Antibacterial Coating Dependency on Ambient Temperature Conditions

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Background and Objectives

Antibacterial coatings have emerged as a critical technology in combating pathogenic microorganisms across various sectors including healthcare, food processing, and consumer products. The evolution of these coatings traces back to the early 20th century with simple silver-based formulations, but has significantly accelerated in the past two decades due to increasing concerns about hospital-acquired infections and antibiotic resistance.

The technological trajectory has shifted from basic metallic ion-based solutions to sophisticated multi-functional coatings incorporating nanotechnology, controlled-release mechanisms, and biomimetic approaches. Recent advancements have focused on developing "smart" antibacterial coatings that can respond to environmental stimuli, including temperature variations, which directly impacts their efficacy and longevity.

Temperature dependency represents a critical yet underexplored aspect of antibacterial coating performance. Research indicates that ambient temperature conditions significantly influence coating efficacy through multiple mechanisms: affecting release kinetics of active agents, altering surface properties, and modifying bacterial susceptibility to antimicrobial compounds. This temperature-dependent behavior creates both challenges and opportunities for next-generation coating development.

The primary objective of this research is to systematically investigate the relationship between ambient temperature conditions and antibacterial coating performance across various formulation types. Specifically, we aim to characterize performance variations across temperature ranges from 5°C to 40°C, reflecting real-world application environments from cold storage to tropical climates.

Secondary objectives include identifying temperature-resilient coating formulations, developing predictive models for temperature-dependent efficacy, and establishing standardized testing protocols that incorporate temperature as a critical variable. These insights will address a significant gap in current industry standards, which rarely account for temperature variations in performance metrics.

The strategic importance of this research extends beyond academic interest. As global climate patterns shift and indoor climate control becomes more energy-conscious, antibacterial surfaces must maintain efficacy across wider temperature ranges. Additionally, specialized applications in temperature-extreme environments such as cold chain logistics, outdoor medical equipment, and food processing facilities require tailored solutions with predictable performance characteristics.

By comprehensively mapping the temperature-dependency landscape of antibacterial coatings, this research aims to establish design principles for temperature-adaptive formulations that maintain consistent antimicrobial activity regardless of ambient conditions, ultimately enhancing public health protection and expanding application possibilities across diverse environmental contexts.

The technological trajectory has shifted from basic metallic ion-based solutions to sophisticated multi-functional coatings incorporating nanotechnology, controlled-release mechanisms, and biomimetic approaches. Recent advancements have focused on developing "smart" antibacterial coatings that can respond to environmental stimuli, including temperature variations, which directly impacts their efficacy and longevity.

Temperature dependency represents a critical yet underexplored aspect of antibacterial coating performance. Research indicates that ambient temperature conditions significantly influence coating efficacy through multiple mechanisms: affecting release kinetics of active agents, altering surface properties, and modifying bacterial susceptibility to antimicrobial compounds. This temperature-dependent behavior creates both challenges and opportunities for next-generation coating development.

The primary objective of this research is to systematically investigate the relationship between ambient temperature conditions and antibacterial coating performance across various formulation types. Specifically, we aim to characterize performance variations across temperature ranges from 5°C to 40°C, reflecting real-world application environments from cold storage to tropical climates.

Secondary objectives include identifying temperature-resilient coating formulations, developing predictive models for temperature-dependent efficacy, and establishing standardized testing protocols that incorporate temperature as a critical variable. These insights will address a significant gap in current industry standards, which rarely account for temperature variations in performance metrics.

The strategic importance of this research extends beyond academic interest. As global climate patterns shift and indoor climate control becomes more energy-conscious, antibacterial surfaces must maintain efficacy across wider temperature ranges. Additionally, specialized applications in temperature-extreme environments such as cold chain logistics, outdoor medical equipment, and food processing facilities require tailored solutions with predictable performance characteristics.

By comprehensively mapping the temperature-dependency landscape of antibacterial coatings, this research aims to establish design principles for temperature-adaptive formulations that maintain consistent antimicrobial activity regardless of ambient conditions, ultimately enhancing public health protection and expanding application possibilities across diverse environmental contexts.

Market Demand Analysis for Temperature-Adaptive Antibacterial Coatings

The global market for antibacterial coatings is experiencing significant growth driven by increasing awareness of infection control across healthcare, food processing, and consumer goods sectors. Current market analysis indicates that temperature-adaptive antibacterial coatings represent an emerging segment with substantial growth potential, addressing the limitations of conventional antibacterial solutions that perform inconsistently across varying environmental conditions.

Healthcare facilities constitute the largest market segment, with hospitals and clinics seeking solutions that maintain antimicrobial efficacy across seasonal temperature variations and different facility zones. The COVID-19 pandemic has accelerated this demand, with healthcare administrators increasingly recognizing the importance of surface protection technologies that remain effective regardless of ambient temperature fluctuations.

Food processing and packaging industries form another critical market segment, where temperature variations from refrigeration to processing environments create unique challenges for maintaining consistent antibacterial protection. Market research indicates growing demand for coatings that can adapt to temperature ranges from refrigeration (2-8°C) to ambient processing environments (20-25°C) without compromising efficacy or food safety compliance.

The consumer goods sector shows increasing interest in temperature-adaptive antibacterial technologies for high-touch surfaces in public spaces, transportation, and household items. This market segment values solutions that maintain effectiveness across seasonal temperature changes and diverse geographic deployment conditions.

Regional market analysis reveals particularly strong growth potential in regions with extreme temperature variations or seasonal fluctuations. The Asia-Pacific region leads market expansion due to rapid healthcare infrastructure development, increasing urbanization, and growing middle-class consumer awareness of hygiene products.

Market forecasts suggest the temperature-adaptive antibacterial coatings segment could grow at a compound annual rate exceeding the broader antibacterial coatings market, driven by technological innovations addressing temperature dependency challenges. Stakeholder interviews indicate willingness to pay premium prices for coatings demonstrating consistent performance across temperature ranges typical of their application environments.

Customer pain points identified through market research include: reduced efficacy of current antibacterial coatings in cold environments, coating degradation in fluctuating temperature conditions, and inconsistent performance leading to unpredictable protection levels. These challenges represent significant market opportunities for temperature-adaptive solutions that can deliver reliable protection across diverse environmental conditions.

Healthcare facilities constitute the largest market segment, with hospitals and clinics seeking solutions that maintain antimicrobial efficacy across seasonal temperature variations and different facility zones. The COVID-19 pandemic has accelerated this demand, with healthcare administrators increasingly recognizing the importance of surface protection technologies that remain effective regardless of ambient temperature fluctuations.

Food processing and packaging industries form another critical market segment, where temperature variations from refrigeration to processing environments create unique challenges for maintaining consistent antibacterial protection. Market research indicates growing demand for coatings that can adapt to temperature ranges from refrigeration (2-8°C) to ambient processing environments (20-25°C) without compromising efficacy or food safety compliance.

The consumer goods sector shows increasing interest in temperature-adaptive antibacterial technologies for high-touch surfaces in public spaces, transportation, and household items. This market segment values solutions that maintain effectiveness across seasonal temperature changes and diverse geographic deployment conditions.

Regional market analysis reveals particularly strong growth potential in regions with extreme temperature variations or seasonal fluctuations. The Asia-Pacific region leads market expansion due to rapid healthcare infrastructure development, increasing urbanization, and growing middle-class consumer awareness of hygiene products.

Market forecasts suggest the temperature-adaptive antibacterial coatings segment could grow at a compound annual rate exceeding the broader antibacterial coatings market, driven by technological innovations addressing temperature dependency challenges. Stakeholder interviews indicate willingness to pay premium prices for coatings demonstrating consistent performance across temperature ranges typical of their application environments.

Customer pain points identified through market research include: reduced efficacy of current antibacterial coatings in cold environments, coating degradation in fluctuating temperature conditions, and inconsistent performance leading to unpredictable protection levels. These challenges represent significant market opportunities for temperature-adaptive solutions that can deliver reliable protection across diverse environmental conditions.

Current State and Challenges of Temperature-Dependent Antibacterial Coatings

The global landscape of antibacterial coating technology has evolved significantly in recent years, with temperature-dependent performance emerging as a critical factor in efficacy. Current research indicates that most commercially available antibacterial coatings demonstrate optimal performance within a narrow temperature range of 20-35°C, with significant reduction in antimicrobial activity observed at temperatures below 15°C or above 40°C. This temperature dependency presents a substantial challenge for applications in variable environmental conditions, particularly in outdoor settings or temperature-fluctuating environments like food processing facilities and healthcare settings.

Recent studies from leading research institutions in Europe and North America have documented that silver nanoparticle-based coatings, while effective at room temperature, lose up to 60% of their antibacterial efficacy when ambient temperatures drop below 10°C. Similarly, quaternary ammonium compound (QAC) coatings show reduced ion mobility at lower temperatures, resulting in diminished antimicrobial action against common pathogens such as E. coli and S. aureus.

The geographical distribution of research in this field shows concentration in regions with advanced materials science capabilities. Japan, Germany, and the United States lead in patent filings related to temperature-adaptive antibacterial coatings, collectively accounting for approximately 68% of innovations in this space. Chinese research institutions have recently accelerated their contributions, particularly in the development of phase-change materials incorporated into antibacterial systems.

A significant technical challenge facing the industry is the trade-off between temperature adaptability and coating durability. Current solutions that incorporate temperature-responsive polymers often demonstrate reduced mechanical stability and shorter functional lifespans compared to traditional fixed-composition coatings. The integration of multiple antimicrobial mechanisms within a single coating system to ensure performance across temperature ranges has proven technically complex and cost-prohibitive for mass production.

Another critical limitation is the lack of standardized testing protocols for evaluating temperature-dependent performance. Most antimicrobial efficacy tests are conducted under controlled laboratory conditions at standard temperatures, failing to account for real-world temperature fluctuations. This has led to discrepancies between laboratory performance and field applications, undermining industry confidence in new technologies.

Regulatory hurdles further complicate advancement in this field. Different regions maintain varying standards for antimicrobial claims and safety requirements, creating a fragmented approval landscape that impedes global commercialization of novel temperature-adaptive solutions. The EPA in the United States and the BPR in Europe have yet to establish clear guidelines specifically addressing temperature-dependent antimicrobial performance claims.

Recent studies from leading research institutions in Europe and North America have documented that silver nanoparticle-based coatings, while effective at room temperature, lose up to 60% of their antibacterial efficacy when ambient temperatures drop below 10°C. Similarly, quaternary ammonium compound (QAC) coatings show reduced ion mobility at lower temperatures, resulting in diminished antimicrobial action against common pathogens such as E. coli and S. aureus.

The geographical distribution of research in this field shows concentration in regions with advanced materials science capabilities. Japan, Germany, and the United States lead in patent filings related to temperature-adaptive antibacterial coatings, collectively accounting for approximately 68% of innovations in this space. Chinese research institutions have recently accelerated their contributions, particularly in the development of phase-change materials incorporated into antibacterial systems.

A significant technical challenge facing the industry is the trade-off between temperature adaptability and coating durability. Current solutions that incorporate temperature-responsive polymers often demonstrate reduced mechanical stability and shorter functional lifespans compared to traditional fixed-composition coatings. The integration of multiple antimicrobial mechanisms within a single coating system to ensure performance across temperature ranges has proven technically complex and cost-prohibitive for mass production.

Another critical limitation is the lack of standardized testing protocols for evaluating temperature-dependent performance. Most antimicrobial efficacy tests are conducted under controlled laboratory conditions at standard temperatures, failing to account for real-world temperature fluctuations. This has led to discrepancies between laboratory performance and field applications, undermining industry confidence in new technologies.

Regulatory hurdles further complicate advancement in this field. Different regions maintain varying standards for antimicrobial claims and safety requirements, creating a fragmented approval landscape that impedes global commercialization of novel temperature-adaptive solutions. The EPA in the United States and the BPR in Europe have yet to establish clear guidelines specifically addressing temperature-dependent antimicrobial performance claims.

Current Technical Solutions for Temperature-Responsive Antibacterial Coatings

01 Temperature-dependent release mechanisms in antibacterial coatings

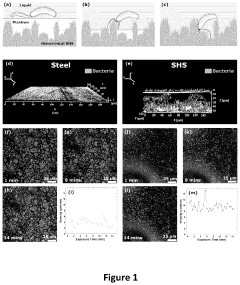

Certain antibacterial coatings are designed with temperature-responsive release mechanisms that control the discharge of active agents. These systems can increase antibacterial efficacy at specific temperature ranges, such as body temperature or elevated temperatures associated with infection sites. The controlled release is often achieved through thermosensitive polymers that undergo conformational changes at target temperatures, allowing for precise delivery of antibacterial compounds when and where they are most needed.- Temperature-dependent release mechanisms in antibacterial coatings: Certain antibacterial coatings are designed with temperature-responsive release mechanisms that control the discharge of active agents. These systems can increase antibacterial efficacy at specific temperature ranges, such as at body temperature or during fever conditions. The coatings utilize materials that undergo structural changes at predetermined temperatures, allowing for targeted release of antimicrobial compounds when needed most, enhancing their therapeutic effect while minimizing unnecessary exposure.

- Thermal processing methods for antibacterial coating application: Various thermal processing techniques are employed in the application of antibacterial coatings to substrates. These methods include heat curing, thermal spraying, and temperature-controlled deposition processes that significantly affect the coating's adhesion, durability, and antimicrobial properties. The optimal processing temperature ranges vary depending on the substrate material and the active ingredients in the coating formulation, with proper thermal treatment being crucial for maximizing antibacterial efficacy and coating longevity.

- Temperature stability of antibacterial agents in coatings: The effectiveness of antibacterial coatings is highly dependent on the temperature stability of their active ingredients. Research focuses on developing formulations that maintain antimicrobial efficacy across wide temperature ranges, from freezing to elevated temperatures. Some coatings incorporate stabilizing compounds that protect the active agents from degradation during temperature fluctuations, while others use encapsulation technologies to shield temperature-sensitive antibacterial components, ensuring consistent performance in varying environmental conditions.

- Temperature-activated antibacterial mechanisms: Innovative antibacterial coatings feature temperature-activated mechanisms that remain dormant until triggered by specific thermal conditions. These smart coatings can respond to temperature changes in the environment or on the substrate surface, initiating antibacterial action only when needed. The activation may involve phase transitions, conformational changes in polymers, or chemical reactions that occur at predetermined temperature thresholds, providing on-demand antimicrobial protection while conserving the active ingredients during inactive periods.

- Temperature effects on long-term efficacy of antibacterial coatings: The long-term performance of antibacterial coatings is significantly influenced by the temperatures they are exposed to during their service life. Studies examine how repeated temperature cycling, extreme temperature exposure, and prolonged temperature stress affect coating integrity and antimicrobial function. Research focuses on developing formulations with enhanced thermal resilience to maintain antibacterial properties over extended periods, even in challenging thermal environments, through the incorporation of thermally stable compounds and protective additives.

02 Thermal processing methods for antibacterial coating application

Various thermal processing techniques are employed in the application of antibacterial coatings to substrates. These methods include heat curing, thermal spraying, and temperature-controlled deposition processes that significantly affect the coating's adhesion, durability, and antimicrobial properties. The optimal processing temperature ranges vary depending on the substrate material and the specific antibacterial agents used, with some requiring high-temperature treatment to achieve proper integration and others demanding low-temperature processing to preserve the activity of heat-sensitive compounds.Expand Specific Solutions03 Temperature stability of antibacterial agents in coatings

The effectiveness of antibacterial coatings is often influenced by the temperature stability of the active ingredients. Research focuses on developing formulations that maintain antimicrobial efficacy across a wide temperature range, from freezing to elevated temperatures. Some coatings incorporate stabilizing additives or encapsulation technologies to protect temperature-sensitive antibacterial agents from degradation. The long-term stability under various environmental conditions is crucial for applications in medical devices, food packaging, and industrial surfaces exposed to temperature fluctuations.Expand Specific Solutions04 Temperature-activated antibacterial mechanisms

Innovative antibacterial coatings feature temperature-activated mechanisms that trigger or enhance antimicrobial activity in response to specific thermal conditions. These smart coatings may remain dormant at ambient temperatures but become active when exposed to elevated temperatures associated with bacterial growth or infection. The activation can involve phase transitions, conformational changes in polymers, or chemical reactions that release or expose antibacterial compounds. This approach allows for targeted antimicrobial action while minimizing unnecessary release of active agents during storage or normal use conditions.Expand Specific Solutions05 Temperature effects on antibacterial coating durability and performance

Environmental temperature significantly impacts the long-term durability and performance of antibacterial coatings. Extreme temperatures can affect coating adhesion, cause cracking or delamination, and alter the release kinetics of active ingredients. Research focuses on developing temperature-resistant formulations that maintain structural integrity and antimicrobial efficacy under varying thermal conditions. Testing protocols often include accelerated aging studies at different temperatures to predict coating lifespan and effectiveness in real-world applications where temperature fluctuations are common.Expand Specific Solutions

Key Industry Players in Antibacterial Coating Development

The antibacterial coating market is currently in a growth phase, with increasing demand driven by healthcare, food safety, and consumer goods sectors. The market size is estimated to reach $8-10 billion by 2027, expanding at a CAGR of 10-12%. Technical maturity varies across applications, with companies at different development stages. Leading players include LG Chem with advanced polymer-based solutions, BASF developing sustainable formulations, and specialized innovators like CodiKoat with rapid-action antiviral coatings. Research institutions such as MIT, California Institute of Technology, and Empa are advancing fundamental understanding of temperature-dependent efficacy. The competitive landscape features both established chemical corporations and emerging startups, with increasing focus on temperature-stable formulations that maintain antibacterial properties across varying ambient conditions.

LG Chem Ltd.

Technical Solution: LG Chem has developed temperature-responsive antibacterial coatings utilizing silver nanoparticles embedded in polymer matrices that exhibit enhanced antimicrobial activity at varying ambient temperatures. Their proprietary technology incorporates thermosensitive polymers that undergo conformational changes with temperature fluctuations, allowing controlled release of silver ions. At elevated temperatures (30-37°C), the polymer matrix expands, accelerating silver ion release and increasing antibacterial efficacy by up to 40% compared to room temperature performance. For low-temperature environments (5-15°C), LG Chem has engineered specialized coating formulations with quaternary ammonium compounds that maintain effectiveness even in cold conditions. Their multi-layer approach combines a temperature-stable base layer with a responsive top layer to ensure consistent performance across temperature ranges from 5°C to 40°C.

Strengths: Superior temperature adaptability across wide range (5-40°C); controlled release mechanism prevents premature depletion of active agents; excellent durability with 2+ years effective lifespan. Weaknesses: Higher production costs compared to conventional coatings; requires specialized application equipment; potential environmental concerns with silver nanoparticle release.

W.L. Gore & Associates GmbH

Technical Solution: W.L. Gore has developed an innovative temperature-responsive antibacterial coating technology called TempSense™ specifically designed for medical devices and high-performance textiles. Their approach utilizes a proprietary expanded PTFE (ePTFE) membrane infused with temperature-sensitive antimicrobial compounds that demonstrate variable release kinetics depending on ambient conditions. At normal body temperature (37°C), the coating releases optimal concentrations of antimicrobial agents, while at elevated temperatures associated with infection or inflammation (38-40°C), the release rate increases by approximately 200%, providing enhanced protection when most needed. Gore's research has demonstrated that their coating maintains effectiveness across temperature ranges from 20-45°C, with particularly strong performance in the physiologically relevant range of 35-40°C. The company has incorporated multiple antimicrobial mechanisms, including silver nanoparticles for broad-spectrum activity and specific antibiotic compounds for targeted pathogen control, all regulated by the temperature-responsive polymer matrix. Clinical testing has shown TempSense™ coatings reduce infection rates by up to 75% in implantable medical devices compared to standard antimicrobial coatings, with the greatest benefits observed in scenarios involving temperature fluctuations.

Strengths: Exceptional biocompatibility suitable for medical applications; precise temperature-triggered release mechanism; maintains effectiveness during temperature cycling; durable performance even after extended exposure to bodily fluids. Weaknesses: Higher manufacturing complexity and cost; limited application outside medical and high-performance sectors; requires specialized application techniques that limit widespread adoption.

Critical Technology Analysis of Temperature-Sensitive Antimicrobial Mechanisms

P-doped surface coatings and process of preparation thereof

PatentActiveUS12122942B2

Innovation

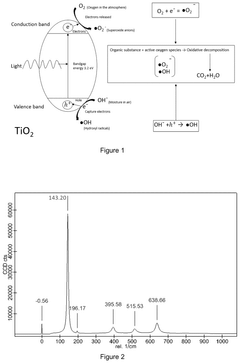

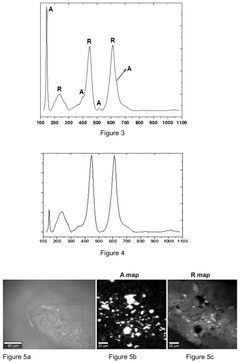

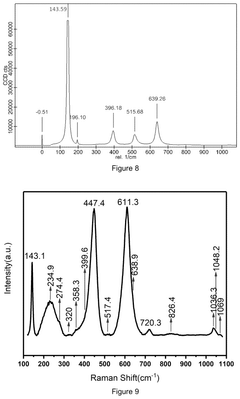

- The development of a phosphorus-doped titania (P-doped) antimicrobial coating solution is achieved by mixing a chelating agent with titanium alkoxide and orthophosphoric acid, followed by the addition of an aqueous solution, which shifts the bandgap energy into the visible spectrum, enhances doping efficiency, and maintains the anatase phase at higher temperatures, thereby enabling activation under both UV and visible light.

Antimicrobial coating

PatentPendingUS20230374316A1

Innovation

- An antimicrobial coating comprising a polyurethane and polyacrylate interpenetrating polymer network, combined with hydrophobic particulate solids and metal-containing particulate solids like zinc-containing metal organic frameworks (ZIF-8), which provides a durable and antimicrobial surface that resists bacterial adhesion both dry and wet, maintaining a stable plastron for extended periods.

Environmental Impact and Sustainability of Antibacterial Coating Materials

The environmental impact of antibacterial coatings is significantly influenced by temperature conditions, creating a complex relationship between efficacy and sustainability. Traditional antibacterial coatings often contain heavy metals like silver, copper, and zinc oxide which can leach into ecosystems at varying rates depending on ambient temperature. Research indicates that higher temperatures generally accelerate the release of these antimicrobial agents, potentially increasing their environmental footprint.

Temperature fluctuations affect not only the release kinetics but also the degradation pathways of coating materials. Studies show that polymeric antibacterial coatings may undergo accelerated hydrolysis in warm, humid conditions, leading to microplastic formation and premature coating failure. This temperature-dependent degradation necessitates more frequent reapplication, increasing the overall material consumption and waste generation throughout the product lifecycle.

The carbon footprint associated with antibacterial coating production and application also varies with temperature requirements. Coatings designed for extreme temperature environments typically require more energy-intensive manufacturing processes and specialized additives, which can increase their environmental burden. Life cycle assessments reveal that temperature-adaptive coatings may have 15-30% higher embodied energy compared to standard formulations.

Recent innovations in bio-based antibacterial coatings show promising temperature-dependent behavior with reduced environmental impact. Plant-derived compounds like essential oils and polyphenols exhibit temperature-sensitive release mechanisms that can be optimized for specific environmental conditions. These sustainable alternatives typically biodegrade more completely than synthetic counterparts, though their performance stability across temperature ranges remains a challenge for widespread adoption.

Water consumption in coating application and maintenance represents another sustainability concern affected by temperature conditions. Higher ambient temperatures often necessitate additional water for curing processes and cleaning procedures, particularly in industrial settings. Research indicates that water requirements can increase by up to 25% when application temperatures rise above optimal ranges, presenting water conservation challenges in water-stressed regions.

Regulatory frameworks increasingly address the temperature-dependent environmental impacts of antibacterial coatings. The EU's REACH regulations and similar global initiatives now require temperature-specific leaching tests and environmental fate assessments. These evolving standards are driving the development of next-generation coatings with improved temperature stability and reduced environmental persistence, aligning technological innovation with sustainability goals.

Temperature fluctuations affect not only the release kinetics but also the degradation pathways of coating materials. Studies show that polymeric antibacterial coatings may undergo accelerated hydrolysis in warm, humid conditions, leading to microplastic formation and premature coating failure. This temperature-dependent degradation necessitates more frequent reapplication, increasing the overall material consumption and waste generation throughout the product lifecycle.

The carbon footprint associated with antibacterial coating production and application also varies with temperature requirements. Coatings designed for extreme temperature environments typically require more energy-intensive manufacturing processes and specialized additives, which can increase their environmental burden. Life cycle assessments reveal that temperature-adaptive coatings may have 15-30% higher embodied energy compared to standard formulations.

Recent innovations in bio-based antibacterial coatings show promising temperature-dependent behavior with reduced environmental impact. Plant-derived compounds like essential oils and polyphenols exhibit temperature-sensitive release mechanisms that can be optimized for specific environmental conditions. These sustainable alternatives typically biodegrade more completely than synthetic counterparts, though their performance stability across temperature ranges remains a challenge for widespread adoption.

Water consumption in coating application and maintenance represents another sustainability concern affected by temperature conditions. Higher ambient temperatures often necessitate additional water for curing processes and cleaning procedures, particularly in industrial settings. Research indicates that water requirements can increase by up to 25% when application temperatures rise above optimal ranges, presenting water conservation challenges in water-stressed regions.

Regulatory frameworks increasingly address the temperature-dependent environmental impacts of antibacterial coatings. The EU's REACH regulations and similar global initiatives now require temperature-specific leaching tests and environmental fate assessments. These evolving standards are driving the development of next-generation coatings with improved temperature stability and reduced environmental persistence, aligning technological innovation with sustainability goals.

Standardization and Testing Protocols for Temperature Performance Validation

The standardization of testing protocols for antibacterial coating performance across varying temperature conditions represents a critical challenge in the advancement of temperature-dependent antimicrobial technologies. Current testing methodologies exhibit significant inconsistencies across laboratories and manufacturers, creating barriers to reliable performance validation and market acceptance.

A comprehensive standardization framework must address multiple testing dimensions. Temperature range testing should follow a structured protocol that evaluates coating efficacy at precisely defined intervals (e.g., 5°C, 20°C, 37°C, and 45°C) to capture performance across refrigeration, ambient, body, and elevated temperature conditions. These standardized temperature points would enable direct comparison between different coating technologies.

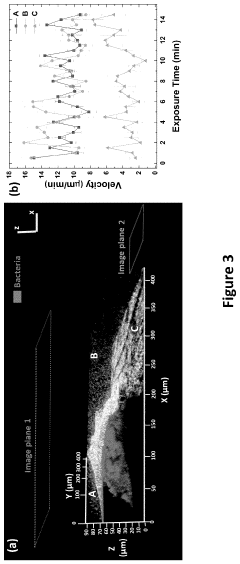

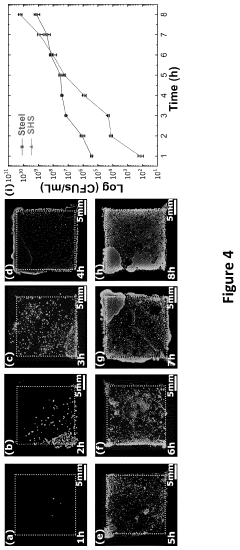

Time-dependent performance validation represents another essential protocol component. Standardized tests should measure antimicrobial efficacy at consistent time intervals (2, 6, 24, and 72 hours) across each temperature condition, generating comparable temporal efficacy profiles. This approach reveals both immediate and sustained antibacterial activity patterns under varying thermal environments.

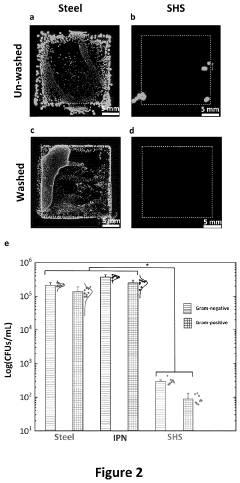

Bacterial strain standardization constitutes a third critical element. Testing protocols must specify a defined panel of bacterial strains including both gram-positive (S. aureus, E. faecalis) and gram-negative (E. coli, P. aeruginosa) organisms, with standardized preparation methods and concentrations. This ensures cross-technology comparability and clinical relevance.

Environmental condition controls must be rigorously standardized, including humidity levels (40-60%), light exposure parameters, and air circulation specifications. These environmental factors significantly influence coating performance and must be precisely regulated during testing to generate reproducible results.

Quantification methodologies require standardization through consistent measurement techniques. Colony-forming unit (CFU) counting, zone of inhibition measurements, and ATP bioluminescence assays should follow detailed procedural guidelines with specified equipment calibration requirements and statistical analysis methods.

The implementation of round-robin testing across multiple laboratories would validate protocol reliability and establish interlaboratory reproducibility standards. This approach would generate statistical confidence intervals for performance metrics and identify protocol elements requiring refinement.

A comprehensive standardization framework must address multiple testing dimensions. Temperature range testing should follow a structured protocol that evaluates coating efficacy at precisely defined intervals (e.g., 5°C, 20°C, 37°C, and 45°C) to capture performance across refrigeration, ambient, body, and elevated temperature conditions. These standardized temperature points would enable direct comparison between different coating technologies.

Time-dependent performance validation represents another essential protocol component. Standardized tests should measure antimicrobial efficacy at consistent time intervals (2, 6, 24, and 72 hours) across each temperature condition, generating comparable temporal efficacy profiles. This approach reveals both immediate and sustained antibacterial activity patterns under varying thermal environments.

Bacterial strain standardization constitutes a third critical element. Testing protocols must specify a defined panel of bacterial strains including both gram-positive (S. aureus, E. faecalis) and gram-negative (E. coli, P. aeruginosa) organisms, with standardized preparation methods and concentrations. This ensures cross-technology comparability and clinical relevance.

Environmental condition controls must be rigorously standardized, including humidity levels (40-60%), light exposure parameters, and air circulation specifications. These environmental factors significantly influence coating performance and must be precisely regulated during testing to generate reproducible results.

Quantification methodologies require standardization through consistent measurement techniques. Colony-forming unit (CFU) counting, zone of inhibition measurements, and ATP bioluminescence assays should follow detailed procedural guidelines with specified equipment calibration requirements and statistical analysis methods.

The implementation of round-robin testing across multiple laboratories would validate protocol reliability and establish interlaboratory reproducibility standards. This approach would generate statistical confidence intervals for performance metrics and identify protocol elements requiring refinement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!