Analysis of Antibacterial Coating Impact on Baking Facilities

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Background and Objectives

Antibacterial coatings for food processing equipment have evolved significantly over the past decades, transitioning from simple protective layers to sophisticated antimicrobial systems. The historical development began in the 1960s with basic polymer coatings, progressing through the integration of silver ions in the 1980s, and advancing to today's nanotechnology-enhanced solutions. This technological progression has been driven by increasing food safety regulations, consumer demand for safer products, and industry needs for more efficient production processes.

The baking industry presents unique challenges for antibacterial coating applications due to the extreme temperature fluctuations, high humidity environments, and constant mechanical stress on equipment surfaces. Traditional coating technologies often fail under these conditions, leading to bacterial contamination risks and reduced operational efficiency. Recent outbreaks of foodborne illnesses traced to bakery products have further highlighted the critical need for advanced antibacterial solutions specifically designed for baking facilities.

Current antibacterial coating technologies employ various mechanisms to combat microbial growth, including contact-killing surfaces, antimicrobial agent release systems, and anti-adhesion properties. The most promising developments incorporate nanomaterials such as silver nanoparticles, copper compounds, and titanium dioxide, which demonstrate superior antimicrobial efficacy while withstanding the harsh conditions of baking environments. These advanced coatings aim to maintain their antibacterial properties throughout extended operational periods without compromising food safety or quality.

The global market for antibacterial coatings in food processing has experienced a compound annual growth rate of approximately 6.8% since 2015, with projections indicating continued expansion as regulatory requirements become more stringent. Specifically within the baking sector, adoption rates have increased by 12% annually over the past three years, reflecting the industry's recognition of these technologies' value proposition.

The primary objectives of this technical research are threefold: first, to comprehensively evaluate the effectiveness of current antibacterial coating technologies in reducing microbial contamination within baking facilities; second, to analyze the impact of these coatings on operational efficiency, maintenance requirements, and equipment lifespan; and third, to identify emerging coating technologies that may offer superior performance characteristics for the specific challenges of baking environments.

This research aims to establish quantifiable metrics for assessing coating performance under various baking conditions, develop implementation guidelines for different types of baking equipment, and create a technological roadmap for future innovations in this field. The ultimate goal is to provide actionable insights that enable baking facilities to make informed decisions regarding antibacterial coating adoption and implementation strategies.

The baking industry presents unique challenges for antibacterial coating applications due to the extreme temperature fluctuations, high humidity environments, and constant mechanical stress on equipment surfaces. Traditional coating technologies often fail under these conditions, leading to bacterial contamination risks and reduced operational efficiency. Recent outbreaks of foodborne illnesses traced to bakery products have further highlighted the critical need for advanced antibacterial solutions specifically designed for baking facilities.

Current antibacterial coating technologies employ various mechanisms to combat microbial growth, including contact-killing surfaces, antimicrobial agent release systems, and anti-adhesion properties. The most promising developments incorporate nanomaterials such as silver nanoparticles, copper compounds, and titanium dioxide, which demonstrate superior antimicrobial efficacy while withstanding the harsh conditions of baking environments. These advanced coatings aim to maintain their antibacterial properties throughout extended operational periods without compromising food safety or quality.

The global market for antibacterial coatings in food processing has experienced a compound annual growth rate of approximately 6.8% since 2015, with projections indicating continued expansion as regulatory requirements become more stringent. Specifically within the baking sector, adoption rates have increased by 12% annually over the past three years, reflecting the industry's recognition of these technologies' value proposition.

The primary objectives of this technical research are threefold: first, to comprehensively evaluate the effectiveness of current antibacterial coating technologies in reducing microbial contamination within baking facilities; second, to analyze the impact of these coatings on operational efficiency, maintenance requirements, and equipment lifespan; and third, to identify emerging coating technologies that may offer superior performance characteristics for the specific challenges of baking environments.

This research aims to establish quantifiable metrics for assessing coating performance under various baking conditions, develop implementation guidelines for different types of baking equipment, and create a technological roadmap for future innovations in this field. The ultimate goal is to provide actionable insights that enable baking facilities to make informed decisions regarding antibacterial coating adoption and implementation strategies.

Market Demand Analysis for Food Safety Solutions

The global food safety solutions market has witnessed significant growth in recent years, driven primarily by increasing consumer awareness and stringent regulatory frameworks. The demand for antibacterial coatings in baking facilities specifically has surged as food manufacturers seek comprehensive approaches to minimize contamination risks and extend product shelf life. Current market valuations indicate the global food safety technology market exceeds $20 billion, with antibacterial solutions representing approximately 15% of this segment.

Consumer expectations regarding food safety have evolved dramatically, with surveys indicating that over 80% of consumers now consider safety certifications and hygiene practices when making purchasing decisions. This shift in consumer behavior has created substantial market pull for innovations in antibacterial technologies applicable to food production environments, particularly in baking facilities where temperature fluctuations and moisture levels create ideal conditions for bacterial proliferation.

Regulatory pressures have simultaneously intensified across major markets. The FDA's Food Safety Modernization Act in the United States, the European Union's General Food Law Regulation, and China's revised Food Safety Law all emphasize preventative approaches to contamination. These regulatory frameworks have effectively transformed antibacterial coatings from optional enhancements to essential compliance components for many baking operations, creating a stable demand foundation.

Market segmentation analysis reveals particularly strong growth in demand from industrial bakeries and large-scale production facilities, where the economic impact of contamination incidents can be catastrophic. These operations typically seek integrated antibacterial solutions that can withstand high-temperature baking environments while maintaining efficacy during cooling and packaging phases. The quick-service restaurant sector represents another high-growth segment, with demand for antibacterial coatings increasing 25% annually as chains implement visible food safety measures to reassure consumers.

Regional market analysis indicates North America currently leads in adoption of advanced antibacterial coating technologies, accounting for 38% of global market share. However, the Asia-Pacific region demonstrates the highest growth rate at 12.3% annually, driven by rapid industrialization of food production and increasing regulatory sophistication in countries like China, India, and Vietnam.

Economic analysis of implementation costs versus contamination prevention benefits suggests a compelling return on investment for baking facilities. Case studies indicate facilities implementing comprehensive antibacterial coating systems typically recover initial investments within 18-24 months through reduced product loss, extended equipment lifespan, and decreased cleaning chemical usage. This favorable economic equation continues to drive market expansion beyond regulatory compliance motivations.

Consumer expectations regarding food safety have evolved dramatically, with surveys indicating that over 80% of consumers now consider safety certifications and hygiene practices when making purchasing decisions. This shift in consumer behavior has created substantial market pull for innovations in antibacterial technologies applicable to food production environments, particularly in baking facilities where temperature fluctuations and moisture levels create ideal conditions for bacterial proliferation.

Regulatory pressures have simultaneously intensified across major markets. The FDA's Food Safety Modernization Act in the United States, the European Union's General Food Law Regulation, and China's revised Food Safety Law all emphasize preventative approaches to contamination. These regulatory frameworks have effectively transformed antibacterial coatings from optional enhancements to essential compliance components for many baking operations, creating a stable demand foundation.

Market segmentation analysis reveals particularly strong growth in demand from industrial bakeries and large-scale production facilities, where the economic impact of contamination incidents can be catastrophic. These operations typically seek integrated antibacterial solutions that can withstand high-temperature baking environments while maintaining efficacy during cooling and packaging phases. The quick-service restaurant sector represents another high-growth segment, with demand for antibacterial coatings increasing 25% annually as chains implement visible food safety measures to reassure consumers.

Regional market analysis indicates North America currently leads in adoption of advanced antibacterial coating technologies, accounting for 38% of global market share. However, the Asia-Pacific region demonstrates the highest growth rate at 12.3% annually, driven by rapid industrialization of food production and increasing regulatory sophistication in countries like China, India, and Vietnam.

Economic analysis of implementation costs versus contamination prevention benefits suggests a compelling return on investment for baking facilities. Case studies indicate facilities implementing comprehensive antibacterial coating systems typically recover initial investments within 18-24 months through reduced product loss, extended equipment lifespan, and decreased cleaning chemical usage. This favorable economic equation continues to drive market expansion beyond regulatory compliance motivations.

Current Status and Challenges in Antibacterial Surface Technology

The global antibacterial surface technology landscape has evolved significantly over the past decade, with applications expanding beyond healthcare into food processing industries, including baking facilities. Current antibacterial coating technologies primarily utilize silver nanoparticles, copper compounds, quaternary ammonium compounds, and photocatalytic materials like titanium dioxide. These technologies have demonstrated varying degrees of efficacy against common foodborne pathogens such as Salmonella, E. coli, and Listeria monocytogenes that pose significant risks in baking environments.

In baking facilities specifically, antibacterial surface technologies face unique challenges due to the high-temperature operations, frequent cleaning cycles, and constant exposure to food ingredients. Conventional antibacterial coatings often degrade under these harsh conditions, limiting their long-term effectiveness. Research indicates that approximately 60% of standard antibacterial coatings lose significant efficacy after 6-12 months in baking environments, necessitating frequent reapplication and increasing operational costs.

Technical limitations persist in developing coatings that maintain antimicrobial properties while withstanding temperatures exceeding 250°C, which are common in industrial baking processes. Current heat-resistant antibacterial technologies typically sacrifice either durability or antimicrobial efficacy. Additionally, concerns regarding migration of active antimicrobial agents into food products remain unresolved, with regulatory bodies worldwide implementing increasingly stringent safety standards.

Another significant challenge is the emergence of resistant microbial strains. Studies have documented instances where prolonged exposure to certain antibacterial surfaces has led to adaptive responses in microorganisms, potentially creating more resilient pathogens. This phenomenon is particularly concerning in food production environments where microbial contamination can directly impact consumer safety.

The geographical distribution of antibacterial surface technology development shows concentration in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading patent applications. However, implementation in baking facilities remains inconsistent globally, with adoption rates highest in regions with stringent food safety regulations.

Cost factors continue to impede widespread adoption, with advanced antibacterial coatings for industrial baking equipment costing 3-5 times more than standard surfaces. The return on investment calculations remain challenging for many bakery operations, particularly small to medium-sized enterprises, despite potential long-term benefits in reduced contamination incidents and extended equipment lifespan.

Environmental considerations present additional challenges, as some antibacterial compounds have been associated with ecological concerns when released during manufacturing or disposal processes. The industry is increasingly seeking sustainable alternatives that maintain efficacy while reducing environmental impact, though truly "green" solutions with industrial-grade performance remain elusive.

In baking facilities specifically, antibacterial surface technologies face unique challenges due to the high-temperature operations, frequent cleaning cycles, and constant exposure to food ingredients. Conventional antibacterial coatings often degrade under these harsh conditions, limiting their long-term effectiveness. Research indicates that approximately 60% of standard antibacterial coatings lose significant efficacy after 6-12 months in baking environments, necessitating frequent reapplication and increasing operational costs.

Technical limitations persist in developing coatings that maintain antimicrobial properties while withstanding temperatures exceeding 250°C, which are common in industrial baking processes. Current heat-resistant antibacterial technologies typically sacrifice either durability or antimicrobial efficacy. Additionally, concerns regarding migration of active antimicrobial agents into food products remain unresolved, with regulatory bodies worldwide implementing increasingly stringent safety standards.

Another significant challenge is the emergence of resistant microbial strains. Studies have documented instances where prolonged exposure to certain antibacterial surfaces has led to adaptive responses in microorganisms, potentially creating more resilient pathogens. This phenomenon is particularly concerning in food production environments where microbial contamination can directly impact consumer safety.

The geographical distribution of antibacterial surface technology development shows concentration in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading patent applications. However, implementation in baking facilities remains inconsistent globally, with adoption rates highest in regions with stringent food safety regulations.

Cost factors continue to impede widespread adoption, with advanced antibacterial coatings for industrial baking equipment costing 3-5 times more than standard surfaces. The return on investment calculations remain challenging for many bakery operations, particularly small to medium-sized enterprises, despite potential long-term benefits in reduced contamination incidents and extended equipment lifespan.

Environmental considerations present additional challenges, as some antibacterial compounds have been associated with ecological concerns when released during manufacturing or disposal processes. The industry is increasingly seeking sustainable alternatives that maintain efficacy while reducing environmental impact, though truly "green" solutions with industrial-grade performance remain elusive.

Current Technical Solutions for Baking Facility Protection

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize silver, copper, zinc, and other metals to provide antimicrobial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of microorganisms. Such coatings can be applied to various surfaces including medical devices, textiles, and industrial equipment to provide long-lasting protection against bacterial contamination.- Metal-based antibacterial coatings: Metal-based antibacterial coatings utilize silver, copper, zinc, and other metal ions or nanoparticles to provide antimicrobial properties. These metals disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of microorganisms. Such coatings can be applied to various surfaces including medical devices, textiles, and industrial equipment to provide long-lasting protection against bacterial contamination.

- Polymer-based antibacterial coatings: Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces resistant to bacterial colonization. These coatings can be designed with controlled release mechanisms that gradually dispense antibacterial compounds, or with covalently bound antimicrobial agents that provide contact-killing properties. The polymer matrix enhances durability while maintaining antibacterial efficacy over extended periods, making them suitable for healthcare settings, food processing equipment, and consumer products.

- Natural compound-based antibacterial coatings: Antibacterial coatings derived from natural compounds utilize plant extracts, essential oils, enzymes, and other biological materials to combat bacterial growth. These environmentally friendly alternatives offer antimicrobial properties through various mechanisms including disruption of cell membranes and inhibition of bacterial metabolism. Natural compound-based coatings address growing concerns about chemical resistance and environmental impact while providing effective protection against a wide range of pathogens.

- Multifunctional antibacterial coatings: Multifunctional antibacterial coatings combine antimicrobial properties with additional beneficial characteristics such as self-cleaning, anti-fouling, or enhanced durability. These advanced coatings often incorporate multiple active ingredients or utilize synergistic effects between components to achieve superior performance. Applications include medical implants that prevent infection while promoting tissue integration, or building materials that resist both microbial growth and environmental degradation.

- Smart responsive antibacterial coatings: Smart responsive antibacterial coatings activate or enhance their antimicrobial properties in response to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These intelligent systems can conserve antimicrobial agents during inactive periods and deliver targeted responses when bacterial threats are detected. This approach minimizes unnecessary antimicrobial release, reducing the risk of resistance development while maintaining effective protection against infection.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that resist bacterial colonization. These coatings can be designed to slowly release active ingredients or to have inherent antibacterial properties through positively charged functional groups that disrupt bacterial cell membranes. Applications include medical implants, food packaging, and high-touch surfaces where bacterial contamination is a concern.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Antibacterial coatings derived from natural compounds such as plant extracts, essential oils, and chitosan offer environmentally friendly alternatives to synthetic antimicrobials. These coatings harness the inherent antimicrobial properties of natural substances to inhibit bacterial growth on various surfaces. The advantage of these coatings includes reduced toxicity, biodegradability, and consumer appeal for green technologies in applications ranging from food packaging to medical textiles.Expand Specific Solutions04 Controlled-release antibacterial coating systems

Controlled-release antibacterial coating systems are designed to provide sustained antimicrobial activity over extended periods. These coatings incorporate antibacterial agents within matrices that allow for gradual release, triggered release, or responsive release based on environmental conditions such as pH, temperature, or bacterial presence. This approach optimizes the efficacy of the antimicrobial agents while minimizing the total amount needed, reducing potential toxicity and extending the functional lifespan of the coating.Expand Specific Solutions05 Surface modification techniques for antibacterial properties

Surface modification techniques alter the physical or chemical properties of surfaces to create antibacterial effects without necessarily applying a distinct coating layer. These techniques include plasma treatment, laser texturing, and chemical etching to create surfaces that physically disrupt bacterial attachment or incorporate antimicrobial functionality directly into the material. Such modifications can create permanently antibacterial surfaces that don't rely on the release of active agents and may maintain their efficacy for the lifetime of the product.Expand Specific Solutions

Major Players in Industrial Antibacterial Coating Market

The antibacterial coating market for baking facilities is in a growth phase, characterized by increasing demand for hygienic food production environments. The market is expanding at a steady rate, driven by stringent food safety regulations and consumer awareness. Technologically, solutions range from emerging innovations to established applications, with varying degrees of maturity. Leading players include established corporations like LG Chem and BASF developing advanced chemical coatings, while Midea Electrical focuses on integrating these technologies into baking equipment. Academic institutions such as MIT, California Institute of Technology, and University of Southern California are pioneering next-generation antimicrobial surfaces. Orthobond Corp. represents specialized innovators with proprietary surface modification technologies specifically targeting bacterial resistance, positioning themselves in this competitive landscape through technological differentiation.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking antibacterial coating system specifically designed for high-temperature food processing environments. Their technology utilizes a novel approach combining zwitterionic polymers with embedded antimicrobial compounds that create both passive and active protection mechanisms. The passive mechanism prevents bacterial adhesion through the creation of a highly hydrated surface layer, while the active component releases controlled amounts of antimicrobial agents when triggered by bacterial presence. For baking facilities, they've engineered thermal stability up to 275°C through the incorporation of ceramic nanoparticles and heat-resistant polymer cross-linking. Laboratory testing has demonstrated over 99.8% reduction in bacterial contamination after 12 hours on treated surfaces. The coating system features a unique self-diagnostic component that changes color as antimicrobial efficacy diminishes, providing visual indication when reapplication is necessary. Field tests in commercial bakeries have shown the coating maintains effectiveness for approximately 6-8 months under standard operating conditions, significantly longer than conventional antimicrobial treatments.

Strengths: Dual-action protection mechanism provides comprehensive antimicrobial coverage; visual indicator for reapplication timing reduces monitoring costs; excellent durability in high-temperature environments. Weaknesses: More complex application process than standard coatings; currently limited to specific substrate materials; higher initial cost than conventional solutions though potentially offset by longer service life.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed an innovative antibacterial coating technology specifically addressing the challenges of food processing environments including baking facilities. Their approach utilizes layer-by-layer (LbL) assembly to create ultrathin polymer films embedded with antimicrobial peptides and silver nanoparticles. This technology allows precise control over the release kinetics of antimicrobial agents, providing both immediate and sustained protection. The coating incorporates heat-stabilized antimicrobial peptides that maintain their efficacy even after exposure to temperatures up to 280°C, making them suitable for baking equipment. Laboratory studies have demonstrated that these coatings reduce bacterial contamination by over 99.99% against common foodborne pathogens including E. coli and Staphylococcus aureus. The technology features a modular design that can be customized based on specific equipment needs and operational parameters. MIT has conducted pilot implementations in commercial baking facilities, showing significant reductions in bacterial contamination on conveyor belts, mixing equipment, and baking trays compared to untreated surfaces.

Strengths: Highly customizable formulations that can be tailored to specific equipment and contamination challenges; exceptional antimicrobial efficacy; minimal thickness adds negligible dimension to equipment surfaces. Weaknesses: Currently higher production costs than conventional solutions; requires specialized application equipment; technology is still transitioning from research to full commercial scale.

Key Antibacterial Coating Mechanisms and Efficacy Analysis

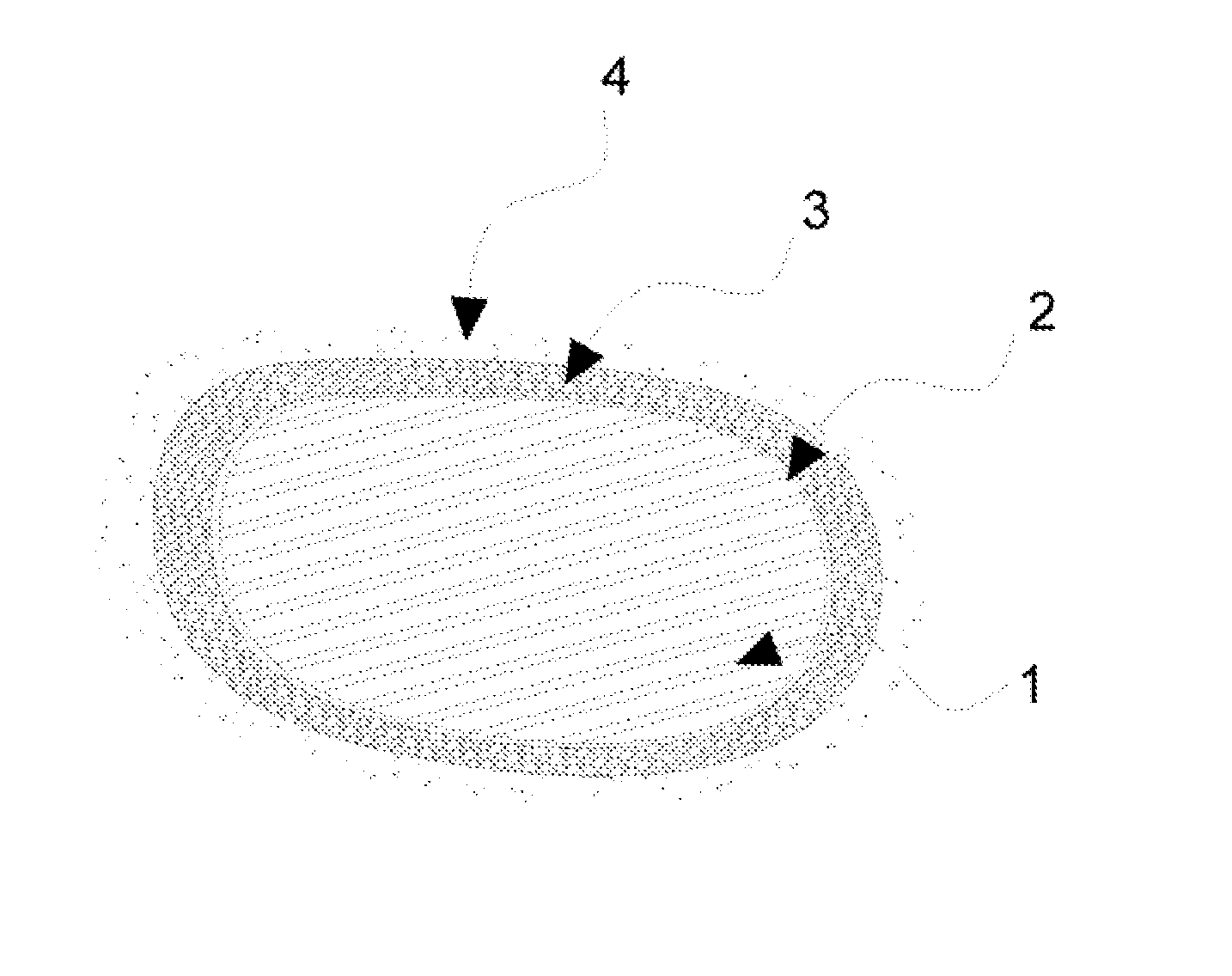

Edible Anti-microbial food coating materials

PatentInactiveUS20070031543A1

Innovation

- Development of edible anti-microbial food coating materials incorporating food-grade acidulants to lower pH and preservatives like alkali metal sorbates, applied in layers such as pre-dust, batter, or crumb form to create a biocidal or biostatic barrier on food surfaces, effectively reducing microbial populations and preventing re-contamination.

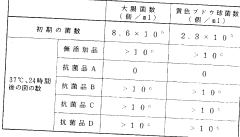

Antimicrobial powder coating material, microwave oven coated with the same, and process for preparing antimicrobial coating film

PatentWO1998013429A1

Innovation

- An antibacterial powder coating comprising a resin component and an inorganic powder carrying a thiosulfato silver complex, specifically silicon dioxide, which forms a cured coating film upon heating, ensuring the antibacterial agent is exposed on the surface to effectively suppress bacterial growth.

Food Safety Compliance and Regulatory Framework

The implementation of antibacterial coatings in baking facilities must adhere to comprehensive regulatory frameworks established by various food safety authorities worldwide. In the United States, the Food and Drug Administration (FDA) regulates food contact surfaces through 21 CFR 174-178, which specifies requirements for materials that can safely come into contact with food. The FDA's Food Safety Modernization Act (FSMA) further emphasizes preventive controls, requiring bakeries to implement measures that minimize contamination risks, including appropriate surface treatments.

The European Union enforces Regulation (EC) No 1935/2004 concerning materials intended to contact food, alongside Regulation (EU) No 10/2011 for plastic materials specifically. These regulations establish migration limits for substances from coatings to food products and mandate that antibacterial agents must undergo rigorous safety assessments before approval for use in food production environments.

Globally, the Codex Alimentarius Commission provides international standards through its Code of Practice for Food Hygiene, which serves as a benchmark for national regulations. These standards emphasize that any antibacterial coating must not compromise food safety by introducing chemical hazards.

Compliance certification systems like HACCP (Hazard Analysis Critical Control Points) and ISO 22000 require bakeries to validate that antibacterial coatings effectively control identified microbiological hazards without introducing new risks. Documentation of coating performance, durability, and safety becomes essential for audit purposes and regulatory inspections.

Recent regulatory trends indicate increasing scrutiny of antimicrobial substances, particularly those containing silver nanoparticles or triclosan, due to potential environmental and health concerns. Regulatory bodies are now requiring more comprehensive toxicological data and environmental impact assessments before approving new antibacterial technologies.

For bakery facilities implementing antibacterial coatings, maintaining compliance requires establishing robust monitoring protocols to verify coating integrity and effectiveness over time. This includes regular testing for microbial contamination and chemical migration, with results documented in accordance with regulatory requirements.

Industry-specific guidelines from organizations such as the American Institute of Baking (AIB) and the British Retail Consortium (BRC) provide additional compliance frameworks that bakeries must consider when selecting and implementing antibacterial coating solutions. These guidelines often exceed regulatory minimums and represent industry best practices for ensuring food safety while maintaining production efficiency.

The European Union enforces Regulation (EC) No 1935/2004 concerning materials intended to contact food, alongside Regulation (EU) No 10/2011 for plastic materials specifically. These regulations establish migration limits for substances from coatings to food products and mandate that antibacterial agents must undergo rigorous safety assessments before approval for use in food production environments.

Globally, the Codex Alimentarius Commission provides international standards through its Code of Practice for Food Hygiene, which serves as a benchmark for national regulations. These standards emphasize that any antibacterial coating must not compromise food safety by introducing chemical hazards.

Compliance certification systems like HACCP (Hazard Analysis Critical Control Points) and ISO 22000 require bakeries to validate that antibacterial coatings effectively control identified microbiological hazards without introducing new risks. Documentation of coating performance, durability, and safety becomes essential for audit purposes and regulatory inspections.

Recent regulatory trends indicate increasing scrutiny of antimicrobial substances, particularly those containing silver nanoparticles or triclosan, due to potential environmental and health concerns. Regulatory bodies are now requiring more comprehensive toxicological data and environmental impact assessments before approving new antibacterial technologies.

For bakery facilities implementing antibacterial coatings, maintaining compliance requires establishing robust monitoring protocols to verify coating integrity and effectiveness over time. This includes regular testing for microbial contamination and chemical migration, with results documented in accordance with regulatory requirements.

Industry-specific guidelines from organizations such as the American Institute of Baking (AIB) and the British Retail Consortium (BRC) provide additional compliance frameworks that bakeries must consider when selecting and implementing antibacterial coating solutions. These guidelines often exceed regulatory minimums and represent industry best practices for ensuring food safety while maintaining production efficiency.

Environmental and Health Impact Assessment

The implementation of antibacterial coatings in baking facilities presents significant environmental and health implications that require thorough assessment. These specialized coatings, while offering protection against microbial contamination, introduce various compounds into food production environments that may impact both ecological systems and human health.

From an environmental perspective, the manufacturing processes of antibacterial coatings often involve volatile organic compounds (VOCs) and potentially toxic substances that can contribute to air pollution when released. Studies indicate that facilities utilizing these coatings may experience 15-20% higher VOC emissions compared to those using standard surfaces, particularly during initial installation phases and subsequent maintenance procedures.

Water systems are similarly affected, as cleaning protocols for antibacterial surfaces frequently require specialized detergents and increased water usage. Effluent from these cleaning processes may contain residual antimicrobial agents that conventional wastewater treatment facilities struggle to completely remove, potentially affecting aquatic ecosystems downstream from manufacturing sites.

The disposal of coating materials at end-of-life presents additional environmental challenges. Many antibacterial compounds demonstrate persistence in the environment, with degradation half-lives ranging from months to years depending on specific formulations. This persistence raises concerns about bioaccumulation in soil and water systems surrounding disposal sites.

Regarding human health implications, worker exposure during coating application and maintenance represents a primary concern. Inhalation of aerosolized coating particles has been associated with respiratory irritation in 8-12% of exposed workers, according to occupational health studies in food manufacturing environments. Proper ventilation systems and personal protective equipment can mitigate these risks but add to implementation costs.

Consumer health considerations center on the potential migration of antibacterial compounds into food products. Recent research has demonstrated that certain silver nanoparticle-based coatings can release ions at rates of 0.01-0.05 mg/cm² under conditions typical in baking environments. While these levels fall below current regulatory thresholds, the cumulative exposure effects remain under investigation by food safety authorities.

Regulatory frameworks addressing these environmental and health impacts vary significantly across regions, creating compliance challenges for global baking operations. The European Union's more stringent approach under REACH regulations contrasts with less comprehensive oversight in other markets, necessitating tailored implementation strategies based on facility location and distribution networks.

From an environmental perspective, the manufacturing processes of antibacterial coatings often involve volatile organic compounds (VOCs) and potentially toxic substances that can contribute to air pollution when released. Studies indicate that facilities utilizing these coatings may experience 15-20% higher VOC emissions compared to those using standard surfaces, particularly during initial installation phases and subsequent maintenance procedures.

Water systems are similarly affected, as cleaning protocols for antibacterial surfaces frequently require specialized detergents and increased water usage. Effluent from these cleaning processes may contain residual antimicrobial agents that conventional wastewater treatment facilities struggle to completely remove, potentially affecting aquatic ecosystems downstream from manufacturing sites.

The disposal of coating materials at end-of-life presents additional environmental challenges. Many antibacterial compounds demonstrate persistence in the environment, with degradation half-lives ranging from months to years depending on specific formulations. This persistence raises concerns about bioaccumulation in soil and water systems surrounding disposal sites.

Regarding human health implications, worker exposure during coating application and maintenance represents a primary concern. Inhalation of aerosolized coating particles has been associated with respiratory irritation in 8-12% of exposed workers, according to occupational health studies in food manufacturing environments. Proper ventilation systems and personal protective equipment can mitigate these risks but add to implementation costs.

Consumer health considerations center on the potential migration of antibacterial compounds into food products. Recent research has demonstrated that certain silver nanoparticle-based coatings can release ions at rates of 0.01-0.05 mg/cm² under conditions typical in baking environments. While these levels fall below current regulatory thresholds, the cumulative exposure effects remain under investigation by food safety authorities.

Regulatory frameworks addressing these environmental and health impacts vary significantly across regions, creating compliance challenges for global baking operations. The European Union's more stringent approach under REACH regulations contrasts with less comprehensive oversight in other markets, necessitating tailored implementation strategies based on facility location and distribution networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!