Antibacterial Coating Methods for Enhanced Sterility in Pharmaceuticals

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Evolution and Objectives

Antibacterial coating technologies have evolved significantly over the past several decades, transforming from simple chemical applications to sophisticated multi-functional systems. The earliest documented use of antimicrobial coatings dates back to the 1940s with silver-based compounds, though their systematic application in pharmaceutical manufacturing emerged only in the 1970s. This evolution has been driven by increasing regulatory requirements for sterility assurance and the growing challenge of antimicrobial resistance in healthcare settings.

The technological progression can be traced through several distinct phases. The initial phase (1970s-1980s) focused primarily on basic chemical inhibitors and simple metallic compounds. The second phase (1990s-early 2000s) saw the introduction of polymer-based coatings with embedded antimicrobial agents, offering improved durability and controlled release mechanisms. The current phase (2010s-present) has witnessed the emergence of nanotechnology-enabled coatings, biomimetic surfaces, and smart responsive systems that can adapt to environmental triggers.

Recent advancements have been particularly noteworthy in the pharmaceutical sector, where coating technologies now serve multiple functions beyond mere antimicrobial properties. Modern coatings simultaneously address issues of biofilm formation, cross-contamination prevention, and maintenance of sterile conditions throughout the product lifecycle. The integration of these technologies with Industry 4.0 principles has further enhanced monitoring capabilities and quality assurance protocols.

The primary objectives of contemporary antibacterial coating research for pharmaceutical applications center around several key areas. First, developing broad-spectrum antimicrobial efficacy against both gram-positive and gram-negative bacteria, fungi, and certain viruses without promoting resistance. Second, ensuring long-term stability and durability under various manufacturing conditions, including resistance to cleaning agents and sterilization processes. Third, achieving biocompatibility and non-toxicity, particularly for coatings used in direct product contact surfaces.

Additional objectives include cost-effectiveness for large-scale implementation, environmental sustainability through reduced use of harmful chemicals, and compatibility with existing manufacturing equipment and processes. Researchers are also pursuing coatings with self-diagnostic capabilities that can indicate contamination or coating degradation through visual or electronic signals.

The trajectory of this technology points toward increasingly sophisticated, multi-functional coating systems that integrate antimicrobial properties with other desirable characteristics such as anti-fouling, self-cleaning, and even self-healing capabilities. These developments align with the pharmaceutical industry's movement toward continuous manufacturing processes and heightened quality assurance standards.

The technological progression can be traced through several distinct phases. The initial phase (1970s-1980s) focused primarily on basic chemical inhibitors and simple metallic compounds. The second phase (1990s-early 2000s) saw the introduction of polymer-based coatings with embedded antimicrobial agents, offering improved durability and controlled release mechanisms. The current phase (2010s-present) has witnessed the emergence of nanotechnology-enabled coatings, biomimetic surfaces, and smart responsive systems that can adapt to environmental triggers.

Recent advancements have been particularly noteworthy in the pharmaceutical sector, where coating technologies now serve multiple functions beyond mere antimicrobial properties. Modern coatings simultaneously address issues of biofilm formation, cross-contamination prevention, and maintenance of sterile conditions throughout the product lifecycle. The integration of these technologies with Industry 4.0 principles has further enhanced monitoring capabilities and quality assurance protocols.

The primary objectives of contemporary antibacterial coating research for pharmaceutical applications center around several key areas. First, developing broad-spectrum antimicrobial efficacy against both gram-positive and gram-negative bacteria, fungi, and certain viruses without promoting resistance. Second, ensuring long-term stability and durability under various manufacturing conditions, including resistance to cleaning agents and sterilization processes. Third, achieving biocompatibility and non-toxicity, particularly for coatings used in direct product contact surfaces.

Additional objectives include cost-effectiveness for large-scale implementation, environmental sustainability through reduced use of harmful chemicals, and compatibility with existing manufacturing equipment and processes. Researchers are also pursuing coatings with self-diagnostic capabilities that can indicate contamination or coating degradation through visual or electronic signals.

The trajectory of this technology points toward increasingly sophisticated, multi-functional coating systems that integrate antimicrobial properties with other desirable characteristics such as anti-fouling, self-cleaning, and even self-healing capabilities. These developments align with the pharmaceutical industry's movement toward continuous manufacturing processes and heightened quality assurance standards.

Pharmaceutical Industry Demand for Enhanced Sterility Solutions

The pharmaceutical industry has witnessed a significant surge in demand for enhanced sterility solutions, particularly in the realm of antibacterial coating methods. This demand is primarily driven by the increasing prevalence of healthcare-associated infections (HAIs) and the growing regulatory pressure to ensure product safety. According to recent market analyses, the global pharmaceutical sterility assurance market is projected to reach $10.2 billion by 2026, with antibacterial coating technologies representing a rapidly expanding segment.

Consumer expectations have evolved dramatically over the past decade, with patients and healthcare providers alike demanding higher standards of safety and sterility in pharmaceutical products. This shift has been accelerated by high-profile contamination incidents that have resulted in product recalls and significant financial losses for pharmaceutical companies. The economic impact of such incidents extends beyond immediate recall costs to include litigation expenses, brand damage, and market share erosion.

Regulatory bodies worldwide have responded by implementing more stringent requirements for pharmaceutical manufacturing processes. The FDA's updated guidance on aseptic processing, the EU GMP Annex 1 revisions, and similar regulatory frameworks in emerging markets have collectively raised the bar for sterility assurance. These regulations increasingly emphasize preventative approaches to contamination control, creating a favorable environment for innovative antibacterial coating solutions.

The COVID-19 pandemic has further intensified this trend, heightening awareness of infection risks and accelerating the adoption of advanced sterility technologies. Pharmaceutical companies have reported a 37% increase in investments related to sterility enhancement since 2020, with antibacterial coating methods receiving particular attention due to their potential for long-lasting protection.

Market research indicates that pharmaceutical manufacturers are specifically seeking coating solutions that offer multiple benefits: long-term antimicrobial efficacy, compatibility with existing manufacturing processes, minimal impact on drug stability, cost-effectiveness, and environmental sustainability. The demand is particularly strong in injectable medications, ophthalmic preparations, and implantable drug delivery systems, where sterility requirements are most stringent.

Regional analysis reveals varying levels of demand across global markets. North America and Europe currently lead in adoption rates for advanced antibacterial coating technologies, driven by mature regulatory frameworks and higher healthcare expenditures. However, the Asia-Pacific region is experiencing the fastest growth rate, with a compound annual growth rate of 12.3% in the pharmaceutical sterility solutions market, creating significant opportunities for technology providers in these emerging economies.

Consumer expectations have evolved dramatically over the past decade, with patients and healthcare providers alike demanding higher standards of safety and sterility in pharmaceutical products. This shift has been accelerated by high-profile contamination incidents that have resulted in product recalls and significant financial losses for pharmaceutical companies. The economic impact of such incidents extends beyond immediate recall costs to include litigation expenses, brand damage, and market share erosion.

Regulatory bodies worldwide have responded by implementing more stringent requirements for pharmaceutical manufacturing processes. The FDA's updated guidance on aseptic processing, the EU GMP Annex 1 revisions, and similar regulatory frameworks in emerging markets have collectively raised the bar for sterility assurance. These regulations increasingly emphasize preventative approaches to contamination control, creating a favorable environment for innovative antibacterial coating solutions.

The COVID-19 pandemic has further intensified this trend, heightening awareness of infection risks and accelerating the adoption of advanced sterility technologies. Pharmaceutical companies have reported a 37% increase in investments related to sterility enhancement since 2020, with antibacterial coating methods receiving particular attention due to their potential for long-lasting protection.

Market research indicates that pharmaceutical manufacturers are specifically seeking coating solutions that offer multiple benefits: long-term antimicrobial efficacy, compatibility with existing manufacturing processes, minimal impact on drug stability, cost-effectiveness, and environmental sustainability. The demand is particularly strong in injectable medications, ophthalmic preparations, and implantable drug delivery systems, where sterility requirements are most stringent.

Regional analysis reveals varying levels of demand across global markets. North America and Europe currently lead in adoption rates for advanced antibacterial coating technologies, driven by mature regulatory frameworks and higher healthcare expenditures. However, the Asia-Pacific region is experiencing the fastest growth rate, with a compound annual growth rate of 12.3% in the pharmaceutical sterility solutions market, creating significant opportunities for technology providers in these emerging economies.

Current Antibacterial Coating Technologies and Limitations

The pharmaceutical industry currently employs several advanced antibacterial coating technologies to enhance product sterility. Silver-based coatings represent one of the most established approaches, utilizing silver ions or nanoparticles that disrupt bacterial cell membranes and inhibit DNA replication. These coatings provide broad-spectrum antimicrobial activity against both Gram-positive and Gram-negative bacteria, with relatively long-lasting effects. However, concerns regarding potential cytotoxicity, environmental impact, and the development of silver-resistant bacterial strains limit their universal application.

Quaternary ammonium compounds (QACs) constitute another widely implemented coating technology, functioning by disrupting bacterial cell membranes through their positively charged molecules. While QACs offer advantages such as low cost and ease of application, their effectiveness diminishes over time due to leaching effects, and increasing bacterial resistance presents a significant challenge to their long-term efficacy.

Chitosan-based coatings have gained prominence as a natural alternative, derived from crustacean shells. These polysaccharide coatings exhibit inherent antimicrobial properties through electrostatic interactions with negatively charged bacterial cell walls. Despite their biocompatibility and biodegradability advantages, chitosan coatings often demonstrate limited efficacy against certain bacterial species and may require additional modifications to enhance their antimicrobial spectrum.

Photocatalytic coatings, particularly those utilizing titanium dioxide (TiO₂), represent an innovative approach that generates reactive oxygen species upon light exposure to destroy microorganisms. While these coatings offer the benefit of self-cleaning properties, their dependence on light activation significantly restricts their application in light-limited pharmaceutical environments.

Hydrogel-based antimicrobial coatings have emerged as promising candidates due to their controlled release capabilities and biocompatibility. However, challenges related to mechanical stability and maintaining consistent drug release profiles over extended periods remain unresolved.

A critical limitation across most current technologies is the trade-off between antimicrobial efficacy and long-term stability. Many coatings exhibit diminished effectiveness over time due to degradation, leaching of active components, or the development of bacterial resistance. Additionally, regulatory hurdles present significant challenges, as novel coating technologies must undergo rigorous safety assessments before pharmaceutical implementation.

Manufacturing scalability represents another substantial limitation, with many promising laboratory-scale technologies facing difficulties in consistent large-scale production. Cost considerations further constrain widespread adoption, particularly for advanced technologies requiring specialized equipment or materials. The pharmaceutical industry continues to seek coating solutions that balance antimicrobial efficacy, durability, regulatory compliance, and economic feasibility.

Quaternary ammonium compounds (QACs) constitute another widely implemented coating technology, functioning by disrupting bacterial cell membranes through their positively charged molecules. While QACs offer advantages such as low cost and ease of application, their effectiveness diminishes over time due to leaching effects, and increasing bacterial resistance presents a significant challenge to their long-term efficacy.

Chitosan-based coatings have gained prominence as a natural alternative, derived from crustacean shells. These polysaccharide coatings exhibit inherent antimicrobial properties through electrostatic interactions with negatively charged bacterial cell walls. Despite their biocompatibility and biodegradability advantages, chitosan coatings often demonstrate limited efficacy against certain bacterial species and may require additional modifications to enhance their antimicrobial spectrum.

Photocatalytic coatings, particularly those utilizing titanium dioxide (TiO₂), represent an innovative approach that generates reactive oxygen species upon light exposure to destroy microorganisms. While these coatings offer the benefit of self-cleaning properties, their dependence on light activation significantly restricts their application in light-limited pharmaceutical environments.

Hydrogel-based antimicrobial coatings have emerged as promising candidates due to their controlled release capabilities and biocompatibility. However, challenges related to mechanical stability and maintaining consistent drug release profiles over extended periods remain unresolved.

A critical limitation across most current technologies is the trade-off between antimicrobial efficacy and long-term stability. Many coatings exhibit diminished effectiveness over time due to degradation, leaching of active components, or the development of bacterial resistance. Additionally, regulatory hurdles present significant challenges, as novel coating technologies must undergo rigorous safety assessments before pharmaceutical implementation.

Manufacturing scalability represents another substantial limitation, with many promising laboratory-scale technologies facing difficulties in consistent large-scale production. Cost considerations further constrain widespread adoption, particularly for advanced technologies requiring specialized equipment or materials. The pharmaceutical industry continues to seek coating solutions that balance antimicrobial efficacy, durability, regulatory compliance, and economic feasibility.

Prevalent Antibacterial Coating Methodologies

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize silver, copper, zinc, or other metal ions to provide antimicrobial properties. These metals can be incorporated into various coating matrices or used as nanoparticles to create surfaces that inhibit bacterial growth and proliferation. The metal ions disrupt bacterial cell membranes and interfere with cellular processes, making them effective for long-term sterility maintenance on medical devices, implants, and healthcare surfaces.- Metal-based antibacterial coatings: Metal-based coatings, particularly those incorporating silver, copper, or zinc nanoparticles, provide effective antibacterial properties for maintaining sterility. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes. The coatings can be applied to various medical devices and surfaces to prevent bacterial colonization and biofilm formation, offering long-lasting protection against a broad spectrum of pathogens.

- Polymer-based antimicrobial coatings: Polymer-based coatings incorporate antimicrobial agents within a polymer matrix to create surfaces resistant to bacterial growth. These coatings can utilize natural or synthetic polymers as carriers for active ingredients such as quaternary ammonium compounds, chitosan, or antimicrobial peptides. The polymer matrix provides controlled release of the antimicrobial agents, extending the duration of sterility while maintaining biocompatibility with human tissues.

- Surface modification techniques for sterility: Various surface modification techniques can enhance the antibacterial properties of materials without requiring additional chemical agents. These include plasma treatment, UV irradiation, and laser texturing to create surfaces that physically prevent bacterial adhesion. Some modifications alter surface energy or create nanoscale patterns that disrupt bacterial cell membranes upon contact. These techniques can be applied to medical implants and devices to maintain sterility in clinical settings.

- Hydrophobic and self-cleaning coatings: Hydrophobic coatings create water-repellent surfaces that prevent bacterial adhesion and biofilm formation. These coatings often incorporate superhydrophobic materials or nanostructures that minimize contact between bacteria and the surface. Some formulations also include self-cleaning properties, where water droplets roll off the surface carrying contaminants with them. This approach is particularly useful for maintaining sterility on surfaces that are difficult to clean manually or are exposed to frequent contamination.

- Controlled-release antimicrobial systems: Controlled-release systems incorporate antibacterial agents within specialized matrices that gradually release active compounds over extended periods. These systems can utilize biodegradable polymers, hydrogels, or layer-by-layer assemblies to control the release kinetics of antimicrobial agents. Some formulations respond to environmental triggers such as pH changes or bacterial presence to activate release. This approach ensures sustained antimicrobial activity and prolonged sterility for medical devices and implants.

02 Polymer-based antimicrobial coatings

Polymer-based antimicrobial coatings incorporate antibacterial agents within polymer matrices to create sterile surfaces. These coatings can be designed with controlled release mechanisms that gradually dispense antimicrobial compounds over time. Various polymers such as polyurethane, silicone, and biodegradable polymers can be functionalized with antimicrobial properties, making them suitable for medical devices, implants, and healthcare environments where maintaining sterility is critical.Expand Specific Solutions03 Surface modification techniques for antibacterial properties

Surface modification techniques alter the physical or chemical properties of materials to impart antibacterial characteristics. These methods include plasma treatment, UV irradiation, chemical etching, and grafting of antimicrobial compounds onto surfaces. By creating micro or nano-structured surfaces or attaching functional groups, these techniques can prevent bacterial adhesion and biofilm formation, thereby maintaining sterility on medical devices and healthcare surfaces without relying solely on eluting antimicrobial agents.Expand Specific Solutions04 Natural and plant-derived antibacterial coating materials

Natural and plant-derived compounds offer environmentally friendly alternatives for antibacterial coatings. Extracts from plants, essential oils, chitosan, and other naturally occurring substances possess inherent antimicrobial properties that can be incorporated into coating formulations. These biocompatible materials provide effective bacterial inhibition while reducing concerns about toxicity and environmental impact, making them suitable for applications in medical devices, food packaging, and consumer products where sterility is required.Expand Specific Solutions05 Multi-functional antibacterial coating systems

Multi-functional antibacterial coating systems combine multiple mechanisms of action to enhance sterility maintenance. These advanced coatings integrate antimicrobial agents with other functional properties such as anti-fouling, self-cleaning, or wound-healing capabilities. By incorporating different active ingredients or using layer-by-layer deposition techniques, these systems provide synergistic effects that improve overall performance and longevity of sterile surfaces in challenging environments such as medical implants, surgical instruments, and high-touch healthcare surfaces.Expand Specific Solutions

Leading Companies in Antibacterial Coating Industry

The antibacterial coating market for pharmaceuticals is in a growth phase, characterized by increasing demand for sterile solutions in healthcare settings. The market size is expanding due to rising concerns about hospital-acquired infections and stringent regulatory requirements for pharmaceutical sterility. Technologically, the field shows moderate maturity with established players like Medtronic MiniMed and Ethicon (Johnson & Johnson) leading commercial applications, while research institutions such as Changchun Institute of Applied Chemistry and Baylor College of Medicine drive innovation. Specialized companies like Jiangsu Biosurf Biotech and Vomaris Innovations are developing advanced surface modification technologies, including microcurrent field generating coatings. The competitive landscape features collaboration between academic institutions and industry partners, with emerging players from Asia, particularly China, challenging established Western companies through cost-effective manufacturing and innovative approaches.

Eidgenössische Materialprüfungs & Forschungsanstalt Empa

Technical Solution: Empa has pioneered innovative plasma-assisted coating methods for pharmaceutical packaging and devices. Their technology utilizes low-temperature plasma deposition to create ultra-thin antibacterial films with precisely controlled release kinetics. The process involves exposing substrate surfaces to ionized gas containing precursor molecules of silver, copper, or zinc compounds, which then form nanoscale coatings with exceptional adhesion properties. Empa's approach is particularly notable for its ability to functionalize temperature-sensitive materials without degradation. Their research has demonstrated that plasma-deposited silver nanoparticle coatings can maintain sterility for extended periods while minimizing silver ion leaching, addressing both efficacy and safety concerns. Additionally, Empa has developed hybrid organic-inorganic coatings that combine the antimicrobial properties of metal ions with the barrier properties of silica-based matrices, creating multifunctional surfaces that prevent both microbial contamination and oxygen permeation in pharmaceutical packaging.

Strengths: Solvent-free process suitable for heat-sensitive pharmaceutical materials; precise control over coating thickness and composition; excellent adhesion properties; minimal leaching of antimicrobial agents. Weaknesses: Requires specialized equipment and expertise; higher initial investment costs; potential challenges in scaling up for mass production; limited long-term stability data for some coating compositions.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced polymer-based antibacterial coating technologies specifically for pharmaceutical applications. Their flagship approach utilizes electrospun nanofiber membranes impregnated with silver nanoparticles and chitosan derivatives, creating a highly effective barrier against microbial contamination. The manufacturing process involves a proprietary electrospinning technique that produces ultra-fine fibers (50-500 nm diameter) with precisely controlled silver nanoparticle distribution, ensuring optimal antimicrobial efficacy while minimizing silver usage. These coatings demonstrate remarkable efficacy against both gram-positive and gram-negative bacteria, with in vitro studies showing >99.99% reduction in bacterial counts within 24 hours of exposure. Toray has also pioneered photocatalytic TiO2-based coatings that provide self-cleaning and continuous antimicrobial properties when exposed to ambient light, making them particularly suitable for pharmaceutical packaging and storage environments. Their latest innovation combines these technologies with hydrophobic surface modifications to create coatings that resist biofilm formation through both chemical and physical mechanisms, addressing a critical challenge in maintaining long-term sterility.

Strengths: Exceptional antimicrobial efficacy with minimal leaching of active agents; versatile application methods compatible with various pharmaceutical substrates; dual-action mechanisms reducing risk of resistance development; extended functional lifetime compared to conventional coatings. Weaknesses: Higher production costs compared to traditional antimicrobial approaches; potential challenges in regulatory approval for direct product contact applications; specialized application equipment requirements; limited effectiveness in low-humidity environments.

Key Patents and Innovations in Pharmaceutical Coating

Method for producing coated medical device

PatentWO2022185833A1

Innovation

- A method involving a contacting step with a solution containing a hydrophilic polymer with a quaternary ammonium cation group, followed by heating to a pH of 6.1 to 8.0, which forms a coating that enhances hydrophilicity and anti-bacterial properties without the need for subsequent neutralization or additional sterilization steps.

Incorporation of antimicrobial combinations onto devices to reduce infection

PatentWO2007050565A2

Innovation

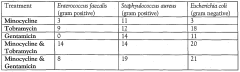

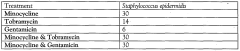

- A novel method involving the simultaneous or consecutive application of a bactericidal and bacteriostatic agent combination on medical devices, either through coating or flushing, to inhibit microbial growth, utilizing effective concentrations that synergistically or additively reduce microbial colonization by at least 10-100%.

Regulatory Compliance and Safety Standards

The pharmaceutical industry operates under stringent regulatory frameworks that govern antibacterial coating methods to ensure product safety and efficacy. The FDA in the United States, the EMA in Europe, and similar agencies worldwide have established comprehensive guidelines for pharmaceutical manufacturing processes, including antibacterial coating applications. These regulations typically address material selection, coating processes, validation protocols, and quality control measures.

ISO standards, particularly ISO 13485 for medical devices and ISO 22716 for cosmetics manufacturing, provide additional frameworks that pharmaceutical companies must adhere to when implementing antibacterial coating technologies. These standards emphasize risk management, process validation, and documentation requirements that are essential for regulatory compliance.

Good Manufacturing Practices (GMP) regulations specifically address sterility concerns in pharmaceutical production environments. They mandate regular environmental monitoring, validation of sterilization processes, and implementation of contamination control strategies. Antibacterial coatings must be validated according to these standards to demonstrate their effectiveness in maintaining sterile conditions.

Material safety is another critical regulatory consideration. The FDA's Inactive Ingredient Database and similar resources provide information on acceptable coating materials for pharmaceutical applications. Novel antibacterial compounds must undergo rigorous toxicological assessment before approval, with particular attention to leachables and extractables that might compromise product safety.

Environmental regulations also impact antibacterial coating technologies. Many traditional antimicrobial agents face increasing scrutiny due to ecological concerns, driving the industry toward more sustainable alternatives. Regulations such as REACH in Europe restrict the use of certain biocides and antimicrobial compounds, influencing coating formulation strategies.

Validation protocols for antibacterial coatings typically include challenge testing against relevant microbial species, stability studies under various environmental conditions, and accelerated aging tests to predict long-term performance. These protocols must align with pharmacopeial standards such as USP <51> for antimicrobial effectiveness testing and USP <1072> for disinfectants and antiseptics.

Emerging regulations are increasingly focusing on antimicrobial resistance concerns. Regulatory bodies are scrutinizing technologies that might contribute to the development of resistant organisms, requiring manufacturers to demonstrate that their antibacterial coating methods do not exacerbate this global health challenge. This has prompted the development of non-traditional antimicrobial approaches that minimize resistance potential while maintaining efficacy.

ISO standards, particularly ISO 13485 for medical devices and ISO 22716 for cosmetics manufacturing, provide additional frameworks that pharmaceutical companies must adhere to when implementing antibacterial coating technologies. These standards emphasize risk management, process validation, and documentation requirements that are essential for regulatory compliance.

Good Manufacturing Practices (GMP) regulations specifically address sterility concerns in pharmaceutical production environments. They mandate regular environmental monitoring, validation of sterilization processes, and implementation of contamination control strategies. Antibacterial coatings must be validated according to these standards to demonstrate their effectiveness in maintaining sterile conditions.

Material safety is another critical regulatory consideration. The FDA's Inactive Ingredient Database and similar resources provide information on acceptable coating materials for pharmaceutical applications. Novel antibacterial compounds must undergo rigorous toxicological assessment before approval, with particular attention to leachables and extractables that might compromise product safety.

Environmental regulations also impact antibacterial coating technologies. Many traditional antimicrobial agents face increasing scrutiny due to ecological concerns, driving the industry toward more sustainable alternatives. Regulations such as REACH in Europe restrict the use of certain biocides and antimicrobial compounds, influencing coating formulation strategies.

Validation protocols for antibacterial coatings typically include challenge testing against relevant microbial species, stability studies under various environmental conditions, and accelerated aging tests to predict long-term performance. These protocols must align with pharmacopeial standards such as USP <51> for antimicrobial effectiveness testing and USP <1072> for disinfectants and antiseptics.

Emerging regulations are increasingly focusing on antimicrobial resistance concerns. Regulatory bodies are scrutinizing technologies that might contribute to the development of resistant organisms, requiring manufacturers to demonstrate that their antibacterial coating methods do not exacerbate this global health challenge. This has prompted the development of non-traditional antimicrobial approaches that minimize resistance potential while maintaining efficacy.

Environmental Impact and Sustainability Considerations

The environmental impact of antibacterial coating technologies in pharmaceutical manufacturing represents a critical consideration as the industry moves toward more sustainable practices. Traditional antibacterial coating methods often rely on heavy metals such as silver, copper, and zinc, which can accumulate in ecosystems and potentially disrupt aquatic life and soil microbiota when released into the environment through manufacturing waste streams or product disposal.

Recent life cycle assessments of pharmaceutical packaging with antibacterial properties indicate that production processes involving solvent-based coating applications generate significant volatile organic compound (VOC) emissions, contributing to air pollution and potential health hazards for manufacturing workers. Additionally, many conventional antibacterial agents demonstrate persistence in the environment, with degradation half-lives exceeding acceptable ecological standards.

Water consumption represents another substantial environmental concern, particularly for wet-application coating processes that require extensive rinsing and cleaning cycles. Studies estimate that water-intensive antibacterial coating operations can consume between 3-7 liters of water per square meter of treated pharmaceutical packaging surface, placing pressure on local water resources in manufacturing regions.

The pharmaceutical industry has begun addressing these challenges through several promising sustainable approaches. Bio-based antibacterial coatings derived from natural sources such as chitosan, plant extracts, and essential oils offer biodegradable alternatives with reduced environmental persistence. These materials typically decompose within 3-6 months under normal environmental conditions, compared to years or decades for certain synthetic compounds.

Energy-efficient coating technologies, including plasma-assisted deposition and UV-curing systems, have demonstrated energy consumption reductions of 40-60% compared to conventional thermal curing methods. These approaches not only minimize carbon footprints but also reduce operational costs, creating economic incentives for sustainability adoption.

Closed-loop manufacturing systems for antibacterial coating applications have emerged as another sustainable innovation, with water recycling capabilities that can recover up to 85% of process water. Similarly, solvent recovery systems can recapture and reuse up to 90% of organic solvents, substantially reducing both waste generation and raw material consumption.

Regulatory frameworks increasingly emphasize environmental considerations, with the European Medicines Agency and FDA both developing guidelines specifically addressing the environmental impact of pharmaceutical manufacturing processes, including coating technologies. Companies demonstrating superior environmental performance in their coating operations may gain competitive advantages through regulatory compliance and enhanced corporate sustainability profiles.

Recent life cycle assessments of pharmaceutical packaging with antibacterial properties indicate that production processes involving solvent-based coating applications generate significant volatile organic compound (VOC) emissions, contributing to air pollution and potential health hazards for manufacturing workers. Additionally, many conventional antibacterial agents demonstrate persistence in the environment, with degradation half-lives exceeding acceptable ecological standards.

Water consumption represents another substantial environmental concern, particularly for wet-application coating processes that require extensive rinsing and cleaning cycles. Studies estimate that water-intensive antibacterial coating operations can consume between 3-7 liters of water per square meter of treated pharmaceutical packaging surface, placing pressure on local water resources in manufacturing regions.

The pharmaceutical industry has begun addressing these challenges through several promising sustainable approaches. Bio-based antibacterial coatings derived from natural sources such as chitosan, plant extracts, and essential oils offer biodegradable alternatives with reduced environmental persistence. These materials typically decompose within 3-6 months under normal environmental conditions, compared to years or decades for certain synthetic compounds.

Energy-efficient coating technologies, including plasma-assisted deposition and UV-curing systems, have demonstrated energy consumption reductions of 40-60% compared to conventional thermal curing methods. These approaches not only minimize carbon footprints but also reduce operational costs, creating economic incentives for sustainability adoption.

Closed-loop manufacturing systems for antibacterial coating applications have emerged as another sustainable innovation, with water recycling capabilities that can recover up to 85% of process water. Similarly, solvent recovery systems can recapture and reuse up to 90% of organic solvents, substantially reducing both waste generation and raw material consumption.

Regulatory frameworks increasingly emphasize environmental considerations, with the European Medicines Agency and FDA both developing guidelines specifically addressing the environmental impact of pharmaceutical manufacturing processes, including coating technologies. Companies demonstrating superior environmental performance in their coating operations may gain competitive advantages through regulatory compliance and enhanced corporate sustainability profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!