Comparison of Antibacterial Coatings in Urban Infrastructure Use

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Evolution and Objectives

Antibacterial coatings have evolved significantly over the past several decades, transitioning from simple antimicrobial treatments to sophisticated multi-functional protective systems. The earliest iterations, developed in the 1950s, primarily utilized silver compounds and basic chemical biocides with limited durability and effectiveness. These early solutions often suffered from rapid degradation when exposed to environmental factors common in urban settings, such as UV radiation, precipitation, and temperature fluctuations.

The 1980s marked a pivotal shift with the introduction of quaternary ammonium compounds and triclosan-based coatings, which offered improved longevity and broader antimicrobial efficacy. However, these advancements were accompanied by growing concerns regarding environmental impact and potential contribution to antimicrobial resistance, prompting researchers to explore more sustainable alternatives.

The early 2000s witnessed the emergence of nanotechnology-based antibacterial coatings, incorporating silver nanoparticles, copper oxide, and zinc oxide nanostructures. These innovations significantly enhanced performance metrics, including durability, efficacy against a wider spectrum of pathogens, and reduced environmental footprint. Concurrently, photocatalytic coatings utilizing titanium dioxide gained prominence for their self-cleaning properties and ability to neutralize microorganisms through oxidation processes activated by ambient light.

Recent developments have focused on biomimetic approaches, drawing inspiration from natural antibacterial surfaces such as shark skin, lotus leaves, and insect wings. These bio-inspired coatings often combine physical bacterial deterrence mechanisms with chemical antimicrobial properties, creating multi-modal protection systems particularly valuable for high-touch urban infrastructure elements like handrails, door handles, and public transportation surfaces.

The current technological trajectory aims to address several critical objectives in urban infrastructure applications. Primary among these is the development of coatings with extended service life under diverse environmental conditions, reducing maintenance requirements and associated costs. Equally important is the enhancement of broad-spectrum antimicrobial efficacy against both gram-positive and gram-negative bacteria, as well as fungi and certain viruses relevant to public health in urban environments.

Additional objectives include minimizing environmental impact through reduced leaching of active compounds, eliminating potentially harmful substances like heavy metals and persistent organic pollutants, and ensuring compatibility with various substrate materials commonly used in urban infrastructure. The industry is also prioritizing cost-effectiveness to enable widespread implementation across public spaces, particularly in developing urban centers where infectious disease burden remains high.

Looking forward, research efforts are increasingly directed toward smart antibacterial coatings capable of responding to environmental triggers, selective targeting of pathogenic microorganisms while preserving beneficial microbial communities, and integration with other functional properties such as anti-corrosion, anti-fouling, and self-healing capabilities.

The 1980s marked a pivotal shift with the introduction of quaternary ammonium compounds and triclosan-based coatings, which offered improved longevity and broader antimicrobial efficacy. However, these advancements were accompanied by growing concerns regarding environmental impact and potential contribution to antimicrobial resistance, prompting researchers to explore more sustainable alternatives.

The early 2000s witnessed the emergence of nanotechnology-based antibacterial coatings, incorporating silver nanoparticles, copper oxide, and zinc oxide nanostructures. These innovations significantly enhanced performance metrics, including durability, efficacy against a wider spectrum of pathogens, and reduced environmental footprint. Concurrently, photocatalytic coatings utilizing titanium dioxide gained prominence for their self-cleaning properties and ability to neutralize microorganisms through oxidation processes activated by ambient light.

Recent developments have focused on biomimetic approaches, drawing inspiration from natural antibacterial surfaces such as shark skin, lotus leaves, and insect wings. These bio-inspired coatings often combine physical bacterial deterrence mechanisms with chemical antimicrobial properties, creating multi-modal protection systems particularly valuable for high-touch urban infrastructure elements like handrails, door handles, and public transportation surfaces.

The current technological trajectory aims to address several critical objectives in urban infrastructure applications. Primary among these is the development of coatings with extended service life under diverse environmental conditions, reducing maintenance requirements and associated costs. Equally important is the enhancement of broad-spectrum antimicrobial efficacy against both gram-positive and gram-negative bacteria, as well as fungi and certain viruses relevant to public health in urban environments.

Additional objectives include minimizing environmental impact through reduced leaching of active compounds, eliminating potentially harmful substances like heavy metals and persistent organic pollutants, and ensuring compatibility with various substrate materials commonly used in urban infrastructure. The industry is also prioritizing cost-effectiveness to enable widespread implementation across public spaces, particularly in developing urban centers where infectious disease burden remains high.

Looking forward, research efforts are increasingly directed toward smart antibacterial coatings capable of responding to environmental triggers, selective targeting of pathogenic microorganisms while preserving beneficial microbial communities, and integration with other functional properties such as anti-corrosion, anti-fouling, and self-healing capabilities.

Urban Infrastructure Demand Analysis

The global urban infrastructure market is experiencing unprecedented demand for antibacterial coatings, driven by increasing urbanization rates and heightened public health awareness following the COVID-19 pandemic. Current projections indicate that by 2030, over 60% of the world's population will reside in urban areas, creating immense pressure on public infrastructure and elevating concerns about pathogen transmission in high-traffic environments.

Urban transportation systems represent a primary application area, with subway handrails, bus seats, and ticket machines serving as significant pathogen transmission vectors. Studies conducted across major metropolitan areas have documented bacterial counts exceeding 400,000 CFU/cm² on frequently touched surfaces, highlighting the urgent need for effective antibacterial solutions.

Healthcare-adjacent infrastructure constitutes another critical demand segment. Public facilities near hospitals, clinics, and healthcare centers require enhanced protection against nosocomial infections. The healthcare-associated infection market, valued at $35.6 billion in 2022, is projected to grow at 3.8% CAGR through 2028, with infrastructure solutions representing an expanding segment.

Water management systems present a third significant application area. Municipal water infrastructure, particularly in aging urban centers, faces challenges from biofilm formation and bacterial contamination. The American Water Works Association estimates that approximately 240,000 water main breaks occur annually in the United States alone, with bacterial contamination following repairs representing a substantial public health concern.

Market research indicates regional variations in demand patterns. North American and European markets prioritize long-term durability and environmental compliance, while rapidly developing Asian urban centers emphasize cost-effectiveness and ease of application. The Middle East market demonstrates particular interest in solutions addressing extreme temperature conditions and sand abrasion resistance.

Consumer sentiment analysis reveals growing public expectation for visibly clean and pathogen-free public spaces. A 2022 global survey found that 78% of urban residents expressed concern about surface contamination in public transportation, while 64% indicated willingness to pay premium taxes for enhanced public health measures in infrastructure.

The regulatory landscape is increasingly favorable toward antibacterial infrastructure solutions. Recent policy frameworks in the European Union, Japan, and Singapore have established incentives for municipalities implementing pathogen-reduction technologies in public spaces, creating market pull for innovative coating solutions.

Urban transportation systems represent a primary application area, with subway handrails, bus seats, and ticket machines serving as significant pathogen transmission vectors. Studies conducted across major metropolitan areas have documented bacterial counts exceeding 400,000 CFU/cm² on frequently touched surfaces, highlighting the urgent need for effective antibacterial solutions.

Healthcare-adjacent infrastructure constitutes another critical demand segment. Public facilities near hospitals, clinics, and healthcare centers require enhanced protection against nosocomial infections. The healthcare-associated infection market, valued at $35.6 billion in 2022, is projected to grow at 3.8% CAGR through 2028, with infrastructure solutions representing an expanding segment.

Water management systems present a third significant application area. Municipal water infrastructure, particularly in aging urban centers, faces challenges from biofilm formation and bacterial contamination. The American Water Works Association estimates that approximately 240,000 water main breaks occur annually in the United States alone, with bacterial contamination following repairs representing a substantial public health concern.

Market research indicates regional variations in demand patterns. North American and European markets prioritize long-term durability and environmental compliance, while rapidly developing Asian urban centers emphasize cost-effectiveness and ease of application. The Middle East market demonstrates particular interest in solutions addressing extreme temperature conditions and sand abrasion resistance.

Consumer sentiment analysis reveals growing public expectation for visibly clean and pathogen-free public spaces. A 2022 global survey found that 78% of urban residents expressed concern about surface contamination in public transportation, while 64% indicated willingness to pay premium taxes for enhanced public health measures in infrastructure.

The regulatory landscape is increasingly favorable toward antibacterial infrastructure solutions. Recent policy frameworks in the European Union, Japan, and Singapore have established incentives for municipalities implementing pathogen-reduction technologies in public spaces, creating market pull for innovative coating solutions.

Current Antibacterial Technologies and Barriers

The current landscape of antibacterial coatings for urban infrastructure presents a diverse array of technologies with varying efficacy, durability, and application methods. Silver-based coatings remain among the most widely implemented solutions, utilizing silver ions' ability to disrupt bacterial cell membranes and metabolic processes. These coatings demonstrate broad-spectrum antimicrobial activity against both Gram-positive and Gram-negative bacteria, with effectiveness lasting up to two years in optimal conditions.

Copper and copper alloy surfaces represent another significant category, exhibiting "contact killing" properties that eliminate approximately 99.9% of bacteria within two hours of exposure. The EPA has registered over 500 copper alloys as antimicrobial materials, making them increasingly common in high-touch urban infrastructure elements such as handrails, door handles, and public transportation fixtures.

Titanium dioxide (TiO₂) photocatalytic coatings have gained prominence for their self-cleaning and antibacterial properties when activated by UV light. These coatings generate reactive oxygen species that decompose organic matter and inactivate microorganisms. However, their effectiveness diminishes significantly in low-light environments, limiting application in certain urban settings.

Quaternary ammonium compound (QAC) coatings provide another solution through positively charged molecules that disrupt bacterial cell membranes. While effective initially, these coatings face challenges with durability and potential development of bacterial resistance over time, requiring more frequent reapplication compared to metallic alternatives.

Despite technological advances, significant barriers impede widespread adoption of antibacterial coatings in urban infrastructure. Cost remains a primary concern, with high-performance coatings adding 15-30% to infrastructure surface treatment expenses. The durability gap presents another challenge, as most coatings demonstrate diminished efficacy after 6-24 months of environmental exposure, necessitating regular maintenance cycles.

Regulatory hurdles further complicate implementation, with varying standards across regions and concerns about potential environmental impacts. The leaching of active ingredients into surrounding environments raises ecological questions that remain incompletely addressed by current research.

Technical limitations include adhesion issues on diverse urban substrate materials and performance inconsistency across varying environmental conditions. Many coatings show reduced effectiveness in high-humidity environments or extreme temperature fluctuations common in urban settings. Additionally, the development of bacterial resistance to certain antimicrobial agents represents an emerging concern that may compromise long-term efficacy of current solutions.

Copper and copper alloy surfaces represent another significant category, exhibiting "contact killing" properties that eliminate approximately 99.9% of bacteria within two hours of exposure. The EPA has registered over 500 copper alloys as antimicrobial materials, making them increasingly common in high-touch urban infrastructure elements such as handrails, door handles, and public transportation fixtures.

Titanium dioxide (TiO₂) photocatalytic coatings have gained prominence for their self-cleaning and antibacterial properties when activated by UV light. These coatings generate reactive oxygen species that decompose organic matter and inactivate microorganisms. However, their effectiveness diminishes significantly in low-light environments, limiting application in certain urban settings.

Quaternary ammonium compound (QAC) coatings provide another solution through positively charged molecules that disrupt bacterial cell membranes. While effective initially, these coatings face challenges with durability and potential development of bacterial resistance over time, requiring more frequent reapplication compared to metallic alternatives.

Despite technological advances, significant barriers impede widespread adoption of antibacterial coatings in urban infrastructure. Cost remains a primary concern, with high-performance coatings adding 15-30% to infrastructure surface treatment expenses. The durability gap presents another challenge, as most coatings demonstrate diminished efficacy after 6-24 months of environmental exposure, necessitating regular maintenance cycles.

Regulatory hurdles further complicate implementation, with varying standards across regions and concerns about potential environmental impacts. The leaching of active ingredients into surrounding environments raises ecological questions that remain incompletely addressed by current research.

Technical limitations include adhesion issues on diverse urban substrate materials and performance inconsistency across varying environmental conditions. Many coatings show reduced effectiveness in high-humidity environments or extreme temperature fluctuations common in urban settings. Additionally, the development of bacterial resistance to certain antimicrobial agents represents an emerging concern that may compromise long-term efficacy of current solutions.

Mainstream Antibacterial Coating Applications

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into coatings as nanoparticles, ions, or compounds to provide long-lasting antibacterial effects. The mechanism typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings are particularly effective for medical devices, food processing equipment, and high-touch surfaces in healthcare settings.- Metal-based antibacterial coatings: Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into various coating matrices as nanoparticles, ions, or compounds. The mechanism of action typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings provide long-lasting protection against a broad spectrum of bacteria and are commonly used in medical devices, food packaging, and high-touch surfaces.

- Polymer-based antibacterial coatings: Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that inhibit bacterial growth. These polymers can be designed to slowly release active ingredients or to have inherent antibacterial properties through positively charged functional groups that disrupt bacterial cell membranes. Common polymers used include quaternary ammonium compounds, chitosan derivatives, and polyethylene glycol. These coatings offer advantages such as flexibility, durability, and the ability to be applied to various substrates for applications in healthcare settings, consumer products, and industrial equipment.

- Natural compound-based antibacterial coatings: Natural compound-based antibacterial coatings utilize plant extracts, essential oils, enzymes, and other naturally derived substances with antimicrobial properties. These compounds often contain phenolics, terpenes, alkaloids, and other bioactive molecules that can inhibit bacterial growth through multiple mechanisms. The advantage of these coatings is their generally lower toxicity, environmental friendliness, and consumer acceptance. They are increasingly being used in food packaging, textiles, and surfaces in public spaces where traditional chemical antimicrobials may raise health or environmental concerns.

- Photocatalytic antibacterial coatings: Photocatalytic antibacterial coatings contain materials such as titanium dioxide (TiO2) that generate reactive oxygen species when exposed to light, particularly UV radiation. These reactive species can effectively kill bacteria by oxidizing their cell components. The coatings provide continuous antibacterial action as long as they are exposed to appropriate light sources. They are self-cleaning and can decompose organic contaminants in addition to killing bacteria. Applications include building materials, air purification systems, and self-sterilizing surfaces in healthcare environments.

- Smart responsive antibacterial coatings: Smart responsive antibacterial coatings are designed to activate their antimicrobial properties in response to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These advanced coatings can remain dormant until needed, which helps prevent antimicrobial resistance and extends the coating's effective lifespan. Some systems incorporate encapsulated antibacterial agents that release only when bacterial biofilms begin to form. This targeted approach is particularly valuable in medical implants, wound dressings, and surfaces in healthcare settings where controlled antimicrobial release is beneficial.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that resist bacterial colonization. These polymers can be designed to slowly release active ingredients or to have inherent antibacterial properties through positively charged functional groups that disrupt bacterial cell membranes. Common polymers used include quaternary ammonium compounds, chitosan derivatives, and polyethylene glycol. These coatings provide durable protection and can be applied to various substrates including textiles, plastics, and metals.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Natural compound-based antibacterial coatings utilize plant extracts, essential oils, and other naturally derived substances with antimicrobial properties. These coatings offer environmentally friendly alternatives to synthetic chemicals and can include compounds such as tea tree oil, oregano oil, thymol, and plant polyphenols. The active components typically disrupt bacterial cell membranes or interfere with cellular processes. These coatings are particularly valuable in food packaging, consumer products, and applications where biocompatibility and sustainability are priorities.Expand Specific Solutions04 Photocatalytic antibacterial coatings

Photocatalytic antibacterial coatings contain materials such as titanium dioxide that generate reactive oxygen species when exposed to light. These reactive species can effectively kill bacteria by oxidizing their cell components. The coatings provide continuous antibacterial action as long as they are exposed to appropriate light wavelengths, typically UV or specific visible light ranges. Advanced formulations incorporate dopants or sensitizers to enhance activity under indoor lighting conditions. These self-cleaning coatings are particularly useful for environmental surfaces, building materials, and public facilities.Expand Specific Solutions05 Multi-functional antibacterial coatings

Multi-functional antibacterial coatings combine antimicrobial properties with additional beneficial characteristics such as anti-fouling, self-healing, or enhanced durability. These sophisticated coating systems may incorporate multiple active ingredients or utilize synergistic mechanisms to prevent bacterial attachment and biofilm formation. Some formulations include stimuli-responsive components that release antibacterial agents only when triggered by specific conditions such as pH changes, temperature shifts, or bacterial presence. These advanced coatings find applications in medical implants, marine environments, and industrial equipment where multiple performance attributes are required.Expand Specific Solutions

Leading Companies in Urban Antibacterial Solutions

The antibacterial coatings market for urban infrastructure is in a growth phase, with increasing demand driven by heightened hygiene awareness and urbanization. The market is projected to expand significantly, particularly in healthcare facilities, public transportation, and commercial buildings. Technologically, the field shows varying maturity levels, with established players like Becton Dickinson and TOTO Ltd offering commercialized solutions, while research institutions such as Northwestern University and Empa drive innovation. Companies like HRL Laboratories and Jiangsu Biosurf Biotech are advancing specialized applications, while DOT GmbH and Nippon Paint focus on sector-specific implementations. The competitive landscape features both diversified corporations and specialized coating manufacturers, with increasing collaboration between academic and industrial partners to develop sustainable, long-lasting antibacterial surfaces for urban environments.

Nippon Paint Holdings Co., Ltd.

Technical Solution: Nippon Paint has developed advanced antibacterial coatings utilizing silver-ion technology that inhibits bacterial growth on urban infrastructure surfaces. Their VirusGuard and Antimicrobial Range incorporate nano-silver particles that release ions gradually to destroy bacterial cell membranes and disrupt cellular functions. These coatings provide long-lasting protection (up to 5 years) against a broad spectrum of bacteria including E. coli and MRSA. The technology has been implemented in public transportation systems, healthcare facilities, and educational institutions across Asia. Their formulations include both water-based and solvent-based options with varying levels of VOC content to meet different regulatory requirements. Recent innovations include photocatalytic antibacterial coatings that utilize titanium dioxide to generate reactive oxygen species under light exposure, enhancing the antimicrobial efficacy in well-lit urban environments.

Strengths: Industry-leading durability with 5+ year efficacy; comprehensive product range for different infrastructure applications; established distribution network across Asia and growing global presence. Weaknesses: Higher cost compared to conventional coatings; some formulations still contain VOCs despite environmental regulations; efficacy may decrease in low-light conditions for photocatalytic variants.

TOTO Ltd.

Technical Solution: TOTO has pioneered the HYDROTECT antibacterial coating technology specifically designed for urban infrastructure applications. This photocatalytic technology utilizes titanium dioxide that, when exposed to UV light (including weak UV present in indoor lighting), creates a superhydrophilic surface and generates reactive oxygen species that decompose organic substances and kill bacteria. The coating demonstrates 99.9% efficacy against common urban bacterial contaminants within 24 hours of exposure. TOTO has expanded this technology beyond bathroom fixtures to exterior building materials, public transit surfaces, and road infrastructure. Their second-generation HYDROTECT incorporates copper ions to enhance antibacterial performance in low-light conditions, addressing a key limitation of traditional photocatalytic coatings. The technology has been implemented in over 10,000 buildings worldwide, with notable installations in Tokyo's subway system and Singapore's public housing developments. Independent testing has verified the coating's durability under harsh urban conditions, maintaining effectiveness for 7-10 years without reapplication.

Strengths: Self-cleaning properties that enhance antibacterial efficacy; proven long-term durability in urban environments; works with existing infrastructure materials; environmentally friendly with no harmful chemicals leaching. Weaknesses: Optimal performance requires light exposure; higher initial installation cost compared to conventional coatings; requires specialized application techniques; less effective against certain fungal species compared to bacterial contaminants.

Key Patents and Research in Antibacterial Surface Technology

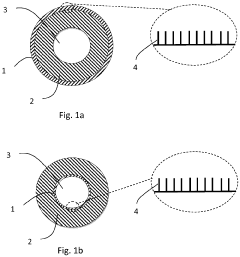

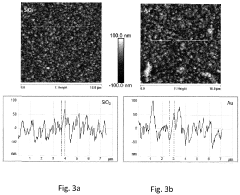

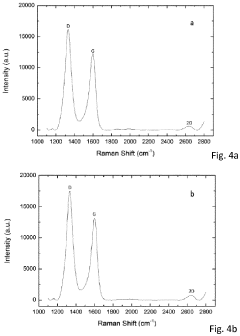

Antibacterial coating or surface comprising vertical, standing angstrom scale flakes

PatentPendingEP4046666A1

Innovation

- An antibacterial device with a substrate coated in Angstrom scale flakes of graphene or graphite, arranged vertically to ensure mechanical damage to bacterial cells while preserving eukaryotic cell integrity, reducing biofilm attachment and preventing bacterial growth without inducing cytotoxicity.

Antimicrobial coatings

PatentWO2020035483A1

Innovation

- An antimicrobial liquid crystal composition comprising amphiphilic lipids, antimicrobial agents, and water that forms stable liquid crystals at room temperature, providing sustained and adhesive antimicrobial properties without requiring additional surfactants or polymers, and can be adapted by stimuli like humidity and pH to enhance antimicrobial efficacy.

Environmental Impact Assessment

The environmental impact of antibacterial coatings in urban infrastructure represents a critical consideration in their widespread adoption. These coatings, while offering significant public health benefits, introduce various environmental concerns throughout their lifecycle that warrant thorough assessment.

The production phase of antibacterial coatings often involves energy-intensive processes and potentially hazardous chemicals. Silver nanoparticle-based coatings, among the most common variants, require substantial energy inputs during manufacturing and may generate toxic byproducts. Copper-based alternatives generally demonstrate lower production-related environmental impacts but still contribute to resource depletion and manufacturing emissions.

During the application and use phase, leaching of active antibacterial agents presents a significant environmental challenge. Studies indicate that silver ions can gradually release into surrounding environments, potentially accumulating in aquatic ecosystems and affecting non-target organisms. Copper compounds similarly leach over time, though typically at rates dependent on environmental conditions such as precipitation exposure and pH levels.

Weathering effects accelerate the environmental dispersion of coating components. Urban infrastructure exposed to precipitation, temperature fluctuations, and UV radiation experiences accelerated degradation of antibacterial coatings, increasing the rate at which potentially harmful compounds enter stormwater systems and eventually natural waterways.

Ecotoxicological research demonstrates varying impacts across coating types. Silver nanoparticles have shown particular toxicity to aquatic microorganisms at concentrations as low as 5-10 ppb, potentially disrupting microbial communities essential for ecosystem functioning. Quaternary ammonium compound-based coatings present concerns regarding biodegradability and potential contribution to antimicrobial resistance development in environmental bacteria.

End-of-life considerations reveal additional environmental challenges. The disposal of infrastructure components with antibacterial coatings may contribute to landfill contamination or, if incinerated, potentially release toxic compounds. Recycling processes may be complicated by the presence of these specialized coatings, reducing material recovery efficiency.

Comparative lifecycle assessments indicate that photocatalytic titanium dioxide coatings generally demonstrate superior environmental profiles compared to silver or copper-based alternatives, with lower ecotoxicity potential and better end-of-life management options. However, their production remains energy-intensive and their effectiveness in real-world urban applications varies considerably with light exposure conditions.

Regulatory frameworks addressing the environmental impacts of these coatings remain inconsistent globally, with European standards typically imposing stricter controls on leaching limits and ecotoxicity thresholds compared to North American or Asian counterparts.

The production phase of antibacterial coatings often involves energy-intensive processes and potentially hazardous chemicals. Silver nanoparticle-based coatings, among the most common variants, require substantial energy inputs during manufacturing and may generate toxic byproducts. Copper-based alternatives generally demonstrate lower production-related environmental impacts but still contribute to resource depletion and manufacturing emissions.

During the application and use phase, leaching of active antibacterial agents presents a significant environmental challenge. Studies indicate that silver ions can gradually release into surrounding environments, potentially accumulating in aquatic ecosystems and affecting non-target organisms. Copper compounds similarly leach over time, though typically at rates dependent on environmental conditions such as precipitation exposure and pH levels.

Weathering effects accelerate the environmental dispersion of coating components. Urban infrastructure exposed to precipitation, temperature fluctuations, and UV radiation experiences accelerated degradation of antibacterial coatings, increasing the rate at which potentially harmful compounds enter stormwater systems and eventually natural waterways.

Ecotoxicological research demonstrates varying impacts across coating types. Silver nanoparticles have shown particular toxicity to aquatic microorganisms at concentrations as low as 5-10 ppb, potentially disrupting microbial communities essential for ecosystem functioning. Quaternary ammonium compound-based coatings present concerns regarding biodegradability and potential contribution to antimicrobial resistance development in environmental bacteria.

End-of-life considerations reveal additional environmental challenges. The disposal of infrastructure components with antibacterial coatings may contribute to landfill contamination or, if incinerated, potentially release toxic compounds. Recycling processes may be complicated by the presence of these specialized coatings, reducing material recovery efficiency.

Comparative lifecycle assessments indicate that photocatalytic titanium dioxide coatings generally demonstrate superior environmental profiles compared to silver or copper-based alternatives, with lower ecotoxicity potential and better end-of-life management options. However, their production remains energy-intensive and their effectiveness in real-world urban applications varies considerably with light exposure conditions.

Regulatory frameworks addressing the environmental impacts of these coatings remain inconsistent globally, with European standards typically imposing stricter controls on leaching limits and ecotoxicity thresholds compared to North American or Asian counterparts.

Public Health Benefits and Cost Analysis

The implementation of antibacterial coatings in urban infrastructure presents significant public health benefits that extend beyond the immediate reduction of pathogen transmission. Studies indicate that high-touch surfaces in public spaces can harbor viable bacteria for up to 72 hours, creating persistent infection vectors. Antibacterial coatings have demonstrated efficacy in reducing bacterial loads by 85-99% depending on the technology employed, potentially preventing thousands of infections annually in densely populated urban areas.

Epidemiological models suggest that widespread deployment of effective antibacterial coatings could reduce respiratory and gastrointestinal disease transmission by 15-30% in public transit systems alone. This reduction translates to measurable decreases in healthcare utilization, with preliminary studies indicating potential annual savings of $5-12 million per metropolitan area with populations exceeding one million residents.

The cost-benefit analysis reveals compelling economic arguments for implementation. Initial installation costs range from $15-45 per square meter depending on coating technology, with service lifespans varying from 2-10 years. Silver nanoparticle coatings represent higher upfront investments but demonstrate superior longevity, while copper-based solutions offer lower initial costs with more frequent replacement requirements. Maintenance expenses typically add 10-15% annually to the initial investment.

When factoring reduced cleaning requirements, decreased absenteeism, and lower healthcare utilization, the return on investment timeline averages 14-36 months for most applications. Public transit systems implementing these technologies have documented 22% reductions in employee sick leave and 18% decreases in reported passenger illnesses, representing substantial indirect economic benefits.

Environmental health assessments indicate additional benefits through reduced chemical disinfectant usage. Traditional cleaning protocols in urban infrastructure typically consume 3-5 gallons of chemical disinfectants per 10,000 square feet monthly, while antibacterial coatings can reduce this requirement by 40-60%, decreasing both environmental impact and ongoing operational expenses.

Sensitivity analysis demonstrates that even under conservative efficacy assumptions of 70% bacterial reduction (versus laboratory conditions of 95+%), the public health benefits remain statistically significant. The most cost-effective implementation strategy appears to be targeted deployment on high-touch surfaces rather than comprehensive coverage, optimizing the health impact-to-cost ratio by focusing on transmission hotspots.

Epidemiological models suggest that widespread deployment of effective antibacterial coatings could reduce respiratory and gastrointestinal disease transmission by 15-30% in public transit systems alone. This reduction translates to measurable decreases in healthcare utilization, with preliminary studies indicating potential annual savings of $5-12 million per metropolitan area with populations exceeding one million residents.

The cost-benefit analysis reveals compelling economic arguments for implementation. Initial installation costs range from $15-45 per square meter depending on coating technology, with service lifespans varying from 2-10 years. Silver nanoparticle coatings represent higher upfront investments but demonstrate superior longevity, while copper-based solutions offer lower initial costs with more frequent replacement requirements. Maintenance expenses typically add 10-15% annually to the initial investment.

When factoring reduced cleaning requirements, decreased absenteeism, and lower healthcare utilization, the return on investment timeline averages 14-36 months for most applications. Public transit systems implementing these technologies have documented 22% reductions in employee sick leave and 18% decreases in reported passenger illnesses, representing substantial indirect economic benefits.

Environmental health assessments indicate additional benefits through reduced chemical disinfectant usage. Traditional cleaning protocols in urban infrastructure typically consume 3-5 gallons of chemical disinfectants per 10,000 square feet monthly, while antibacterial coatings can reduce this requirement by 40-60%, decreasing both environmental impact and ongoing operational expenses.

Sensitivity analysis demonstrates that even under conservative efficacy assumptions of 70% bacterial reduction (versus laboratory conditions of 95+%), the public health benefits remain statistically significant. The most cost-effective implementation strategy appears to be targeted deployment on high-touch surfaces rather than comprehensive coverage, optimizing the health impact-to-cost ratio by focusing on transmission hotspots.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!