Antibacterial Coatings for Consumer Electronics: Challenges and Solutions

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Background and Objectives

Antibacterial coatings for consumer electronics have emerged as a critical technological development in response to growing health concerns and the ubiquitous nature of personal electronic devices in daily life. The evolution of this technology can be traced back to early antimicrobial applications in healthcare settings, which have gradually expanded into consumer products over the past two decades. Research indicates that smartphones and other frequently handled electronic devices can harbor up to 10 times more bacteria than toilet seats, highlighting the urgent need for effective antibacterial solutions.

The technological trajectory has evolved from simple silver ion-based coatings to more sophisticated multi-functional surfaces that combine antibacterial properties with other desirable characteristics such as scratch resistance, oleophobic qualities, and transparency. This progression reflects the increasing consumer demand for devices that not only perform well but also contribute to personal hygiene and health protection, particularly in the post-COVID era where sanitation awareness has heightened significantly.

Current antibacterial coating technologies primarily utilize mechanisms such as contact killing (where bacteria are destroyed upon contact with the surface), anti-adhesion (preventing bacterial attachment), and release-based strategies (slow release of antimicrobial agents). Each approach presents distinct advantages and limitations in terms of longevity, effectiveness, and compatibility with electronic device materials and usage patterns.

The primary objective of antibacterial coating technology development is to create solutions that effectively reduce bacterial load on device surfaces by at least 99.9% (3-log reduction) while maintaining long-term efficacy throughout the product lifecycle. Additionally, these coatings must be non-toxic to users, environmentally sustainable, and compatible with existing manufacturing processes to ensure commercial viability.

Technical challenges include developing coatings that can withstand frequent handling, exposure to various environmental conditions, and cleaning agents without degradation of antibacterial properties. Furthermore, these coatings must not interfere with device functionality, such as touch sensitivity or display clarity, which presents significant material science and engineering hurdles.

Looking forward, the field is moving toward smart antibacterial coatings that can respond to environmental triggers or bacterial presence, as well as solutions that incorporate nanotechnology to enhance efficacy while minimizing material usage. The integration of antibacterial properties directly into device materials, rather than as surface treatments, represents another promising frontier that could revolutionize how we approach hygiene in consumer electronics.

The ultimate goal is to establish antibacterial functionality as a standard feature in consumer electronics, similar to how water resistance has evolved from a premium feature to an expected specification in modern devices, thereby creating healthier interactions between users and their increasingly indispensable electronic companions.

The technological trajectory has evolved from simple silver ion-based coatings to more sophisticated multi-functional surfaces that combine antibacterial properties with other desirable characteristics such as scratch resistance, oleophobic qualities, and transparency. This progression reflects the increasing consumer demand for devices that not only perform well but also contribute to personal hygiene and health protection, particularly in the post-COVID era where sanitation awareness has heightened significantly.

Current antibacterial coating technologies primarily utilize mechanisms such as contact killing (where bacteria are destroyed upon contact with the surface), anti-adhesion (preventing bacterial attachment), and release-based strategies (slow release of antimicrobial agents). Each approach presents distinct advantages and limitations in terms of longevity, effectiveness, and compatibility with electronic device materials and usage patterns.

The primary objective of antibacterial coating technology development is to create solutions that effectively reduce bacterial load on device surfaces by at least 99.9% (3-log reduction) while maintaining long-term efficacy throughout the product lifecycle. Additionally, these coatings must be non-toxic to users, environmentally sustainable, and compatible with existing manufacturing processes to ensure commercial viability.

Technical challenges include developing coatings that can withstand frequent handling, exposure to various environmental conditions, and cleaning agents without degradation of antibacterial properties. Furthermore, these coatings must not interfere with device functionality, such as touch sensitivity or display clarity, which presents significant material science and engineering hurdles.

Looking forward, the field is moving toward smart antibacterial coatings that can respond to environmental triggers or bacterial presence, as well as solutions that incorporate nanotechnology to enhance efficacy while minimizing material usage. The integration of antibacterial properties directly into device materials, rather than as surface treatments, represents another promising frontier that could revolutionize how we approach hygiene in consumer electronics.

The ultimate goal is to establish antibacterial functionality as a standard feature in consumer electronics, similar to how water resistance has evolved from a premium feature to an expected specification in modern devices, thereby creating healthier interactions between users and their increasingly indispensable electronic companions.

Market Demand Analysis for Antibacterial Electronics

The global market for antibacterial coatings in consumer electronics has witnessed significant growth in recent years, driven primarily by increasing health consciousness among consumers and the COVID-19 pandemic's lasting impact on hygiene awareness. Market research indicates that the antibacterial coatings sector for electronics is projected to grow at a compound annual growth rate of 12.3% from 2023 to 2028, reaching a market value of approximately $4.7 billion by the end of this period.

Consumer electronics represent high-touch surfaces that can harbor bacteria for extended periods. Studies have shown that smartphones typically carry ten times more bacteria than most toilet seats, with the average device hosting over 25,000 bacteria per square inch. This reality has created substantial market demand for protective solutions, particularly in high-use environments such as healthcare facilities, educational institutions, and public spaces.

The demand segmentation reveals interesting patterns across different consumer electronics categories. Smartphones and tablets represent the largest market segment at 42% of the total demand, followed by laptops and keyboards at 28%, touchscreen kiosks at 17%, and other consumer electronics at 13%. Geographically, North America and Europe currently lead the market adoption, though Asia-Pacific regions are showing the fastest growth rates, particularly in Japan, South Korea, and China.

Consumer willingness to pay premium prices for antibacterial features has increased substantially. Recent surveys indicate that 67% of consumers would pay 15-20% more for electronics with proven antibacterial properties, representing a significant shift from pre-pandemic figures of only 24%. This price elasticity varies by product category and region but demonstrates a clear market opportunity for manufacturers.

The business-to-business (B2B) sector presents another substantial market opportunity. Corporate procurement departments increasingly include antibacterial properties in their requirements specifications, particularly for shared devices and equipment. Healthcare institutions represent the largest B2B customer segment, followed by educational institutions and hospitality businesses.

Market analysis reveals several unmet needs that present opportunities for innovation. These include the development of longer-lasting antibacterial solutions that maintain efficacy beyond the current 6-12 month standard, coatings that can withstand frequent cleaning with harsh disinfectants, and solutions that combine antibacterial properties with other functional benefits such as scratch resistance or anti-glare capabilities.

Consumer awareness and education remain critical market factors. While demand is growing, approximately 38% of potential customers still report limited understanding of how antibacterial coatings work and their effectiveness against different pathogens. This knowledge gap represents both a challenge and an opportunity for companies to differentiate through educational marketing and transparent efficacy reporting.

Consumer electronics represent high-touch surfaces that can harbor bacteria for extended periods. Studies have shown that smartphones typically carry ten times more bacteria than most toilet seats, with the average device hosting over 25,000 bacteria per square inch. This reality has created substantial market demand for protective solutions, particularly in high-use environments such as healthcare facilities, educational institutions, and public spaces.

The demand segmentation reveals interesting patterns across different consumer electronics categories. Smartphones and tablets represent the largest market segment at 42% of the total demand, followed by laptops and keyboards at 28%, touchscreen kiosks at 17%, and other consumer electronics at 13%. Geographically, North America and Europe currently lead the market adoption, though Asia-Pacific regions are showing the fastest growth rates, particularly in Japan, South Korea, and China.

Consumer willingness to pay premium prices for antibacterial features has increased substantially. Recent surveys indicate that 67% of consumers would pay 15-20% more for electronics with proven antibacterial properties, representing a significant shift from pre-pandemic figures of only 24%. This price elasticity varies by product category and region but demonstrates a clear market opportunity for manufacturers.

The business-to-business (B2B) sector presents another substantial market opportunity. Corporate procurement departments increasingly include antibacterial properties in their requirements specifications, particularly for shared devices and equipment. Healthcare institutions represent the largest B2B customer segment, followed by educational institutions and hospitality businesses.

Market analysis reveals several unmet needs that present opportunities for innovation. These include the development of longer-lasting antibacterial solutions that maintain efficacy beyond the current 6-12 month standard, coatings that can withstand frequent cleaning with harsh disinfectants, and solutions that combine antibacterial properties with other functional benefits such as scratch resistance or anti-glare capabilities.

Consumer awareness and education remain critical market factors. While demand is growing, approximately 38% of potential customers still report limited understanding of how antibacterial coatings work and their effectiveness against different pathogens. This knowledge gap represents both a challenge and an opportunity for companies to differentiate through educational marketing and transparent efficacy reporting.

Current State and Challenges in Antibacterial Coating Technology

Antibacterial coating technology for consumer electronics has evolved significantly over the past decade, with various approaches being developed to address the growing concern of bacterial contamination on frequently touched devices. Currently, several major technologies dominate the market, including silver ion-based coatings, copper-based solutions, titanium dioxide photocatalytic coatings, and quaternary ammonium compound (QAC) treatments. Each of these technologies offers distinct advantages while facing specific limitations in practical applications.

Silver-based coatings remain the most widely adopted solution due to their broad-spectrum antimicrobial efficacy and relatively long-lasting performance. However, these coatings face challenges related to cost, potential environmental concerns, and gradual efficacy reduction over time. Recent advancements have focused on silver nanoparticle integration into polymer matrices to enhance durability while reducing material costs.

Copper and copper oxide coatings have gained traction as alternatives, demonstrating excellent antibacterial properties with potentially lower environmental impact. The primary challenges include ensuring uniform application, preventing oxidation that can affect device aesthetics, and maintaining effectiveness throughout the product lifecycle.

Photocatalytic coatings based on titanium dioxide represent an innovative approach that activates under light exposure. While promising for their self-cleaning properties, these coatings struggle with consistent performance in low-light conditions and may require specific light wavelengths to function optimally, limiting their practical application in many consumer electronics scenarios.

A significant technical challenge across all coating technologies is achieving the delicate balance between antibacterial efficacy and user safety. Many highly effective antibacterial compounds pose potential toxicity concerns with prolonged skin contact, necessitating careful formulation and extensive safety testing before commercial deployment.

Durability presents another major hurdle, as consumer electronics endure frequent handling, cleaning with various solutions, and exposure to diverse environmental conditions. Current coatings often demonstrate diminished effectiveness after repeated cleaning cycles or extended use periods, typically showing significant degradation within 6-12 months of regular use.

Manufacturing integration poses additional complications, as coating processes must be compatible with existing production lines without compromising device functionality or aesthetic qualities. Temperature-sensitive components in modern electronics limit the application methods and curing processes available for antibacterial treatments.

Regulatory compliance varies significantly across global markets, creating a complex landscape for manufacturers seeking international distribution. While some regions have established clear guidelines for antibacterial claims on consumer products, others maintain stringent requirements for safety documentation and efficacy testing that can delay market entry and increase development costs.

Recent research has begun exploring biomimetic approaches and smart-release systems that activate in response to environmental triggers, potentially addressing many current limitations. However, these technologies remain largely in laboratory development stages, with significant work needed before commercial viability can be achieved.

Silver-based coatings remain the most widely adopted solution due to their broad-spectrum antimicrobial efficacy and relatively long-lasting performance. However, these coatings face challenges related to cost, potential environmental concerns, and gradual efficacy reduction over time. Recent advancements have focused on silver nanoparticle integration into polymer matrices to enhance durability while reducing material costs.

Copper and copper oxide coatings have gained traction as alternatives, demonstrating excellent antibacterial properties with potentially lower environmental impact. The primary challenges include ensuring uniform application, preventing oxidation that can affect device aesthetics, and maintaining effectiveness throughout the product lifecycle.

Photocatalytic coatings based on titanium dioxide represent an innovative approach that activates under light exposure. While promising for their self-cleaning properties, these coatings struggle with consistent performance in low-light conditions and may require specific light wavelengths to function optimally, limiting their practical application in many consumer electronics scenarios.

A significant technical challenge across all coating technologies is achieving the delicate balance between antibacterial efficacy and user safety. Many highly effective antibacterial compounds pose potential toxicity concerns with prolonged skin contact, necessitating careful formulation and extensive safety testing before commercial deployment.

Durability presents another major hurdle, as consumer electronics endure frequent handling, cleaning with various solutions, and exposure to diverse environmental conditions. Current coatings often demonstrate diminished effectiveness after repeated cleaning cycles or extended use periods, typically showing significant degradation within 6-12 months of regular use.

Manufacturing integration poses additional complications, as coating processes must be compatible with existing production lines without compromising device functionality or aesthetic qualities. Temperature-sensitive components in modern electronics limit the application methods and curing processes available for antibacterial treatments.

Regulatory compliance varies significantly across global markets, creating a complex landscape for manufacturers seeking international distribution. While some regions have established clear guidelines for antibacterial claims on consumer products, others maintain stringent requirements for safety documentation and efficacy testing that can delay market entry and increase development costs.

Recent research has begun exploring biomimetic approaches and smart-release systems that activate in response to environmental triggers, potentially addressing many current limitations. However, these technologies remain largely in laboratory development stages, with significant work needed before commercial viability can be achieved.

Current Antibacterial Coating Solutions for Electronics

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into coatings as nanoparticles, ions, or compounds that slowly release active metal ions to inhibit bacterial growth. The mechanism typically involves disruption of bacterial cell membranes, interference with enzyme functions, or generation of reactive oxygen species. These coatings are particularly effective for medical devices, food processing equipment, and high-touch surfaces in healthcare settings.- Metal-based antibacterial coatings: Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into various coating matrices as nanoparticles, ions, or compounds. The mechanism of action typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings provide long-lasting protection against a broad spectrum of bacteria and are commonly used in medical devices, food packaging, and high-touch surfaces.

- Polymer-based antibacterial coatings: Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices to create surfaces resistant to bacterial colonization. These polymers can be designed to slowly release active ingredients or to have inherent antibacterial properties through positively charged functional groups that disrupt bacterial cell membranes. Common polymers used include quaternary ammonium compounds, chitosan derivatives, and polyethylene glycol. These coatings provide durable protection and can be applied to various substrates including textiles, plastics, and metals.

- Natural compound-based antibacterial coatings: Natural compound-based antibacterial coatings utilize plant extracts, essential oils, and other naturally derived substances with antimicrobial properties. These compounds include polyphenols, terpenes, alkaloids, and peptides that can inhibit bacterial growth through various mechanisms. The advantage of these coatings is their reduced environmental impact, biocompatibility, and lower risk of developing bacterial resistance. Applications include food packaging, medical textiles, and eco-friendly consumer products.

- Photocatalytic antibacterial coatings: Photocatalytic antibacterial coatings contain materials such as titanium dioxide, zinc oxide, or other semiconductor materials that generate reactive oxygen species when exposed to light. These reactive species can effectively kill bacteria by oxidizing their cell components. The coatings provide continuous antibacterial action as long as they are exposed to appropriate light wavelengths. They are self-cleaning and particularly useful for outdoor applications, hospital environments, and public spaces where light exposure is consistent.

- Smart responsive antibacterial coatings: Smart responsive antibacterial coatings are designed to activate their antimicrobial properties in response to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These coatings can remain dormant until needed, which helps to extend their effective lifespan and reduce the development of bacterial resistance. Applications include wound dressings that release antimicrobial agents only when infection is present, surfaces that respond to biofilm formation, and coatings that activate in response to specific bacterial species.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices that can provide controlled release of active ingredients. These polymers can be natural (chitosan, alginate) or synthetic (polyurethane, epoxy) and may be functionalized with quaternary ammonium compounds, antimicrobial peptides, or other biocides. The polymer matrix provides durability while controlling the release rate of antimicrobial agents, offering long-term protection against bacterial colonization on various surfaces including medical implants, textiles, and industrial equipment.Expand Specific Solutions03 Nanostructured antibacterial coatings

Nanostructured antibacterial coatings utilize nanomaterials and nanotechnology to create surfaces with enhanced antimicrobial properties. These coatings may incorporate carbon nanotubes, graphene, metal oxide nanoparticles, or nanocomposites that provide antibacterial effects through multiple mechanisms including physical disruption of bacterial cells, photocatalytic activity, and controlled release of antimicrobial agents. The nanoscale features can also create superhydrophobic surfaces that prevent bacterial adhesion. These advanced coatings offer high efficacy with minimal material usage for applications in healthcare, food packaging, and water treatment systems.Expand Specific Solutions04 Natural and bio-based antibacterial coatings

Natural and bio-based antibacterial coatings utilize compounds derived from plants, animals, or microorganisms as alternatives to synthetic antimicrobials. These include essential oils, plant extracts, enzymes, antimicrobial peptides, and chitosan. Such coatings offer advantages of biodegradability, sustainability, and reduced environmental impact. They are particularly valuable in food packaging, textiles, and consumer products where environmental concerns and consumer preferences favor natural ingredients. These coatings can provide effective protection against a broad spectrum of bacteria while addressing concerns about chemical residues and antimicrobial resistance.Expand Specific Solutions05 Smart and stimuli-responsive antibacterial coatings

Smart and stimuli-responsive antibacterial coatings activate or enhance their antimicrobial properties in response to specific environmental triggers such as pH changes, temperature fluctuations, light exposure, or bacterial presence. These advanced coatings may incorporate photocatalytic materials that generate reactive oxygen species under light exposure, pH-sensitive polymers that release antimicrobial agents in response to bacterial metabolism, or temperature-responsive systems that adjust their properties based on environmental conditions. This targeted approach allows for on-demand antimicrobial activity, extending coating lifetime and reducing unnecessary release of antimicrobial agents when not needed.Expand Specific Solutions

Key Industry Players in Antibacterial Coating Sector

The antibacterial coatings market for consumer electronics is in a growth phase, driven by increasing hygiene awareness and technological advancements. The market is expanding rapidly with an estimated value exceeding $1 billion globally. From a technological maturity perspective, the landscape shows varying degrees of development. Industry leaders like Samsung Electronics and IBM are investing heavily in advanced antimicrobial solutions, while specialized coating manufacturers such as Microban Products Co. and Jiangsu Biosurf Biotech are developing proprietary technologies. Research institutions including Beihang University and California Institute of Technology are contributing breakthrough innovations. The competitive environment features both established chemical companies like BASF Coatings and Nippon Shokubai alongside emerging players focused specifically on antimicrobial applications, creating a dynamic ecosystem of innovation.

Microban Products Co.

Technical Solution: Microban has developed a comprehensive antimicrobial technology portfolio specifically designed for consumer electronics. Their approach integrates silver ion technology directly into device materials during manufacturing, creating inherent antibacterial properties that last for the product's lifetime. The technology works by disrupting bacterial cell walls and interfering with cellular metabolism when microbes contact the treated surface. Microban's solutions are engineered to withstand frequent handling and cleaning routines typical of consumer electronics without degradation of antimicrobial efficacy. Their zinc-based technologies provide broad-spectrum protection against bacteria while maintaining material integrity and appearance. Microban has also developed specialized coatings that can be applied post-manufacturing, featuring nano-silver particles dispersed in polymer matrices that create durable, transparent protective layers with minimal impact on device aesthetics or functionality.

Strengths: Industry-leading expertise in antimicrobial technologies with proven efficacy across multiple material types; formulations specifically optimized for electronics applications; regulatory compliance across global markets. Weaknesses: Higher implementation cost compared to standard materials; potential for technology to become less effective over extended product lifecycles; limited efficacy against certain viral pathogens.

BASF Coatings GmbH

Technical Solution: BASF has developed advanced antibacterial coating solutions for consumer electronics through their proprietary "HyGentic" technology platform. This system utilizes a combination of silver ion technology and quaternary ammonium compounds (QACs) embedded in specialized polymer matrices that can be applied to various electronic device surfaces. The dual-action mechanism provides both immediate contact killing of bacteria and long-term protection through controlled ion release. BASF's innovation includes the development of transparent, ultra-thin coatings (less than 5 microns) that maintain device aesthetics while providing antibacterial protection. Their formulations incorporate hydrophobic properties that reduce bacterial adhesion and biofilm formation, addressing a key challenge in maintaining long-term efficacy. BASF has also pioneered self-healing polymer technologies that can repair minor surface damage, extending the functional lifespan of the antibacterial properties. These coatings are engineered to withstand over 10,000 abrasion cycles, simulating years of regular device handling and cleaning.

Strengths: Extensive chemical expertise allowing for customized formulations across different substrate materials; global manufacturing capabilities ensuring consistent quality and supply chain reliability; comprehensive regulatory compliance framework. Weaknesses: Application typically requires post-manufacturing processing; potential for coating degradation with certain cleaning chemicals; higher implementation costs compared to standard finishes.

Core Patents and Innovations in Antimicrobial Surfaces

Antibacterial coating composition and method for manufacturing antibacterial product using same

PatentWO2025116087A1

Innovation

- An antibacterial coating composition is developed, comprising an antibacterial agent with silver, a paint containing a viscosity modifier, and an additive, which maintains excellent solubility, prevents discoloration, and ensures high antibacterial efficacy while preserving the physical properties of the product.

Antibacterial medical product and method for producing same

PatentActiveUS20210169071A1

Innovation

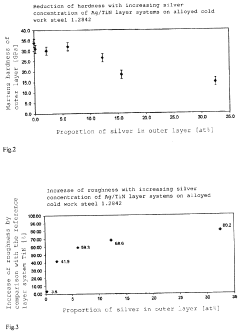

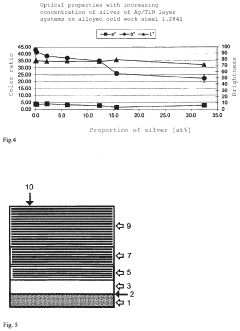

- A biocide-containing antibacterial hard material coating with a specific layer structure, including an inner layer with varying silver concentration and an outer layer with a constant high biocide concentration, applied using PVD or PACVD methods, to enhance adhesiveness and maintain optical properties.

Environmental and Health Impact Assessment

The application of antibacterial coatings on consumer electronics presents significant environmental and health considerations that must be thoroughly evaluated. Traditional antibacterial agents such as silver nanoparticles, triclosan, and quaternary ammonium compounds have demonstrated efficacy against microbial contamination but raise concerns regarding their long-term impact on both human health and ecosystems.

Silver nanoparticles, while highly effective against a broad spectrum of microorganisms, have been shown to leach into aquatic environments during disposal phases, potentially disrupting aquatic ecosystems and accumulating in the food chain. Studies indicate that silver ions can be toxic to beneficial soil microorganisms and may contribute to the development of silver-resistant bacterial strains, creating unforeseen ecological consequences.

Chemical compounds like triclosan present additional concerns, as they have been linked to endocrine disruption in laboratory studies and may contribute to antimicrobial resistance development. The European Union has already implemented restrictions on triclosan in certain consumer products, reflecting growing regulatory awareness of these risks.

Direct human exposure represents another critical dimension of impact assessment. Users maintain constant physical contact with electronic devices, creating potential dermal absorption pathways for antibacterial compounds. Children, who increasingly interact with electronics from an early age, may be particularly vulnerable to cumulative exposure effects, necessitating stringent safety evaluations for coatings intended for devices marketed to younger demographics.

Manufacturing processes for antibacterial coatings often involve volatile organic compounds (VOCs) and other hazardous substances that contribute to air pollution and occupational health risks. Life cycle assessments reveal that certain coating production methods generate substantial carbon footprints, contradicting sustainability objectives that many electronics manufacturers have publicly committed to achieving.

Emerging alternatives such as plant-derived antimicrobial compounds and photocatalytic coatings offer promising environmental profiles. These bio-based solutions typically demonstrate lower ecotoxicity and better biodegradability compared to conventional options. Preliminary studies suggest that essential oil derivatives and chitosan-based formulations provide effective antimicrobial protection while minimizing environmental persistence and bioaccumulation potential.

Regulatory frameworks worldwide are evolving to address these concerns, with the EU's REACH regulations and similar initiatives in other regions increasingly scrutinizing antimicrobial substances. Forward-thinking manufacturers are adopting green chemistry principles in coating development, prioritizing substances that demonstrate minimal environmental persistence, low bioaccumulation potential, and reduced toxicity profiles while maintaining effective antimicrobial performance.

Silver nanoparticles, while highly effective against a broad spectrum of microorganisms, have been shown to leach into aquatic environments during disposal phases, potentially disrupting aquatic ecosystems and accumulating in the food chain. Studies indicate that silver ions can be toxic to beneficial soil microorganisms and may contribute to the development of silver-resistant bacterial strains, creating unforeseen ecological consequences.

Chemical compounds like triclosan present additional concerns, as they have been linked to endocrine disruption in laboratory studies and may contribute to antimicrobial resistance development. The European Union has already implemented restrictions on triclosan in certain consumer products, reflecting growing regulatory awareness of these risks.

Direct human exposure represents another critical dimension of impact assessment. Users maintain constant physical contact with electronic devices, creating potential dermal absorption pathways for antibacterial compounds. Children, who increasingly interact with electronics from an early age, may be particularly vulnerable to cumulative exposure effects, necessitating stringent safety evaluations for coatings intended for devices marketed to younger demographics.

Manufacturing processes for antibacterial coatings often involve volatile organic compounds (VOCs) and other hazardous substances that contribute to air pollution and occupational health risks. Life cycle assessments reveal that certain coating production methods generate substantial carbon footprints, contradicting sustainability objectives that many electronics manufacturers have publicly committed to achieving.

Emerging alternatives such as plant-derived antimicrobial compounds and photocatalytic coatings offer promising environmental profiles. These bio-based solutions typically demonstrate lower ecotoxicity and better biodegradability compared to conventional options. Preliminary studies suggest that essential oil derivatives and chitosan-based formulations provide effective antimicrobial protection while minimizing environmental persistence and bioaccumulation potential.

Regulatory frameworks worldwide are evolving to address these concerns, with the EU's REACH regulations and similar initiatives in other regions increasingly scrutinizing antimicrobial substances. Forward-thinking manufacturers are adopting green chemistry principles in coating development, prioritizing substances that demonstrate minimal environmental persistence, low bioaccumulation potential, and reduced toxicity profiles while maintaining effective antimicrobial performance.

Durability and Longevity Testing Methodologies

Testing the durability and longevity of antibacterial coatings for consumer electronics requires comprehensive methodologies that simulate real-world usage conditions. The primary challenge lies in developing accelerated testing protocols that can reliably predict coating performance over extended periods without waiting for natural degradation processes to occur.

Standard abrasion testing represents a fundamental methodology, typically employing linear or rotational abrasion machines with standardized materials like cotton, wool, or synthetic fabrics to simulate daily handling. These tests often follow established protocols such as ASTM D4060 or ISO 11998, with measurements taken at predetermined intervals to track performance degradation.

Chemical resistance testing evaluates coating integrity when exposed to common substances encountered in daily use. This includes acidic and alkaline solutions, oils from human skin, cosmetics, and household cleaning agents. Samples undergo controlled exposure followed by antibacterial efficacy assessment to determine if chemical interactions compromise the coating's functional properties.

Environmental stress testing subjects coated devices to varying temperature and humidity conditions, typically cycling between extremes (e.g., -20°C to 60°C) while maintaining high humidity levels (80-95%). UV exposure testing using specialized chambers simulates years of light exposure in compressed timeframes, critical for determining photostability of antibacterial compounds.

Sweat resistance testing employs artificial perspiration solutions based on international standards like ISO 3160-2, with samples immersed or repeatedly exposed to these solutions while monitoring for coating degradation or leaching of active ingredients.

Advanced methodologies include atomic force microscopy (AFM) and scanning electron microscopy (SEM) to visualize nanoscale changes in coating morphology after stress testing. These techniques provide valuable insights into failure mechanisms that might not be apparent through macroscopic observation alone.

Correlation studies between accelerated aging and real-world performance represent perhaps the most challenging aspect of durability testing. Leading manufacturers maintain reference devices in controlled environments for years, periodically testing them against accelerated-aged counterparts to establish reliable conversion factors between laboratory and real-world performance.

Standardization efforts by organizations like ISO and ASTM continue to evolve, with recent focus on developing testing protocols specifically for antimicrobial surfaces in high-touch consumer products, addressing the unique challenges of maintaining both antibacterial efficacy and physical integrity over the product lifecycle.

Standard abrasion testing represents a fundamental methodology, typically employing linear or rotational abrasion machines with standardized materials like cotton, wool, or synthetic fabrics to simulate daily handling. These tests often follow established protocols such as ASTM D4060 or ISO 11998, with measurements taken at predetermined intervals to track performance degradation.

Chemical resistance testing evaluates coating integrity when exposed to common substances encountered in daily use. This includes acidic and alkaline solutions, oils from human skin, cosmetics, and household cleaning agents. Samples undergo controlled exposure followed by antibacterial efficacy assessment to determine if chemical interactions compromise the coating's functional properties.

Environmental stress testing subjects coated devices to varying temperature and humidity conditions, typically cycling between extremes (e.g., -20°C to 60°C) while maintaining high humidity levels (80-95%). UV exposure testing using specialized chambers simulates years of light exposure in compressed timeframes, critical for determining photostability of antibacterial compounds.

Sweat resistance testing employs artificial perspiration solutions based on international standards like ISO 3160-2, with samples immersed or repeatedly exposed to these solutions while monitoring for coating degradation or leaching of active ingredients.

Advanced methodologies include atomic force microscopy (AFM) and scanning electron microscopy (SEM) to visualize nanoscale changes in coating morphology after stress testing. These techniques provide valuable insights into failure mechanisms that might not be apparent through macroscopic observation alone.

Correlation studies between accelerated aging and real-world performance represent perhaps the most challenging aspect of durability testing. Leading manufacturers maintain reference devices in controlled environments for years, periodically testing them against accelerated-aged counterparts to establish reliable conversion factors between laboratory and real-world performance.

Standardization efforts by organizations like ISO and ASTM continue to evolve, with recent focus on developing testing protocols specifically for antimicrobial surfaces in high-touch consumer products, addressing the unique challenges of maintaining both antibacterial efficacy and physical integrity over the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!