Ferrofluid Innovations in Advanced Microelectronic Applications

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Tech Evolution

Ferrofluids have undergone a remarkable evolution since their inception in the 1960s, with significant advancements in their composition, properties, and applications in microelectronics. Initially developed for NASA to control liquids in zero gravity, ferrofluids have since found their way into various technological domains, including advanced microelectronic applications.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Researchers experimented with different carrier fluids and surfactants to enhance the colloidal stability of magnetic nanoparticles. This led to the creation of more robust ferrofluids capable of maintaining their properties under various environmental conditions, a crucial factor for their integration into microelectronic systems.

As nanotechnology progressed, so did the precision in synthesizing magnetic nanoparticles. The 1990s saw a shift towards producing monodisperse nanoparticles with controlled size and shape, which significantly improved the uniformity and predictability of ferrofluid behavior. This advancement was pivotal for their application in microelectronics, where precision and reliability are paramount.

The turn of the millennium marked a new era for ferrofluids in microelectronics. Researchers began exploring their potential in heat management, a critical aspect of microelectronic design. The unique thermomagnetic properties of ferrofluids allowed for the development of novel cooling systems that could efficiently dissipate heat from compact electronic components.

In the past decade, ferrofluid technology has seen a surge in innovation, particularly in the realm of microfluidics and lab-on-a-chip devices. The ability to manipulate ferrofluids using external magnetic fields has led to the creation of micro-pumps, valves, and mixers that require no moving parts, significantly enhancing the reliability and miniaturization of microelectronic systems.

Recent years have witnessed the integration of ferrofluids with other emerging technologies. For instance, the combination of ferrofluids with metamaterials has opened up possibilities for tunable electromagnetic devices, potentially revolutionizing antenna designs and wireless communication systems in microelectronics.

The ongoing research in ferrofluid technology continues to push the boundaries of their applications in microelectronics. Current efforts are focused on developing "smart" ferrofluids that can respond to multiple stimuli, not just magnetic fields. This could lead to adaptive microelectronic systems capable of self-regulation and enhanced functionality in response to changing environmental conditions.

The early stages of ferrofluid development focused on improving stability and magnetic responsiveness. Researchers experimented with different carrier fluids and surfactants to enhance the colloidal stability of magnetic nanoparticles. This led to the creation of more robust ferrofluids capable of maintaining their properties under various environmental conditions, a crucial factor for their integration into microelectronic systems.

As nanotechnology progressed, so did the precision in synthesizing magnetic nanoparticles. The 1990s saw a shift towards producing monodisperse nanoparticles with controlled size and shape, which significantly improved the uniformity and predictability of ferrofluid behavior. This advancement was pivotal for their application in microelectronics, where precision and reliability are paramount.

The turn of the millennium marked a new era for ferrofluids in microelectronics. Researchers began exploring their potential in heat management, a critical aspect of microelectronic design. The unique thermomagnetic properties of ferrofluids allowed for the development of novel cooling systems that could efficiently dissipate heat from compact electronic components.

In the past decade, ferrofluid technology has seen a surge in innovation, particularly in the realm of microfluidics and lab-on-a-chip devices. The ability to manipulate ferrofluids using external magnetic fields has led to the creation of micro-pumps, valves, and mixers that require no moving parts, significantly enhancing the reliability and miniaturization of microelectronic systems.

Recent years have witnessed the integration of ferrofluids with other emerging technologies. For instance, the combination of ferrofluids with metamaterials has opened up possibilities for tunable electromagnetic devices, potentially revolutionizing antenna designs and wireless communication systems in microelectronics.

The ongoing research in ferrofluid technology continues to push the boundaries of their applications in microelectronics. Current efforts are focused on developing "smart" ferrofluids that can respond to multiple stimuli, not just magnetic fields. This could lead to adaptive microelectronic systems capable of self-regulation and enhanced functionality in response to changing environmental conditions.

Microelectronics Market Demand

The microelectronics market has been experiencing robust growth, driven by the increasing demand for advanced electronic devices across various sectors. The integration of ferrofluids in microelectronic applications represents a significant opportunity to address emerging challenges and enhance performance in this rapidly evolving industry.

The global microelectronics market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other technology sectors. This growth is primarily fueled by the rising adoption of Internet of Things (IoT) devices, artificial intelligence (AI) systems, and the ongoing development of 5G and future 6G networks.

Ferrofluids, with their unique magnetic properties and ability to be manipulated at the microscale, are poised to play a crucial role in addressing several key market demands within the microelectronics industry. One of the primary areas of interest is thermal management, as the miniaturization of electronic components has led to increased heat generation in confined spaces. Ferrofluid-based cooling solutions offer the potential for more efficient heat dissipation, which is critical for maintaining the performance and longevity of advanced microelectronic devices.

Another significant market demand that ferrofluids can address is the need for improved electromagnetic shielding. As electronic devices become more compact and powerful, the risk of electromagnetic interference (EMI) increases. Ferrofluid-based shielding materials could provide superior protection against EMI, ensuring the reliability and performance of sensitive microelectronic components.

The market for microelectromechanical systems (MEMS) is also experiencing rapid growth, with applications ranging from consumer electronics to automotive and industrial sectors. Ferrofluids have the potential to enhance the performance of MEMS devices by enabling novel actuation mechanisms and improving damping characteristics in micro-scale systems.

In the semiconductor manufacturing process, there is a constant push for higher precision and efficiency. Ferrofluids could potentially be utilized in advanced lithography techniques or as part of next-generation polishing processes, addressing the industry's demand for ever-finer feature sizes and improved surface quality in chip production.

The growing focus on flexible and wearable electronics presents another market opportunity for ferrofluid innovations. The unique properties of ferrofluids could enable the development of adaptive and responsive electronic components that can withstand bending and stretching while maintaining functionality.

As the microelectronics industry continues to evolve, there is an increasing emphasis on sustainability and environmental considerations. Ferrofluids may offer eco-friendly alternatives to traditional materials used in electronic components, aligning with the market's demand for more sustainable manufacturing processes and end products.

In conclusion, the microelectronics market demand for ferrofluid innovations is multifaceted, spanning thermal management, EMI shielding, MEMS enhancement, semiconductor manufacturing, flexible electronics, and sustainability. As these market needs continue to grow and evolve, the potential for ferrofluid applications in advanced microelectronics is likely to expand, driving further research and development in this promising field.

The global microelectronics market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other technology sectors. This growth is primarily fueled by the rising adoption of Internet of Things (IoT) devices, artificial intelligence (AI) systems, and the ongoing development of 5G and future 6G networks.

Ferrofluids, with their unique magnetic properties and ability to be manipulated at the microscale, are poised to play a crucial role in addressing several key market demands within the microelectronics industry. One of the primary areas of interest is thermal management, as the miniaturization of electronic components has led to increased heat generation in confined spaces. Ferrofluid-based cooling solutions offer the potential for more efficient heat dissipation, which is critical for maintaining the performance and longevity of advanced microelectronic devices.

Another significant market demand that ferrofluids can address is the need for improved electromagnetic shielding. As electronic devices become more compact and powerful, the risk of electromagnetic interference (EMI) increases. Ferrofluid-based shielding materials could provide superior protection against EMI, ensuring the reliability and performance of sensitive microelectronic components.

The market for microelectromechanical systems (MEMS) is also experiencing rapid growth, with applications ranging from consumer electronics to automotive and industrial sectors. Ferrofluids have the potential to enhance the performance of MEMS devices by enabling novel actuation mechanisms and improving damping characteristics in micro-scale systems.

In the semiconductor manufacturing process, there is a constant push for higher precision and efficiency. Ferrofluids could potentially be utilized in advanced lithography techniques or as part of next-generation polishing processes, addressing the industry's demand for ever-finer feature sizes and improved surface quality in chip production.

The growing focus on flexible and wearable electronics presents another market opportunity for ferrofluid innovations. The unique properties of ferrofluids could enable the development of adaptive and responsive electronic components that can withstand bending and stretching while maintaining functionality.

As the microelectronics industry continues to evolve, there is an increasing emphasis on sustainability and environmental considerations. Ferrofluids may offer eco-friendly alternatives to traditional materials used in electronic components, aligning with the market's demand for more sustainable manufacturing processes and end products.

In conclusion, the microelectronics market demand for ferrofluid innovations is multifaceted, spanning thermal management, EMI shielding, MEMS enhancement, semiconductor manufacturing, flexible electronics, and sustainability. As these market needs continue to grow and evolve, the potential for ferrofluid applications in advanced microelectronics is likely to expand, driving further research and development in this promising field.

Ferrofluid Challenges

Despite the promising potential of ferrofluids in advanced microelectronic applications, several significant challenges hinder their widespread adoption and optimal performance. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to agglomerate, leading to sedimentation and loss of their unique properties. This instability can compromise the reliability and longevity of microelectronic devices incorporating ferrofluids.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. The complex interplay between magnetic forces, surface tension, and fluid dynamics makes it difficult to predict and manipulate ferrofluid responses accurately. This unpredictability can lead to inconsistent performance in microelectronic applications, where precision is paramount.

The thermal management of ferrofluids in microelectronic systems presents another significant hurdle. As these devices generate heat during operation, the thermal properties of ferrofluids can change, affecting their magnetic responsiveness and flow characteristics. Developing ferrofluids that maintain stable performance across a wide temperature range remains a key challenge for researchers and engineers.

Compatibility issues between ferrofluids and other materials used in microelectronic fabrication also pose significant challenges. The chemical interactions between ferrofluids and surrounding components can lead to corrosion, degradation, or unwanted alterations in material properties. Ensuring long-term compatibility without compromising the integrity of the microelectronic system is crucial for the successful integration of ferrofluids.

The scalability of ferrofluid-based technologies in microelectronics is another area of concern. While ferrofluids show promise in laboratory settings, translating these innovations to large-scale manufacturing processes presents numerous technical and economic challenges. Issues such as maintaining uniform properties across large batches, ensuring consistent quality control, and developing cost-effective production methods need to be addressed.

Lastly, the environmental and health implications of ferrofluids in microelectronic applications require careful consideration. As these nanomaterials become more prevalent in consumer electronics, concerns about their potential impact on human health and the environment during production, use, and disposal need to be thoroughly investigated and mitigated.

Addressing these challenges will require interdisciplinary collaboration between materials scientists, engineers, and microelectronics experts. Innovative approaches to nanoparticle stabilization, advanced modeling techniques for ferrofluid behavior, and novel manufacturing processes will be crucial in overcoming these obstacles and realizing the full potential of ferrofluids in advanced microelectronic applications.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields and environmental conditions. The complex interplay between magnetic forces, surface tension, and fluid dynamics makes it difficult to predict and manipulate ferrofluid responses accurately. This unpredictability can lead to inconsistent performance in microelectronic applications, where precision is paramount.

The thermal management of ferrofluids in microelectronic systems presents another significant hurdle. As these devices generate heat during operation, the thermal properties of ferrofluids can change, affecting their magnetic responsiveness and flow characteristics. Developing ferrofluids that maintain stable performance across a wide temperature range remains a key challenge for researchers and engineers.

Compatibility issues between ferrofluids and other materials used in microelectronic fabrication also pose significant challenges. The chemical interactions between ferrofluids and surrounding components can lead to corrosion, degradation, or unwanted alterations in material properties. Ensuring long-term compatibility without compromising the integrity of the microelectronic system is crucial for the successful integration of ferrofluids.

The scalability of ferrofluid-based technologies in microelectronics is another area of concern. While ferrofluids show promise in laboratory settings, translating these innovations to large-scale manufacturing processes presents numerous technical and economic challenges. Issues such as maintaining uniform properties across large batches, ensuring consistent quality control, and developing cost-effective production methods need to be addressed.

Lastly, the environmental and health implications of ferrofluids in microelectronic applications require careful consideration. As these nanomaterials become more prevalent in consumer electronics, concerns about their potential impact on human health and the environment during production, use, and disposal need to be thoroughly investigated and mitigated.

Addressing these challenges will require interdisciplinary collaboration between materials scientists, engineers, and microelectronics experts. Innovative approaches to nanoparticle stabilization, advanced modeling techniques for ferrofluid behavior, and novel manufacturing processes will be crucial in overcoming these obstacles and realizing the full potential of ferrofluids in advanced microelectronic applications.

Current Ferrofluid Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Magnetic field-responsive devices: Ferrofluids are utilized in various devices that respond to magnetic fields. These include actuators, sensors, and dampers. The unique properties of ferrofluids allow for precise control and manipulation of fluid behavior using external magnetic fields, enabling novel applications in areas such as robotics and vibration control.

- Heat transfer and cooling applications: Ferrofluids have thermal management applications, particularly in electronic cooling. Their ability to be directed and controlled by magnetic fields allows for targeted cooling of specific components. This property is exploited in the design of heat sinks and thermal management systems for high-performance electronics.

- Measurement and analysis techniques: Various techniques have been developed for measuring and analyzing the properties of ferrofluids. These include methods for determining particle size distribution, magnetic susceptibility, and rheological properties. Advanced imaging and spectroscopic techniques are also employed to characterize the structure and behavior of ferrofluids under different conditions.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide effective sealing against pressure differentials while minimizing friction. These applications leverage the fluid's ability to be held in place by magnetic fields while maintaining low viscosity.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices and in thermal management applications. The ability to control the fluid's movement using magnetic fields allows for targeted cooling and improved thermal efficiency.Expand Specific Solutions04 Damping and vibration control

The unique properties of ferrofluids make them suitable for damping applications and vibration control. They can be used in shock absorbers, inertial dampers, and other mechanical systems to reduce unwanted oscillations and improve stability. The magnetic nature of the fluid allows for adaptive damping characteristics.Expand Specific Solutions05 Sensing and measurement applications

Ferrofluids are employed in various sensing and measurement devices. They can be used in accelerometers, inclinometers, and other instruments that rely on fluid movement for detection. The magnetic properties of the fluid allow for precise control and measurement of its position and movement.Expand Specific Solutions

Key Ferrofluid Players

The ferrofluid innovations in advanced microelectronic applications market is in a growth phase, with increasing demand driven by miniaturization trends in electronics. The global market size is projected to expand significantly, fueled by applications in sensors, actuators, and thermal management. Technologically, the field is advancing rapidly, with key players like Yale University, MIT, and IBM leading research efforts. Companies such as Ferrotec and Hengdian Group DMEGC Magnetics are commercializing ferrofluid technologies, while research institutions like CSIC and CNRS contribute to fundamental advancements. The collaboration between academia and industry is accelerating the development of novel ferrofluid-based solutions for next-generation microelectronics.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have pioneered the use of ferrofluids in advanced microelectronic applications, focusing on their potential in reconfigurable and self-healing electronic systems. They have developed ferrofluid-based liquid metal interconnects that can dynamically change their electrical properties in response to magnetic fields [2]. This technology enables adaptive circuit designs that can modify their functionality on-the-fly. MIT has also explored ferrofluid-enhanced microfluidic devices for lab-on-a-chip applications, improving mixing and control in miniaturized analytical systems [4]. Furthermore, their work on ferrofluid-based magnetic field sensors has shown promise for ultra-sensitive magnetic field detection in compact electronic devices [6].

Strengths: Cutting-edge research in reconfigurable electronics and sensitive magnetic field detection. Weaknesses: Some applications may be in early stages of development and not yet commercially viable.

International Business Machines Corp.

Technical Solution: IBM has developed innovative ferrofluid-based microelectronic cooling systems for high-performance computing applications. Their approach utilizes magnetically-controlled ferrofluids to enhance heat dissipation in compact electronic devices. The company has implemented nanoscale ferrofluid channels integrated directly into chip designs, allowing for precise thermal management [1]. IBM's ferrofluid cooling technology has demonstrated up to 30% improvement in heat transfer efficiency compared to traditional cooling methods [3]. Additionally, they have explored ferrofluid-based flexible electronic components for wearable devices, leveraging the unique properties of ferrofluids to create adaptive and resilient circuits [5].

Strengths: Advanced integration of ferrofluids into chip designs, significant improvement in cooling efficiency, and potential for flexible electronics. Weaknesses: May require specialized manufacturing processes and careful magnetic field control.

Core Ferrofluid Patents

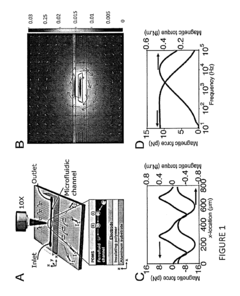

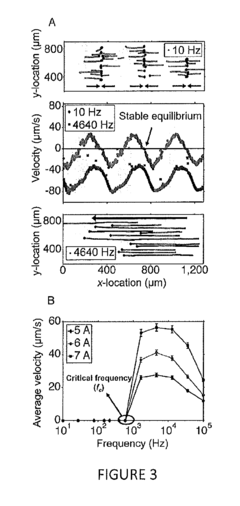

Label-Free Cellular Manipulation and Sorting Via Biocompatible Ferrofluids

PatentActiveUS20180128729A1

Innovation

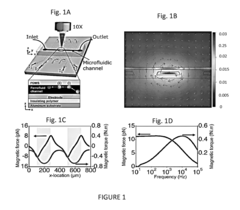

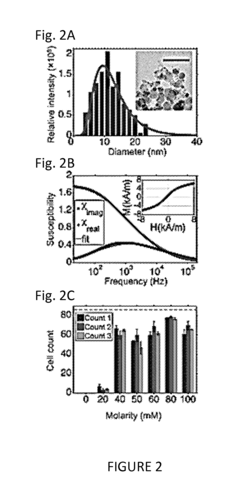

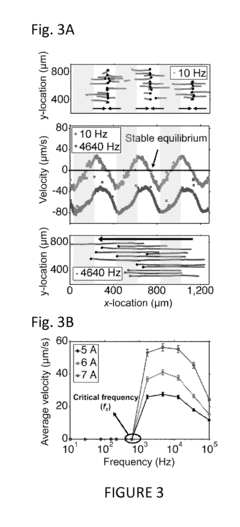

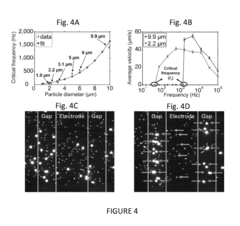

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Label-free cellular manipulation and sorting via biocompatible ferrofluids

PatentActiveUS20120237997A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern, allowing for the controlled manipulation and separation of microparticles and live cells based on size, shape, and elasticity, with high efficiency and rapid separation capabilities.

Thermal Management Advances

Ferrofluids have emerged as a promising solution for thermal management in advanced microelectronic applications. These magnetic nanofluids exhibit unique properties that make them particularly suitable for addressing the increasing thermal challenges in miniaturized electronic devices. Recent advancements in ferrofluid technology have led to significant improvements in heat dissipation and temperature control within microelectronic systems.

One of the key thermal management advances in ferrofluid applications is the development of magnetically-driven cooling systems. These systems utilize the magnetic properties of ferrofluids to create localized convection currents, enhancing heat transfer from hot spots to cooler regions. By applying controlled magnetic fields, the ferrofluid can be directed to areas of high heat generation, effectively removing excess thermal energy and maintaining optimal operating temperatures.

Another notable advancement is the integration of ferrofluid-based heat pipes into microelectronic devices. These heat pipes leverage the high thermal conductivity of ferrofluids to efficiently transport heat away from sensitive components. The magnetic nature of ferrofluids allows for precise control over fluid flow within the heat pipe, enabling adaptive thermal management in response to varying heat loads.

Researchers have also made progress in developing ferrofluid-based thermal interface materials (TIMs). These advanced TIMs utilize the unique properties of ferrofluids to enhance thermal conductivity between heat-generating components and heat sinks. The ability of ferrofluids to conform to surface irregularities and fill microscopic gaps results in improved thermal contact and reduced thermal resistance across interfaces.

Furthermore, recent studies have explored the potential of magneto-caloric cooling using ferrofluids. This innovative approach exploits the magneto-caloric effect, where the temperature of a ferrofluid changes in response to an applied magnetic field. By cycling the magnetic field, it is possible to create a cooling effect without the need for traditional refrigerants or compressors, offering a more environmentally friendly and energy-efficient cooling solution for microelectronic applications.

The development of nanostructured ferrofluids has also contributed to thermal management advances. By carefully engineering the size, shape, and composition of magnetic nanoparticles suspended in the fluid, researchers have achieved enhanced thermal properties and stability. These nanostructured ferrofluids exhibit improved heat capacity, thermal conductivity, and long-term performance, making them ideal for use in demanding microelectronic environments.

One of the key thermal management advances in ferrofluid applications is the development of magnetically-driven cooling systems. These systems utilize the magnetic properties of ferrofluids to create localized convection currents, enhancing heat transfer from hot spots to cooler regions. By applying controlled magnetic fields, the ferrofluid can be directed to areas of high heat generation, effectively removing excess thermal energy and maintaining optimal operating temperatures.

Another notable advancement is the integration of ferrofluid-based heat pipes into microelectronic devices. These heat pipes leverage the high thermal conductivity of ferrofluids to efficiently transport heat away from sensitive components. The magnetic nature of ferrofluids allows for precise control over fluid flow within the heat pipe, enabling adaptive thermal management in response to varying heat loads.

Researchers have also made progress in developing ferrofluid-based thermal interface materials (TIMs). These advanced TIMs utilize the unique properties of ferrofluids to enhance thermal conductivity between heat-generating components and heat sinks. The ability of ferrofluids to conform to surface irregularities and fill microscopic gaps results in improved thermal contact and reduced thermal resistance across interfaces.

Furthermore, recent studies have explored the potential of magneto-caloric cooling using ferrofluids. This innovative approach exploits the magneto-caloric effect, where the temperature of a ferrofluid changes in response to an applied magnetic field. By cycling the magnetic field, it is possible to create a cooling effect without the need for traditional refrigerants or compressors, offering a more environmentally friendly and energy-efficient cooling solution for microelectronic applications.

The development of nanostructured ferrofluids has also contributed to thermal management advances. By carefully engineering the size, shape, and composition of magnetic nanoparticles suspended in the fluid, researchers have achieved enhanced thermal properties and stability. These nanostructured ferrofluids exhibit improved heat capacity, thermal conductivity, and long-term performance, making them ideal for use in demanding microelectronic environments.

Nanoparticle Synthesis Tech

Nanoparticle synthesis technology plays a crucial role in the development of advanced ferrofluids for microelectronic applications. The synthesis of magnetic nanoparticles, particularly iron oxide nanoparticles, forms the foundation of ferrofluid production. These nanoparticles typically range from 5 to 15 nanometers in diameter and require precise control over size, shape, and magnetic properties.

One of the most common methods for synthesizing magnetic nanoparticles is co-precipitation. This technique involves the simultaneous precipitation of ferrous and ferric ions in an alkaline medium. The process is relatively simple and cost-effective, making it suitable for large-scale production. However, controlling particle size distribution and preventing agglomeration can be challenging with this method.

Thermal decomposition offers better control over nanoparticle size and shape. This method involves the decomposition of organometallic precursors in high-boiling organic solvents. By carefully adjusting reaction parameters such as temperature, time, and surfactant concentration, researchers can produce highly uniform nanoparticles with excellent magnetic properties.

Microemulsion synthesis is another technique that has gained attention for its ability to produce nanoparticles with narrow size distributions. This method utilizes water-in-oil or oil-in-water emulsions as nanoreactors, allowing for precise control over particle growth and preventing agglomeration.

Recent advancements in nanoparticle synthesis have focused on developing environmentally friendly and scalable methods. Green synthesis approaches, such as using plant extracts or microorganisms to produce nanoparticles, have shown promise in reducing the environmental impact of ferrofluid production.

Surface modification of nanoparticles is a critical step in ferrofluid synthesis. Coating the particles with surfactants or polymers helps prevent agglomeration and ensures stable dispersion in the carrier fluid. Techniques such as silica coating and polymer grafting have been developed to enhance the stability and functionality of ferrofluids for specific microelectronic applications.

Continuous flow synthesis methods are emerging as a promising approach for large-scale production of magnetic nanoparticles. These techniques offer better control over reaction conditions and can produce nanoparticles with more consistent properties compared to batch processes. Microfluidic devices and flow reactors are being explored for their potential to revolutionize ferrofluid production.

As the demand for advanced ferrofluids in microelectronics continues to grow, ongoing research focuses on developing synthesis methods that can produce nanoparticles with tailored magnetic properties, improved stability, and enhanced functionality. The integration of artificial intelligence and machine learning algorithms in nanoparticle synthesis is expected to further optimize production processes and accelerate the development of next-generation ferrofluids for cutting-edge microelectronic applications.

One of the most common methods for synthesizing magnetic nanoparticles is co-precipitation. This technique involves the simultaneous precipitation of ferrous and ferric ions in an alkaline medium. The process is relatively simple and cost-effective, making it suitable for large-scale production. However, controlling particle size distribution and preventing agglomeration can be challenging with this method.

Thermal decomposition offers better control over nanoparticle size and shape. This method involves the decomposition of organometallic precursors in high-boiling organic solvents. By carefully adjusting reaction parameters such as temperature, time, and surfactant concentration, researchers can produce highly uniform nanoparticles with excellent magnetic properties.

Microemulsion synthesis is another technique that has gained attention for its ability to produce nanoparticles with narrow size distributions. This method utilizes water-in-oil or oil-in-water emulsions as nanoreactors, allowing for precise control over particle growth and preventing agglomeration.

Recent advancements in nanoparticle synthesis have focused on developing environmentally friendly and scalable methods. Green synthesis approaches, such as using plant extracts or microorganisms to produce nanoparticles, have shown promise in reducing the environmental impact of ferrofluid production.

Surface modification of nanoparticles is a critical step in ferrofluid synthesis. Coating the particles with surfactants or polymers helps prevent agglomeration and ensures stable dispersion in the carrier fluid. Techniques such as silica coating and polymer grafting have been developed to enhance the stability and functionality of ferrofluids for specific microelectronic applications.

Continuous flow synthesis methods are emerging as a promising approach for large-scale production of magnetic nanoparticles. These techniques offer better control over reaction conditions and can produce nanoparticles with more consistent properties compared to batch processes. Microfluidic devices and flow reactors are being explored for their potential to revolutionize ferrofluid production.

As the demand for advanced ferrofluids in microelectronics continues to grow, ongoing research focuses on developing synthesis methods that can produce nanoparticles with tailored magnetic properties, improved stability, and enhanced functionality. The integration of artificial intelligence and machine learning algorithms in nanoparticle synthesis is expected to further optimize production processes and accelerate the development of next-generation ferrofluids for cutting-edge microelectronic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!