Assessing Ferrofluid's Impact on Innovative Material Sciences

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Evolution

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution over the past six decades. Initially conceived as a solution for controlling liquids in zero gravity, these magnetic liquids have since found applications across various fields, marking key milestones in material science innovation.

The early stages of ferrofluid development focused primarily on refining the synthesis process and improving stability. Scientists worked on optimizing the size and distribution of magnetic nanoparticles, as well as enhancing the surfactant coating to prevent agglomeration. This period saw the emergence of different types of ferrofluids, including water-based and oil-based variants, each suited for specific applications.

In the 1970s and 1980s, ferrofluids transitioned from laboratory curiosities to practical industrial applications. The technology found its first commercial uses in sealing and damping applications, particularly in computer hard drives and loudspeakers. This phase marked a crucial step in demonstrating the real-world potential of ferrofluids beyond their initial space-oriented purpose.

The 1990s and early 2000s witnessed a surge in research exploring the unique properties of ferrofluids. Scientists began investigating their potential in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment. Concurrently, advances in nanotechnology led to more precise control over ferrofluid properties, enabling the development of smart materials with tunable characteristics.

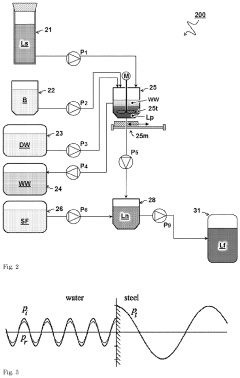

Recent years have seen a convergence of ferrofluid technology with other emerging fields. The integration of ferrofluids with microfluidics has opened new avenues in lab-on-a-chip devices and miniaturized sensors. Additionally, researchers have explored the use of ferrofluids in energy harvesting applications, leveraging their unique response to magnetic fields to generate electricity from low-frequency vibrations.

The evolution of ferrofluids has also been marked by advancements in characterization techniques. High-resolution imaging methods and sophisticated modeling tools have provided deeper insights into the behavior of these complex fluids at the nanoscale. This enhanced understanding has, in turn, facilitated the design of more advanced ferrofluid formulations tailored for specific applications.

Looking ahead, the trajectory of ferrofluid evolution points towards even more sophisticated and multifunctional materials. Current research is exploring the development of stimuli-responsive ferrofluids that can change properties in response to multiple external triggers, not just magnetic fields. The potential integration of ferrofluids with other smart materials, such as shape-memory alloys or piezoelectric materials, promises to unlock new possibilities in adaptive and self-regulating systems.

The early stages of ferrofluid development focused primarily on refining the synthesis process and improving stability. Scientists worked on optimizing the size and distribution of magnetic nanoparticles, as well as enhancing the surfactant coating to prevent agglomeration. This period saw the emergence of different types of ferrofluids, including water-based and oil-based variants, each suited for specific applications.

In the 1970s and 1980s, ferrofluids transitioned from laboratory curiosities to practical industrial applications. The technology found its first commercial uses in sealing and damping applications, particularly in computer hard drives and loudspeakers. This phase marked a crucial step in demonstrating the real-world potential of ferrofluids beyond their initial space-oriented purpose.

The 1990s and early 2000s witnessed a surge in research exploring the unique properties of ferrofluids. Scientists began investigating their potential in biomedical applications, such as targeted drug delivery and magnetic hyperthermia for cancer treatment. Concurrently, advances in nanotechnology led to more precise control over ferrofluid properties, enabling the development of smart materials with tunable characteristics.

Recent years have seen a convergence of ferrofluid technology with other emerging fields. The integration of ferrofluids with microfluidics has opened new avenues in lab-on-a-chip devices and miniaturized sensors. Additionally, researchers have explored the use of ferrofluids in energy harvesting applications, leveraging their unique response to magnetic fields to generate electricity from low-frequency vibrations.

The evolution of ferrofluids has also been marked by advancements in characterization techniques. High-resolution imaging methods and sophisticated modeling tools have provided deeper insights into the behavior of these complex fluids at the nanoscale. This enhanced understanding has, in turn, facilitated the design of more advanced ferrofluid formulations tailored for specific applications.

Looking ahead, the trajectory of ferrofluid evolution points towards even more sophisticated and multifunctional materials. Current research is exploring the development of stimuli-responsive ferrofluids that can change properties in response to multiple external triggers, not just magnetic fields. The potential integration of ferrofluids with other smart materials, such as shape-memory alloys or piezoelectric materials, promises to unlock new possibilities in adaptive and self-regulating systems.

Market Applications

Ferrofluids have emerged as a groundbreaking material with diverse market applications across various industries. In the automotive sector, these magnetic liquids are revolutionizing shock absorbers and damping systems, offering enhanced vehicle stability and improved ride comfort. The aerospace industry is exploring ferrofluids for advanced sealing solutions in high-pressure environments, potentially leading to more efficient and reliable aircraft components.

In the medical field, ferrofluids show promise in targeted drug delivery systems, where magnetic nanoparticles can be guided to specific areas of the body for precise treatment. This technology could significantly improve cancer therapies and reduce side effects associated with traditional treatments. Additionally, ferrofluids are being investigated for use in magnetic resonance imaging (MRI) contrast agents, potentially enhancing diagnostic capabilities and image quality.

The electronics industry is leveraging ferrofluids for cooling applications in high-performance computing systems and data centers. By utilizing the unique heat transfer properties of these magnetic liquids, more efficient thermal management solutions can be developed, leading to improved performance and energy savings in electronic devices.

In renewable energy, ferrofluids are being explored for use in advanced solar thermal collectors and wind turbine generators. Their ability to enhance heat transfer and reduce friction in moving parts could lead to more efficient energy production systems, contributing to the global shift towards sustainable energy sources.

The manufacturing sector is adopting ferrofluids for precision polishing and machining processes. The controllable nature of these magnetic liquids allows for ultra-smooth surface finishes on optical components and semiconductor wafers, meeting the demanding requirements of high-tech industries.

Environmental applications of ferrofluids include oil spill cleanup and water purification. The magnetic properties of these materials enable efficient separation of contaminants from water bodies, offering a potential solution to pressing environmental challenges.

In the consumer electronics market, ferrofluids are finding applications in audio speakers, where they can improve sound quality and reduce distortion. This technology is particularly relevant for high-end audio systems and portable devices, where space constraints and performance demands are critical factors.

As research in material sciences continues to advance, new applications for ferrofluids are constantly emerging. From smart textiles with adaptive properties to novel energy storage solutions, the potential market impact of ferrofluids spans across multiple sectors, driving innovation and creating new opportunities for product development and technological advancements.

In the medical field, ferrofluids show promise in targeted drug delivery systems, where magnetic nanoparticles can be guided to specific areas of the body for precise treatment. This technology could significantly improve cancer therapies and reduce side effects associated with traditional treatments. Additionally, ferrofluids are being investigated for use in magnetic resonance imaging (MRI) contrast agents, potentially enhancing diagnostic capabilities and image quality.

The electronics industry is leveraging ferrofluids for cooling applications in high-performance computing systems and data centers. By utilizing the unique heat transfer properties of these magnetic liquids, more efficient thermal management solutions can be developed, leading to improved performance and energy savings in electronic devices.

In renewable energy, ferrofluids are being explored for use in advanced solar thermal collectors and wind turbine generators. Their ability to enhance heat transfer and reduce friction in moving parts could lead to more efficient energy production systems, contributing to the global shift towards sustainable energy sources.

The manufacturing sector is adopting ferrofluids for precision polishing and machining processes. The controllable nature of these magnetic liquids allows for ultra-smooth surface finishes on optical components and semiconductor wafers, meeting the demanding requirements of high-tech industries.

Environmental applications of ferrofluids include oil spill cleanup and water purification. The magnetic properties of these materials enable efficient separation of contaminants from water bodies, offering a potential solution to pressing environmental challenges.

In the consumer electronics market, ferrofluids are finding applications in audio speakers, where they can improve sound quality and reduce distortion. This technology is particularly relevant for high-end audio systems and portable devices, where space constraints and performance demands are critical factors.

As research in material sciences continues to advance, new applications for ferrofluids are constantly emerging. From smart textiles with adaptive properties to novel energy storage solutions, the potential market impact of ferrofluids spans across multiple sectors, driving innovation and creating new opportunities for product development and technological advancements.

Technical Challenges

Ferrofluids, despite their remarkable properties and potential applications, face several technical challenges that hinder their widespread adoption in innovative material sciences. One of the primary obstacles is the long-term stability of ferrofluids. These colloidal suspensions tend to aggregate over time, leading to sedimentation and loss of their unique magnetic properties. This instability limits their practical use in long-term applications and poses significant challenges for storage and transportation.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. While ferrofluids respond to external magnetic fields, achieving fine-tuned control over their shape, movement, and properties remains difficult. This lack of precise control hampers their integration into advanced systems where predictable and consistent performance is crucial.

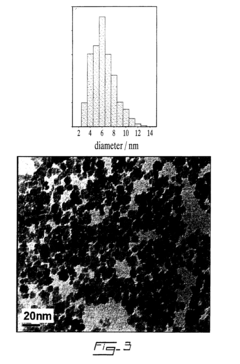

The synthesis of ferrofluids with tailored properties for specific applications presents another hurdle. Current manufacturing processes often struggle to produce ferrofluids with uniform particle size distributions and consistent magnetic properties at scale. This variability in production quality impacts the reproducibility of experiments and the reliability of ferrofluid-based devices.

Biocompatibility is a significant concern for ferrofluids in biomedical applications. While some progress has been made in developing biocompatible ferrofluids, ensuring their long-term safety and efficacy within living organisms remains challenging. Issues such as potential toxicity, immune system responses, and the body's ability to metabolize or excrete the nanoparticles need further investigation.

The thermal stability of ferrofluids under various operating conditions is another area of concern. Many potential applications require ferrofluids to maintain their properties across a wide temperature range. However, thermal fluctuations can affect the stability of the suspension and alter the magnetic properties of the nanoparticles, limiting their use in extreme environments.

Scaling up ferrofluid production for industrial applications presents both technical and economic challenges. Current manufacturing methods are often costly and not easily scalable, making large-scale production economically unfeasible for many potential applications. Developing more efficient and cost-effective production techniques is crucial for the widespread adoption of ferrofluid technology.

Lastly, the integration of ferrofluids with other materials and systems poses significant engineering challenges. Designing interfaces that allow ferrofluids to interact effectively with solid materials, electronics, or other liquids while maintaining their unique properties requires innovative solutions. This integration challenge is particularly evident in areas such as adaptive optics, microfluidics, and smart materials, where the seamless incorporation of ferrofluids could lead to groundbreaking advancements.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic fields. While ferrofluids respond to external magnetic fields, achieving fine-tuned control over their shape, movement, and properties remains difficult. This lack of precise control hampers their integration into advanced systems where predictable and consistent performance is crucial.

The synthesis of ferrofluids with tailored properties for specific applications presents another hurdle. Current manufacturing processes often struggle to produce ferrofluids with uniform particle size distributions and consistent magnetic properties at scale. This variability in production quality impacts the reproducibility of experiments and the reliability of ferrofluid-based devices.

Biocompatibility is a significant concern for ferrofluids in biomedical applications. While some progress has been made in developing biocompatible ferrofluids, ensuring their long-term safety and efficacy within living organisms remains challenging. Issues such as potential toxicity, immune system responses, and the body's ability to metabolize or excrete the nanoparticles need further investigation.

The thermal stability of ferrofluids under various operating conditions is another area of concern. Many potential applications require ferrofluids to maintain their properties across a wide temperature range. However, thermal fluctuations can affect the stability of the suspension and alter the magnetic properties of the nanoparticles, limiting their use in extreme environments.

Scaling up ferrofluid production for industrial applications presents both technical and economic challenges. Current manufacturing methods are often costly and not easily scalable, making large-scale production economically unfeasible for many potential applications. Developing more efficient and cost-effective production techniques is crucial for the widespread adoption of ferrofluid technology.

Lastly, the integration of ferrofluids with other materials and systems poses significant engineering challenges. Designing interfaces that allow ferrofluids to interact effectively with solid materials, electronics, or other liquids while maintaining their unique properties requires innovative solutions. This integration challenge is particularly evident in areas such as adaptive optics, microfluidics, and smart materials, where the seamless incorporation of ferrofluids could lead to groundbreaking advancements.

Current Solutions

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with a surfactant to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments. These properties make them valuable in various industrial and mechanical systems.

- Magnetic field sensing and control: Ferrofluids are utilized in magnetic field sensing and control applications. Their unique response to magnetic fields allows for precise measurement and manipulation of magnetic properties. This capability is exploited in various devices, including sensors, actuators, and magnetic field visualization tools.

- Thermal management applications: Ferrofluids have found applications in thermal management systems, particularly in electronic cooling. Their ability to be manipulated by magnetic fields allows for enhanced heat transfer and targeted cooling in compact electronic devices. This property is utilized in the design of more efficient cooling systems for various electronic components.

- Novel applications and emerging technologies: Ferrofluids are being explored for various novel applications and emerging technologies. These include their use in microfluidic devices, biomedical applications such as drug delivery and hyperthermia treatment, energy harvesting systems, and advanced manufacturing processes. The unique properties of ferrofluids continue to inspire new and innovative applications across multiple fields.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.Expand Specific Solutions03 Thermal management and cooling systems

Ferrofluids are employed in thermal management solutions, particularly for electronic devices and power systems. Their ability to be manipulated by magnetic fields allows for efficient heat transfer and targeted cooling. This technology is used in various applications, including computer cooling systems and power transformers.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are utilized in various sensor and actuator designs, leveraging their responsiveness to magnetic fields. They can be used to create pressure sensors, accelerometers, and position sensors. In actuators, ferrofluids enable precise control of movement and force application in response to applied magnetic fields.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have emerging applications in the medical and biomedical fields. They are being researched for use in targeted drug delivery, magnetic hyperthermia for cancer treatment, and as contrast agents in magnetic resonance imaging (MRI). The ability to control ferrofluids using external magnetic fields makes them promising for minimally invasive medical procedures.Expand Specific Solutions

Industry Leaders

The ferrofluid technology market is in a growth phase, with increasing applications in material sciences driving innovation. The global market size for ferrofluids is projected to expand significantly in the coming years, fueled by advancements in nanotechnology and growing demand across various industries. While the technology is maturing, there is still room for further development and novel applications. Key players in this field include Massachusetts Institute of Technology (MIT), a pioneer in ferrofluid research, and TDK Corporation, which has been actively developing ferrofluid-based products. Other notable contributors include Delft University of Technology and the French National Center for Scientific Research (CNRS), indicating a strong academic presence in advancing ferrofluid technology.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced ferrofluid-based materials with enhanced magnetic and thermal properties. Their research focuses on creating nanostructured ferrofluids with improved stability and responsiveness to external magnetic fields[1]. These materials show potential in various applications, including heat transfer systems, magnetic seals, and biomedical devices. MIT's approach involves synthesizing custom magnetic nanoparticles and optimizing the carrier fluid composition to achieve desired rheological properties[3]. They have also explored the use of ferrofluids in energy harvesting devices, demonstrating the ability to convert mechanical energy into electrical energy through ferrofluid oscillations[5].

Strengths: Cutting-edge research in nanostructured ferrofluids, diverse application potential, strong interdisciplinary collaboration. Weaknesses: Potential scalability challenges for industrial production, high development costs.

TDK Corp.

Technical Solution: TDK has leveraged its expertise in magnetic materials to develop innovative ferrofluid-based products. They have focused on creating high-performance ferrofluids for use in electronic components, such as speakers and hard disk drives[10]. TDK's research includes the development of ferrofluids with improved thermal stability and magnetic properties, enabling their use in challenging environments. They have also explored the application of ferrofluids in sensors and actuators, particularly for automotive and industrial applications[11]. TDK's approach combines materials science with precision manufacturing techniques to produce consistent, high-quality ferrofluid products.

Strengths: Strong industrial application focus, established manufacturing capabilities, integration with existing product lines. Weaknesses: Potentially limited exploration of emerging applications outside current product areas, reliance on existing market demands.

Key Innovations

Magnetically deformable ferrofluids and mirrors

PatentInactiveUS20100277820A1

Innovation

- Coating magnetic particles with an organic ligand having a hydrophilic chain, such as 2-[2-(2-methoxyethoxy)ethoxy]acetic acid (MOEEAA), before suspending them in a polar carrier liquid, which allows for the deposition of a stable reflective layer and prevents particle aggregation, enabling the creation of magnetically deformable mirrors with improved stability and reflectivity.

ferrofluid

PatentPendingUS20220351887A1

Innovation

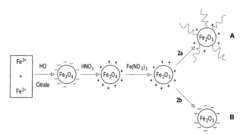

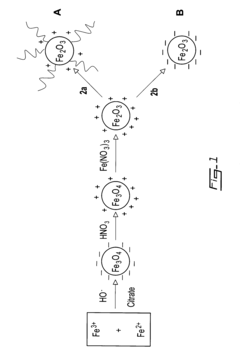

- A method involving a stock solution of Fe(II) and Fe(III) mixed with a base to form magnetic nanoparticles, followed by magnetic separation and washing, allowing for the production of ferrofluids in a semi-continuous and scalable process using only aqueous solutions, eliminating the need for organic solvents and high temperatures.

Environmental Impact

The environmental impact of ferrofluids in innovative material sciences is a critical aspect that requires thorough examination. These magnetic nanofluids, while offering remarkable potential for technological advancements, also pose unique environmental considerations. The production process of ferrofluids involves the synthesis of nanoparticles, which can be energy-intensive and may generate waste products. However, the small quantities typically required in applications can mitigate some of these concerns.

One of the primary environmental benefits of ferrofluids lies in their potential to enhance energy efficiency in various systems. For instance, in magnetic sealing applications, ferrofluids can reduce friction and wear, leading to longer-lasting components and decreased need for replacements. This reduction in material consumption and waste generation contributes positively to environmental sustainability. Additionally, ferrofluids' ability to improve heat transfer in cooling systems can lead to more energy-efficient electronic devices and industrial processes.

However, the potential release of nanoparticles into the environment raises concerns about their long-term ecological effects. While ferrofluids are typically contained within closed systems, accidental spills or improper disposal could lead to environmental contamination. The behavior of these nanoparticles in natural ecosystems is not fully understood, and there is a need for comprehensive studies on their potential bioaccumulation and effects on aquatic and terrestrial organisms.

The recyclability and end-of-life management of ferrofluid-containing products present both challenges and opportunities. On one hand, the magnetic properties of ferrofluids could facilitate their separation and recovery from waste streams, potentially enabling efficient recycling processes. On the other hand, the complex nature of ferrofluid-based materials may complicate traditional recycling methods, necessitating the development of specialized recycling technologies.

From a lifecycle perspective, the environmental impact of ferrofluids extends beyond their production and use phases. The extraction of raw materials, particularly rare earth elements often used in high-performance ferrofluids, can have significant environmental implications. Sustainable sourcing practices and the development of alternative materials could help address these concerns. Furthermore, the potential for ferrofluids to enable more efficient and durable products could lead to an overall reduction in resource consumption and waste generation throughout the product lifecycle.

As research in ferrofluid applications continues to expand, there is a growing emphasis on developing environmentally friendly formulations. This includes exploring bio-based carriers and surfactants, as well as investigating the use of more abundant and less environmentally impactful magnetic materials. Such advancements could significantly improve the environmental profile of ferrofluids, aligning their innovative potential with sustainability goals.

One of the primary environmental benefits of ferrofluids lies in their potential to enhance energy efficiency in various systems. For instance, in magnetic sealing applications, ferrofluids can reduce friction and wear, leading to longer-lasting components and decreased need for replacements. This reduction in material consumption and waste generation contributes positively to environmental sustainability. Additionally, ferrofluids' ability to improve heat transfer in cooling systems can lead to more energy-efficient electronic devices and industrial processes.

However, the potential release of nanoparticles into the environment raises concerns about their long-term ecological effects. While ferrofluids are typically contained within closed systems, accidental spills or improper disposal could lead to environmental contamination. The behavior of these nanoparticles in natural ecosystems is not fully understood, and there is a need for comprehensive studies on their potential bioaccumulation and effects on aquatic and terrestrial organisms.

The recyclability and end-of-life management of ferrofluid-containing products present both challenges and opportunities. On one hand, the magnetic properties of ferrofluids could facilitate their separation and recovery from waste streams, potentially enabling efficient recycling processes. On the other hand, the complex nature of ferrofluid-based materials may complicate traditional recycling methods, necessitating the development of specialized recycling technologies.

From a lifecycle perspective, the environmental impact of ferrofluids extends beyond their production and use phases. The extraction of raw materials, particularly rare earth elements often used in high-performance ferrofluids, can have significant environmental implications. Sustainable sourcing practices and the development of alternative materials could help address these concerns. Furthermore, the potential for ferrofluids to enable more efficient and durable products could lead to an overall reduction in resource consumption and waste generation throughout the product lifecycle.

As research in ferrofluid applications continues to expand, there is a growing emphasis on developing environmentally friendly formulations. This includes exploring bio-based carriers and surfactants, as well as investigating the use of more abundant and less environmentally impactful magnetic materials. Such advancements could significantly improve the environmental profile of ferrofluids, aligning their innovative potential with sustainability goals.

Intellectual Property

Ferrofluids, as a unique class of magnetic nanomaterials, have garnered significant attention in the field of material sciences due to their distinctive properties and potential applications. The intellectual property landscape surrounding ferrofluids is complex and rapidly evolving, reflecting the growing interest in this innovative material.

Patents related to ferrofluid technology cover a wide range of applications and manufacturing processes. Key areas of patent activity include the synthesis of ferrofluids with enhanced stability and magnetic properties, novel applications in biomedical fields such as targeted drug delivery and magnetic hyperthermia, and the development of advanced sensors and actuators utilizing ferrofluid properties. Major patent holders in this domain include both academic institutions and industrial players, with notable contributions from companies like Ferrotec Corporation and BASF SE.

The intellectual property surrounding ferrofluids extends beyond patents to include trade secrets and proprietary manufacturing techniques. Many companies have developed proprietary methods for producing high-quality ferrofluids with specific characteristics tailored to particular applications. These trade secrets often involve the precise composition of surfactants used to stabilize the magnetic nanoparticles and prevent agglomeration, as well as techniques for controlling particle size distribution and magnetic properties.

Licensing agreements play a crucial role in the commercialization of ferrofluid technology. Several universities and research institutions have established licensing partnerships with industrial entities to facilitate the transfer of ferrofluid-related intellectual property. These agreements often cover specific applications or manufacturing processes, allowing companies to leverage academic research for commercial purposes while providing funding for further research and development.

The global nature of ferrofluid research and development has led to a complex international patent landscape. Cross-border collaborations and multinational research efforts have resulted in patents being filed in multiple jurisdictions, necessitating careful consideration of international intellectual property laws and regulations. This complexity is further compounded by the interdisciplinary nature of ferrofluid applications, which span fields such as materials science, physics, chemistry, and bioengineering.

As the field of ferrofluid technology continues to advance, intellectual property strategies are likely to evolve. There is a growing trend towards open innovation and collaborative research in certain areas, particularly in fundamental science and early-stage applications. However, as commercial applications become more mature, companies are expected to increasingly focus on building strong patent portfolios to protect their market positions and secure competitive advantages.

Patents related to ferrofluid technology cover a wide range of applications and manufacturing processes. Key areas of patent activity include the synthesis of ferrofluids with enhanced stability and magnetic properties, novel applications in biomedical fields such as targeted drug delivery and magnetic hyperthermia, and the development of advanced sensors and actuators utilizing ferrofluid properties. Major patent holders in this domain include both academic institutions and industrial players, with notable contributions from companies like Ferrotec Corporation and BASF SE.

The intellectual property surrounding ferrofluids extends beyond patents to include trade secrets and proprietary manufacturing techniques. Many companies have developed proprietary methods for producing high-quality ferrofluids with specific characteristics tailored to particular applications. These trade secrets often involve the precise composition of surfactants used to stabilize the magnetic nanoparticles and prevent agglomeration, as well as techniques for controlling particle size distribution and magnetic properties.

Licensing agreements play a crucial role in the commercialization of ferrofluid technology. Several universities and research institutions have established licensing partnerships with industrial entities to facilitate the transfer of ferrofluid-related intellectual property. These agreements often cover specific applications or manufacturing processes, allowing companies to leverage academic research for commercial purposes while providing funding for further research and development.

The global nature of ferrofluid research and development has led to a complex international patent landscape. Cross-border collaborations and multinational research efforts have resulted in patents being filed in multiple jurisdictions, necessitating careful consideration of international intellectual property laws and regulations. This complexity is further compounded by the interdisciplinary nature of ferrofluid applications, which span fields such as materials science, physics, chemistry, and bioengineering.

As the field of ferrofluid technology continues to advance, intellectual property strategies are likely to evolve. There is a growing trend towards open innovation and collaborative research in certain areas, particularly in fundamental science and early-stage applications. However, as commercial applications become more mature, companies are expected to increasingly focus on building strong patent portfolios to protect their market positions and secure competitive advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!