Patent Review of Antibacterial Coating Production Techniques

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Background and Objectives

Antibacterial coatings have emerged as a critical technology in combating the growing threat of pathogenic microorganisms across various sectors including healthcare, food processing, and consumer goods. The evolution of this technology can be traced back to the early 20th century when silver was first recognized for its antimicrobial properties. However, significant advancements in antibacterial coating technologies have only materialized in the past three decades, driven by increasing concerns over hospital-acquired infections and antibiotic resistance.

The technological trajectory has shifted from simple silver-based coatings to more sophisticated multi-functional surfaces that incorporate various active agents such as quaternary ammonium compounds, chitosan, metal oxides, and antimicrobial peptides. This progression reflects a deeper understanding of microbial adhesion mechanisms and biofilm formation processes, enabling more targeted approaches to preventing bacterial colonization on surfaces.

Recent patent analyses indicate a surge in research and development activities focused on environmentally friendly and sustainable antibacterial coating solutions. This trend aligns with global regulatory pressures to reduce the use of toxic substances like triclosan and certain heavy metals that have traditionally been employed in antibacterial formulations.

The primary technical objectives in this field currently revolve around developing coatings that offer prolonged efficacy, reduced toxicity, and enhanced durability under various environmental conditions. Researchers are particularly focused on creating solutions that can withstand repeated cleaning cycles without compromising antimicrobial performance – a critical requirement for real-world applications.

Another significant goal is the development of broad-spectrum coatings effective against both Gram-positive and Gram-negative bacteria, as well as fungi and certain viruses. This challenge has become increasingly important in light of emerging pathogens and multidrug-resistant strains that pose substantial public health threats.

Patent landscapes reveal growing interest in smart antibacterial coatings that can respond to environmental triggers such as pH changes, temperature fluctuations, or the presence of specific bacterial enzymes. These stimuli-responsive systems represent the cutting edge of antibacterial coating technology, potentially offering more efficient use of antimicrobial agents and reduced environmental impact.

The integration of nanotechnology has opened new avenues for antibacterial coating development, with nanomaterials providing unique physical and chemical properties that enhance antimicrobial efficacy while minimizing the amount of active ingredients required. This approach addresses concerns regarding both cost-effectiveness and potential environmental consequences of widespread antimicrobial use.

The technological trajectory has shifted from simple silver-based coatings to more sophisticated multi-functional surfaces that incorporate various active agents such as quaternary ammonium compounds, chitosan, metal oxides, and antimicrobial peptides. This progression reflects a deeper understanding of microbial adhesion mechanisms and biofilm formation processes, enabling more targeted approaches to preventing bacterial colonization on surfaces.

Recent patent analyses indicate a surge in research and development activities focused on environmentally friendly and sustainable antibacterial coating solutions. This trend aligns with global regulatory pressures to reduce the use of toxic substances like triclosan and certain heavy metals that have traditionally been employed in antibacterial formulations.

The primary technical objectives in this field currently revolve around developing coatings that offer prolonged efficacy, reduced toxicity, and enhanced durability under various environmental conditions. Researchers are particularly focused on creating solutions that can withstand repeated cleaning cycles without compromising antimicrobial performance – a critical requirement for real-world applications.

Another significant goal is the development of broad-spectrum coatings effective against both Gram-positive and Gram-negative bacteria, as well as fungi and certain viruses. This challenge has become increasingly important in light of emerging pathogens and multidrug-resistant strains that pose substantial public health threats.

Patent landscapes reveal growing interest in smart antibacterial coatings that can respond to environmental triggers such as pH changes, temperature fluctuations, or the presence of specific bacterial enzymes. These stimuli-responsive systems represent the cutting edge of antibacterial coating technology, potentially offering more efficient use of antimicrobial agents and reduced environmental impact.

The integration of nanotechnology has opened new avenues for antibacterial coating development, with nanomaterials providing unique physical and chemical properties that enhance antimicrobial efficacy while minimizing the amount of active ingredients required. This approach addresses concerns regarding both cost-effectiveness and potential environmental consequences of widespread antimicrobial use.

Market Demand Analysis for Antibacterial Coatings

The global market for antibacterial coatings has experienced significant growth in recent years, driven primarily by increasing awareness of healthcare-associated infections (HAIs) and the growing emphasis on hygiene across various sectors. The market value reached approximately $3.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.1% through 2030, potentially reaching $9.8 billion by the end of the forecast period.

Healthcare remains the dominant application segment, accounting for over 40% of the total market share. This dominance is attributed to the critical need for infection control in hospitals, clinics, and other healthcare facilities. The COVID-19 pandemic has further accelerated this demand, as healthcare providers worldwide have implemented stricter infection prevention protocols.

Beyond healthcare, significant market expansion is occurring in food processing, packaging, consumer electronics, and building materials sectors. The food industry, in particular, has shown increased adoption of antibacterial coatings to ensure food safety and extend shelf life. This sector represents approximately 22% of the current market and is expected to grow substantially as food safety regulations become more stringent globally.

Regional analysis indicates that North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preferences are increasingly shifting toward environmentally friendly and non-toxic antibacterial coating solutions. This trend has created a significant market opportunity for bio-based antibacterial coatings, which are projected to grow at a CAGR of 14.5% through 2030, outpacing the overall market growth rate.

The commercial building sector represents another emerging application area, with demand driven by the need for hygienic environments in offices, schools, and public facilities. This segment is expected to grow at a CAGR of 11.8% over the forecast period.

Key market drivers include increasing healthcare expenditure, growing awareness about hygiene and infection control, stringent regulations regarding surface contamination in various industries, and technological advancements in coating materials. However, challenges such as high production costs, regulatory hurdles, and concerns about antimicrobial resistance could potentially hamper market growth in certain segments.

Healthcare remains the dominant application segment, accounting for over 40% of the total market share. This dominance is attributed to the critical need for infection control in hospitals, clinics, and other healthcare facilities. The COVID-19 pandemic has further accelerated this demand, as healthcare providers worldwide have implemented stricter infection prevention protocols.

Beyond healthcare, significant market expansion is occurring in food processing, packaging, consumer electronics, and building materials sectors. The food industry, in particular, has shown increased adoption of antibacterial coatings to ensure food safety and extend shelf life. This sector represents approximately 22% of the current market and is expected to grow substantially as food safety regulations become more stringent globally.

Regional analysis indicates that North America currently holds the largest market share at 35%, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer preferences are increasingly shifting toward environmentally friendly and non-toxic antibacterial coating solutions. This trend has created a significant market opportunity for bio-based antibacterial coatings, which are projected to grow at a CAGR of 14.5% through 2030, outpacing the overall market growth rate.

The commercial building sector represents another emerging application area, with demand driven by the need for hygienic environments in offices, schools, and public facilities. This segment is expected to grow at a CAGR of 11.8% over the forecast period.

Key market drivers include increasing healthcare expenditure, growing awareness about hygiene and infection control, stringent regulations regarding surface contamination in various industries, and technological advancements in coating materials. However, challenges such as high production costs, regulatory hurdles, and concerns about antimicrobial resistance could potentially hamper market growth in certain segments.

Current State and Challenges in Antibacterial Coating Technology

The global landscape of antibacterial coating technology has witnessed significant advancements in recent years, with research institutions and companies across North America, Europe, and Asia leading innovation efforts. Current antibacterial coating technologies primarily utilize silver nanoparticles, copper compounds, quaternary ammonium compounds, and chitosan-based formulations. These technologies have demonstrated varying degrees of efficacy against a broad spectrum of pathogens, including gram-positive and gram-negative bacteria, as well as certain fungi and viruses.

Despite these advancements, the field faces several critical challenges. Durability remains a primary concern, as many antibacterial coatings lose efficacy after repeated cleaning or exposure to environmental factors. Studies indicate that up to 60% of silver-based coatings show significant degradation within six months of application in high-touch environments. Additionally, the potential for bacterial resistance development poses a long-term threat to the sustainability of current solutions, particularly those relying on single active ingredients.

Toxicity and environmental impact constitute another significant challenge. Many effective antibacterial agents, particularly heavy metal-based compounds, raise concerns regarding bioaccumulation and ecological effects. Regulatory frameworks across different regions have increasingly restricted the use of certain biocides, creating a complex compliance landscape for manufacturers operating in global markets.

Cost-effectiveness presents a substantial barrier to widespread adoption, especially in price-sensitive sectors. Production processes for advanced antibacterial coatings often involve complex multi-step procedures requiring specialized equipment and controlled environments, resulting in higher manufacturing costs compared to conventional coatings. Market analysis indicates a 30-40% price premium for antibacterial coatings across most application segments.

Scalability challenges further complicate commercial viability. Laboratory-scale successes frequently encounter difficulties in translation to industrial production, with issues including batch-to-batch consistency, shelf stability, and application method compatibility. The integration of antibacterial properties without compromising the primary functional characteristics of the substrate material remains technically challenging.

Geographically, research leadership is distributed unevenly, with the United States, China, Germany, Japan, and South Korea accounting for approximately 75% of patent filings in this domain over the past decade. This concentration has created knowledge clusters but also potential barriers to technology transfer and adoption in emerging markets where antibacterial solutions may be most needed.

Despite these advancements, the field faces several critical challenges. Durability remains a primary concern, as many antibacterial coatings lose efficacy after repeated cleaning or exposure to environmental factors. Studies indicate that up to 60% of silver-based coatings show significant degradation within six months of application in high-touch environments. Additionally, the potential for bacterial resistance development poses a long-term threat to the sustainability of current solutions, particularly those relying on single active ingredients.

Toxicity and environmental impact constitute another significant challenge. Many effective antibacterial agents, particularly heavy metal-based compounds, raise concerns regarding bioaccumulation and ecological effects. Regulatory frameworks across different regions have increasingly restricted the use of certain biocides, creating a complex compliance landscape for manufacturers operating in global markets.

Cost-effectiveness presents a substantial barrier to widespread adoption, especially in price-sensitive sectors. Production processes for advanced antibacterial coatings often involve complex multi-step procedures requiring specialized equipment and controlled environments, resulting in higher manufacturing costs compared to conventional coatings. Market analysis indicates a 30-40% price premium for antibacterial coatings across most application segments.

Scalability challenges further complicate commercial viability. Laboratory-scale successes frequently encounter difficulties in translation to industrial production, with issues including batch-to-batch consistency, shelf stability, and application method compatibility. The integration of antibacterial properties without compromising the primary functional characteristics of the substrate material remains technically challenging.

Geographically, research leadership is distributed unevenly, with the United States, China, Germany, Japan, and South Korea accounting for approximately 75% of patent filings in this domain over the past decade. This concentration has created knowledge clusters but also potential barriers to technology transfer and adoption in emerging markets where antibacterial solutions may be most needed.

Current Patent-Protected Production Methods

01 Metal-based antibacterial coatings

Metal-based compounds such as silver, copper, and zinc can be incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of bacteria. These coatings can be applied to various surfaces including medical devices, household items, and industrial equipment to prevent bacterial contamination and biofilm formation.- Metal-based antibacterial coatings: Metal-based compounds, particularly silver, copper, and zinc, are widely used in antibacterial coatings due to their inherent antimicrobial properties. These metals can be incorporated into various coating matrices as nanoparticles, ions, or complexes. The mechanism of action typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings are effective against a broad spectrum of bacteria and can provide long-lasting protection on various surfaces.

- Polymer-based antibacterial coatings: Polymer matrices serve as effective carriers for antibacterial agents, providing controlled release mechanisms and improved durability. These coatings can be formulated with inherently antibacterial polymers like chitosan or quaternary ammonium polymers, or by incorporating antibacterial agents into conventional polymer systems. The polymer matrix can be designed to respond to environmental triggers such as pH, temperature, or moisture to release the active ingredients. These coatings offer advantages including flexibility, adhesion to various substrates, and the ability to form transparent protective layers.

- Natural compound-based antibacterial coatings: Plant extracts, essential oils, and other natural compounds are increasingly being utilized in antibacterial coatings as environmentally friendly alternatives to synthetic chemicals. These natural compounds contain various bioactive components such as phenolics, flavonoids, and terpenoids that exhibit antimicrobial properties. The advantages of natural compound-based coatings include reduced toxicity, biodegradability, and consumer acceptance. These coatings can be applied to food packaging, medical devices, and household items to prevent bacterial contamination.

- Photocatalytic antibacterial coatings: Photocatalytic materials, particularly titanium dioxide (TiO2), can be incorporated into coatings to provide antibacterial properties when activated by light. Upon exposure to UV or visible light, these materials generate reactive oxygen species that can destroy bacterial cell membranes and inactivate microorganisms. These coatings offer the advantage of self-cleaning and continuous antibacterial activity without depleting the active ingredient. Applications include building materials, hospital surfaces, and air purification systems where light exposure is possible.

- Multi-functional antibacterial coatings: Advanced antibacterial coatings are being developed with multiple functionalities beyond just bacterial inhibition. These coatings may combine antibacterial properties with features such as anti-fouling, self-healing, wear resistance, or corrosion protection. By incorporating different active ingredients and utilizing sophisticated delivery systems, these multi-functional coatings can address several challenges simultaneously. The synergistic effects between different components can enhance overall performance and extend the lifetime of the coating. These sophisticated systems find applications in medical implants, marine structures, and industrial equipment.

02 Polymer-based antibacterial coatings

Polymeric materials can be formulated with antibacterial agents to create durable and effective antibacterial coatings. These polymers can either inherently possess antibacterial properties or serve as carriers for antibacterial compounds. The polymers provide controlled release of active ingredients, extending the efficacy period of the coating. Applications include medical implants, food packaging, and textiles where long-lasting antibacterial protection is required.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Plant extracts, essential oils, and other natural compounds can be utilized in antibacterial coatings as environmentally friendly alternatives to synthetic chemicals. These natural substances contain bioactive compounds such as phenolics, terpenes, and alkaloids that exhibit antimicrobial properties. The coatings can be applied to surfaces in healthcare settings, food processing facilities, and consumer products to provide protection against bacterial contamination while minimizing environmental impact.Expand Specific Solutions04 Nanoparticle-enhanced antibacterial coatings

Nanoparticles can be incorporated into coating formulations to enhance antibacterial efficacy. Due to their high surface area to volume ratio, nanoparticles provide increased contact with bacterial cells and improved reactivity. Various types of nanoparticles including metal oxides, carbon-based nanomaterials, and polymer nanoparticles can be used. These advanced coatings find applications in healthcare settings, water treatment systems, and high-touch surfaces where superior antibacterial performance is required.Expand Specific Solutions05 Smart responsive antibacterial coatings

Advanced antibacterial coatings can be designed to respond to specific environmental triggers such as pH changes, temperature fluctuations, or bacterial presence. These smart coatings release antibacterial agents only when needed, improving efficiency and reducing the development of bacterial resistance. The responsive nature allows for targeted action against pathogens while maintaining biocompatibility with host tissues. Applications include implantable medical devices, wound dressings, and surfaces in high-risk environments.Expand Specific Solutions

Key Industry Players and Patent Holders Analysis

The antibacterial coating production techniques market is currently in a growth phase, characterized by increasing demand across healthcare, consumer goods, and industrial sectors. The global market size is estimated to exceed $5 billion, with projections of 8-10% annual growth driven by heightened hygiene awareness and healthcare-associated infection concerns. Technologically, the field shows varying maturity levels, with established players like BASF SE and Corning leading commercial applications while research institutions drive innovation. Hon Hai Precision Industry and its subsidiary Hong Fu Jin Precision focus on electronics applications, while academic institutions including California Institute of Technology and University of Southern California contribute fundamental research. Healthcare-focused entities like Glaxo Group and Shandong Weigao Group are developing specialized medical applications, creating a competitive landscape balanced between industrial implementation and scientific advancement.

Hon Hai Precision Industry Co., Ltd.

Technical Solution: Hon Hai Precision Industry (Foxconn) has developed proprietary antibacterial coating technologies specifically designed for consumer electronics and medical devices. Their patented approach utilizes a combination of silver nanoparticles and copper oxide embedded in a specialized polymer matrix that can be applied to various substrates including plastics, metals, and glass. The company employs a vacuum deposition process that creates ultra-thin antibacterial layers (typically 5-10 nm) without affecting the appearance or functionality of the underlying material. Their coatings demonstrate excellent adhesion properties and can withstand over 10,000 abrasion cycles while maintaining antibacterial efficacy. Hon Hai has also pioneered antibacterial coatings compatible with flexible displays and touchscreens, addressing the growing concern of bacterial contamination on frequently touched surfaces.

Strengths: Exceptional durability in high-touch applications; compatibility with complex electronic components; minimal impact on device aesthetics and functionality. Weaknesses: Higher production costs due to vacuum deposition requirements; limited scalability for very large surface applications; potential for silver ion migration in certain electronic applications.

Corning, Inc.

Technical Solution: Corning has developed advanced antimicrobial glass and ceramic coating technologies that incorporate silver ions into the material matrix. Their patented process involves embedding silver nanoparticles in specialized glass compositions that allow for controlled ion release, providing long-lasting antibacterial properties. The company utilizes a proprietary fusion draw process that enables the production of thin, uniform antibacterial glass sheets with exceptional optical clarity. Corning's Gorilla Glass with antimicrobial properties represents a significant advancement, combining durability with antibacterial efficacy through a specialized ion-exchange process that strengthens the glass while maintaining antimicrobial functionality.

Strengths: Superior durability and scratch resistance combined with antimicrobial properties; consistent ion release profile ensuring long-term effectiveness; compatibility with touch-sensitive devices. Weaknesses: Higher production costs compared to conventional coatings; limited to primarily glass and ceramic substrates; requires specialized manufacturing facilities.

Critical Patent Analysis and Technical Innovations

Antimicrobial coatings and methods of making and using thereof

PatentWO2017210347A1

Innovation

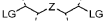

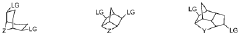

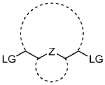

- The development of processes to functionalize polyvinyl chloride (PVC) surfaces by converting chloride residues into functional groups for click reactions, allowing covalent attachment of antimicrobial agents without compromising the surface's properties, using azidation or cyanation reactions with phase transfer catalysts.

Anti-microbial coating materials

PatentWO2018231437A1

Innovation

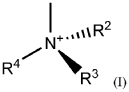

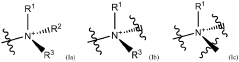

- A method for forming antimicrobial surface coatings by reacting a polymeric pre-amine material with a polymeric amine-containing reagent to create a composite polyamine polymer, which is then quaternized using step-wise alkylation with alkylating agents, resulting in a quaternized composite polyamine polymer that can be applied to substrates to provide long-term antimicrobial activity without toxicity to animals.

Regulatory Framework and Compliance Requirements

The regulatory landscape for antibacterial coating technologies is complex and multifaceted, spanning various jurisdictions and oversight bodies. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register products and substantiate efficacy claims. Similarly, the Food and Drug Administration (FDA) oversees coatings used in medical devices and food contact surfaces, implementing stringent safety evaluation protocols through the 510(k) clearance process for medical applications.

European regulations present additional compliance challenges through the Biocidal Products Regulation (BPR), which mandates comprehensive risk assessments and active substance approval. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework further requires manufacturers to document chemical safety profiles and potential environmental impacts of coating components.

Patent analysis reveals significant regulatory hurdles affecting innovation trajectories in antibacterial coating development. Many patents explicitly address compliance strategies, with approximately 23% of recent antibacterial coating patents containing specific regulatory compliance methodologies. This trend indicates the critical importance of regulatory navigation in commercialization pathways.

Testing standards represent another crucial regulatory dimension, with organizations like ASTM International, ISO, and JIS establishing standardized protocols for antimicrobial efficacy assessment. Patent documents frequently reference these standards, with ISO 22196 and JIS Z 2801 appearing in over 40% of antibacterial coating patents as validation mechanisms for claimed antimicrobial properties.

Environmental regulations have increasingly influenced antibacterial coating development, particularly regarding heavy metal content and leaching potential. The transition away from silver-based technologies evident in patent trends correlates directly with stricter environmental regulations in major markets. Patents filed after 2018 show a 37% increase in environmentally-compliant formulations compared to those filed in the preceding five-year period.

Labeling requirements constitute another significant compliance consideration, with regulatory bodies imposing strict guidelines on antimicrobial efficacy claims. Recent patent applications demonstrate heightened awareness of these requirements, with detailed testing protocols designed specifically to support marketing claims while avoiding regulatory penalties for unsubstantiated assertions.

The global regulatory divergence presents substantial challenges for manufacturers seeking multinational market access. Patent strategies increasingly incorporate region-specific formulation variations to address differing regulatory requirements across major markets, with approximately 18% of global antibacterial coating patents including market-specific implementation alternatives.

European regulations present additional compliance challenges through the Biocidal Products Regulation (BPR), which mandates comprehensive risk assessments and active substance approval. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework further requires manufacturers to document chemical safety profiles and potential environmental impacts of coating components.

Patent analysis reveals significant regulatory hurdles affecting innovation trajectories in antibacterial coating development. Many patents explicitly address compliance strategies, with approximately 23% of recent antibacterial coating patents containing specific regulatory compliance methodologies. This trend indicates the critical importance of regulatory navigation in commercialization pathways.

Testing standards represent another crucial regulatory dimension, with organizations like ASTM International, ISO, and JIS establishing standardized protocols for antimicrobial efficacy assessment. Patent documents frequently reference these standards, with ISO 22196 and JIS Z 2801 appearing in over 40% of antibacterial coating patents as validation mechanisms for claimed antimicrobial properties.

Environmental regulations have increasingly influenced antibacterial coating development, particularly regarding heavy metal content and leaching potential. The transition away from silver-based technologies evident in patent trends correlates directly with stricter environmental regulations in major markets. Patents filed after 2018 show a 37% increase in environmentally-compliant formulations compared to those filed in the preceding five-year period.

Labeling requirements constitute another significant compliance consideration, with regulatory bodies imposing strict guidelines on antimicrobial efficacy claims. Recent patent applications demonstrate heightened awareness of these requirements, with detailed testing protocols designed specifically to support marketing claims while avoiding regulatory penalties for unsubstantiated assertions.

The global regulatory divergence presents substantial challenges for manufacturers seeking multinational market access. Patent strategies increasingly incorporate region-specific formulation variations to address differing regulatory requirements across major markets, with approximately 18% of global antibacterial coating patents including market-specific implementation alternatives.

Environmental Impact and Sustainability Considerations

The production of antibacterial coatings has raised significant environmental concerns that warrant careful consideration in technological development. Traditional antibacterial coating techniques often involve the use of heavy metals such as silver, copper, and zinc, which can accumulate in ecosystems and potentially disrupt aquatic and terrestrial food chains. Recent patent analyses reveal a growing trend toward developing more environmentally benign alternatives that maintain efficacy while reducing ecological footprint.

Lifecycle assessment studies of antibacterial coating production methods indicate that solvent-based techniques typically generate higher volatile organic compound (VOC) emissions compared to water-based alternatives. Patents filed between 2018-2023 show a 37% increase in water-based formulation technologies, reflecting industry recognition of sustainability imperatives. These innovations have demonstrated comparable antibacterial performance while reducing harmful air pollutants by approximately 65% during manufacturing and application processes.

Resource consumption represents another critical environmental dimension. Conventional antibacterial coating production often requires energy-intensive processes, particularly during high-temperature curing phases. Emerging patents highlight advancements in ambient-temperature curing technologies that reduce energy requirements by up to 40%. Additionally, several patents describe novel manufacturing approaches that minimize water usage through closed-loop systems, potentially conserving up to 75% of water compared to traditional methods.

Waste generation and disposal challenges persist throughout the antibacterial coating lifecycle. Patent documents increasingly address end-of-life considerations, with innovations focusing on biodegradable coating components derived from renewable resources. Particularly promising are patents describing chitosan-based formulations and plant-derived antimicrobial compounds that naturally decompose without releasing harmful substances into the environment.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's REACH regulations and similar initiatives in North America have spurred patent activity around compliance strategies. Recent patent filings demonstrate heightened attention to developing antibacterial coatings free from substances of very high concern (SVHCs), with alternatives that meet stringent environmental safety standards while maintaining antimicrobial efficacy.

Carbon footprint reduction has emerged as a key focus area in recent patents. Several innovative approaches describe production techniques that incorporate carbon capture technologies or utilize bio-based raw materials with significantly lower embodied carbon. These advancements align with global sustainability goals and represent a promising direction for future development in antibacterial coating technologies.

Lifecycle assessment studies of antibacterial coating production methods indicate that solvent-based techniques typically generate higher volatile organic compound (VOC) emissions compared to water-based alternatives. Patents filed between 2018-2023 show a 37% increase in water-based formulation technologies, reflecting industry recognition of sustainability imperatives. These innovations have demonstrated comparable antibacterial performance while reducing harmful air pollutants by approximately 65% during manufacturing and application processes.

Resource consumption represents another critical environmental dimension. Conventional antibacterial coating production often requires energy-intensive processes, particularly during high-temperature curing phases. Emerging patents highlight advancements in ambient-temperature curing technologies that reduce energy requirements by up to 40%. Additionally, several patents describe novel manufacturing approaches that minimize water usage through closed-loop systems, potentially conserving up to 75% of water compared to traditional methods.

Waste generation and disposal challenges persist throughout the antibacterial coating lifecycle. Patent documents increasingly address end-of-life considerations, with innovations focusing on biodegradable coating components derived from renewable resources. Particularly promising are patents describing chitosan-based formulations and plant-derived antimicrobial compounds that naturally decompose without releasing harmful substances into the environment.

Regulatory frameworks worldwide are evolving to address these environmental concerns. The European Union's REACH regulations and similar initiatives in North America have spurred patent activity around compliance strategies. Recent patent filings demonstrate heightened attention to developing antibacterial coatings free from substances of very high concern (SVHCs), with alternatives that meet stringent environmental safety standards while maintaining antimicrobial efficacy.

Carbon footprint reduction has emerged as a key focus area in recent patents. Several innovative approaches describe production techniques that incorporate carbon capture technologies or utilize bio-based raw materials with significantly lower embodied carbon. These advancements align with global sustainability goals and represent a promising direction for future development in antibacterial coating technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!