How to Harness Ferrofluid for Evolutionary Structural Designs?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluid technology has undergone significant evolution since its inception in the 1960s. Initially developed by NASA for rocket fuel control in zero gravity, ferrofluids have since found applications across various industries. The technology's progression has been marked by advancements in material science, nanotechnology, and magnetic field manipulation.

The primary objective in harnessing ferrofluid for evolutionary structural designs is to leverage its unique properties to create adaptive, responsive, and efficient structures. This goal encompasses the development of smart materials that can change shape, strength, or other physical properties in response to external stimuli, particularly magnetic fields.

One key area of focus is the improvement of ferrofluid stability and longevity. Early ferrofluids suffered from particle agglomeration and oxidation, limiting their practical applications. Recent research has aimed at developing more stable ferrofluids with enhanced magnetic properties and reduced susceptibility to environmental factors.

Another significant objective is the integration of ferrofluids into composite materials. This approach seeks to combine the dynamic properties of ferrofluids with the structural integrity of traditional materials, opening up new possibilities for adaptive structures in aerospace, civil engineering, and robotics.

The miniaturization of ferrofluid-based systems is also a crucial goal. As nanotechnology advances, researchers are exploring ways to create micro- and nano-scale ferrofluid devices for applications in microfluidics, targeted drug delivery, and miniature actuators.

In the realm of energy harvesting, ferrofluids are being investigated for their potential in converting mechanical energy into electrical energy. This objective aligns with the growing demand for sustainable energy solutions and could lead to novel power generation methods in various environments.

The development of precise control mechanisms for ferrofluid behavior is another critical objective. This involves creating sophisticated algorithms and control systems that can manipulate ferrofluids with high accuracy, enabling more complex and responsive structural designs.

Lastly, there is a growing focus on exploring the self-assembly properties of ferrofluids. Researchers aim to harness these properties to create structures that can autonomously adapt to their environment or self-repair, potentially revolutionizing fields such as adaptive architecture and self-healing materials.

The primary objective in harnessing ferrofluid for evolutionary structural designs is to leverage its unique properties to create adaptive, responsive, and efficient structures. This goal encompasses the development of smart materials that can change shape, strength, or other physical properties in response to external stimuli, particularly magnetic fields.

One key area of focus is the improvement of ferrofluid stability and longevity. Early ferrofluids suffered from particle agglomeration and oxidation, limiting their practical applications. Recent research has aimed at developing more stable ferrofluids with enhanced magnetic properties and reduced susceptibility to environmental factors.

Another significant objective is the integration of ferrofluids into composite materials. This approach seeks to combine the dynamic properties of ferrofluids with the structural integrity of traditional materials, opening up new possibilities for adaptive structures in aerospace, civil engineering, and robotics.

The miniaturization of ferrofluid-based systems is also a crucial goal. As nanotechnology advances, researchers are exploring ways to create micro- and nano-scale ferrofluid devices for applications in microfluidics, targeted drug delivery, and miniature actuators.

In the realm of energy harvesting, ferrofluids are being investigated for their potential in converting mechanical energy into electrical energy. This objective aligns with the growing demand for sustainable energy solutions and could lead to novel power generation methods in various environments.

The development of precise control mechanisms for ferrofluid behavior is another critical objective. This involves creating sophisticated algorithms and control systems that can manipulate ferrofluids with high accuracy, enabling more complex and responsive structural designs.

Lastly, there is a growing focus on exploring the self-assembly properties of ferrofluids. Researchers aim to harness these properties to create structures that can autonomously adapt to their environment or self-repair, potentially revolutionizing fields such as adaptive architecture and self-healing materials.

Market Demand for Ferrofluid-Based Structures

The market demand for ferrofluid-based structures is experiencing significant growth, driven by the unique properties and versatile applications of ferrofluids in various industries. Ferrofluids, which are colloidal liquids containing magnetic nanoparticles, offer a combination of fluid dynamics and magnetic responsiveness that opens up new possibilities for innovative structural designs.

In the automotive sector, there is a growing interest in using ferrofluid-based structures for adaptive suspension systems and vibration damping. These applications can enhance vehicle performance and comfort, leading to increased demand from high-end car manufacturers and motorsport teams. The aerospace industry is also exploring ferrofluid-based structures for improved control surfaces and adaptive wing designs, potentially revolutionizing aircraft efficiency and maneuverability.

The construction industry has shown interest in ferrofluid-based structures for earthquake-resistant buildings and dynamic architecture. By incorporating ferrofluids into structural elements, engineers can create buildings that adapt to seismic activity or environmental conditions, enhancing safety and sustainability. This has led to increased research and development investments from major construction firms and government agencies responsible for infrastructure projects.

In the field of robotics and automation, ferrofluid-based structures are gaining traction for their potential in creating soft, adaptable robotic components. The ability to control the shape and properties of ferrofluids using magnetic fields enables the development of more versatile and responsive robotic systems. This has sparked interest from both industrial automation companies and research institutions focused on next-generation robotics.

The medical device industry is another sector driving demand for ferrofluid-based structures. Applications in targeted drug delivery systems, adaptive prosthetics, and minimally invasive surgical tools are being explored, with several promising prototypes in development. The potential for ferrofluids to create dynamic, controllable structures within the human body has attracted significant investment from pharmaceutical companies and medical technology firms.

Consumer electronics manufacturers are also exploring ferrofluid-based structures for haptic feedback systems and adaptive cooling solutions in smartphones and wearable devices. The unique visual properties of ferrofluids have led to their use in artistic and design applications, creating a niche market for ferrofluid-based decorative items and interactive displays.

As research continues to uncover new applications for ferrofluid-based structures, the market demand is expected to grow across multiple sectors. However, challenges such as long-term stability of ferrofluids, scalability of production, and integration with existing manufacturing processes need to be addressed to fully realize the market potential. Despite these challenges, the versatility and innovative potential of ferrofluid-based structures continue to drive investment and research in this emerging field.

In the automotive sector, there is a growing interest in using ferrofluid-based structures for adaptive suspension systems and vibration damping. These applications can enhance vehicle performance and comfort, leading to increased demand from high-end car manufacturers and motorsport teams. The aerospace industry is also exploring ferrofluid-based structures for improved control surfaces and adaptive wing designs, potentially revolutionizing aircraft efficiency and maneuverability.

The construction industry has shown interest in ferrofluid-based structures for earthquake-resistant buildings and dynamic architecture. By incorporating ferrofluids into structural elements, engineers can create buildings that adapt to seismic activity or environmental conditions, enhancing safety and sustainability. This has led to increased research and development investments from major construction firms and government agencies responsible for infrastructure projects.

In the field of robotics and automation, ferrofluid-based structures are gaining traction for their potential in creating soft, adaptable robotic components. The ability to control the shape and properties of ferrofluids using magnetic fields enables the development of more versatile and responsive robotic systems. This has sparked interest from both industrial automation companies and research institutions focused on next-generation robotics.

The medical device industry is another sector driving demand for ferrofluid-based structures. Applications in targeted drug delivery systems, adaptive prosthetics, and minimally invasive surgical tools are being explored, with several promising prototypes in development. The potential for ferrofluids to create dynamic, controllable structures within the human body has attracted significant investment from pharmaceutical companies and medical technology firms.

Consumer electronics manufacturers are also exploring ferrofluid-based structures for haptic feedback systems and adaptive cooling solutions in smartphones and wearable devices. The unique visual properties of ferrofluids have led to their use in artistic and design applications, creating a niche market for ferrofluid-based decorative items and interactive displays.

As research continues to uncover new applications for ferrofluid-based structures, the market demand is expected to grow across multiple sectors. However, challenges such as long-term stability of ferrofluids, scalability of production, and integration with existing manufacturing processes need to be addressed to fully realize the market potential. Despite these challenges, the versatility and innovative potential of ferrofluid-based structures continue to drive investment and research in this emerging field.

Current Challenges in Ferrofluid Structural Applications

Despite the promising potential of ferrofluids in structural applications, several significant challenges currently hinder their widespread adoption and implementation. One of the primary obstacles is the long-term stability of ferrofluid-based structures. Ferrofluids tend to degrade over time due to oxidation and particle agglomeration, which can lead to a loss of their unique magnetic properties and structural integrity. This instability poses a significant hurdle for creating durable and reliable ferrofluid-based structures that can withstand prolonged use in various environmental conditions.

Another critical challenge lies in the precise control and manipulation of ferrofluid structures. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control over complex shapes and configurations remains difficult. This limitation restricts the potential applications of ferrofluids in advanced structural designs that require intricate geometries or dynamic shape-shifting capabilities. The development of more sophisticated magnetic field generation and control systems is necessary to overcome this obstacle.

The scalability of ferrofluid-based structures presents yet another challenge. Most current applications and research focus on small-scale demonstrations or laboratory experiments. Scaling up these concepts to practical, real-world dimensions while maintaining the desired structural properties and magnetic responsiveness is a significant engineering challenge. This scaling issue affects both the manufacturing processes and the magnetic field requirements for larger structures.

Furthermore, the integration of ferrofluids with other materials and systems poses compatibility challenges. Ferrofluids may interact unpredictably with certain materials, potentially causing corrosion, degradation, or interference with other system components. This compatibility issue limits the range of materials that can be used in conjunction with ferrofluids, potentially restricting design options and application scenarios.

The environmental impact and safety concerns associated with ferrofluids also present challenges for their widespread use in structural applications. The potential leakage or disposal of ferrofluids raises questions about their long-term environmental effects and the need for proper containment and handling protocols. Additionally, the magnetic properties of ferrofluids may interfere with sensitive electronic equipment or pose health risks in certain environments, necessitating careful consideration of safety measures and application constraints.

Lastly, the cost-effectiveness of ferrofluid-based structural solutions remains a significant hurdle. The production of high-quality ferrofluids and the development of specialized magnetic control systems can be expensive, potentially limiting their economic viability for many applications. Balancing the unique capabilities of ferrofluid structures with their associated costs is crucial for their successful implementation in practical engineering solutions.

Another critical challenge lies in the precise control and manipulation of ferrofluid structures. While ferrofluids respond readily to magnetic fields, achieving fine-tuned control over complex shapes and configurations remains difficult. This limitation restricts the potential applications of ferrofluids in advanced structural designs that require intricate geometries or dynamic shape-shifting capabilities. The development of more sophisticated magnetic field generation and control systems is necessary to overcome this obstacle.

The scalability of ferrofluid-based structures presents yet another challenge. Most current applications and research focus on small-scale demonstrations or laboratory experiments. Scaling up these concepts to practical, real-world dimensions while maintaining the desired structural properties and magnetic responsiveness is a significant engineering challenge. This scaling issue affects both the manufacturing processes and the magnetic field requirements for larger structures.

Furthermore, the integration of ferrofluids with other materials and systems poses compatibility challenges. Ferrofluids may interact unpredictably with certain materials, potentially causing corrosion, degradation, or interference with other system components. This compatibility issue limits the range of materials that can be used in conjunction with ferrofluids, potentially restricting design options and application scenarios.

The environmental impact and safety concerns associated with ferrofluids also present challenges for their widespread use in structural applications. The potential leakage or disposal of ferrofluids raises questions about their long-term environmental effects and the need for proper containment and handling protocols. Additionally, the magnetic properties of ferrofluids may interfere with sensitive electronic equipment or pose health risks in certain environments, necessitating careful consideration of safety measures and application constraints.

Lastly, the cost-effectiveness of ferrofluid-based structural solutions remains a significant hurdle. The production of high-quality ferrofluids and the development of specialized magnetic control systems can be expensive, potentially limiting their economic viability for many applications. Balancing the unique capabilities of ferrofluid structures with their associated costs is crucial for their successful implementation in practical engineering solutions.

Existing Ferrofluid Structural Design Solutions

01 Ferrofluid sealing systems

Ferrofluid seals are used in various structural designs to provide effective sealing in rotating shaft applications. These seals utilize the unique properties of ferrofluids to create a liquid barrier that prevents the passage of contaminants while allowing smooth rotation. The designs often incorporate permanent magnets to retain the ferrofluid in place, ensuring long-term stability and performance.- Ferrofluid sealing systems: Ferrofluid structural designs are utilized in sealing systems for various applications. These designs incorporate magnetic fluids to create effective seals in rotating shafts, bearings, and other mechanical components. The ferrofluid is held in place by magnetic fields, providing a dynamic and adaptive seal that can withstand pressure differences and prevent contamination.

- Ferrofluid-based damping mechanisms: Ferrofluids are employed in structural designs for damping mechanisms. These designs utilize the magnetic properties of ferrofluids to create adaptive damping systems in various applications, such as vibration control in machinery, shock absorption in vehicles, and stabilization in precision instruments. The ferrofluid's viscosity can be controlled by adjusting the magnetic field strength, allowing for tunable damping characteristics.

- Ferrofluid heat transfer systems: Structural designs incorporating ferrofluids are used in heat transfer applications. These designs leverage the thermal properties of ferrofluids and their ability to be manipulated by magnetic fields to enhance heat transfer efficiency. Applications include cooling systems for electronic components, thermal management in industrial processes, and energy harvesting devices.

- Ferrofluid-based actuators and sensors: Ferrofluids are utilized in structural designs for actuators and sensors. These designs exploit the magnetic responsiveness of ferrofluids to create compact and efficient actuators for precise positioning and force generation. In sensor applications, ferrofluid structures are used to detect changes in magnetic fields, pressure, or acceleration, offering high sensitivity and rapid response times.

- Ferrofluid optical devices: Structural designs incorporating ferrofluids are employed in optical devices. These designs utilize the unique optical properties of ferrofluids, such as their ability to form patterns and structures when subjected to magnetic fields. Applications include adaptive lenses, light modulators, displays, and optical switches, where the ferrofluid's shape and properties can be dynamically controlled to manipulate light.

02 Ferrofluid-based damping systems

Structural designs incorporating ferrofluids for damping purposes are utilized in various applications. These systems exploit the magnetic properties of ferrofluids to provide adjustable damping characteristics. The designs may include chambers or cavities filled with ferrofluid, which can be manipulated by external magnetic fields to alter the damping response of the system.Expand Specific Solutions03 Ferrofluid heat transfer systems

Ferrofluids are employed in structural designs for enhanced heat transfer applications. These systems utilize the thermal conductivity and magnetic properties of ferrofluids to improve heat dissipation in various devices. The designs may incorporate channels or cavities filled with ferrofluid, which can be manipulated by magnetic fields to optimize heat transfer efficiency.Expand Specific Solutions04 Ferrofluid-based actuators and sensors

Structural designs incorporating ferrofluids for actuation and sensing purposes are developed for various applications. These systems utilize the magnetic responsiveness of ferrofluids to create motion or detect changes in magnetic fields. The designs may include chambers or channels filled with ferrofluid, which can be manipulated or monitored to achieve the desired actuation or sensing functionality.Expand Specific Solutions05 Ferrofluid separation and filtration systems

Structural designs utilizing ferrofluids for separation and filtration processes are developed for various applications. These systems exploit the magnetic properties of ferrofluids to separate particles or molecules based on their magnetic susceptibility. The designs may incorporate channels, membranes, or other structures that allow for the manipulation of ferrofluids to achieve efficient separation or filtration.Expand Specific Solutions

Key Players in Ferrofluid Research and Development

The ferrofluid structural design market is in an early growth stage, with increasing research interest and potential applications across various industries. The market size is relatively small but expanding, driven by advancements in nanotechnology and materials science. Technologically, ferrofluid applications are still evolving, with academic institutions like Huazhong University of Science & Technology and Chongqing University leading research efforts. Companies such as TDK Corp. and Seiko Epson Corp. are exploring commercial applications, indicating a growing industrial interest. However, the technology's maturity varies across different applications, ranging from experimental to early commercial stages.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed a novel approach to harness ferrofluid for evolutionary structural designs. Their method involves using magnetic fields to manipulate ferrofluid in real-time, creating dynamic and adaptive structures. The university's research team has successfully demonstrated the ability to form complex 3D shapes and patterns using ferrofluid, controlled by precisely calibrated electromagnetic fields[1]. This technique allows for rapid prototyping and testing of various structural configurations, enabling the exploration of biomimetic designs and self-assembling structures. The team has also integrated sensors and feedback systems to create responsive ferrofluid-based structures that can adapt to environmental changes or external stimuli[3].

Strengths: Highly adaptive and responsive structures, rapid prototyping capabilities, potential for self-healing materials. Weaknesses: Scalability challenges, long-term stability of ferrofluid structures, energy requirements for maintaining magnetic fields.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research at the Chinese Academy of Sciences has pioneered a groundbreaking approach to harnessing ferrofluid for evolutionary structural designs. Their research focuses on developing ferrofluid-based smart materials with tunable properties. By manipulating the magnetic nanoparticles within the ferrofluid, they have created structures that can change their shape, stiffness, and other physical properties in response to external magnetic fields[2]. The institute has successfully demonstrated the use of these materials in adaptive shock absorbers, vibration dampers, and self-repairing surfaces. Their latest breakthrough involves the development of a ferrofluid-infused composite material that can alter its thermal conductivity on demand, opening up new possibilities for thermal management in electronics and aerospace applications[4].

Strengths: Highly responsive and tunable materials, potential for multi-functional structures, advanced thermal management capabilities. Weaknesses: Complexity in manufacturing process, potential for particle agglomeration over time, limited load-bearing capacity in certain applications.

Breakthrough Innovations in Ferrofluid Manipulation

Development of water based ferrofluid for efficient heat transfer

PatentUndeterminedIN202021015289A

Innovation

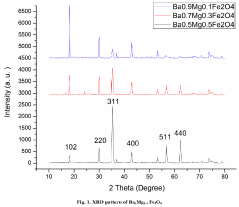

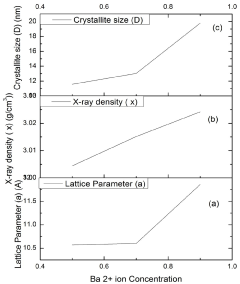

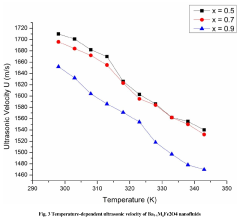

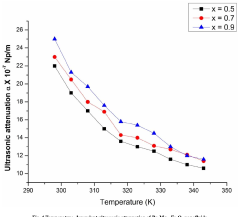

- The synthesis of Ba substituted Mg ferrite nanoparticles and their incorporation into water-based ferrofluids using ultrasonication to enhance thermal conductivity, ensuring stable single-phase formation and optimized thermoacoustical properties.

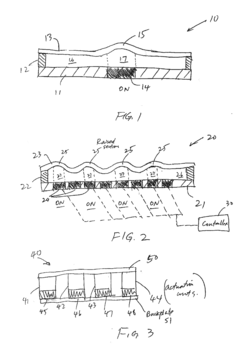

Texture-inducible substrate

PatentActiveUS20160225505A1

Innovation

- A texture-inducible substrate using a combination of a backplate, a deformable membrane, and ferrofluid, where electromagnets induce localized expansion and viscosity increase in the ferrofluid to deform the membrane and create a textured surface pattern, which can be controlled to alter friction and tactile sensations.

Environmental Impact of Ferrofluid Technologies

The environmental impact of ferrofluid technologies is a critical consideration as these innovative materials gain traction in various applications. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, offer unique properties that can revolutionize structural designs. However, their widespread adoption necessitates a thorough examination of potential ecological consequences.

One primary environmental concern is the production process of ferrofluids. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. These processes can contribute to air and water pollution if not properly managed. Additionally, the energy-intensive nature of nanoparticle production raises questions about the carbon footprint associated with large-scale ferrofluid manufacturing.

The disposal and potential release of ferrofluids into the environment pose another significant challenge. While the carrier fluids are typically biodegradable, the magnetic nanoparticles themselves may persist in ecosystems for extended periods. There is a need for comprehensive studies on the long-term effects of these particles on soil and aquatic environments, including their potential to bioaccumulate in food chains.

On a positive note, ferrofluid technologies have the potential to contribute to more sustainable structural designs. Their unique properties allow for the creation of adaptive and responsive structures that can optimize energy efficiency and reduce material waste. For instance, ferrofluid-based damping systems in buildings can enhance seismic resistance, potentially reducing the need for extensive rebuilding after natural disasters.

The use of ferrofluids in renewable energy applications, such as improved solar thermal collectors and wind turbine efficiency enhancements, could indirectly contribute to reducing greenhouse gas emissions. However, a comprehensive life cycle assessment is necessary to quantify the net environmental impact of these applications compared to conventional technologies.

As research in ferrofluid technologies progresses, there is a growing emphasis on developing more environmentally friendly production methods and exploring bio-based alternatives for carrier fluids. These efforts aim to mitigate potential negative impacts while harnessing the benefits of ferrofluids for evolutionary structural designs.

In conclusion, while ferrofluid technologies offer promising advancements in structural design and energy efficiency, their environmental impact requires careful consideration and ongoing research. Balancing the potential benefits with ecological concerns will be crucial for the sustainable development and implementation of ferrofluid-based solutions in various industries.

One primary environmental concern is the production process of ferrofluids. The synthesis of magnetic nanoparticles often involves chemical reactions that may generate hazardous byproducts. These processes can contribute to air and water pollution if not properly managed. Additionally, the energy-intensive nature of nanoparticle production raises questions about the carbon footprint associated with large-scale ferrofluid manufacturing.

The disposal and potential release of ferrofluids into the environment pose another significant challenge. While the carrier fluids are typically biodegradable, the magnetic nanoparticles themselves may persist in ecosystems for extended periods. There is a need for comprehensive studies on the long-term effects of these particles on soil and aquatic environments, including their potential to bioaccumulate in food chains.

On a positive note, ferrofluid technologies have the potential to contribute to more sustainable structural designs. Their unique properties allow for the creation of adaptive and responsive structures that can optimize energy efficiency and reduce material waste. For instance, ferrofluid-based damping systems in buildings can enhance seismic resistance, potentially reducing the need for extensive rebuilding after natural disasters.

The use of ferrofluids in renewable energy applications, such as improved solar thermal collectors and wind turbine efficiency enhancements, could indirectly contribute to reducing greenhouse gas emissions. However, a comprehensive life cycle assessment is necessary to quantify the net environmental impact of these applications compared to conventional technologies.

As research in ferrofluid technologies progresses, there is a growing emphasis on developing more environmentally friendly production methods and exploring bio-based alternatives for carrier fluids. These efforts aim to mitigate potential negative impacts while harnessing the benefits of ferrofluids for evolutionary structural designs.

In conclusion, while ferrofluid technologies offer promising advancements in structural design and energy efficiency, their environmental impact requires careful consideration and ongoing research. Balancing the potential benefits with ecological concerns will be crucial for the sustainable development and implementation of ferrofluid-based solutions in various industries.

Intellectual Property Landscape for Ferrofluid Designs

The intellectual property landscape for ferrofluid designs is characterized by a diverse array of patents and innovations spanning multiple industries. Key players in this field include major technology companies, research institutions, and specialized ferrofluid manufacturers. Patents related to ferrofluid applications in structural design primarily focus on adaptive structures, smart materials, and responsive systems.

One significant area of patent activity involves the use of ferrofluids in damping systems for buildings and bridges. These patents describe methods for incorporating ferrofluid-filled chambers into structural elements to absorb vibrations and mitigate seismic forces. Another prominent category of patents covers the development of shape-morphing structures that utilize ferrofluids to alter their geometry in response to external stimuli.

Magnetic field-responsive architectural elements represent a growing segment of ferrofluid-related patents. These innovations include smart windows that can change opacity, self-adjusting shading systems, and reconfigurable interior partitions. Patents in this area often combine ferrofluids with other smart materials to achieve enhanced functionality.

In the realm of product design, numerous patents explore the use of ferrofluids for creating dynamic, interactive surfaces. These range from tactile displays to adaptive grip surfaces for consumer electronics and sporting equipment. Some patents also describe methods for incorporating ferrofluids into 3D printing processes to produce objects with magnetically-responsive properties.

A notable trend in recent patent filings is the integration of ferrofluids with advanced control systems and sensors. These patents aim to create intelligent structures capable of real-time adaptation to environmental conditions or user inputs. Such systems often leverage machine learning algorithms to optimize the behavior of ferrofluid-based components.

While many patents focus on practical applications, there is also a subset dedicated to novel manufacturing techniques for ferrofluid-infused materials. These include methods for creating composite materials with embedded ferrofluid channels, as well as techniques for precisely controlling the distribution of magnetic particles within a substrate.

The geographical distribution of ferrofluid-related patents shows concentrations in technology hubs across North America, Europe, and East Asia. However, there is a growing number of filings from emerging economies, particularly in the fields of construction and consumer products.

One significant area of patent activity involves the use of ferrofluids in damping systems for buildings and bridges. These patents describe methods for incorporating ferrofluid-filled chambers into structural elements to absorb vibrations and mitigate seismic forces. Another prominent category of patents covers the development of shape-morphing structures that utilize ferrofluids to alter their geometry in response to external stimuli.

Magnetic field-responsive architectural elements represent a growing segment of ferrofluid-related patents. These innovations include smart windows that can change opacity, self-adjusting shading systems, and reconfigurable interior partitions. Patents in this area often combine ferrofluids with other smart materials to achieve enhanced functionality.

In the realm of product design, numerous patents explore the use of ferrofluids for creating dynamic, interactive surfaces. These range from tactile displays to adaptive grip surfaces for consumer electronics and sporting equipment. Some patents also describe methods for incorporating ferrofluids into 3D printing processes to produce objects with magnetically-responsive properties.

A notable trend in recent patent filings is the integration of ferrofluids with advanced control systems and sensors. These patents aim to create intelligent structures capable of real-time adaptation to environmental conditions or user inputs. Such systems often leverage machine learning algorithms to optimize the behavior of ferrofluid-based components.

While many patents focus on practical applications, there is also a subset dedicated to novel manufacturing techniques for ferrofluid-infused materials. These include methods for creating composite materials with embedded ferrofluid channels, as well as techniques for precisely controlling the distribution of magnetic particles within a substrate.

The geographical distribution of ferrofluid-related patents shows concentrations in technology hubs across North America, Europe, and East Asia. However, there is a growing number of filings from emerging economies, particularly in the fields of construction and consumer products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!