assessment and protocol updates are necessary to address emerging safety concerns. As research applications for ferrofluids expand, safety protocols must evolve to encompass new potential hazards and best practices. Regular review and revision of safety guidelines, in collaboration with safety experts and regulatory bodies, ensure that high-stakes research initiatives maintain the highest standards of safety and responsibility in ferrofluid handling and use.

Ferrofluid Sustainability

Ferrofluid sustainability is a critical aspect of its long-term viability in high-stakes research initiatives. As these magnetic nanofluids gain prominence in various scientific and industrial applications, ensuring their sustainable production, use, and disposal becomes paramount. The sustainability of ferrofluids encompasses several key dimensions that warrant careful consideration.

The production of ferrofluids involves the synthesis of magnetic nanoparticles, typically iron oxides, suspended in a carrier fluid. Sustainable manufacturing processes aim to minimize energy consumption and reduce the use of harmful chemicals. Advanced green chemistry techniques are being explored to develop eco-friendly synthesis methods that maintain the quality and performance of ferrofluids while reducing environmental impact.

Resource efficiency is another crucial factor in ferrofluid sustainability. The rare earth elements often used in ferrofluid production are finite resources, necessitating the development of recycling and recovery processes. Researchers are investigating methods to reclaim magnetic nanoparticles from used ferrofluids, potentially creating a closed-loop system that significantly reduces the demand for raw materials.

The environmental impact of ferrofluids throughout their lifecycle is a growing concern. Studies are being conducted to assess the potential risks associated with the release of nanoparticles into ecosystems. Developing biodegradable carrier fluids and environmentally benign nanoparticle coatings could mitigate these risks and enhance the overall sustainability of ferrofluid applications.

In high-stakes research initiatives, the longevity and stability of ferrofluids are critical for maintaining experimental integrity and reducing waste. Efforts are underway to improve the chemical stability of ferrofluids, extending their useful life and minimizing the frequency of replacement. This not only reduces the environmental footprint but also enhances the economic viability of ferrofluid-based technologies.

The energy efficiency of ferrofluid-enabled systems is another aspect of sustainability. Researchers are exploring ways to optimize the magnetic and thermal properties of ferrofluids to maximize their performance in applications such as heat transfer and energy harvesting. By improving efficiency, these advancements could lead to reduced energy consumption in various industrial processes.

As ferrofluids find new applications in cutting-edge research, their sustainability profile becomes increasingly important. Developing standardized protocols for the safe handling, storage, and disposal of ferrofluids is essential for minimizing environmental risks and ensuring regulatory compliance. This includes creating guidelines for the proper decontamination of equipment and facilities used in ferrofluid research.

The production of ferrofluids involves the synthesis of magnetic nanoparticles, typically iron oxides, suspended in a carrier fluid. Sustainable manufacturing processes aim to minimize energy consumption and reduce the use of harmful chemicals. Advanced green chemistry techniques are being explored to develop eco-friendly synthesis methods that maintain the quality and performance of ferrofluids while reducing environmental impact.

Resource efficiency is another crucial factor in ferrofluid sustainability. The rare earth elements often used in ferrofluid production are finite resources, necessitating the development of recycling and recovery processes. Researchers are investigating methods to reclaim magnetic nanoparticles from used ferrofluids, potentially creating a closed-loop system that significantly reduces the demand for raw materials.

The environmental impact of ferrofluids throughout their lifecycle is a growing concern. Studies are being conducted to assess the potential risks associated with the release of nanoparticles into ecosystems. Developing biodegradable carrier fluids and environmentally benign nanoparticle coatings could mitigate these risks and enhance the overall sustainability of ferrofluid applications.

In high-stakes research initiatives, the longevity and stability of ferrofluids are critical for maintaining experimental integrity and reducing waste. Efforts are underway to improve the chemical stability of ferrofluids, extending their useful life and minimizing the frequency of replacement. This not only reduces the environmental footprint but also enhances the economic viability of ferrofluid-based technologies.

The energy efficiency of ferrofluid-enabled systems is another aspect of sustainability. Researchers are exploring ways to optimize the magnetic and thermal properties of ferrofluids to maximize their performance in applications such as heat transfer and energy harvesting. By improving efficiency, these advancements could lead to reduced energy consumption in various industrial processes.

As ferrofluids find new applications in cutting-edge research, their sustainability profile becomes increasingly important. Developing standardized protocols for the safe handling, storage, and disposal of ferrofluids is essential for minimizing environmental risks and ensuring regulatory compliance. This includes creating guidelines for the proper decontamination of equipment and facilities used in ferrofluid research.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!