What are the Best Practices for Antibacterial Coating Deployment

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Evolution and Objectives

Antibacterial coatings have evolved significantly over the past several decades, transitioning from simple chemical treatments to sophisticated engineered surfaces with targeted antimicrobial properties. The evolution began in the 1940s with the discovery of silver's antimicrobial properties, which led to the first generation of antibacterial coatings primarily used in medical settings. By the 1970s, triclosan and quaternary ammonium compounds emerged as effective antibacterial agents, expanding applications to consumer products.

The 1990s marked a significant turning point with the development of nano-based antibacterial coatings, utilizing silver nanoparticles, copper oxide, and zinc oxide. These materials offered enhanced efficacy due to their high surface-to-volume ratio and unique physical properties. The early 2000s saw the introduction of photocatalytic coatings based on titanium dioxide, which could neutralize bacteria when exposed to light.

Recent technological advancements have focused on smart antibacterial coatings that respond to environmental triggers, releasing antimicrobial agents only when needed. This approach minimizes the risk of developing bacterial resistance while extending the coating's effective lifespan. Parallel to this, research into biomimetic antibacterial surfaces has gained momentum, drawing inspiration from naturally antibacterial surfaces like shark skin or lotus leaves.

The primary objective of modern antibacterial coating technology is to develop solutions that provide long-lasting protection against a broad spectrum of pathogens while addressing key challenges such as durability, toxicity, and bacterial resistance. Specifically, the industry aims to create coatings that maintain efficacy for extended periods under various environmental conditions, including frequent cleaning, UV exposure, and mechanical abrasion.

Another critical objective is developing environmentally friendly alternatives to traditional biocides, responding to increasing regulatory pressure and consumer demand for sustainable products. This includes exploring naturally derived antimicrobial compounds and biodegradable polymers as coating matrices.

The healthcare sector drives significant innovation, with objectives focused on preventing healthcare-associated infections through effective surface treatments in hospitals and medical devices. Meanwhile, the food industry seeks coatings that can prevent contamination without affecting taste or safety, and the consumer goods market demands invisible, non-toxic solutions for high-touch surfaces.

Looking forward, the field is moving toward multifunctional coatings that combine antibacterial properties with other desirable characteristics such as self-cleaning, anti-fouling, or anti-corrosion capabilities. The ultimate goal remains developing universal deployment protocols that can be adapted across industries while maintaining consistent efficacy and safety standards.

The 1990s marked a significant turning point with the development of nano-based antibacterial coatings, utilizing silver nanoparticles, copper oxide, and zinc oxide. These materials offered enhanced efficacy due to their high surface-to-volume ratio and unique physical properties. The early 2000s saw the introduction of photocatalytic coatings based on titanium dioxide, which could neutralize bacteria when exposed to light.

Recent technological advancements have focused on smart antibacterial coatings that respond to environmental triggers, releasing antimicrobial agents only when needed. This approach minimizes the risk of developing bacterial resistance while extending the coating's effective lifespan. Parallel to this, research into biomimetic antibacterial surfaces has gained momentum, drawing inspiration from naturally antibacterial surfaces like shark skin or lotus leaves.

The primary objective of modern antibacterial coating technology is to develop solutions that provide long-lasting protection against a broad spectrum of pathogens while addressing key challenges such as durability, toxicity, and bacterial resistance. Specifically, the industry aims to create coatings that maintain efficacy for extended periods under various environmental conditions, including frequent cleaning, UV exposure, and mechanical abrasion.

Another critical objective is developing environmentally friendly alternatives to traditional biocides, responding to increasing regulatory pressure and consumer demand for sustainable products. This includes exploring naturally derived antimicrobial compounds and biodegradable polymers as coating matrices.

The healthcare sector drives significant innovation, with objectives focused on preventing healthcare-associated infections through effective surface treatments in hospitals and medical devices. Meanwhile, the food industry seeks coatings that can prevent contamination without affecting taste or safety, and the consumer goods market demands invisible, non-toxic solutions for high-touch surfaces.

Looking forward, the field is moving toward multifunctional coatings that combine antibacterial properties with other desirable characteristics such as self-cleaning, anti-fouling, or anti-corrosion capabilities. The ultimate goal remains developing universal deployment protocols that can be adapted across industries while maintaining consistent efficacy and safety standards.

Market Demand Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surface solutions has experienced significant growth in recent years, driven primarily by heightened awareness of infection control and hygiene standards across multiple sectors. The COVID-19 pandemic has substantially accelerated this trend, with healthcare facilities, public transportation, educational institutions, and commercial buildings all seeking effective solutions to minimize pathogen transmission through surfaces.

Healthcare remains the dominant market segment, accounting for approximately 40% of the total antimicrobial coatings market. Hospitals and medical facilities are increasingly implementing comprehensive surface protection strategies to combat healthcare-associated infections (HAIs), which affect millions of patients annually and result in substantial healthcare costs. The aging population in developed countries further amplifies this demand, as elderly individuals typically require more frequent healthcare interventions and are more susceptible to infections.

Consumer awareness regarding hygiene has reached unprecedented levels, creating new market opportunities in previously untapped sectors. Food processing facilities, restaurants, and packaging companies are adopting antimicrobial surfaces to extend product shelf life and ensure food safety. Similarly, the transportation sector has begun integrating these solutions in high-touch areas of public transit systems, airports, and shared mobility services.

Market research indicates that the antimicrobial coatings market is projected to grow at a compound annual growth rate of 12.8% through 2027. North America currently holds the largest market share, followed by Europe and Asia-Pacific. However, the fastest growth is anticipated in emerging economies where rapid urbanization, healthcare infrastructure development, and increasing disposable incomes are creating favorable market conditions.

Customer preferences are evolving toward solutions that offer multiple benefits beyond antimicrobial properties. Products that combine antibacterial efficacy with durability, ease of application, environmental sustainability, and aesthetic appeal command premium pricing and greater market acceptance. Particularly, there is growing demand for non-toxic, environmentally friendly antimicrobial coatings that do not rely on heavy metals or harmful chemicals.

Regulatory frameworks significantly influence market dynamics, with increasingly stringent standards regarding chemical safety, efficacy claims, and environmental impact. Manufacturers must navigate complex approval processes across different jurisdictions, which can impact time-to-market and development costs. However, these regulations also create barriers to entry that benefit established players with regulatory expertise and compliant product portfolios.

The competitive landscape is characterized by both large multinational corporations and specialized niche players. Strategic partnerships between coating manufacturers, surface material producers, and end-user industries are becoming more common as the market matures and solutions become more specialized for particular applications and environments.

Healthcare remains the dominant market segment, accounting for approximately 40% of the total antimicrobial coatings market. Hospitals and medical facilities are increasingly implementing comprehensive surface protection strategies to combat healthcare-associated infections (HAIs), which affect millions of patients annually and result in substantial healthcare costs. The aging population in developed countries further amplifies this demand, as elderly individuals typically require more frequent healthcare interventions and are more susceptible to infections.

Consumer awareness regarding hygiene has reached unprecedented levels, creating new market opportunities in previously untapped sectors. Food processing facilities, restaurants, and packaging companies are adopting antimicrobial surfaces to extend product shelf life and ensure food safety. Similarly, the transportation sector has begun integrating these solutions in high-touch areas of public transit systems, airports, and shared mobility services.

Market research indicates that the antimicrobial coatings market is projected to grow at a compound annual growth rate of 12.8% through 2027. North America currently holds the largest market share, followed by Europe and Asia-Pacific. However, the fastest growth is anticipated in emerging economies where rapid urbanization, healthcare infrastructure development, and increasing disposable incomes are creating favorable market conditions.

Customer preferences are evolving toward solutions that offer multiple benefits beyond antimicrobial properties. Products that combine antibacterial efficacy with durability, ease of application, environmental sustainability, and aesthetic appeal command premium pricing and greater market acceptance. Particularly, there is growing demand for non-toxic, environmentally friendly antimicrobial coatings that do not rely on heavy metals or harmful chemicals.

Regulatory frameworks significantly influence market dynamics, with increasingly stringent standards regarding chemical safety, efficacy claims, and environmental impact. Manufacturers must navigate complex approval processes across different jurisdictions, which can impact time-to-market and development costs. However, these regulations also create barriers to entry that benefit established players with regulatory expertise and compliant product portfolios.

The competitive landscape is characterized by both large multinational corporations and specialized niche players. Strategic partnerships between coating manufacturers, surface material producers, and end-user industries are becoming more common as the market matures and solutions become more specialized for particular applications and environments.

Current Antibacterial Coating Technologies and Limitations

The antibacterial coating market currently features several established technologies with varying degrees of effectiveness, application methods, and limitations. Silver-based coatings remain the most widely adopted solution, leveraging silver ions' ability to disrupt bacterial cell membranes and metabolic processes. These coatings demonstrate broad-spectrum efficacy against both Gram-positive and Gram-negative bacteria, with relatively long-lasting effects. However, they face challenges including potential environmental toxicity, higher production costs, and gradual efficacy reduction over time due to ion depletion.

Copper-based coatings represent another significant category, utilizing copper's inherent antimicrobial properties through contact killing mechanisms. These coatings have gained traction in healthcare settings due to their effectiveness against hospital-acquired infection pathogens and relatively lower cost compared to silver alternatives. Their limitations include potential surface discoloration, variable effectiveness depending on environmental conditions, and reduced efficacy against certain bacterial strains.

Quaternary ammonium compound (QAC) coatings function by disrupting bacterial cell membranes through their positively charged molecules. These coatings offer advantages in terms of cost-effectiveness and ease of application across various substrates. However, they demonstrate shorter active lifespans compared to metallic alternatives and face increasing concerns regarding bacterial resistance development with prolonged exposure.

Photocatalytic coatings, particularly those utilizing titanium dioxide (TiO₂), represent an emerging technology that activates under light exposure to generate reactive oxygen species that destroy microorganisms. While offering the benefit of self-cleaning properties and environmental sustainability, these coatings require sufficient light exposure to maintain efficacy and may demonstrate reduced performance in low-light environments.

Hydrophobic and superhydrophobic coatings prevent bacterial adhesion rather than actively killing microorganisms. This approach offers advantages in reducing biofilm formation but provides limited protection against airborne contamination. Their effectiveness can diminish with physical wear, and they often require combination with active antimicrobial agents for comprehensive protection.

Current technological limitations across all coating types include challenges in achieving uniform application on complex geometries, maintaining long-term durability under mechanical stress and cleaning protocols, and balancing antimicrobial efficacy with potential cytotoxicity concerns for human contact surfaces. Additionally, most existing solutions struggle with providing sustained release mechanisms that maintain effectiveness throughout the product lifecycle without requiring frequent reapplication or regeneration.

The regulatory landscape presents another significant limitation, with varying approval requirements across regions and application contexts, particularly for food-contact surfaces and medical devices. This regulatory complexity often extends development timelines and increases compliance costs for manufacturers seeking multi-market deployment.

Copper-based coatings represent another significant category, utilizing copper's inherent antimicrobial properties through contact killing mechanisms. These coatings have gained traction in healthcare settings due to their effectiveness against hospital-acquired infection pathogens and relatively lower cost compared to silver alternatives. Their limitations include potential surface discoloration, variable effectiveness depending on environmental conditions, and reduced efficacy against certain bacterial strains.

Quaternary ammonium compound (QAC) coatings function by disrupting bacterial cell membranes through their positively charged molecules. These coatings offer advantages in terms of cost-effectiveness and ease of application across various substrates. However, they demonstrate shorter active lifespans compared to metallic alternatives and face increasing concerns regarding bacterial resistance development with prolonged exposure.

Photocatalytic coatings, particularly those utilizing titanium dioxide (TiO₂), represent an emerging technology that activates under light exposure to generate reactive oxygen species that destroy microorganisms. While offering the benefit of self-cleaning properties and environmental sustainability, these coatings require sufficient light exposure to maintain efficacy and may demonstrate reduced performance in low-light environments.

Hydrophobic and superhydrophobic coatings prevent bacterial adhesion rather than actively killing microorganisms. This approach offers advantages in reducing biofilm formation but provides limited protection against airborne contamination. Their effectiveness can diminish with physical wear, and they often require combination with active antimicrobial agents for comprehensive protection.

Current technological limitations across all coating types include challenges in achieving uniform application on complex geometries, maintaining long-term durability under mechanical stress and cleaning protocols, and balancing antimicrobial efficacy with potential cytotoxicity concerns for human contact surfaces. Additionally, most existing solutions struggle with providing sustained release mechanisms that maintain effectiveness throughout the product lifecycle without requiring frequent reapplication or regeneration.

The regulatory landscape presents another significant limitation, with varying approval requirements across regions and application contexts, particularly for food-contact surfaces and medical devices. This regulatory complexity often extends development timelines and increases compliance costs for manufacturers seeking multi-market deployment.

Current Implementation Methods for Antibacterial Surface Protection

01 Metal-based antibacterial coatings

Metal-based compounds such as silver, copper, and zinc can be incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of bacteria. These coatings can be applied to various surfaces including medical devices, textiles, and household items to prevent bacterial contamination and growth.- Metal-based antibacterial coatings: Metal-based compounds such as silver, copper, and zinc are incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of bacteria. These coatings can be applied to various surfaces including medical devices, textiles, and consumer products to provide long-lasting protection against bacterial contamination.

- Polymer-based antibacterial coatings: Polymeric materials with inherent or modified antibacterial properties are used to create protective coatings. These polymers can be designed to release antibacterial agents gradually or to have contact-killing properties through positively charged functional groups that disrupt bacterial cell membranes. Polymer-based coatings offer advantages such as durability, flexibility, and the ability to be tailored for specific applications including medical implants, food packaging, and industrial surfaces.

- Natural compound-based antibacterial coatings: Antibacterial coatings derived from natural sources such as plant extracts, essential oils, and chitosan provide environmentally friendly alternatives to synthetic antibacterial agents. These natural compounds contain bioactive components that can inhibit bacterial growth through various mechanisms including disruption of cell membranes and inhibition of enzyme activity. Natural compound-based coatings are particularly valuable in applications where biocompatibility and sustainability are important considerations.

- Nanoparticle-enhanced antibacterial coatings: Nanoparticles are incorporated into coating formulations to enhance antibacterial efficacy through increased surface area and unique physicochemical properties. These nanostructured coatings can provide superior antibacterial performance due to their ability to penetrate bacterial cell walls and disrupt cellular functions. Various types of nanoparticles including metal oxides, carbon-based nanomaterials, and composite nanostructures are utilized in these advanced coating systems for applications ranging from healthcare surfaces to consumer electronics.

- Smart responsive antibacterial coatings: Advanced coating systems that can respond to environmental stimuli such as pH, temperature, or bacterial presence to trigger antibacterial action. These smart coatings can remain dormant until needed, then release antibacterial agents or change surface properties in response to specific triggers. This targeted approach enhances efficiency and longevity of antibacterial action while minimizing unnecessary release of active compounds. Applications include wound dressings, implantable medical devices, and surfaces in high-risk environments.

02 Polymer-based antibacterial coatings

Polymeric materials can be formulated with antibacterial agents to create durable coatings with long-lasting protection. These polymers can either inherently possess antibacterial properties or serve as carriers for antibacterial compounds. The polymers provide a controlled release mechanism for the active ingredients, ensuring sustained antibacterial activity. Applications include medical implants, food packaging, and industrial equipment where bacterial contamination is a concern.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Antibacterial coatings can be formulated using natural compounds derived from plants, animals, or microorganisms. These include essential oils, plant extracts, chitosan, and antimicrobial peptides. These natural compounds offer advantages such as biodegradability, reduced toxicity, and lower risk of developing bacterial resistance. They can be incorporated into various coating matrices for applications in food preservation, healthcare products, and environmentally friendly consumer goods.Expand Specific Solutions04 Nanoparticle-enhanced antibacterial coatings

Nanoparticles can significantly enhance the efficacy of antibacterial coatings due to their high surface area to volume ratio and unique physical properties. Materials such as nano-silver, nano-zinc oxide, and nano-titanium dioxide can be dispersed in coating formulations to provide potent antibacterial activity. These nanoparticle-enhanced coatings can be applied to surfaces where bacterial contamination is a concern, such as medical devices, textiles, and public touch surfaces.Expand Specific Solutions05 Smart responsive antibacterial coatings

Advanced antibacterial coatings can be designed to respond to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These smart coatings release antibacterial agents only when needed, improving efficiency and reducing the risk of developing bacterial resistance. Applications include wound dressings, implantable medical devices, and surfaces in healthcare settings where targeted antibacterial action is beneficial.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Antibacterial Coatings

The antibacterial coating market is currently in a growth phase, characterized by increasing adoption across healthcare, food packaging, and industrial sectors. The global market size is estimated to reach $8-10 billion by 2026, growing at a CAGR of approximately 12%. Technologically, the field shows varying maturity levels, with established players like Henkel AG and Stryker developing commercial solutions, while research institutions such as California Institute of Technology, Zhejiang University, and Empa are advancing next-generation technologies. Companies like CodiKoat, Nano Global, and Jiangsu Biosurf Biotech are emerging with innovative approaches, focusing on enhanced durability, reduced toxicity, and broader antimicrobial efficacy. The competitive landscape reflects a blend of multinational corporations, specialized coating manufacturers, and research-driven startups collaborating with academic institutions.

Eidgenössische Materialprüfungs & Forschungsanstalt Empa

Technical Solution: Empa has developed advanced antibacterial coatings using silver nanoparticles embedded in polymer matrices that provide controlled ion release mechanisms. Their technology employs a sophisticated approach where silver ions are gradually released to maintain long-term antimicrobial efficacy while minimizing environmental impact. The research team has pioneered methods to control the dissolution rate of silver ions, ensuring sustained antibacterial activity for extended periods (up to several years) without requiring reapplication. Additionally, Empa has developed transparent antibacterial coatings that can be applied to various surfaces without altering their appearance, making them particularly suitable for healthcare settings and public spaces. Their coatings have demonstrated effectiveness against a broad spectrum of bacteria, including antibiotic-resistant strains such as MRSA.

Strengths: Superior longevity with controlled release mechanisms that extend coating effectiveness; environmentally conscious formulations with reduced silver content while maintaining efficacy; transparent application options for aesthetic preservation. Weaknesses: Higher initial production costs compared to conventional coatings; potential regulatory hurdles in some markets due to nanomaterial content; requires specialized application equipment for optimal performance.

CodiKoat Ltd.

Technical Solution: CodiKoat has developed a revolutionary rapid-action antiviral and antibacterial coating technology called CodiKoat Virushield that can be applied to virtually any surface. Their proprietary technology destroys pathogens on contact within seconds, representing a significant advancement over traditional coatings that may take hours to be effective. The coating works through a photocatalytic mechanism that generates reactive oxygen species when exposed to light, creating a continuous self-cleaning effect. CodiKoat's formulation incorporates copper nanoparticles that provide broad-spectrum antimicrobial activity against bacteria, viruses, and fungi. The company has engineered their coatings to be extremely durable, with efficacy lasting up to three years even on high-touch surfaces. Their technology has been independently verified to kill 99.9% of bacteria within seconds of contact and maintains effectiveness even after repeated cleaning cycles.

Strengths: Exceptionally fast-acting antimicrobial action (seconds vs. hours for competitors); versatile application across multiple surface types; durable performance even with frequent cleaning and abrasion. Weaknesses: Relatively new to market with limited long-term field data; higher cost point than conventional antibacterial solutions; optimal performance depends on adequate light exposure for photocatalytic action.

Key Patents and Scientific Breakthroughs in Antimicrobial Coatings

Incorporation of antimicrobial combinations onto devices to reduce infection

PatentInactiveUS20070093894A1

Innovation

- A novel method involving a combination of bacteriostatic and bactericidal agents is applied to medical devices through coating or flushing, utilizing aminoglycosides and tetracyclines in effective concentrations to inhibit microbial growth synergistically or additively, reducing microbial colonization by at least 10% to 100%.

Antimicrobial monomer coatings and methods of making and using same

PatentWO2023200915A1

Innovation

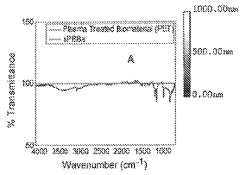

- The development of antimicrobial coatings, referred to as smart Polymer Brush Biocoatings (sPBBs), which are produced through a process involving inert plasma treatment, air exposure, and ammonium monomer graft polymerization on biomaterial substrates, creating a broad-spectrum, antibiotic-free, and biocompatible surface that inhibits bacterial adherence and biofilm formation.

Environmental Impact and Sustainability of Antimicrobial Coatings

The environmental impact of antimicrobial coatings represents a critical consideration in their widespread deployment. Traditional antimicrobial agents, particularly those containing heavy metals like silver, copper, and zinc, pose significant environmental concerns during their lifecycle. When these coatings degrade, they can release toxic compounds into water systems, potentially disrupting aquatic ecosystems and accumulating in the food chain. Studies have documented bioaccumulation of silver nanoparticles in various organisms, with potential long-term ecological consequences that remain incompletely understood.

Manufacturing processes for conventional antimicrobial coatings often involve energy-intensive methods and hazardous chemicals, contributing to their overall environmental footprint. The production of silver nanoparticles, for example, typically requires substantial energy inputs and generates waste streams containing potentially harmful byproducts. Additionally, the disposal of products treated with these coatings presents challenges for waste management systems, as they may leach antimicrobial agents into landfill environments.

Recent sustainability innovations have focused on developing environmentally friendly alternatives. Bio-based antimicrobial coatings derived from natural sources such as chitosan (from crustacean shells), plant extracts, and essential oils demonstrate promising antimicrobial efficacy while offering improved biodegradability. These nature-inspired solutions generally exhibit lower toxicity profiles and reduced environmental persistence compared to their synthetic counterparts.

Life cycle assessment (LCA) studies comparing traditional and eco-friendly antimicrobial coatings reveal significant differences in environmental impact categories including global warming potential, ecotoxicity, and resource depletion. For instance, chitosan-based coatings typically show 40-60% lower environmental impact scores across multiple categories compared to silver-based alternatives, though their antimicrobial performance may be more context-dependent.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of antimicrobial coatings. The European Union's REACH regulation and the US EPA's pesticide registration requirements now incorporate more stringent environmental risk assessments for antimicrobial products. These evolving regulatory landscapes are driving innovation toward greener formulations and application methods.

Industry adoption of sustainable practices in antimicrobial coating deployment has accelerated, with major manufacturers implementing closed-loop production systems, solvent recovery technologies, and water-based formulations to reduce environmental footprints. Additionally, emerging technologies such as UV-curable coatings and powder coating methods offer reduced VOC emissions and energy consumption compared to conventional solvent-based systems.

The healthcare sector, a primary user of antimicrobial coatings, faces particular challenges in balancing infection control imperatives with sustainability goals. Recent innovations in this space include antimicrobial surfaces with programmable degradation timelines, ensuring efficacy during critical use periods while minimizing long-term environmental persistence.

Manufacturing processes for conventional antimicrobial coatings often involve energy-intensive methods and hazardous chemicals, contributing to their overall environmental footprint. The production of silver nanoparticles, for example, typically requires substantial energy inputs and generates waste streams containing potentially harmful byproducts. Additionally, the disposal of products treated with these coatings presents challenges for waste management systems, as they may leach antimicrobial agents into landfill environments.

Recent sustainability innovations have focused on developing environmentally friendly alternatives. Bio-based antimicrobial coatings derived from natural sources such as chitosan (from crustacean shells), plant extracts, and essential oils demonstrate promising antimicrobial efficacy while offering improved biodegradability. These nature-inspired solutions generally exhibit lower toxicity profiles and reduced environmental persistence compared to their synthetic counterparts.

Life cycle assessment (LCA) studies comparing traditional and eco-friendly antimicrobial coatings reveal significant differences in environmental impact categories including global warming potential, ecotoxicity, and resource depletion. For instance, chitosan-based coatings typically show 40-60% lower environmental impact scores across multiple categories compared to silver-based alternatives, though their antimicrobial performance may be more context-dependent.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of antimicrobial coatings. The European Union's REACH regulation and the US EPA's pesticide registration requirements now incorporate more stringent environmental risk assessments for antimicrobial products. These evolving regulatory landscapes are driving innovation toward greener formulations and application methods.

Industry adoption of sustainable practices in antimicrobial coating deployment has accelerated, with major manufacturers implementing closed-loop production systems, solvent recovery technologies, and water-based formulations to reduce environmental footprints. Additionally, emerging technologies such as UV-curable coatings and powder coating methods offer reduced VOC emissions and energy consumption compared to conventional solvent-based systems.

The healthcare sector, a primary user of antimicrobial coatings, faces particular challenges in balancing infection control imperatives with sustainability goals. Recent innovations in this space include antimicrobial surfaces with programmable degradation timelines, ensuring efficacy during critical use periods while minimizing long-term environmental persistence.

Regulatory Compliance and Safety Standards for Antibacterial Products

The regulatory landscape for antibacterial coatings is complex and multifaceted, requiring manufacturers and deployers to navigate various international, national, and industry-specific standards. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of active ingredients and efficacy data submission. Similarly, the Food and Drug Administration (FDA) oversees antibacterial coatings used in medical devices and food contact surfaces, with specific requirements outlined in 21 CFR Part 175-178.

In the European Union, the Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs antibacterial coatings, mandating rigorous safety assessments and authorization processes. The regulation specifically addresses treated articles in Article 58, requiring proper labeling and claims substantiation. Additionally, the EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes obligations for chemical substances used in these coatings.

ISO standards provide globally recognized frameworks for antibacterial efficacy testing, with ISO 22196 being the primary standard for measuring antibacterial activity on plastics and non-porous surfaces. For healthcare settings, ISO 13485 outlines quality management systems for medical devices, including those with antibacterial properties.

Safety assessment protocols typically include cytotoxicity testing (ISO 10993-5), skin irritation and sensitization evaluations (ISO 10993-10), and leaching studies to determine potential migration of active ingredients. Environmental impact assessments are increasingly required, particularly in the EU, to evaluate ecotoxicity and biodegradation characteristics of antibacterial agents.

Compliance documentation must include comprehensive technical files with test reports, safety data sheets, and risk assessments. For medical applications, clinical evaluation reports may be necessary to demonstrate both safety and efficacy in the intended use environment. Many jurisdictions also require ongoing post-market surveillance to monitor adverse events and maintain regulatory compliance.

Emerging regulations are focusing on nanomaterials used in antibacterial coatings, with specific reporting requirements in both the US and EU. The EU's Medical Device Regulation (MDR 2017/745) has introduced stricter requirements for antimicrobial claims on medical devices, requiring robust clinical data to support marketing claims.

Industry best practices include developing a regulatory strategy early in product development, conducting gap analyses against applicable standards, and maintaining regular communication with regulatory bodies. Manufacturers should also implement robust quality management systems that address the entire product lifecycle from development through post-market surveillance.

In the European Union, the Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs antibacterial coatings, mandating rigorous safety assessments and authorization processes. The regulation specifically addresses treated articles in Article 58, requiring proper labeling and claims substantiation. Additionally, the EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) imposes obligations for chemical substances used in these coatings.

ISO standards provide globally recognized frameworks for antibacterial efficacy testing, with ISO 22196 being the primary standard for measuring antibacterial activity on plastics and non-porous surfaces. For healthcare settings, ISO 13485 outlines quality management systems for medical devices, including those with antibacterial properties.

Safety assessment protocols typically include cytotoxicity testing (ISO 10993-5), skin irritation and sensitization evaluations (ISO 10993-10), and leaching studies to determine potential migration of active ingredients. Environmental impact assessments are increasingly required, particularly in the EU, to evaluate ecotoxicity and biodegradation characteristics of antibacterial agents.

Compliance documentation must include comprehensive technical files with test reports, safety data sheets, and risk assessments. For medical applications, clinical evaluation reports may be necessary to demonstrate both safety and efficacy in the intended use environment. Many jurisdictions also require ongoing post-market surveillance to monitor adverse events and maintain regulatory compliance.

Emerging regulations are focusing on nanomaterials used in antibacterial coatings, with specific reporting requirements in both the US and EU. The EU's Medical Device Regulation (MDR 2017/745) has introduced stricter requirements for antimicrobial claims on medical devices, requiring robust clinical data to support marketing claims.

Industry best practices include developing a regulatory strategy early in product development, conducting gap analyses against applicable standards, and maintaining regular communication with regulatory bodies. Manufacturers should also implement robust quality management systems that address the entire product lifecycle from development through post-market surveillance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!