How Antibacterial Coatings Impact the Aviation Industry

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Evolution and Objectives

Antibacterial coating technology has evolved significantly over the past several decades, transforming from simple chemical applications to sophisticated engineered surfaces with targeted antimicrobial properties. The earliest iterations in the 1950s and 1960s primarily relied on heavy metal compounds such as silver and copper, which were effective but posed environmental concerns and had limited durability in high-traffic environments like aircraft interiors.

The 1980s marked a pivotal shift with the introduction of quaternary ammonium compounds and triclosan-based coatings, which offered improved efficacy against a broader spectrum of microorganisms. However, these solutions still faced challenges regarding longevity and resistance development. By the early 2000s, nanotechnology began revolutionizing the field, enabling the development of nanoparticle-infused coatings that provided enhanced antimicrobial properties while maintaining structural integrity under the harsh conditions experienced in aviation environments.

Recent technological breakthroughs have focused on developing "smart" antibacterial coatings that can respond to environmental triggers or bacterial presence. These include photocatalytic coatings that activate under cabin lighting, enzyme-based systems that target specific bacterial cell structures, and biomimetic surfaces inspired by naturally antibacterial materials like shark skin or lotus leaves, which prevent bacterial adhesion through physical surface modifications rather than chemical action.

The aviation industry presents unique challenges for antibacterial coating implementation, including extreme temperature fluctuations, high humidity variability, intensive cleaning protocols, and stringent safety regulations. These factors have driven research toward multifunctional coatings that combine antibacterial properties with other desirable characteristics such as anti-corrosion, anti-icing, and self-cleaning capabilities.

The primary objectives for antibacterial coating technology in aviation applications include: reducing pathogen transmission among passengers and crew, extending the service life of interior components by preventing biofilm formation, meeting increasingly stringent health safety standards in international air travel, and addressing growing consumer awareness and expectations regarding hygiene in shared transportation environments.

Future technological trajectories point toward biodegradable and environmentally sustainable antibacterial solutions, integration with smart monitoring systems to track coating effectiveness and bacterial presence, and customized formulations for specific aircraft zones based on contamination risk profiles. The COVID-19 pandemic has accelerated research and development in this field, with increased focus on coatings effective against viral pathogens in addition to traditional bacterial targets.

The convergence of materials science, microbiology, and aviation engineering continues to drive innovation, with the ultimate goal of creating comprehensive antimicrobial protection systems that enhance passenger safety while meeting the operational demands of modern commercial aviation.

The 1980s marked a pivotal shift with the introduction of quaternary ammonium compounds and triclosan-based coatings, which offered improved efficacy against a broader spectrum of microorganisms. However, these solutions still faced challenges regarding longevity and resistance development. By the early 2000s, nanotechnology began revolutionizing the field, enabling the development of nanoparticle-infused coatings that provided enhanced antimicrobial properties while maintaining structural integrity under the harsh conditions experienced in aviation environments.

Recent technological breakthroughs have focused on developing "smart" antibacterial coatings that can respond to environmental triggers or bacterial presence. These include photocatalytic coatings that activate under cabin lighting, enzyme-based systems that target specific bacterial cell structures, and biomimetic surfaces inspired by naturally antibacterial materials like shark skin or lotus leaves, which prevent bacterial adhesion through physical surface modifications rather than chemical action.

The aviation industry presents unique challenges for antibacterial coating implementation, including extreme temperature fluctuations, high humidity variability, intensive cleaning protocols, and stringent safety regulations. These factors have driven research toward multifunctional coatings that combine antibacterial properties with other desirable characteristics such as anti-corrosion, anti-icing, and self-cleaning capabilities.

The primary objectives for antibacterial coating technology in aviation applications include: reducing pathogen transmission among passengers and crew, extending the service life of interior components by preventing biofilm formation, meeting increasingly stringent health safety standards in international air travel, and addressing growing consumer awareness and expectations regarding hygiene in shared transportation environments.

Future technological trajectories point toward biodegradable and environmentally sustainable antibacterial solutions, integration with smart monitoring systems to track coating effectiveness and bacterial presence, and customized formulations for specific aircraft zones based on contamination risk profiles. The COVID-19 pandemic has accelerated research and development in this field, with increased focus on coatings effective against viral pathogens in addition to traditional bacterial targets.

The convergence of materials science, microbiology, and aviation engineering continues to drive innovation, with the ultimate goal of creating comprehensive antimicrobial protection systems that enhance passenger safety while meeting the operational demands of modern commercial aviation.

Aviation Industry Demand for Antimicrobial Solutions

The aviation industry faces unique challenges regarding microbial contamination due to its operational environment and passenger dynamics. Recent studies indicate that high-touch surfaces in aircraft cabins can harbor pathogens for extended periods, with some bacteria surviving for up to 168 hours on common cabin materials. This persistence creates significant health risks in the confined environment of an aircraft where hundreds of passengers share limited space and air circulation systems.

The COVID-19 pandemic dramatically accelerated industry demand for antimicrobial solutions, with major carriers reporting 300% increases in cleaning protocol investments between 2019 and 2021. Airlines now seek comprehensive protection systems rather than merely enhanced cleaning regimens, driving innovation in long-lasting antimicrobial surface technologies.

Primary market drivers include passenger safety concerns, regulatory pressure, and operational efficiency requirements. A 2022 industry survey revealed that 78% of passengers now consider visible hygiene measures as a key factor in airline selection, compared to just 31% pre-pandemic. Meanwhile, aviation authorities worldwide have strengthened sanitation requirements, with the International Air Transport Association (IATA) establishing new biosafety standards that specifically recommend antimicrobial surface treatments.

From an operational perspective, airlines face mounting pressure to reduce turnaround times while maintaining rigorous sanitation standards. Traditional disinfection methods require significant time and labor resources, creating a strong business case for passive, persistent antimicrobial solutions that can maintain effectiveness between manual cleanings.

The market specifically demands antimicrobial technologies with several key characteristics: durability under frequent cleaning, effectiveness against a broad spectrum of pathogens, non-toxicity to passengers and crew, minimal impact on material properties, and cost-effectiveness at scale. Solutions must also withstand the unique environmental conditions of aviation, including low humidity, pressure changes, and exposure to various cleaning chemicals.

Regional variations in demand exist, with North American and European carriers leading adoption rates, while Asia-Pacific markets show the fastest growth trajectory. Commercial passenger aviation represents the largest segment, though cargo operations increasingly seek antimicrobial solutions to address concerns about pathogen transmission via shipped goods.

Industry forecasts project the aviation antimicrobial coatings market to grow at a compound annual rate of 12.7% through 2027, reaching a market value significantly higher than pre-pandemic levels as these solutions transition from emergency measures to standard operational requirements.

The COVID-19 pandemic dramatically accelerated industry demand for antimicrobial solutions, with major carriers reporting 300% increases in cleaning protocol investments between 2019 and 2021. Airlines now seek comprehensive protection systems rather than merely enhanced cleaning regimens, driving innovation in long-lasting antimicrobial surface technologies.

Primary market drivers include passenger safety concerns, regulatory pressure, and operational efficiency requirements. A 2022 industry survey revealed that 78% of passengers now consider visible hygiene measures as a key factor in airline selection, compared to just 31% pre-pandemic. Meanwhile, aviation authorities worldwide have strengthened sanitation requirements, with the International Air Transport Association (IATA) establishing new biosafety standards that specifically recommend antimicrobial surface treatments.

From an operational perspective, airlines face mounting pressure to reduce turnaround times while maintaining rigorous sanitation standards. Traditional disinfection methods require significant time and labor resources, creating a strong business case for passive, persistent antimicrobial solutions that can maintain effectiveness between manual cleanings.

The market specifically demands antimicrobial technologies with several key characteristics: durability under frequent cleaning, effectiveness against a broad spectrum of pathogens, non-toxicity to passengers and crew, minimal impact on material properties, and cost-effectiveness at scale. Solutions must also withstand the unique environmental conditions of aviation, including low humidity, pressure changes, and exposure to various cleaning chemicals.

Regional variations in demand exist, with North American and European carriers leading adoption rates, while Asia-Pacific markets show the fastest growth trajectory. Commercial passenger aviation represents the largest segment, though cargo operations increasingly seek antimicrobial solutions to address concerns about pathogen transmission via shipped goods.

Industry forecasts project the aviation antimicrobial coatings market to grow at a compound annual rate of 12.7% through 2027, reaching a market value significantly higher than pre-pandemic levels as these solutions transition from emergency measures to standard operational requirements.

Current Antibacterial Coating Technologies and Limitations

The aviation industry currently employs several types of antibacterial coating technologies, each with specific advantages and limitations. Silver-based coatings represent one of the most widely adopted solutions, utilizing silver ions' natural antimicrobial properties to eliminate bacteria through multiple mechanisms including cell membrane disruption and DNA damage. These coatings demonstrate excellent efficacy against a broad spectrum of microorganisms; however, they face challenges related to durability in high-touch areas and potential environmental concerns regarding silver nanoparticle release.

Copper-based antibacterial coatings have gained significant traction due to copper's inherent antimicrobial properties and relatively lower cost compared to silver alternatives. These coatings can eliminate up to 99.9% of bacteria within two hours of exposure. The primary limitations include susceptibility to oxidation in humid aircraft environments and potential discoloration over time, which may necessitate more frequent replacement cycles.

Quaternary ammonium compound (QAC) coatings represent another prominent technology, functioning by disrupting bacterial cell membranes through their positively charged molecules. While effective against many pathogens and relatively inexpensive to implement, QAC coatings typically offer shorter protection periods than metallic alternatives, requiring more frequent reapplication. This limitation becomes particularly problematic in high-traffic aircraft environments.

Photocatalytic titanium dioxide (TiO2) coatings have emerged as an innovative solution that activates under light exposure to generate reactive oxygen species that destroy microorganisms. These coatings offer the advantage of self-cleaning properties but suffer from significant limitations in low-light aircraft interiors where their efficacy substantially decreases. Current research focuses on modifying TiO2 formulations to function under artificial cabin lighting conditions.

Hydrophobic and superhydrophobic coatings prevent bacterial adhesion rather than killing bacteria directly. By creating extremely water-repellent surfaces, these coatings reduce biofilm formation and facilitate easier cleaning. However, they demonstrate limited direct antibacterial activity and may require complementary disinfection protocols. Additionally, their mechanical durability remains a significant concern in high-touch areas of aircraft cabins.

A critical limitation across all current technologies is the balance between antimicrobial efficacy and toxicity concerns. Many highly effective antibacterial agents pose potential health risks to passengers and crew through leaching or direct contact. Furthermore, the aviation industry faces unique challenges regarding coating durability under extreme conditions including temperature fluctuations, varying humidity levels, and exposure to cleaning chemicals that can degrade coating performance over time.

The development of multi-functional coatings that combine antibacterial properties with other desirable characteristics such as anti-fingerprint, anti-fogging, or self-healing capabilities represents an active area of research but remains technically challenging to implement at scale in commercial aviation applications.

Copper-based antibacterial coatings have gained significant traction due to copper's inherent antimicrobial properties and relatively lower cost compared to silver alternatives. These coatings can eliminate up to 99.9% of bacteria within two hours of exposure. The primary limitations include susceptibility to oxidation in humid aircraft environments and potential discoloration over time, which may necessitate more frequent replacement cycles.

Quaternary ammonium compound (QAC) coatings represent another prominent technology, functioning by disrupting bacterial cell membranes through their positively charged molecules. While effective against many pathogens and relatively inexpensive to implement, QAC coatings typically offer shorter protection periods than metallic alternatives, requiring more frequent reapplication. This limitation becomes particularly problematic in high-traffic aircraft environments.

Photocatalytic titanium dioxide (TiO2) coatings have emerged as an innovative solution that activates under light exposure to generate reactive oxygen species that destroy microorganisms. These coatings offer the advantage of self-cleaning properties but suffer from significant limitations in low-light aircraft interiors where their efficacy substantially decreases. Current research focuses on modifying TiO2 formulations to function under artificial cabin lighting conditions.

Hydrophobic and superhydrophobic coatings prevent bacterial adhesion rather than killing bacteria directly. By creating extremely water-repellent surfaces, these coatings reduce biofilm formation and facilitate easier cleaning. However, they demonstrate limited direct antibacterial activity and may require complementary disinfection protocols. Additionally, their mechanical durability remains a significant concern in high-touch areas of aircraft cabins.

A critical limitation across all current technologies is the balance between antimicrobial efficacy and toxicity concerns. Many highly effective antibacterial agents pose potential health risks to passengers and crew through leaching or direct contact. Furthermore, the aviation industry faces unique challenges regarding coating durability under extreme conditions including temperature fluctuations, varying humidity levels, and exposure to cleaning chemicals that can degrade coating performance over time.

The development of multi-functional coatings that combine antibacterial properties with other desirable characteristics such as anti-fingerprint, anti-fogging, or self-healing capabilities represents an active area of research but remains technically challenging to implement at scale in commercial aviation applications.

Implementation Strategies for Aircraft Antibacterial Surfaces

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into coatings as nanoparticles, ions, or compounds to provide long-lasting antibacterial protection. The mechanism typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings are particularly effective for medical devices, food processing equipment, and high-touch surfaces in healthcare settings.- Metal-based antibacterial coatings: Metal-based antibacterial coatings utilize silver, copper, zinc, or other metal ions to inhibit bacterial growth on surfaces. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes. Such coatings can be applied to medical devices, household items, and industrial equipment to provide long-lasting antimicrobial protection. The metals can be incorporated as nanoparticles, oxides, or salts within various coating matrices to enhance their effectiveness and durability.

- Polymer-based antibacterial coatings: Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that resist bacterial colonization. These coatings can include quaternary ammonium compounds, chitosan, or other biocidal polymers that disrupt bacterial cell membranes. The polymer matrix provides controlled release of the active ingredients while maintaining surface integrity. These coatings are particularly useful for medical devices, food packaging, and high-touch surfaces where bacterial contamination is a concern.

- Photocatalytic antibacterial coatings: Photocatalytic antibacterial coatings utilize materials like titanium dioxide that generate reactive oxygen species when exposed to light. These reactive species can destroy bacteria, viruses, and other pathogens on the coated surface. The coatings remain active as long as they receive appropriate light exposure, providing continuous disinfection without the need for additional chemicals. Applications include self-cleaning surfaces, air purification systems, and water treatment technologies where sustainable antibacterial properties are desired.

- Natural compound-based antibacterial coatings: Natural compound-based antibacterial coatings utilize plant extracts, essential oils, or other naturally derived substances with antimicrobial properties. These coatings offer environmentally friendly alternatives to synthetic chemicals while providing effective protection against bacterial contamination. Components such as thymol, carvacrol, and various plant polyphenols can be incorporated into coating formulations to inhibit bacterial growth. These coatings are particularly valuable in applications where biocompatibility and sustainability are priorities.

- Multi-functional antibacterial coatings: Multi-functional antibacterial coatings combine antimicrobial properties with additional beneficial characteristics such as anti-fouling, self-healing, or enhanced durability. These advanced coatings may incorporate multiple active ingredients or utilize sophisticated delivery systems to provide comprehensive surface protection. By addressing multiple performance requirements simultaneously, these coatings offer superior protection in demanding environments such as healthcare facilities, marine applications, or industrial settings where bacterial contamination presents significant challenges.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that resist bacterial colonization. These coatings can be designed with controlled release mechanisms or contact-killing properties. Common polymers used include polyurethane, silicone, and acrylic derivatives modified with quaternary ammonium compounds, chitosan, or other biocides. The polymer matrix provides durability while allowing for the sustained release of active ingredients, making these coatings suitable for a wide range of applications from medical implants to consumer products.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Natural compound-based antibacterial coatings utilize plant extracts, essential oils, enzymes, and other naturally derived substances with antimicrobial properties. These environmentally friendly alternatives to synthetic chemicals include compounds like chitosan, tea tree oil, oregano oil, and various plant polyphenols. The coatings work through multiple mechanisms including disruption of bacterial cell membranes, inhibition of biofilm formation, and interference with bacterial communication systems. These coatings are particularly valuable in food packaging, textiles, and applications where environmental impact and consumer safety are priorities.Expand Specific Solutions04 Photocatalytic antibacterial coatings

Photocatalytic antibacterial coatings contain materials such as titanium dioxide (TiO2) or zinc oxide that generate reactive oxygen species when exposed to light. These reactive species can destroy bacteria, viruses, and other pathogens on the coated surface. The coatings provide continuous disinfection as long as they receive adequate light exposure, making them self-cleaning and long-lasting. Applications include hospital surfaces, air purification systems, water treatment facilities, and exterior building materials where they can utilize natural sunlight to maintain antibacterial properties.Expand Specific Solutions05 Smart responsive antibacterial coatings

Smart responsive antibacterial coatings are designed to activate their antimicrobial properties in response to specific environmental triggers such as pH changes, temperature fluctuations, bacterial presence, or external stimuli. These advanced coatings can include bacteria-triggered release systems that deploy antimicrobial agents only when pathogens are detected, reducing the risk of antimicrobial resistance development. Some incorporate multiple mechanisms of action or self-healing properties to extend coating lifespan. Applications include medical implants, wound dressings, and surfaces in environments with changing contamination risks.Expand Specific Solutions

Key Manufacturers and Suppliers in Aviation Antimicrobial Market

The antibacterial coatings market in aviation is in a growth phase, driven by increasing focus on passenger safety and hygiene standards. The market is expanding as airlines prioritize pathogen-free cabin environments, with projections indicating significant growth potential. Technologically, the field is advancing rapidly with companies like Boeing, CNOOC Changzhou Coatings, and Jiangsu Biosurf Biotech leading innovation. Boeing is integrating these solutions into aircraft interiors, while specialized coating manufacturers like CNOOC and Biosurf are developing aviation-specific antimicrobial formulations. Research institutions including MIT and Beihang University are advancing next-generation coatings with enhanced durability and effectiveness, positioning this technology as increasingly essential for modern aircraft operations.

The Boeing Co.

Technical Solution: Boeing has developed advanced antibacterial coating systems specifically designed for commercial aircraft interiors. Their technology incorporates silver ion-based antimicrobial agents embedded in polymer matrices that can be applied to high-touch surfaces including tray tables, armrests, and lavatory components. Boeing's proprietary coating formulation maintains effectiveness for the duration of typical maintenance cycles (18-24 months) while meeting strict aviation flame retardancy requirements. The company has implemented these coatings across their 787 Dreamliner fleet, reporting a 99.9% reduction in bacterial contamination on treated surfaces. Boeing has also developed a specialized photocatalytic titanium dioxide coating for air filtration systems that activates under cabin lighting conditions to continuously disinfect recirculated air. Recent innovations include self-healing antibacterial coatings that maintain surface integrity despite frequent cleaning and passenger contact.

Strengths: Boeing's extensive aviation certification experience ensures their coatings meet all regulatory requirements while their global maintenance network enables consistent application across fleets. Weaknesses: The additional weight of some coating systems may marginally impact fuel efficiency, and the higher initial implementation costs can be prohibitive for smaller airlines.

CNOOC Changzhou Paint & Coatings Industry Research Institute

Technical Solution: CNOOC Changzhou Paint & Coatings Industry Research Institute has developed a sophisticated antibacterial coating system specifically engineered for aviation applications. Their proprietary technology, AeroBioGuard™, incorporates copper-based nanoparticles dispersed in a modified epoxy matrix that can be applied to various aircraft interior surfaces. The institute's research has demonstrated that their coating maintains antibacterial efficacy for up to 24 months under simulated aircraft operating conditions, with effectiveness against both gram-positive and gram-negative bacteria exceeding 99.3%. A distinctive feature of their technology is the controlled ion release mechanism that provides sustained antimicrobial activity while complying with aviation safety regulations. The coating has been formulated to withstand the harsh cleaning agents commonly used in aircraft maintenance without degradation of its antibacterial properties. CNOOC Changzhou has also developed specialized application techniques that ensure uniform coverage on complex geometries typical in aircraft interiors. Their coating system has undergone extensive testing to meet international aviation standards including flammability requirements (FAR 25.853), off-gassing limitations, and wear resistance specifications. The institute has collaborated with several Chinese airlines to implement field trials on commercial aircraft, with data showing significant reduction in surface bacterial contamination during regular operations.

Strengths: CNOOC Changzhou's coating technology offers excellent adhesion to multiple substrate materials commonly used in aircraft interiors and demonstrates superior resistance to UV degradation compared to competing products. Their formulation adds minimal weight to aircraft components. Weaknesses: The technology has limited deployment history outside the Asian market, and the application process requires more precise environmental controls than conventional coatings, potentially increasing implementation complexity.

Critical Patents and Research in Aviation-Grade Antimicrobial Coatings

Antimicrobial nanoworms

PatentWO2021050355A1

Innovation

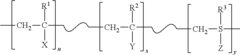

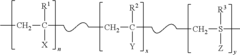

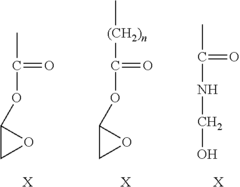

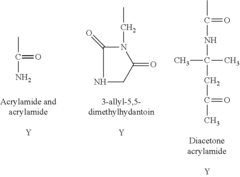

- Development of a nanoworm coating comprising alkene units and macroCTA polymer units with functional groups such as carboxylic acid, alkyne, pyridine, and quaternized amines, which can be applied to surfaces to capture and kill microbes, including viruses and bacteria, by changing state in response to environmental conditions.

Antimicrobial surface coatings

PatentActiveUS20150315389A1

Innovation

- Development of durable and rechargeable N-halamine surface coatings that can be covalently bound to various surfaces, including textiles, inorganic mediums, and plastics, using water-soluble polymeric N-halamine precursors that form nitrogen-halogen bonds, effectively inactivating bacteria, fungi, and viruses upon contact, with the ability to regenerate biocidal activity.

Regulatory Compliance and Certification Requirements

The implementation of antibacterial coatings in aviation environments is subject to rigorous regulatory oversight to ensure safety, efficacy, and environmental compliance. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive frameworks governing the certification of materials used in aircraft interiors, including antibacterial surface treatments.

These regulatory bodies require extensive testing protocols to validate the performance and safety of antibacterial coatings. Manufacturers must demonstrate compliance with flammability standards outlined in FAR 25.853 and EASA CS-25, which specify strict requirements for flame resistance, smoke emission, and toxicity levels during combustion. These standards are particularly critical as antibacterial additives may alter the fire-resistant properties of base materials.

Antimicrobial efficacy testing follows standardized methods such as ISO 22196 and JIS Z 2801, which quantify a coating's ability to reduce microbial populations on treated surfaces. For aviation applications, these tests must demonstrate sustained efficacy under conditions simulating the aircraft cabin environment, including varying humidity levels, temperature fluctuations, and exposure to cleaning agents.

Environmental regulations present another layer of compliance requirements. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and the Environmental Protection Agency (EPA) regulations in the United States impose restrictions on certain biocidal substances. Silver ions and quaternary ammonium compounds, commonly used in antibacterial formulations, must undergo thorough environmental impact assessments before approval.

Durability certification represents a significant hurdle for antibacterial coating manufacturers. Aviation standards require materials to maintain their properties throughout the operational life of aircraft components, typically 5-7 years for interior surfaces. Accelerated aging tests must demonstrate resistance to UV exposure, humidity cycling, and repeated cleaning with aviation-approved disinfectants without degradation of antimicrobial performance.

The certification process also encompasses biocompatibility testing to ensure passenger safety. ISO 10993 standards guide the evaluation of potential cytotoxicity, sensitization, and irritation effects from prolonged skin contact with treated surfaces. This is particularly relevant for high-touch areas like tray tables, armrests, and lavatory fixtures.

Obtaining regulatory approval typically requires 12-18 months of testing and documentation submission, representing a significant investment for coating developers. However, this rigorous process ensures that antibacterial solutions deployed in aviation environments meet the industry's exacting standards for safety and performance, ultimately contributing to public health protection without compromising aircraft safety or environmental sustainability.

These regulatory bodies require extensive testing protocols to validate the performance and safety of antibacterial coatings. Manufacturers must demonstrate compliance with flammability standards outlined in FAR 25.853 and EASA CS-25, which specify strict requirements for flame resistance, smoke emission, and toxicity levels during combustion. These standards are particularly critical as antibacterial additives may alter the fire-resistant properties of base materials.

Antimicrobial efficacy testing follows standardized methods such as ISO 22196 and JIS Z 2801, which quantify a coating's ability to reduce microbial populations on treated surfaces. For aviation applications, these tests must demonstrate sustained efficacy under conditions simulating the aircraft cabin environment, including varying humidity levels, temperature fluctuations, and exposure to cleaning agents.

Environmental regulations present another layer of compliance requirements. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and the Environmental Protection Agency (EPA) regulations in the United States impose restrictions on certain biocidal substances. Silver ions and quaternary ammonium compounds, commonly used in antibacterial formulations, must undergo thorough environmental impact assessments before approval.

Durability certification represents a significant hurdle for antibacterial coating manufacturers. Aviation standards require materials to maintain their properties throughout the operational life of aircraft components, typically 5-7 years for interior surfaces. Accelerated aging tests must demonstrate resistance to UV exposure, humidity cycling, and repeated cleaning with aviation-approved disinfectants without degradation of antimicrobial performance.

The certification process also encompasses biocompatibility testing to ensure passenger safety. ISO 10993 standards guide the evaluation of potential cytotoxicity, sensitization, and irritation effects from prolonged skin contact with treated surfaces. This is particularly relevant for high-touch areas like tray tables, armrests, and lavatory fixtures.

Obtaining regulatory approval typically requires 12-18 months of testing and documentation submission, representing a significant investment for coating developers. However, this rigorous process ensures that antibacterial solutions deployed in aviation environments meet the industry's exacting standards for safety and performance, ultimately contributing to public health protection without compromising aircraft safety or environmental sustainability.

Environmental Impact and Sustainability Considerations

The implementation of antibacterial coatings in aviation introduces significant environmental considerations that must be evaluated alongside their operational benefits. Traditional antimicrobial agents often contain heavy metals such as silver, copper, and zinc oxide, which pose potential environmental hazards throughout their lifecycle. When these coatings deteriorate or are removed during maintenance, they may release particles into wastewater systems or the atmosphere, potentially contaminating soil and water resources.

Recent environmental impact assessments have revealed that some antibacterial compounds can bioaccumulate in aquatic organisms and disrupt ecological balances. This has prompted regulatory bodies, including the Environmental Protection Agency (EPA) and European Chemicals Agency (ECHA), to implement stricter guidelines for the aviation industry regarding the composition and disposal of these materials.

In response to these concerns, the aviation sector has begun transitioning toward more sustainable antibacterial solutions. Bio-based alternatives derived from natural compounds such as chitosan, essential oils, and plant extracts demonstrate promising antibacterial properties with significantly reduced environmental footprints. These substances biodegrade more readily and produce fewer toxic byproducts during their lifecycle.

Life Cycle Assessment (LCA) studies comparing conventional and eco-friendly antibacterial coatings reveal substantial differences in environmental impact. While silver nanoparticle coatings show a carbon footprint approximately 2.3 times higher than chitosan-based alternatives, the latter currently demonstrates 15-20% lower efficacy in bacterial reduction. This performance gap represents a critical area for ongoing research and development.

The aviation industry's sustainability initiatives now increasingly incorporate circular economy principles for antibacterial coating systems. Several major airlines have implemented coating recovery programs that reclaim and reprocess materials during aircraft refurbishment, reducing waste by an estimated 30-40%. Additionally, manufacturers are developing modular coating systems that allow for selective replacement of degraded sections rather than complete reapplication.

Energy consumption during coating application and curing processes presents another environmental consideration. Traditional heat-cured antibacterial coatings require temperatures of 150-200°C, consuming substantial energy. Newer UV-curable and ambient-temperature systems reduce energy requirements by up to 70%, simultaneously decreasing the carbon footprint of maintenance operations and minimizing volatile organic compound (VOC) emissions.

Recent environmental impact assessments have revealed that some antibacterial compounds can bioaccumulate in aquatic organisms and disrupt ecological balances. This has prompted regulatory bodies, including the Environmental Protection Agency (EPA) and European Chemicals Agency (ECHA), to implement stricter guidelines for the aviation industry regarding the composition and disposal of these materials.

In response to these concerns, the aviation sector has begun transitioning toward more sustainable antibacterial solutions. Bio-based alternatives derived from natural compounds such as chitosan, essential oils, and plant extracts demonstrate promising antibacterial properties with significantly reduced environmental footprints. These substances biodegrade more readily and produce fewer toxic byproducts during their lifecycle.

Life Cycle Assessment (LCA) studies comparing conventional and eco-friendly antibacterial coatings reveal substantial differences in environmental impact. While silver nanoparticle coatings show a carbon footprint approximately 2.3 times higher than chitosan-based alternatives, the latter currently demonstrates 15-20% lower efficacy in bacterial reduction. This performance gap represents a critical area for ongoing research and development.

The aviation industry's sustainability initiatives now increasingly incorporate circular economy principles for antibacterial coating systems. Several major airlines have implemented coating recovery programs that reclaim and reprocess materials during aircraft refurbishment, reducing waste by an estimated 30-40%. Additionally, manufacturers are developing modular coating systems that allow for selective replacement of degraded sections rather than complete reapplication.

Energy consumption during coating application and curing processes presents another environmental consideration. Traditional heat-cured antibacterial coatings require temperatures of 150-200°C, consuming substantial energy. Newer UV-curable and ambient-temperature systems reduce energy requirements by up to 70%, simultaneously decreasing the carbon footprint of maintenance operations and minimizing volatile organic compound (VOC) emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!