Antibacterial Coating Selection Criteria for Textile Applications

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Textile Coating Background and Objectives

Antibacterial textiles have evolved significantly over the past several decades, transitioning from simple applications in healthcare settings to widespread use in consumer products, athletic wear, and industrial textiles. The development trajectory began in the 1940s with the introduction of quaternary ammonium compounds, followed by the integration of metal-based agents such as silver and copper in the 1970s. Recent advancements have focused on nanotechnology-enabled coatings and sustainable bio-based alternatives that address growing environmental concerns.

The global market for antibacterial textiles has experienced robust growth, expanding at a CAGR of approximately 6.8% since 2015, with projections indicating continued acceleration through 2030. This growth is driven by increasing awareness of hygiene, rising healthcare-associated infections, and the COVID-19 pandemic's lasting impact on consumer preferences for antimicrobial products. The technical evolution has shifted from temporary treatments with limited wash durability to permanent modifications that maintain efficacy throughout the textile's lifecycle.

Current antibacterial coating technologies can be categorized into four primary approaches: metal and metal oxide-based (silver, copper, zinc oxide), organic compound-based (quaternary ammonium compounds, triclosan), natural derivative-based (chitosan, essential oils), and hybrid systems that combine multiple mechanisms. Each approach presents distinct advantages and limitations regarding efficacy spectrum, durability, environmental impact, and cost-effectiveness.

The primary technical objectives for antibacterial textile coatings include developing solutions that demonstrate broad-spectrum antimicrobial activity against both gram-positive and gram-negative bacteria, maintain efficacy after multiple washing cycles (minimum 50 standard washes), exhibit minimal leaching of active components, and comply with increasingly stringent environmental and toxicological regulations. Additionally, these coatings must preserve the textile's inherent properties such as breathability, flexibility, and tactile comfort.

Emerging research directions focus on stimuli-responsive antibacterial coatings that activate only when needed, reducing the potential for bacterial resistance development. Biomimetic approaches that replicate natural antibacterial mechanisms found in certain plants and animals are gaining traction. The integration of antibacterial functionality with other performance features such as moisture management, UV protection, and self-cleaning capabilities represents another frontier in multifunctional textile development.

The selection criteria for antibacterial coatings must balance technical performance with commercial viability, regulatory compliance, and sustainability considerations. This necessitates a comprehensive evaluation framework that accounts for the specific application requirements, target market expectations, and long-term environmental impact of the chosen technology.

The global market for antibacterial textiles has experienced robust growth, expanding at a CAGR of approximately 6.8% since 2015, with projections indicating continued acceleration through 2030. This growth is driven by increasing awareness of hygiene, rising healthcare-associated infections, and the COVID-19 pandemic's lasting impact on consumer preferences for antimicrobial products. The technical evolution has shifted from temporary treatments with limited wash durability to permanent modifications that maintain efficacy throughout the textile's lifecycle.

Current antibacterial coating technologies can be categorized into four primary approaches: metal and metal oxide-based (silver, copper, zinc oxide), organic compound-based (quaternary ammonium compounds, triclosan), natural derivative-based (chitosan, essential oils), and hybrid systems that combine multiple mechanisms. Each approach presents distinct advantages and limitations regarding efficacy spectrum, durability, environmental impact, and cost-effectiveness.

The primary technical objectives for antibacterial textile coatings include developing solutions that demonstrate broad-spectrum antimicrobial activity against both gram-positive and gram-negative bacteria, maintain efficacy after multiple washing cycles (minimum 50 standard washes), exhibit minimal leaching of active components, and comply with increasingly stringent environmental and toxicological regulations. Additionally, these coatings must preserve the textile's inherent properties such as breathability, flexibility, and tactile comfort.

Emerging research directions focus on stimuli-responsive antibacterial coatings that activate only when needed, reducing the potential for bacterial resistance development. Biomimetic approaches that replicate natural antibacterial mechanisms found in certain plants and animals are gaining traction. The integration of antibacterial functionality with other performance features such as moisture management, UV protection, and self-cleaning capabilities represents another frontier in multifunctional textile development.

The selection criteria for antibacterial coatings must balance technical performance with commercial viability, regulatory compliance, and sustainability considerations. This necessitates a comprehensive evaluation framework that accounts for the specific application requirements, target market expectations, and long-term environmental impact of the chosen technology.

Market Analysis for Antimicrobial Textile Products

The global antimicrobial textile market has experienced significant growth in recent years, driven by increasing awareness of hygiene and health concerns. As of 2023, the market is valued at approximately 12.3 billion USD, with projections indicating a compound annual growth rate (CAGR) of 6.4% through 2028. This growth trajectory is supported by rising consumer demand for products with enhanced protection against bacteria, fungi, and viruses, particularly in healthcare, sportswear, and home textile segments.

Healthcare applications represent the largest market segment, accounting for nearly 38% of the total antimicrobial textile market. This dominance is attributed to the critical need for infection control in hospitals, clinics, and long-term care facilities. The COVID-19 pandemic has further accelerated this trend, with healthcare facilities worldwide implementing stricter hygiene protocols and increasing their procurement of antimicrobial textiles for bedding, uniforms, and patient gowns.

The sportswear and athleisure segment has emerged as the fastest-growing application area, with a CAGR of 7.8%. Consumer preference for odor-resistant and hygienic activewear has driven major brands to incorporate antimicrobial technologies into their product lines. This trend is particularly strong in premium sportswear markets across North America and Europe, where consumers demonstrate willingness to pay premium prices for enhanced functionality.

Geographically, North America leads the market with a 34% share, followed closely by Europe at 29% and Asia-Pacific at 27%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer behavior analysis reveals a significant shift toward sustainable antimicrobial solutions. Approximately 62% of consumers now express preference for eco-friendly antimicrobial treatments over conventional chemical-based options. This has prompted manufacturers to develop bio-based antimicrobial agents derived from natural sources such as chitosan, essential oils, and plant extracts.

Regulatory frameworks significantly impact market dynamics, with stringent regulations in Europe under the Biocidal Products Regulation (BPR) and in the US under the Environmental Protection Agency (EPA) guidelines. These regulations have created entry barriers but also ensure product safety and efficacy, which ultimately benefits consumer confidence in antimicrobial textile products.

Price sensitivity varies across market segments, with healthcare institutions demonstrating lower price elasticity compared to consumer retail markets. The average price premium for antimicrobial textiles ranges from 15-30% above conventional alternatives, with acceptance rates highest in medical and premium consumer applications.

Healthcare applications represent the largest market segment, accounting for nearly 38% of the total antimicrobial textile market. This dominance is attributed to the critical need for infection control in hospitals, clinics, and long-term care facilities. The COVID-19 pandemic has further accelerated this trend, with healthcare facilities worldwide implementing stricter hygiene protocols and increasing their procurement of antimicrobial textiles for bedding, uniforms, and patient gowns.

The sportswear and athleisure segment has emerged as the fastest-growing application area, with a CAGR of 7.8%. Consumer preference for odor-resistant and hygienic activewear has driven major brands to incorporate antimicrobial technologies into their product lines. This trend is particularly strong in premium sportswear markets across North America and Europe, where consumers demonstrate willingness to pay premium prices for enhanced functionality.

Geographically, North America leads the market with a 34% share, followed closely by Europe at 29% and Asia-Pacific at 27%. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene in countries like China, India, and Japan.

Consumer behavior analysis reveals a significant shift toward sustainable antimicrobial solutions. Approximately 62% of consumers now express preference for eco-friendly antimicrobial treatments over conventional chemical-based options. This has prompted manufacturers to develop bio-based antimicrobial agents derived from natural sources such as chitosan, essential oils, and plant extracts.

Regulatory frameworks significantly impact market dynamics, with stringent regulations in Europe under the Biocidal Products Regulation (BPR) and in the US under the Environmental Protection Agency (EPA) guidelines. These regulations have created entry barriers but also ensure product safety and efficacy, which ultimately benefits consumer confidence in antimicrobial textile products.

Price sensitivity varies across market segments, with healthcare institutions demonstrating lower price elasticity compared to consumer retail markets. The average price premium for antimicrobial textiles ranges from 15-30% above conventional alternatives, with acceptance rates highest in medical and premium consumer applications.

Current Antibacterial Coating Technologies and Challenges

The antibacterial coating landscape for textiles is currently dominated by several key technologies, each with distinct advantages and limitations. Silver-based coatings remain the most widely adopted solution, leveraging silver nanoparticles' broad-spectrum antimicrobial properties. These coatings demonstrate excellent efficacy against both gram-positive and gram-negative bacteria, with relatively long-lasting effects. However, concerns regarding silver leaching into the environment and potential cytotoxicity at higher concentrations present significant challenges for widespread application.

Quaternary ammonium compounds (QACs) represent another prominent technology, functioning through disruption of bacterial cell membranes. While QACs offer cost-effective solutions with straightforward application processes, their durability through repeated washing cycles remains limited, often requiring reapplication after 15-20 washes. Additionally, emerging bacterial resistance to QACs poses a long-term concern for textile applications.

Triclosan-based coatings, once popular in consumer textiles, face increasing regulatory scrutiny due to environmental persistence and potential endocrine-disrupting effects. Many jurisdictions have restricted triclosan use, forcing manufacturers to seek alternatives despite its proven antibacterial efficacy.

Natural compound-based solutions, including chitosan, essential oils, and plant extracts, have gained significant attention as sustainable alternatives. These bio-based coatings offer reduced environmental impact and address growing consumer demand for "green" products. However, they typically demonstrate lower antimicrobial efficacy compared to synthetic counterparts and often suffer from stability issues during textile processing and laundering.

Metal oxide nanoparticles, particularly zinc oxide and titanium dioxide, represent an emerging technology with photocatalytic antimicrobial properties. While showing promise in laboratory settings, challenges remain in achieving uniform dispersion across textile surfaces and ensuring particle adhesion throughout the product lifecycle.

A critical technical challenge across all coating technologies is achieving the delicate balance between antimicrobial efficacy and biocompatibility. Coatings must effectively eliminate harmful microorganisms while remaining safe for human skin contact. This challenge is particularly pronounced in medical textiles and intimate apparel applications.

Durability represents another significant hurdle, as most current technologies struggle to maintain antimicrobial performance through industrial laundering processes. The mechanical abrasion and chemical exposure during washing cycles typically degrade coating integrity, necessitating reapplication or resulting in diminished protection over time.

Manufacturing scalability also presents challenges, as laboratory-proven technologies often encounter difficulties in transition to industrial-scale production. Ensuring consistent coating quality, thickness, and antimicrobial performance across large production volumes remains problematic for many emerging technologies.

Quaternary ammonium compounds (QACs) represent another prominent technology, functioning through disruption of bacterial cell membranes. While QACs offer cost-effective solutions with straightforward application processes, their durability through repeated washing cycles remains limited, often requiring reapplication after 15-20 washes. Additionally, emerging bacterial resistance to QACs poses a long-term concern for textile applications.

Triclosan-based coatings, once popular in consumer textiles, face increasing regulatory scrutiny due to environmental persistence and potential endocrine-disrupting effects. Many jurisdictions have restricted triclosan use, forcing manufacturers to seek alternatives despite its proven antibacterial efficacy.

Natural compound-based solutions, including chitosan, essential oils, and plant extracts, have gained significant attention as sustainable alternatives. These bio-based coatings offer reduced environmental impact and address growing consumer demand for "green" products. However, they typically demonstrate lower antimicrobial efficacy compared to synthetic counterparts and often suffer from stability issues during textile processing and laundering.

Metal oxide nanoparticles, particularly zinc oxide and titanium dioxide, represent an emerging technology with photocatalytic antimicrobial properties. While showing promise in laboratory settings, challenges remain in achieving uniform dispersion across textile surfaces and ensuring particle adhesion throughout the product lifecycle.

A critical technical challenge across all coating technologies is achieving the delicate balance between antimicrobial efficacy and biocompatibility. Coatings must effectively eliminate harmful microorganisms while remaining safe for human skin contact. This challenge is particularly pronounced in medical textiles and intimate apparel applications.

Durability represents another significant hurdle, as most current technologies struggle to maintain antimicrobial performance through industrial laundering processes. The mechanical abrasion and chemical exposure during washing cycles typically degrade coating integrity, necessitating reapplication or resulting in diminished protection over time.

Manufacturing scalability also presents challenges, as laboratory-proven technologies often encounter difficulties in transition to industrial-scale production. Ensuring consistent coating quality, thickness, and antimicrobial performance across large production volumes remains problematic for many emerging technologies.

Comparative Analysis of Commercial Antibacterial Coating Solutions

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into various coating matrices as nanoparticles, ions, or compounds. The mechanism of action typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings provide long-lasting protection against a broad spectrum of bacteria and are commonly used in medical devices, food packaging, and high-touch surfaces.- Metal-based antibacterial coatings: Metal-based compounds such as silver, copper, and zinc can be incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of bacteria. These coatings can be applied to various surfaces including medical devices, textiles, and household items to prevent bacterial contamination and growth.

- Polymer-based antibacterial coatings: Polymeric materials can be formulated with antibacterial agents to create durable coatings with long-lasting protection. These polymers can either inherently possess antibacterial properties or serve as carriers for antibacterial compounds. The polymers provide a controlled release mechanism for the active ingredients, ensuring sustained antibacterial activity. Applications include medical implants, food packaging, and industrial surfaces where bacterial contamination is a concern.

- Natural compound-based antibacterial coatings: Antibacterial coatings can be formulated using natural compounds derived from plants, essential oils, and other biological sources. These natural antibacterial agents include extracts from plants like tea tree, oregano, and thyme, which contain compounds that disrupt bacterial cell functions. These environmentally friendly alternatives offer effective antibacterial protection while reducing reliance on synthetic chemicals and addressing concerns about antimicrobial resistance.

- Nanoparticle-enhanced antibacterial coatings: Nanoparticles can significantly enhance the effectiveness of antibacterial coatings due to their high surface area to volume ratio and unique physical properties. Materials such as nano-silver, nano-zinc oxide, and nano-titanium dioxide can be incorporated into coating formulations to provide powerful antibacterial effects. These nanoparticle-enhanced coatings offer improved durability, broader spectrum activity against various bacterial strains, and can be applied to diverse surfaces including textiles, plastics, and metals.

- Smart responsive antibacterial coatings: Advanced antibacterial coatings can be designed to respond to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These smart coatings release antibacterial agents only when needed, improving efficiency and reducing the risk of developing bacterial resistance. Applications include wound dressings that release antimicrobials in response to infection, surfaces that activate under specific conditions, and coatings that can regenerate their antibacterial properties over time.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces that inhibit bacterial growth. These coatings can be designed with controlled-release mechanisms that gradually dispense antibacterial compounds, or with permanent antimicrobial properties through covalently bound active groups. Common polymers used include polyurethanes, acrylics, and silicones, which can be modified with quaternary ammonium compounds, chitosan, or other antimicrobial agents. These coatings offer versatility in application methods and can be tailored for specific environments.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Natural compound-based antibacterial coatings utilize plant extracts, essential oils, enzymes, and other naturally derived substances with antimicrobial properties. These environmentally friendly alternatives often contain active components like polyphenols, terpenes, and flavonoids that disrupt bacterial cell membranes or inhibit critical metabolic pathways. The coatings can be formulated as films, sprays, or incorporated into various matrices. They are particularly valuable in applications where toxicity concerns or environmental impact are important considerations, such as food packaging, children's products, and eco-friendly consumer goods.Expand Specific Solutions04 Nanostructured antibacterial coatings

Nanostructured antibacterial coatings leverage nanoscale materials and surface modifications to create antibacterial properties. These include nanoparticles, nanocomposites, and surfaces with nanoscale topography that can physically disrupt bacterial cell membranes. The nanoscale dimensions enhance the surface area and reactivity, improving antibacterial efficacy while using smaller amounts of active ingredients. Advanced techniques like layer-by-layer assembly, electrospinning, and plasma deposition are used to create these sophisticated coating structures. Applications range from medical implants to consumer electronics and textiles.Expand Specific Solutions05 Smart responsive antibacterial coatings

Smart responsive antibacterial coatings are designed to activate or enhance their antimicrobial properties in response to specific environmental triggers. These triggers can include changes in pH, temperature, light exposure, or the presence of bacterial enzymes. Some coatings incorporate microcapsules that rupture upon contact with bacteria, releasing encapsulated antimicrobial agents. Others feature materials that undergo conformational changes to expose antibacterial functional groups when needed. This targeted approach minimizes unnecessary antimicrobial agent release, reducing the risk of developing bacterial resistance while extending the coating's effective lifespan.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Antibacterial Coatings

The antibacterial coating market for textile applications is in a growth phase, characterized by increasing demand for hygienic textiles across healthcare, sportswear, and home furnishings sectors. The global market size is expanding rapidly, projected to reach significant value due to heightened health awareness post-pandemic. Technologically, the field shows varying maturity levels, with companies like Nano & Advanced Materials Institute and Taiwan Textile Research Institute leading in advanced research, while established manufacturers such as Asahi Kasei, Nicca Chemical, and Matsumoto Yushi-Seiyaku offer commercialized solutions. Academic institutions including Texas A&M University and Shenzhen University are advancing fundamental research, while specialized players like Kornerstone Materials Technology and Suzhou Bailing Weichao Fine Materials focus on innovative antimicrobial formulations, indicating a competitive landscape balancing established technologies with emerging solutions.

Nano & Advanced Materials Institute Ltd.

Technical Solution: Nano & Advanced Materials Institute (NAMI) has developed a cutting-edge antibacterial coating system for textiles utilizing metal oxide nanoparticles (primarily zinc oxide and titanium dioxide) embedded in a silica-based matrix. Their proprietary sol-gel process creates a transparent, breathable coating that bonds effectively to various textile substrates while providing photocatalytic antibacterial properties. When exposed to light, these nanoparticles generate reactive oxygen species that destroy bacterial cell membranes and degrade organic contaminants. NAMI's research demonstrates that their coated textiles exhibit over 99.9% reduction in bacterial populations within 4 hours of light exposure. A key innovation in their approach is the controlled release mechanism that maintains antibacterial efficacy for extended periods while minimizing nanoparticle leaching. The institute has also developed specialized surface modification techniques that enhance the coating's adhesion to synthetic fibers, addressing a common challenge in antibacterial textile treatments.

Strengths: Photocatalytic action provides self-cleaning properties beyond antibacterial effects; environmentally triggered activity reduces unnecessary antimicrobial release; transparent coating preserves fabric appearance and feel. Weaknesses: Reduced efficacy in low-light conditions; potential concerns about nanoparticle safety despite controlled release design; higher production complexity requiring specialized application equipment.

Matsumoto Yushi-Seiyaku Co., Ltd.

Technical Solution: Matsumoto Yushi-Seiyaku has developed a bio-based antibacterial coating system for textiles called "NaturGuard" that utilizes chitosan derivatives and plant-based antimicrobial compounds. Their technology employs a proprietary crosslinking process that chemically bonds these natural antimicrobials to fabric surfaces, creating a durable treatment that resists washing and wear. The company's approach focuses on sustainability while maintaining performance, with laboratory tests showing over 90% reduction in bacterial populations after 24 hours of contact even after 30 wash cycles. A key innovation in their system is the microencapsulation of essential oil components that provides controlled release of additional antimicrobial compounds when triggered by moisture or friction. This creates a responsive system that intensifies antibacterial activity during wear when protection is most needed. Matsumoto has also developed specialized application techniques that optimize the distribution of active ingredients across different fabric structures, ensuring consistent performance across various textile types.

Strengths: Eco-friendly formulation appeals to sustainability-focused consumers and brands; natural ingredients minimize skin irritation potential; responsive release system provides enhanced protection during actual use conditions. Weaknesses: Lower overall efficacy compared to synthetic antimicrobial systems; more variable performance across different bacterial species; shorter effective lifespan compared to metal-based technologies.

Key Patents and Scientific Advancements in Antimicrobial Textiles

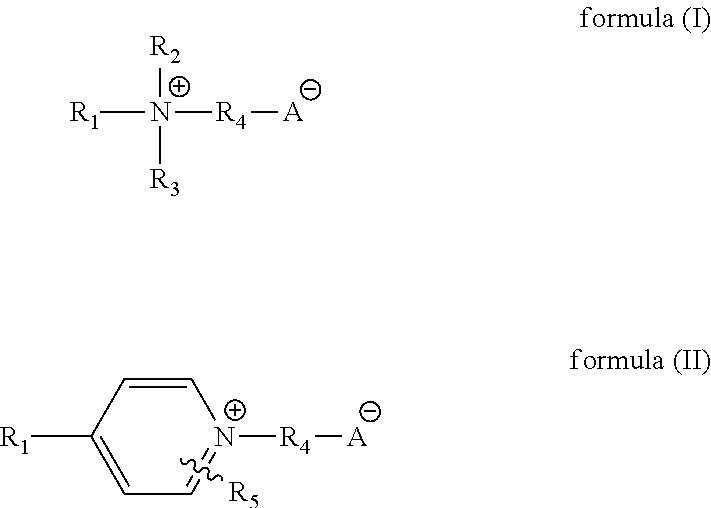

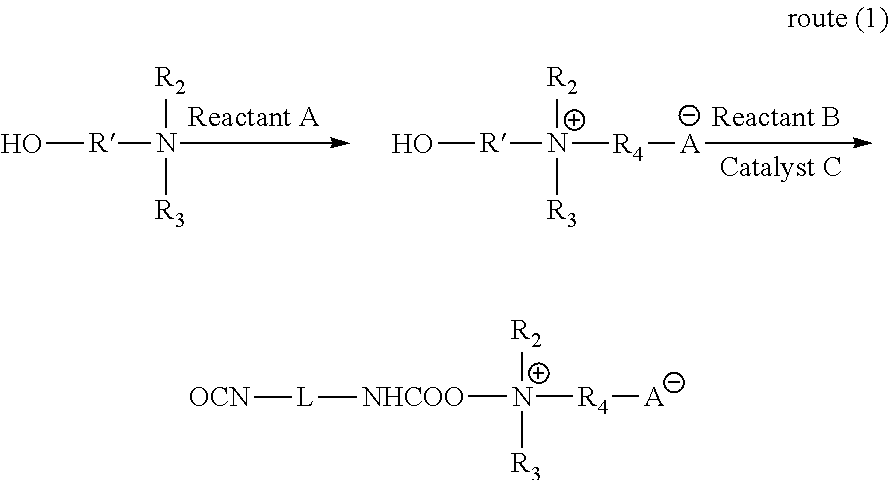

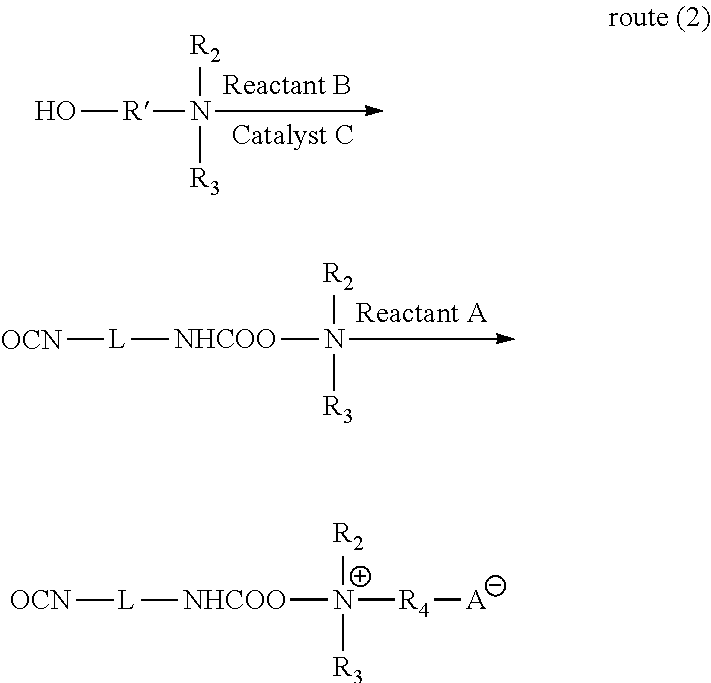

Antibacterial textile and method for preparing the same

PatentActiveUS20170339960A1

Innovation

- An antibacterial and antifouling textile is developed by coating a textile with an isocyanate-terminated betaine compound, which provides durable antibacterial activity and strong hydrophilicity through chemical bonding of the isocyanate functional group, using a method that is easy to implement and suitable for industrial production.

Hybrid antibacterial coatings having contact with foodstuff

PatentWO2017217955A1

Innovation

- A hybrid antibacterial coating solution using Ag+, Cu2+, and Zn2+ ions in a mono-alcohol medium with organo-silan and titanium isopropoxide, applied at low temperatures, allowing for easy application and hardening without additional thermal processes, while enhancing antibacterial properties and reducing production costs.

Environmental Impact and Toxicity Assessment

The environmental impact and toxicity assessment of antibacterial coatings for textiles represents a critical dimension in selection criteria, particularly as sustainability concerns gain prominence in manufacturing decisions. Traditional antibacterial agents such as triclosan and silver nanoparticles have demonstrated significant ecological footprints, with studies indicating their persistence in aquatic environments following textile washing cycles. These compounds can bioaccumulate in aquatic organisms and potentially disrupt ecosystem balance through selective toxicity against beneficial microorganisms.

Leaching behavior constitutes a primary environmental concern, as antibacterial compounds gradually release from textiles during use and laundering. Recent research indicates that up to 30% of certain antibacterial agents may leach during the first washing cycle, with cumulative environmental loading occurring throughout the product lifecycle. This necessitates comprehensive assessment of degradation pathways and persistence profiles when evaluating coating options.

Regulatory frameworks increasingly address these environmental considerations, with the European Union's REACH regulations and the United States EPA imposing stringent requirements for toxicological profiling of antibacterial compounds. Manufacturers must now provide extensive ecotoxicological data, including acute and chronic toxicity assessments across multiple trophic levels, before market approval.

Biodegradability characteristics have emerged as a decisive selection factor, with preference shifting toward compounds that demonstrate complete mineralization under environmental conditions. Natural antimicrobials derived from plant extracts, essential oils, and chitosan-based formulations generally exhibit superior environmental profiles compared to synthetic alternatives, though efficacy and durability challenges remain.

Human toxicity considerations parallel environmental concerns, particularly regarding dermal contact and potential sensitization. Skin-friendly antibacterial coatings must demonstrate minimal cytotoxicity while maintaining efficacy against pathogenic microorganisms. Quaternary ammonium compounds, while effective antimicrobials, have raised concerns regarding skin irritation and potential contribution to antimicrobial resistance development.

Life cycle assessment (LCA) methodologies increasingly inform selection decisions, enabling quantitative comparison of environmental impacts across production, use, and disposal phases. Recent LCA studies reveal that water consumption and energy requirements during coating application can sometimes outweigh the environmental benefits of biodegradable formulations, necessitating holistic evaluation approaches.

Emerging green chemistry principles are driving innovation toward inherently safer antibacterial technologies, including enzyme-based systems and photocatalytic coatings that activate only under specific conditions, thereby minimizing unnecessary environmental exposure and toxicological risks while maintaining protective functionality.

Leaching behavior constitutes a primary environmental concern, as antibacterial compounds gradually release from textiles during use and laundering. Recent research indicates that up to 30% of certain antibacterial agents may leach during the first washing cycle, with cumulative environmental loading occurring throughout the product lifecycle. This necessitates comprehensive assessment of degradation pathways and persistence profiles when evaluating coating options.

Regulatory frameworks increasingly address these environmental considerations, with the European Union's REACH regulations and the United States EPA imposing stringent requirements for toxicological profiling of antibacterial compounds. Manufacturers must now provide extensive ecotoxicological data, including acute and chronic toxicity assessments across multiple trophic levels, before market approval.

Biodegradability characteristics have emerged as a decisive selection factor, with preference shifting toward compounds that demonstrate complete mineralization under environmental conditions. Natural antimicrobials derived from plant extracts, essential oils, and chitosan-based formulations generally exhibit superior environmental profiles compared to synthetic alternatives, though efficacy and durability challenges remain.

Human toxicity considerations parallel environmental concerns, particularly regarding dermal contact and potential sensitization. Skin-friendly antibacterial coatings must demonstrate minimal cytotoxicity while maintaining efficacy against pathogenic microorganisms. Quaternary ammonium compounds, while effective antimicrobials, have raised concerns regarding skin irritation and potential contribution to antimicrobial resistance development.

Life cycle assessment (LCA) methodologies increasingly inform selection decisions, enabling quantitative comparison of environmental impacts across production, use, and disposal phases. Recent LCA studies reveal that water consumption and energy requirements during coating application can sometimes outweigh the environmental benefits of biodegradable formulations, necessitating holistic evaluation approaches.

Emerging green chemistry principles are driving innovation toward inherently safer antibacterial technologies, including enzyme-based systems and photocatalytic coatings that activate only under specific conditions, thereby minimizing unnecessary environmental exposure and toxicological risks while maintaining protective functionality.

Regulatory Compliance and Certification Standards

Regulatory compliance and certification standards play a crucial role in the selection and implementation of antibacterial coatings for textile applications. The global textile industry faces increasingly stringent regulations designed to ensure consumer safety, environmental protection, and product efficacy claims validation.

The primary regulatory frameworks governing antibacterial textiles include the European Union's Biocidal Products Regulation (BPR), which requires thorough assessment of active substances and treated articles. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial agents under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), while the Food and Drug Administration (FDA) oversees textiles making medical claims. Asian markets, particularly Japan and South Korea, have established their own comprehensive regulatory systems for antibacterial textiles.

Certification standards provide measurable benchmarks for antibacterial performance and safety. ISO 20743 stands as the international standard for determining antibacterial activity of textile products, while AATCC 100 offers an alternative testing methodology widely accepted in North America. The OEKO-TEX Standard 100 certification ensures textiles are free from harmful substances, with specific provisions for antimicrobial treatments.

Environmental certifications have gained prominence as sustainability concerns increase. The Global Organic Textile Standard (GOTS) and ZDHC (Zero Discharge of Hazardous Chemicals) programs establish strict criteria for environmentally responsible antibacterial treatments. Bluesign certification addresses the entire textile production chain, ensuring antibacterial agents meet ecological requirements.

Compliance documentation requirements vary by jurisdiction but typically include technical dossiers, safety data sheets, efficacy test reports, and environmental impact assessments. Companies must maintain comprehensive records demonstrating ongoing compliance with evolving regulations.

Market access increasingly depends on meeting these regulatory and certification requirements. Non-compliance can result in product recalls, market exclusion, financial penalties, and reputational damage. Forward-thinking textile manufacturers are adopting proactive compliance strategies, engaging with regulatory experts early in product development cycles.

The regulatory landscape continues to evolve, with increasing focus on sustainable chemistry, reduced biocide usage, and enhanced transparency in supply chains. Emerging regulations are addressing novel antibacterial technologies such as non-leaching bound antimicrobials and bio-based solutions, requiring manufacturers to stay vigilant regarding compliance obligations.

The primary regulatory frameworks governing antibacterial textiles include the European Union's Biocidal Products Regulation (BPR), which requires thorough assessment of active substances and treated articles. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial agents under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), while the Food and Drug Administration (FDA) oversees textiles making medical claims. Asian markets, particularly Japan and South Korea, have established their own comprehensive regulatory systems for antibacterial textiles.

Certification standards provide measurable benchmarks for antibacterial performance and safety. ISO 20743 stands as the international standard for determining antibacterial activity of textile products, while AATCC 100 offers an alternative testing methodology widely accepted in North America. The OEKO-TEX Standard 100 certification ensures textiles are free from harmful substances, with specific provisions for antimicrobial treatments.

Environmental certifications have gained prominence as sustainability concerns increase. The Global Organic Textile Standard (GOTS) and ZDHC (Zero Discharge of Hazardous Chemicals) programs establish strict criteria for environmentally responsible antibacterial treatments. Bluesign certification addresses the entire textile production chain, ensuring antibacterial agents meet ecological requirements.

Compliance documentation requirements vary by jurisdiction but typically include technical dossiers, safety data sheets, efficacy test reports, and environmental impact assessments. Companies must maintain comprehensive records demonstrating ongoing compliance with evolving regulations.

Market access increasingly depends on meeting these regulatory and certification requirements. Non-compliance can result in product recalls, market exclusion, financial penalties, and reputational damage. Forward-thinking textile manufacturers are adopting proactive compliance strategies, engaging with regulatory experts early in product development cycles.

The regulatory landscape continues to evolve, with increasing focus on sustainable chemistry, reduced biocide usage, and enhanced transparency in supply chains. Emerging regulations are addressing novel antibacterial technologies such as non-leaching bound antimicrobials and bio-based solutions, requiring manufacturers to stay vigilant regarding compliance obligations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!