Evaluating Ferrofluid's Efficiency in Strategic Product Lifecycles

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid Technology Evolution and Objectives

Ferrofluids, first developed in the 1960s by NASA, have undergone significant evolution in their composition, properties, and applications. Initially conceived for controlling liquids in zero gravity, these magnetic nanofluids have since found their way into various industrial and consumer products. The technology's progression has been marked by advancements in nanoparticle synthesis, surfactant chemistry, and carrier fluid optimization.

The primary objective in evaluating ferrofluid efficiency in strategic product lifecycles is to enhance their performance, stability, and versatility across diverse applications. This involves improving their magnetic responsiveness, thermal properties, and long-term stability under various environmental conditions. Additionally, there is a focus on developing environmentally friendly and cost-effective ferrofluid formulations to broaden their industrial adoption.

Recent technological advancements have led to the creation of smart ferrofluids with tunable properties, opening up new possibilities in fields such as biomedicine, energy harvesting, and advanced manufacturing. The integration of ferrofluids with other emerging technologies, such as microfluidics and 3D printing, is also being explored to create novel hybrid systems with enhanced functionalities.

One of the key trends in ferrofluid technology is the development of biocompatible formulations for medical applications. These specialized ferrofluids are being engineered for targeted drug delivery, hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). The goal is to create highly efficient, non-toxic ferrofluids that can navigate through the human body with precision.

In the industrial sector, there is a growing interest in using ferrofluids for energy-efficient cooling systems, particularly in electronics and high-performance computing. The objective is to leverage the unique heat transfer properties of ferrofluids to develop more compact and effective thermal management solutions. This aligns with the broader trend of miniaturization and energy efficiency in technology products.

Another area of focus is the development of ferrofluid-based sensors and actuators for various applications, including automotive systems, robotics, and aerospace. The aim is to create highly responsive and precise control mechanisms that can operate in challenging environments. This involves optimizing the magnetic and rheological properties of ferrofluids to achieve faster response times and greater force output.

As we look towards the future, the objectives for ferrofluid technology include enhancing their stability in extreme conditions, improving their magnetic saturation limits, and developing new synthesis methods for large-scale production. There is also a push towards creating multi-functional ferrofluids that can simultaneously perform multiple tasks, such as sensing, actuation, and self-healing in a single system.

The primary objective in evaluating ferrofluid efficiency in strategic product lifecycles is to enhance their performance, stability, and versatility across diverse applications. This involves improving their magnetic responsiveness, thermal properties, and long-term stability under various environmental conditions. Additionally, there is a focus on developing environmentally friendly and cost-effective ferrofluid formulations to broaden their industrial adoption.

Recent technological advancements have led to the creation of smart ferrofluids with tunable properties, opening up new possibilities in fields such as biomedicine, energy harvesting, and advanced manufacturing. The integration of ferrofluids with other emerging technologies, such as microfluidics and 3D printing, is also being explored to create novel hybrid systems with enhanced functionalities.

One of the key trends in ferrofluid technology is the development of biocompatible formulations for medical applications. These specialized ferrofluids are being engineered for targeted drug delivery, hyperthermia treatment of cancer, and as contrast agents in magnetic resonance imaging (MRI). The goal is to create highly efficient, non-toxic ferrofluids that can navigate through the human body with precision.

In the industrial sector, there is a growing interest in using ferrofluids for energy-efficient cooling systems, particularly in electronics and high-performance computing. The objective is to leverage the unique heat transfer properties of ferrofluids to develop more compact and effective thermal management solutions. This aligns with the broader trend of miniaturization and energy efficiency in technology products.

Another area of focus is the development of ferrofluid-based sensors and actuators for various applications, including automotive systems, robotics, and aerospace. The aim is to create highly responsive and precise control mechanisms that can operate in challenging environments. This involves optimizing the magnetic and rheological properties of ferrofluids to achieve faster response times and greater force output.

As we look towards the future, the objectives for ferrofluid technology include enhancing their stability in extreme conditions, improving their magnetic saturation limits, and developing new synthesis methods for large-scale production. There is also a push towards creating multi-functional ferrofluids that can simultaneously perform multiple tasks, such as sensing, actuation, and self-healing in a single system.

Market Demand Analysis for Ferrofluid Applications

The market demand for ferrofluid applications has been steadily growing across various industries, driven by its unique properties and versatile applications. In the electronics sector, ferrofluids are increasingly utilized in speakers and hard drives, enhancing their performance and durability. The automotive industry has shown significant interest in ferrofluids for their potential in improving shock absorbers and sealing systems, leading to more efficient and reliable vehicle components.

Medical applications of ferrofluids have garnered substantial attention, particularly in targeted drug delivery and magnetic hyperthermia for cancer treatment. This sector is expected to witness rapid growth as research progresses and clinical trials demonstrate promising results. The aerospace industry has also recognized the potential of ferrofluids in developing advanced cooling systems and vibration dampers for spacecraft and satellites.

In the energy sector, ferrofluids are being explored for their potential in enhancing the efficiency of solar thermal power plants and improving heat transfer in various industrial processes. This application is likely to see increased demand as the push for renewable energy sources intensifies globally.

The global ferrofluid market size was valued at approximately $57 million in 2020 and is projected to reach $73 million by 2025, growing at a CAGR of around 5.1% during the forecast period. North America currently holds the largest market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing industrialization and technological advancements in countries like China, Japan, and South Korea.

Key factors driving market demand include the growing adoption of ferrofluids in miniaturized devices, increasing research and development activities, and the expansion of end-use industries. However, challenges such as high production costs and limited awareness about ferrofluid applications in some regions may hinder market growth to some extent.

The COVID-19 pandemic initially caused disruptions in the supply chain and manufacturing processes, temporarily impacting market growth. However, the increased focus on healthcare and medical research has created new opportunities for ferrofluid applications, particularly in diagnostic tools and drug delivery systems.

As industries continue to seek innovative solutions for improving product efficiency and performance, the demand for ferrofluids is expected to rise. Emerging applications in areas such as environmental remediation, smart materials, and nanotechnology are likely to further expand the market potential in the coming years.

Medical applications of ferrofluids have garnered substantial attention, particularly in targeted drug delivery and magnetic hyperthermia for cancer treatment. This sector is expected to witness rapid growth as research progresses and clinical trials demonstrate promising results. The aerospace industry has also recognized the potential of ferrofluids in developing advanced cooling systems and vibration dampers for spacecraft and satellites.

In the energy sector, ferrofluids are being explored for their potential in enhancing the efficiency of solar thermal power plants and improving heat transfer in various industrial processes. This application is likely to see increased demand as the push for renewable energy sources intensifies globally.

The global ferrofluid market size was valued at approximately $57 million in 2020 and is projected to reach $73 million by 2025, growing at a CAGR of around 5.1% during the forecast period. North America currently holds the largest market share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate due to increasing industrialization and technological advancements in countries like China, Japan, and South Korea.

Key factors driving market demand include the growing adoption of ferrofluids in miniaturized devices, increasing research and development activities, and the expansion of end-use industries. However, challenges such as high production costs and limited awareness about ferrofluid applications in some regions may hinder market growth to some extent.

The COVID-19 pandemic initially caused disruptions in the supply chain and manufacturing processes, temporarily impacting market growth. However, the increased focus on healthcare and medical research has created new opportunities for ferrofluid applications, particularly in diagnostic tools and drug delivery systems.

As industries continue to seek innovative solutions for improving product efficiency and performance, the demand for ferrofluids is expected to rise. Emerging applications in areas such as environmental remediation, smart materials, and nanotechnology are likely to further expand the market potential in the coming years.

Current Challenges in Ferrofluid Efficiency

Despite the promising potential of ferrofluids in various applications, several challenges currently hinder their widespread adoption and efficiency in strategic product lifecycles. One of the primary obstacles is the long-term stability of ferrofluids. Over time, these magnetic nanofluids tend to agglomerate, leading to a reduction in their magnetic responsiveness and overall performance. This instability can significantly impact the lifespan and reliability of products incorporating ferrofluids, particularly in applications requiring sustained performance over extended periods.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving consistent and predictable responses across different operational conditions remains difficult. This unpredictability can lead to inefficiencies in energy transfer and reduced performance in applications such as heat transfer systems, damping mechanisms, and sealing technologies.

The environmental impact and biocompatibility of ferrofluids also present significant concerns. Many ferrofluids contain synthetic oil-based carriers or potentially toxic nanoparticles, which can pose risks in case of leakage or disposal. This limitation restricts their use in environmentally sensitive applications or in products that may come into contact with living organisms, thereby narrowing their potential market and application scope.

Manufacturing scalability and cost-effectiveness represent another set of challenges. The production of high-quality, uniform ferrofluids at large scales remains technically demanding and expensive. This factor significantly impacts the economic viability of incorporating ferrofluids into mass-produced consumer products or industrial applications, limiting their adoption to niche, high-value sectors.

Furthermore, the integration of ferrofluids into existing product designs and manufacturing processes poses substantial engineering challenges. Many potential applications require custom-designed magnetic field generators, specialized containment systems, and novel interfacing mechanisms to effectively harness the unique properties of ferrofluids. These requirements often necessitate significant redesigns of existing products or the development of entirely new manufacturing processes, adding complexity and cost to product development cycles.

Lastly, the lack of standardized testing and characterization methods for ferrofluids hampers their efficient evaluation and comparison across different formulations and applications. This absence of universal benchmarks makes it difficult for product developers to accurately assess the performance and suitability of different ferrofluid options for their specific needs, potentially leading to suboptimal choices or missed opportunities for innovation.

Another critical challenge lies in the precise control of ferrofluid behavior under varying magnetic field strengths and configurations. While ferrofluids respond readily to magnetic fields, achieving consistent and predictable responses across different operational conditions remains difficult. This unpredictability can lead to inefficiencies in energy transfer and reduced performance in applications such as heat transfer systems, damping mechanisms, and sealing technologies.

The environmental impact and biocompatibility of ferrofluids also present significant concerns. Many ferrofluids contain synthetic oil-based carriers or potentially toxic nanoparticles, which can pose risks in case of leakage or disposal. This limitation restricts their use in environmentally sensitive applications or in products that may come into contact with living organisms, thereby narrowing their potential market and application scope.

Manufacturing scalability and cost-effectiveness represent another set of challenges. The production of high-quality, uniform ferrofluids at large scales remains technically demanding and expensive. This factor significantly impacts the economic viability of incorporating ferrofluids into mass-produced consumer products or industrial applications, limiting their adoption to niche, high-value sectors.

Furthermore, the integration of ferrofluids into existing product designs and manufacturing processes poses substantial engineering challenges. Many potential applications require custom-designed magnetic field generators, specialized containment systems, and novel interfacing mechanisms to effectively harness the unique properties of ferrofluids. These requirements often necessitate significant redesigns of existing products or the development of entirely new manufacturing processes, adding complexity and cost to product development cycles.

Lastly, the lack of standardized testing and characterization methods for ferrofluids hampers their efficient evaluation and comparison across different formulations and applications. This absence of universal benchmarks makes it difficult for product developers to accurately assess the performance and suitability of different ferrofluid options for their specific needs, potentially leading to suboptimal choices or missed opportunities for innovation.

Existing Ferrofluid Efficiency Solutions

01 Ferrofluid sealing systems

Ferrofluid seals are used to improve efficiency in various mechanical systems. These seals utilize the unique properties of ferrofluids to create a barrier that prevents leakage while reducing friction. The seals can be applied in rotating shaft assemblies, bearings, and other moving parts to enhance overall system performance and longevity.- Ferrofluid sealing systems: Ferrofluids are used in sealing systems to improve efficiency and prevent leakage in various applications. These systems utilize the magnetic properties of ferrofluids to create a dynamic seal that can adapt to different pressures and temperatures, enhancing overall performance and reliability.

- Ferrofluid-based heat transfer systems: Ferrofluids are employed in heat transfer applications to enhance thermal management efficiency. By manipulating the magnetic properties of ferrofluids, these systems can improve heat dissipation and cooling in various devices, leading to better overall performance and energy efficiency.

- Ferrofluid-enhanced bearings and dampers: Ferrofluids are utilized in bearings and damping systems to reduce friction and improve efficiency. By incorporating ferrofluids into these components, designers can achieve better performance, longer lifespan, and reduced energy consumption in various mechanical systems.

- Ferrofluid-based sensors and actuators: Ferrofluids are employed in the development of highly sensitive sensors and efficient actuators. These devices leverage the unique properties of ferrofluids to achieve improved accuracy, responsiveness, and energy efficiency in various applications, including position sensing and precision control systems.

- Ferrofluid synthesis and composition optimization: Research focuses on improving ferrofluid efficiency through advanced synthesis methods and optimized compositions. By fine-tuning the magnetic particle size, surfactant selection, and carrier fluid properties, researchers aim to enhance the overall performance and stability of ferrofluids for various applications.

02 Ferrofluid-based heat transfer systems

Ferrofluids are employed in heat transfer applications to improve thermal management efficiency. By utilizing the magnetic properties of ferrofluids, these systems can enhance heat dissipation in electronic devices, cooling systems, and other thermal management applications. The controlled movement of ferrofluids under magnetic fields allows for more effective heat transfer and improved overall system efficiency.Expand Specific Solutions03 Ferrofluid-enhanced bearings and lubricants

Ferrofluids are used to improve the efficiency of bearings and lubrication systems. By incorporating ferrofluids into these components, friction can be reduced, and wear resistance can be increased. This leads to improved performance, longer component life, and reduced energy consumption in various mechanical systems.Expand Specific Solutions04 Ferrofluid-based energy harvesting and conversion

Ferrofluids are utilized in energy harvesting and conversion systems to improve efficiency. These applications include magnetohydrodynamic generators, energy harvesters that convert mechanical vibrations into electrical energy, and other novel energy conversion devices. The unique properties of ferrofluids allow for enhanced energy capture and conversion in these systems.Expand Specific Solutions05 Ferrofluid-enhanced sensors and actuators

Ferrofluids are employed to improve the efficiency and sensitivity of various sensors and actuators. By incorporating ferrofluids into these devices, their response time, accuracy, and overall performance can be enhanced. Applications include accelerometers, pressure sensors, and precision positioning systems, where the unique properties of ferrofluids contribute to improved efficiency and functionality.Expand Specific Solutions

Key Players in Ferrofluid Industry

The ferrofluid efficiency evaluation in strategic product lifecycles is in an emerging stage, with the market showing promising growth potential. The technology's maturity varies across industries, with companies like L'Oréal SA, Siemens Corp., and Robert Bosch GmbH leading in application development. Research institutions such as Yale University and Auburn University are contributing to fundamental advancements. The competitive landscape is diverse, including established corporations and specialized firms like Ferrotec (USA) Corp. and Urban Mining Corp. B.V. As the technology evolves, collaborations between academia and industry players are likely to drive innovation and market expansion in sectors ranging from cosmetics to industrial applications.

Siemens Corp.

Technical Solution: Siemens has been investigating the use of ferrofluids in improving the efficiency and lifespan of various industrial products. Their approach includes the development of ferrofluid-based sealing systems for rotating shafts in large industrial machinery, significantly reducing wear and extending equipment life[7]. Siemens has also explored the use of ferrofluids in transformer cooling systems, potentially improving heat dissipation and extending the operational life of power distribution equipment[8]. In the field of medical imaging, Siemens has researched ferrofluid contrast agents for MRI, which could enhance diagnostic capabilities and extend the useful life of imaging equipment through improved resolution and reduced wear[9].

Strengths: Extensive industrial expertise, global reach for implementation, synergy with existing product lines. Weaknesses: May require significant investment in retooling existing manufacturing processes.

Robert Bosch GmbH

Technical Solution: Bosch has been exploring ferrofluid applications to enhance the efficiency and longevity of automotive and industrial products. Their research includes the development of ferrofluid-based damping systems for vehicle suspensions, potentially improving ride quality and extending the life of suspension components[10]. Bosch has also investigated the use of ferrofluids in precision manufacturing processes, such as in polishing and finishing operations, which could extend the life of cutting tools and improve product quality[11]. Additionally, they have explored ferrofluid applications in sensor technologies, particularly for automotive safety systems, potentially increasing the durability and reliability of these critical components[12].

Strengths: Strong presence in automotive and industrial sectors, established manufacturing capabilities, potential for rapid adoption. Weaknesses: May face challenges in integrating ferrofluid technology with existing product lines.

Core Innovations in Ferrofluid Technology

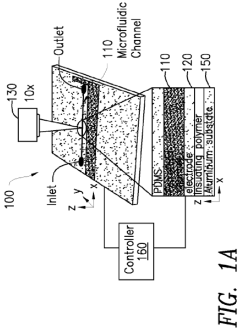

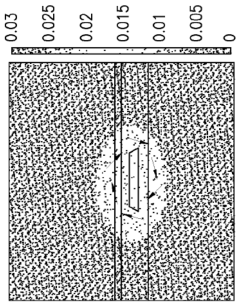

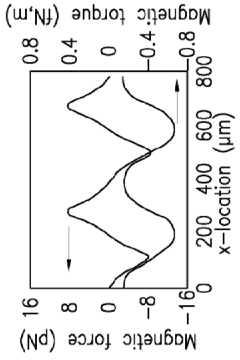

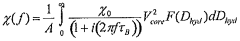

Microfluidic processing of target species in ferrofluids

PatentInactiveAU2019202374A1

Innovation

- A microfluidic device and system using biocompatible ferrofluids with a microfluidic channel and electrodes to generate a magnetic field pattern, allowing for the separation of target species based on size, shape, and elasticity, with controllable current amplitudes, frequencies, and phases, enabling efficient and rapid separation of cells.

Microfluidic processing of target species in ferrofluids

PatentWO2012057878A1

Innovation

- A microfluidic platform using biocompatible ferrofluids with a microfluidic channel and electrodes that generate a magnetic field pattern to separate target species based on size, shape, and elasticity, allowing for efficient and rapid separation of cells without the need for labels or electromagnetic fields.

Environmental Impact of Ferrofluid Usage

The environmental impact of ferrofluid usage in strategic product lifecycles is a critical consideration for sustainable development and responsible innovation. Ferrofluids, composed of nanoscale magnetic particles suspended in a carrier fluid, have found applications in various industries, including electronics, mechanical engineering, and biomedical technologies. However, their widespread adoption raises concerns about potential environmental consequences throughout their lifecycle.

During the production phase, the synthesis of ferrofluids involves the use of chemicals and energy-intensive processes. The manufacturing of nanoparticles, typically iron oxides, requires careful control of reaction conditions and may generate hazardous waste. Additionally, the production of surfactants used to stabilize the magnetic particles in the carrier fluid can contribute to water pollution if not properly managed. These environmental impacts can be mitigated through the implementation of green chemistry principles and closed-loop manufacturing systems.

In the application phase, ferrofluids generally exhibit low environmental risk due to their stable nature and containment within sealed systems. However, potential leaks or improper disposal of ferrofluid-containing devices could lead to localized contamination. The magnetic properties of ferrofluids may also interfere with natural magnetic fields, potentially affecting wildlife navigation or sensitive ecosystems if released into the environment. Proper handling, maintenance, and disposal protocols are essential to minimize these risks.

End-of-life considerations for ferrofluid-based products present both challenges and opportunities. The recovery and recycling of magnetic nanoparticles from spent ferrofluids can reduce the demand for raw materials and minimize waste. However, the separation process may require additional energy and chemical inputs. Innovative recycling technologies, such as magnetic separation techniques, are being developed to improve the efficiency and environmental sustainability of ferrofluid recovery.

Long-term environmental effects of ferrofluids remain an area of ongoing research. The potential for nanoparticle accumulation in soil and water systems, as well as their interactions with biological organisms, requires careful monitoring and assessment. Studies have shown that some magnetic nanoparticles can be biodegraded or transformed in the environment, but the fate and behavior of ferrofluids in complex ecosystems are not fully understood.

To address these environmental concerns, lifecycle assessments (LCAs) of ferrofluid-based products are crucial. LCAs can identify hotspots of environmental impact and guide the development of more sustainable ferrofluid formulations and applications. Furthermore, the adoption of eco-design principles in product development can minimize the environmental footprint of ferrofluid technologies from conception to disposal.

During the production phase, the synthesis of ferrofluids involves the use of chemicals and energy-intensive processes. The manufacturing of nanoparticles, typically iron oxides, requires careful control of reaction conditions and may generate hazardous waste. Additionally, the production of surfactants used to stabilize the magnetic particles in the carrier fluid can contribute to water pollution if not properly managed. These environmental impacts can be mitigated through the implementation of green chemistry principles and closed-loop manufacturing systems.

In the application phase, ferrofluids generally exhibit low environmental risk due to their stable nature and containment within sealed systems. However, potential leaks or improper disposal of ferrofluid-containing devices could lead to localized contamination. The magnetic properties of ferrofluids may also interfere with natural magnetic fields, potentially affecting wildlife navigation or sensitive ecosystems if released into the environment. Proper handling, maintenance, and disposal protocols are essential to minimize these risks.

End-of-life considerations for ferrofluid-based products present both challenges and opportunities. The recovery and recycling of magnetic nanoparticles from spent ferrofluids can reduce the demand for raw materials and minimize waste. However, the separation process may require additional energy and chemical inputs. Innovative recycling technologies, such as magnetic separation techniques, are being developed to improve the efficiency and environmental sustainability of ferrofluid recovery.

Long-term environmental effects of ferrofluids remain an area of ongoing research. The potential for nanoparticle accumulation in soil and water systems, as well as their interactions with biological organisms, requires careful monitoring and assessment. Studies have shown that some magnetic nanoparticles can be biodegraded or transformed in the environment, but the fate and behavior of ferrofluids in complex ecosystems are not fully understood.

To address these environmental concerns, lifecycle assessments (LCAs) of ferrofluid-based products are crucial. LCAs can identify hotspots of environmental impact and guide the development of more sustainable ferrofluid formulations and applications. Furthermore, the adoption of eco-design principles in product development can minimize the environmental footprint of ferrofluid technologies from conception to disposal.

Lifecycle Assessment of Ferrofluid Products

Lifecycle Assessment of Ferrofluid Products is a critical component in evaluating the efficiency and sustainability of ferrofluid applications across various industries. This assessment encompasses the entire lifespan of ferrofluid-based products, from raw material extraction to end-of-life disposal or recycling.

The production phase of ferrofluid products involves the synthesis of magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. This process requires careful control of particle size distribution and surface modification to ensure stability and performance. The environmental impact of nanoparticle synthesis, including energy consumption and potential emissions, must be carefully considered.

During the use phase, ferrofluid products demonstrate unique properties that enable a wide range of applications. In electronic devices, ferrofluids are used for heat dissipation and vibration damping, potentially extending product lifespans. In medical applications, ferrofluids show promise in targeted drug delivery and magnetic hyperthermia for cancer treatment, offering potential improvements in patient outcomes and treatment efficiency.

The longevity of ferrofluid products varies significantly depending on the application. In industrial settings, such as rotary seals and dampers, ferrofluids can maintain their performance for extended periods, reducing the need for frequent replacements. However, in consumer electronics or medical devices, the overall product lifecycle may be shorter due to rapid technological advancements or regulatory requirements.

End-of-life considerations for ferrofluid products present unique challenges. The magnetic properties of ferrofluids necessitate specialized recycling processes to recover valuable materials and prevent environmental contamination. Developing efficient recycling methods for ferrofluid-containing products is crucial for improving the overall sustainability of these technologies.

Comparative analysis of ferrofluid products against conventional alternatives is essential in assessing their overall efficiency. For instance, in cooling applications, ferrofluid-based systems may offer improved heat transfer capabilities and energy efficiency compared to traditional cooling methods. However, the potential environmental impact of nanoparticle production and disposal must be weighed against these benefits.

Future developments in ferrofluid technology, such as bio-based carrier fluids or more easily recyclable nanoparticles, could significantly enhance the sustainability profile of these products. Ongoing research into green synthesis methods and improved recycling techniques will play a crucial role in optimizing the lifecycle efficiency of ferrofluid applications.

The production phase of ferrofluid products involves the synthesis of magnetic nanoparticles, typically iron oxide, suspended in a carrier fluid. This process requires careful control of particle size distribution and surface modification to ensure stability and performance. The environmental impact of nanoparticle synthesis, including energy consumption and potential emissions, must be carefully considered.

During the use phase, ferrofluid products demonstrate unique properties that enable a wide range of applications. In electronic devices, ferrofluids are used for heat dissipation and vibration damping, potentially extending product lifespans. In medical applications, ferrofluids show promise in targeted drug delivery and magnetic hyperthermia for cancer treatment, offering potential improvements in patient outcomes and treatment efficiency.

The longevity of ferrofluid products varies significantly depending on the application. In industrial settings, such as rotary seals and dampers, ferrofluids can maintain their performance for extended periods, reducing the need for frequent replacements. However, in consumer electronics or medical devices, the overall product lifecycle may be shorter due to rapid technological advancements or regulatory requirements.

End-of-life considerations for ferrofluid products present unique challenges. The magnetic properties of ferrofluids necessitate specialized recycling processes to recover valuable materials and prevent environmental contamination. Developing efficient recycling methods for ferrofluid-containing products is crucial for improving the overall sustainability of these technologies.

Comparative analysis of ferrofluid products against conventional alternatives is essential in assessing their overall efficiency. For instance, in cooling applications, ferrofluid-based systems may offer improved heat transfer capabilities and energy efficiency compared to traditional cooling methods. However, the potential environmental impact of nanoparticle production and disposal must be weighed against these benefits.

Future developments in ferrofluid technology, such as bio-based carrier fluids or more easily recyclable nanoparticles, could significantly enhance the sustainability profile of these products. Ongoing research into green synthesis methods and improved recycling techniques will play a crucial role in optimizing the lifecycle efficiency of ferrofluid applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!