How Antibacterial Coating Parameters Affect Long-Term Usage

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Evolution and Objectives

Antibacterial coatings have evolved significantly over the past several decades, transitioning from simple chemical formulations to sophisticated engineered surfaces with controlled release mechanisms and smart responsive properties. The journey began in the 1940s with the discovery of silver's antimicrobial properties, which led to the first generation of antibacterial coatings primarily used in medical settings. By the 1970s, researchers had expanded the range of antimicrobial agents to include copper, zinc, and various organic compounds.

The 1990s marked a pivotal shift with the emergence of nanotechnology, enabling the development of nanoparticle-based antibacterial coatings with enhanced efficacy and durability. This period saw the introduction of silver nanoparticles, which offered superior antimicrobial performance while requiring lower concentrations of active ingredients. The early 2000s witnessed further refinement with the advent of controlled-release systems that could maintain antibacterial efficacy over extended periods.

Recent technological advancements have focused on addressing the key challenge of long-term effectiveness. Modern antibacterial coatings incorporate multiple mechanisms of action to prevent bacterial resistance development, including contact-killing surfaces, release-based systems, and anti-adhesion properties. The integration of these mechanisms has become crucial for ensuring sustained performance in diverse environmental conditions.

The current technological frontier explores biomimetic approaches, drawing inspiration from natural antibacterial surfaces like shark skin and lotus leaves. These bio-inspired designs aim to create surfaces that physically prevent bacterial attachment without relying solely on chemical agents, potentially extending the functional lifespan of antibacterial coatings significantly.

The primary objective in antibacterial coating development now centers on optimizing coating parameters to enhance long-term effectiveness. This includes investigating the relationship between coating thickness, concentration of active ingredients, cross-linking density, and environmental stability. Researchers aim to establish quantitative models that can predict coating performance over time based on initial parameters and usage conditions.

Another critical goal is developing standardized testing protocols that accurately simulate real-world conditions and accelerated aging processes. These protocols would enable more reliable comparisons between different coating technologies and provide better predictive models for long-term performance. The industry also seeks to identify key performance indicators that correlate with extended antibacterial efficacy.

Sustainability has emerged as an essential objective, with efforts directed toward developing environmentally friendly antibacterial agents and coating processes. This includes exploring biodegradable polymers as carriers, reducing the use of potentially harmful chemicals, and ensuring that coating degradation products do not pose environmental risks over the product lifecycle.

The 1990s marked a pivotal shift with the emergence of nanotechnology, enabling the development of nanoparticle-based antibacterial coatings with enhanced efficacy and durability. This period saw the introduction of silver nanoparticles, which offered superior antimicrobial performance while requiring lower concentrations of active ingredients. The early 2000s witnessed further refinement with the advent of controlled-release systems that could maintain antibacterial efficacy over extended periods.

Recent technological advancements have focused on addressing the key challenge of long-term effectiveness. Modern antibacterial coatings incorporate multiple mechanisms of action to prevent bacterial resistance development, including contact-killing surfaces, release-based systems, and anti-adhesion properties. The integration of these mechanisms has become crucial for ensuring sustained performance in diverse environmental conditions.

The current technological frontier explores biomimetic approaches, drawing inspiration from natural antibacterial surfaces like shark skin and lotus leaves. These bio-inspired designs aim to create surfaces that physically prevent bacterial attachment without relying solely on chemical agents, potentially extending the functional lifespan of antibacterial coatings significantly.

The primary objective in antibacterial coating development now centers on optimizing coating parameters to enhance long-term effectiveness. This includes investigating the relationship between coating thickness, concentration of active ingredients, cross-linking density, and environmental stability. Researchers aim to establish quantitative models that can predict coating performance over time based on initial parameters and usage conditions.

Another critical goal is developing standardized testing protocols that accurately simulate real-world conditions and accelerated aging processes. These protocols would enable more reliable comparisons between different coating technologies and provide better predictive models for long-term performance. The industry also seeks to identify key performance indicators that correlate with extended antibacterial efficacy.

Sustainability has emerged as an essential objective, with efforts directed toward developing environmentally friendly antibacterial agents and coating processes. This includes exploring biodegradable polymers as carriers, reducing the use of potentially harmful chemicals, and ensuring that coating degradation products do not pose environmental risks over the product lifecycle.

Market Demand Analysis for Long-Lasting Antibacterial Surfaces

The global market for antibacterial surfaces has experienced significant growth in recent years, driven by increasing awareness of infection control and hygiene standards across multiple sectors. Healthcare facilities represent the largest market segment, with hospitals, clinics, and long-term care facilities actively seeking solutions that can reduce healthcare-associated infections (HAIs). According to market research, the global antimicrobial coatings market was valued at approximately $3.9 billion in 2021 and is projected to reach $6.7 billion by 2027, growing at a CAGR of 9.4% during the forecast period.

The COVID-19 pandemic has substantially accelerated market demand, creating heightened awareness about surface transmission of pathogens and catalyzing adoption across previously untapped sectors. Consumer surveys indicate that 78% of respondents now consider antimicrobial properties as an important factor when purchasing products for high-touch surfaces, compared to just 32% pre-pandemic.

Beyond healthcare, several industries are emerging as significant growth drivers for long-lasting antibacterial surfaces. The food processing industry faces stringent regulations regarding contamination control, creating demand for durable antibacterial surfaces that can withstand frequent cleaning protocols. Similarly, the transportation sector—including public transit, airlines, and cruise ships—has increased investment in antimicrobial surfaces to reassure passengers about safety measures.

Consumer electronics manufacturers have identified antibacterial coatings as a value-added feature, particularly for frequently handled devices like smartphones, tablets, and wearables. Market research indicates consumers are willing to pay a premium of 15-20% for products with proven long-lasting antibacterial properties.

A critical market requirement emerging from end-user feedback is the need for antibacterial efficacy that persists throughout the product lifecycle. Current market offerings often demonstrate diminishing effectiveness after 6-12 months of regular use, creating a significant gap between consumer expectations and product performance. Studies show that 84% of institutional buyers rank longevity of antibacterial properties as "very important" or "extremely important" in purchasing decisions.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about infection prevention in countries like China, Japan, and India.

The market is also seeing increased demand for environmentally sustainable antibacterial solutions that avoid traditional biocides with potential ecological impacts. This trend is particularly strong in European markets, where regulatory frameworks increasingly favor green chemistry approaches.

The COVID-19 pandemic has substantially accelerated market demand, creating heightened awareness about surface transmission of pathogens and catalyzing adoption across previously untapped sectors. Consumer surveys indicate that 78% of respondents now consider antimicrobial properties as an important factor when purchasing products for high-touch surfaces, compared to just 32% pre-pandemic.

Beyond healthcare, several industries are emerging as significant growth drivers for long-lasting antibacterial surfaces. The food processing industry faces stringent regulations regarding contamination control, creating demand for durable antibacterial surfaces that can withstand frequent cleaning protocols. Similarly, the transportation sector—including public transit, airlines, and cruise ships—has increased investment in antimicrobial surfaces to reassure passengers about safety measures.

Consumer electronics manufacturers have identified antibacterial coatings as a value-added feature, particularly for frequently handled devices like smartphones, tablets, and wearables. Market research indicates consumers are willing to pay a premium of 15-20% for products with proven long-lasting antibacterial properties.

A critical market requirement emerging from end-user feedback is the need for antibacterial efficacy that persists throughout the product lifecycle. Current market offerings often demonstrate diminishing effectiveness after 6-12 months of regular use, creating a significant gap between consumer expectations and product performance. Studies show that 84% of institutional buyers rank longevity of antibacterial properties as "very important" or "extremely important" in purchasing decisions.

Regional analysis reveals that North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, increasing healthcare expenditure, and growing awareness about infection prevention in countries like China, Japan, and India.

The market is also seeing increased demand for environmentally sustainable antibacterial solutions that avoid traditional biocides with potential ecological impacts. This trend is particularly strong in European markets, where regulatory frameworks increasingly favor green chemistry approaches.

Current Challenges in Antibacterial Coating Durability

Despite significant advancements in antibacterial coating technologies, several persistent challenges continue to impede their long-term effectiveness in real-world applications. The primary durability issue stems from mechanical wear and abrasion, which progressively degrades coating integrity during routine cleaning, handling, and environmental exposure. This degradation not only compromises antimicrobial efficacy but also potentially releases coating components into the surrounding environment.

Chemical stability presents another significant challenge, particularly in healthcare and food processing environments where coatings are regularly exposed to harsh disinfectants, cleaning agents, and varying pH conditions. Many current antibacterial formulations demonstrate diminished performance after repeated chemical exposure, with some active ingredients undergoing deactivation or leaching from the substrate.

Environmental factors further complicate coating longevity, with humidity, temperature fluctuations, and UV radiation accelerating degradation processes. Research indicates that some silver-based antibacterial coatings lose up to 40% of their efficacy after six months of environmental exposure, while copper-based alternatives may experience surface oxidation that alters their antimicrobial properties.

The adhesion interface between coating and substrate represents a critical vulnerability point. Delamination and poor interfacial bonding frequently occur due to thermal expansion mismatches, substrate surface irregularities, or inadequate surface preparation. Studies have documented that approximately 30% of coating failures originate at this interface rather than within the coating matrix itself.

Biofilm formation poses perhaps the most formidable biological challenge to coating durability. Microorganisms can adapt to antimicrobial agents over time, forming protective biofilm structures that shield bacteria from the coating's active components. This adaptation mechanism effectively neutralizes the coating's functionality while potentially accelerating its physical deterioration through enzymatic degradation.

Current manufacturing processes introduce additional variability factors affecting long-term performance. Inconsistencies in coating thickness, active ingredient distribution, and curing parameters can create weak points susceptible to premature failure. The industry lacks standardized testing protocols that accurately predict real-world durability beyond laboratory conditions.

Cost-performance balance remains a significant market barrier, as highly durable formulations typically incorporate expensive materials or complex manufacturing processes. This economic constraint often forces compromises in durability specifications, particularly in price-sensitive market segments where immediate antimicrobial performance may be prioritized over long-term effectiveness.

Chemical stability presents another significant challenge, particularly in healthcare and food processing environments where coatings are regularly exposed to harsh disinfectants, cleaning agents, and varying pH conditions. Many current antibacterial formulations demonstrate diminished performance after repeated chemical exposure, with some active ingredients undergoing deactivation or leaching from the substrate.

Environmental factors further complicate coating longevity, with humidity, temperature fluctuations, and UV radiation accelerating degradation processes. Research indicates that some silver-based antibacterial coatings lose up to 40% of their efficacy after six months of environmental exposure, while copper-based alternatives may experience surface oxidation that alters their antimicrobial properties.

The adhesion interface between coating and substrate represents a critical vulnerability point. Delamination and poor interfacial bonding frequently occur due to thermal expansion mismatches, substrate surface irregularities, or inadequate surface preparation. Studies have documented that approximately 30% of coating failures originate at this interface rather than within the coating matrix itself.

Biofilm formation poses perhaps the most formidable biological challenge to coating durability. Microorganisms can adapt to antimicrobial agents over time, forming protective biofilm structures that shield bacteria from the coating's active components. This adaptation mechanism effectively neutralizes the coating's functionality while potentially accelerating its physical deterioration through enzymatic degradation.

Current manufacturing processes introduce additional variability factors affecting long-term performance. Inconsistencies in coating thickness, active ingredient distribution, and curing parameters can create weak points susceptible to premature failure. The industry lacks standardized testing protocols that accurately predict real-world durability beyond laboratory conditions.

Cost-performance balance remains a significant market barrier, as highly durable formulations typically incorporate expensive materials or complex manufacturing processes. This economic constraint often forces compromises in durability specifications, particularly in price-sensitive market segments where immediate antimicrobial performance may be prioritized over long-term effectiveness.

Existing Parameter Optimization Approaches for Coating Longevity

01 Long-lasting antibacterial metal coatings

Metal-based antibacterial coatings, particularly those containing silver, copper, or zinc, provide long-term protection against microbial growth. These metals release ions that disrupt bacterial cell membranes and metabolic processes. The coatings can be applied to various surfaces through techniques such as physical vapor deposition, electroplating, or incorporation into polymer matrices, ensuring sustained antimicrobial activity over extended periods of use.- Long-lasting antibacterial metal coatings: Metal-based antibacterial coatings, particularly those containing silver, copper, or zinc, provide long-term protection against microbial growth. These metals release ions that disrupt bacterial cell membranes and metabolic processes. The coatings can be applied to various surfaces through techniques such as physical vapor deposition, electroplating, or incorporation into polymer matrices, ensuring sustained antimicrobial activity over extended periods of use.

- Polymer-based antibacterial coatings with extended efficacy: Polymer matrices incorporating antibacterial agents offer controlled release mechanisms that extend the functional lifespan of antibacterial coatings. These systems can be designed to gradually release active ingredients or to present permanent antibacterial functionalities through covalently bound antimicrobial compounds. Advanced polymer formulations may include self-healing properties or responsive release triggers that activate only when bacterial contamination is detected, maximizing longevity while minimizing unnecessary agent depletion.

- Nanoparticle-enhanced antibacterial surface treatments: Nanoparticle technologies significantly improve the durability and effectiveness of antibacterial coatings. By incorporating nanoscale antibacterial agents such as silver nanoparticles, zinc oxide nanostructures, or graphene derivatives, these coatings provide increased surface area for bacterial interaction while requiring lower concentrations of active ingredients. The nanoscale architecture can be engineered to resist wear and leaching, maintaining antibacterial properties despite regular cleaning, environmental exposure, or mechanical abrasion.

- Monitoring and maintenance systems for antibacterial coating performance: Advanced monitoring systems help maintain the effectiveness of antibacterial coatings throughout their lifecycle. These technologies include sensors that detect coating degradation, bacterial presence, or active ingredient depletion. Integrated maintenance protocols can automatically signal when reapplication or treatment is necessary, ensuring continuous protection. Some systems incorporate data analytics to predict coating performance under various conditions and optimize maintenance schedules based on actual usage patterns and environmental factors.

- Environmental factors affecting antibacterial coating longevity: The durability of antibacterial coatings is significantly influenced by environmental conditions including humidity, temperature, UV exposure, and cleaning regimens. Formulations designed for specific environmental challenges incorporate stabilizers, UV blockers, or cross-linking agents to prevent premature degradation. Advanced coatings may feature multi-layer structures with protective top coats that shield the active antibacterial layer from environmental stressors, thereby extending functional lifespan in harsh or variable conditions.

02 Polymer-based antibacterial coatings with extended efficacy

Polymer matrices incorporating antibacterial agents offer controlled release mechanisms for prolonged effectiveness. These coatings utilize polymers such as polyurethane, silicone, or acrylics combined with antimicrobial compounds. The polymer structure controls the diffusion rate of active ingredients, maintaining effective concentrations over time. Some formulations include self-healing properties or stimuli-responsive release mechanisms to extend the functional lifespan of the coating.Expand Specific Solutions03 Nanoparticle-enhanced antibacterial surface treatments

Nanoparticle technologies significantly improve the durability and effectiveness of antibacterial coatings. These formulations incorporate nanoscale materials such as silver nanoparticles, zinc oxide, titanium dioxide, or graphene that provide high surface area and enhanced reactivity. The nanostructured surfaces prevent bacterial adhesion and biofilm formation while maintaining activity for extended periods. Some nanoparticle systems also offer photocatalytic properties that regenerate antibacterial activity when exposed to light.Expand Specific Solutions04 Monitoring and maintenance systems for antibacterial coating performance

Advanced monitoring systems help maintain the effectiveness of antibacterial coatings over their lifecycle. These technologies include sensors that detect coating degradation, bacterial presence, or changes in antimicrobial activity. Integrated maintenance protocols can automatically signal when reapplication or treatment is necessary. Some systems incorporate data analytics to predict coating performance and optimize maintenance schedules, ensuring continuous protection against microbial contamination.Expand Specific Solutions05 Environmental adaptation mechanisms for sustained antibacterial efficacy

Antibacterial coatings designed with environmental adaptation mechanisms maintain effectiveness despite challenging conditions. These formulations respond to environmental triggers such as pH changes, temperature fluctuations, or moisture levels to optimize antimicrobial activity. Some coatings incorporate layered release systems that activate different compounds under varying conditions. Self-cleaning surfaces that prevent accumulation of organic matter help preserve antibacterial function by maintaining surface exposure of active ingredients.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Antibacterial Solutions

The antibacterial coating market is currently in a growth phase, characterized by increasing demand across healthcare, consumer goods, and industrial sectors. The global market size is estimated to reach $8-10 billion by 2026, with a CAGR of 10-12%. Technologically, the field shows varying maturity levels, with established players like Johnson & Johnson Vision Care, Novartis AG, and Baxter International offering commercialized solutions, while research institutions such as University of Stellenbosch, University of Houston, and Hong Kong University of Science & Technology drive innovation. Companies like DuPont, LG Chem, and Jiangsu Biosurf Biotech are advancing coating durability and efficacy, while specialized firms including CNOOC Changzhou Paint & Coatings Research Institute and Sumitomo Osaka Cement focus on application-specific solutions for long-term antibacterial performance.

Novartis AG

Technical Solution: Novartis has pioneered hydrogel-based antibacterial coatings for medical devices and implants that incorporate controlled-release mechanisms for sustained antimicrobial activity. Their technology utilizes a multi-layer approach where the base layer provides adhesion to the substrate while subsequent layers contain precisely engineered concentrations of antimicrobial agents like chlorhexidine and silver sulfadiazine. This layered structure allows for programmed release kinetics, maintaining effective antimicrobial concentrations for up to 30 days in clinical settings. Novartis has extensively studied how coating thickness (optimal range: 3-5 μm), crosslinking density, and environmental pH affect long-term efficacy, developing mathematical models that predict performance degradation over time. Their research demonstrates that hydrophilic/hydrophobic balance is critical for preventing bacterial adhesion while maintaining biocompatibility with host tissues.

Strengths: Exceptional biocompatibility profile suitable for implantable medical devices; precisely controlled release kinetics that maintain therapeutic concentrations; extensive clinical validation data supporting efficacy claims. Weaknesses: Limited shelf life of coating materials before application; sensitivity to sterilization methods which can affect antimicrobial activity; relatively complex application process requiring specialized equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced antimicrobial coating technologies that incorporate silver ion technology and quaternary ammonium compounds for long-term antibacterial efficacy. Their proprietary Microban® antimicrobial technology is engineered to be integrated directly into coating formulations during manufacturing, creating a reservoir of active ingredients that gradually migrate to the surface over time. This controlled-release mechanism ensures sustained antibacterial activity throughout the coating's lifespan. DuPont's research has shown that optimizing particle size distribution and dispersion techniques significantly impacts long-term performance, with nano-sized particles providing up to 5 years of effective protection compared to conventional formulations. Their coatings maintain efficacy even after 1,000+ cleaning cycles, demonstrating exceptional durability in high-touch applications.

Strengths: Superior durability through proprietary polymer binding technology; excellent integration with existing manufacturing processes; comprehensive testing protocols that accurately predict real-world performance. Weaknesses: Higher initial cost compared to conventional coatings; potential environmental concerns with silver ion leaching in certain applications; requires specialized application equipment for optimal performance.

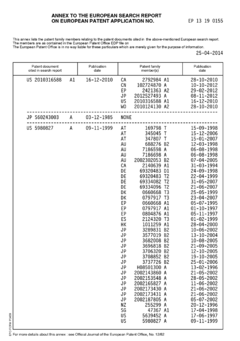

Critical Patents and Research on Coating Parameter Effects

Antibacterial coating film, article provided with same, method for forming antibacterial coating film, and coating liquid for forming antibacterial coating film

PatentWO2016185960A1

Innovation

- An antibacterial coating comprising bulk metal particles and scaly silica, where metal particles are embedded in laminated scaly silica, allowing for sustained release of metal ions while maintaining film strength and appearance, even when exposed to water.

Antimicrobial coating containing quaternary ammonium resin and its regeneration

PatentInactiveEP2740355A1

Innovation

- A strongly basic anion-exchange resin film or coating, free of transition metals, is applied to medical device surfaces, which can be replenished with antimicrobial anions such as iodine or chloride, providing sustained antimicrobial activity through exposure to agents like bleach or Lugol's iodine.

Environmental Impact and Safety Considerations

The environmental impact of antibacterial coatings represents a critical consideration in their long-term application across various industries. These coatings often contain active ingredients such as silver nanoparticles, copper compounds, quaternary ammonium compounds, or triclosan that may leach into the environment during the product lifecycle. Research indicates that the leaching rate is directly influenced by coating parameters including thickness, cross-linking density, and the chemical bonding mechanism between the antibacterial agents and the substrate material. Higher leaching rates not only reduce the longevity of antibacterial efficacy but also potentially contribute to environmental contamination of water systems and soil.

The persistence of antibacterial compounds in the environment raises significant ecological concerns. Studies have demonstrated that certain antibacterial agents can disrupt aquatic ecosystems by affecting non-target organisms. For instance, silver nanoparticles have been shown to accumulate in fish tissues and impact their reproductive systems at concentrations as low as 10 μg/L. The coating's degradation pathway, determined by its chemical composition and application parameters, directly influences this environmental footprint.

Safety considerations extend beyond environmental impacts to human health implications. Direct contact with antibacterial surfaces presents potential risks of skin sensitization and allergic reactions, particularly with prolonged exposure. The coating parameters that enhance durability—such as higher concentrations of active ingredients or stronger chemical bonding—may simultaneously increase bioavailability of potentially harmful compounds. Regulatory frameworks worldwide, including the European Union's Biocidal Products Regulation and the U.S. EPA's antimicrobial registration requirements, increasingly demand comprehensive safety assessments that address both acute and chronic exposure scenarios.

The potential contribution of antibacterial coatings to antimicrobial resistance development represents perhaps the most significant long-term safety concern. Sub-lethal concentrations of antibacterial agents, which may occur as coatings degrade over time, can create selective pressure favoring resistant bacterial strains. Coating parameters that result in inconsistent release rates or uneven surface coverage may inadvertently create these sub-lethal concentration zones. Recent research has identified genetic mechanisms through which exposure to certain coating agents can co-select for antibiotic resistance, highlighting the importance of designing coatings with resistance management in mind.

Sustainable approaches to antibacterial coating development are emerging in response to these environmental and safety challenges. These include biodegradable coating matrices that decompose into non-toxic components, biomimetic approaches that replicate natural antibacterial mechanisms, and physical rather than chemical antibacterial strategies such as microstructured surfaces. The optimization of coating parameters to minimize environmental impact while maintaining efficacy represents a key frontier in antibacterial coating research and development.

The persistence of antibacterial compounds in the environment raises significant ecological concerns. Studies have demonstrated that certain antibacterial agents can disrupt aquatic ecosystems by affecting non-target organisms. For instance, silver nanoparticles have been shown to accumulate in fish tissues and impact their reproductive systems at concentrations as low as 10 μg/L. The coating's degradation pathway, determined by its chemical composition and application parameters, directly influences this environmental footprint.

Safety considerations extend beyond environmental impacts to human health implications. Direct contact with antibacterial surfaces presents potential risks of skin sensitization and allergic reactions, particularly with prolonged exposure. The coating parameters that enhance durability—such as higher concentrations of active ingredients or stronger chemical bonding—may simultaneously increase bioavailability of potentially harmful compounds. Regulatory frameworks worldwide, including the European Union's Biocidal Products Regulation and the U.S. EPA's antimicrobial registration requirements, increasingly demand comprehensive safety assessments that address both acute and chronic exposure scenarios.

The potential contribution of antibacterial coatings to antimicrobial resistance development represents perhaps the most significant long-term safety concern. Sub-lethal concentrations of antibacterial agents, which may occur as coatings degrade over time, can create selective pressure favoring resistant bacterial strains. Coating parameters that result in inconsistent release rates or uneven surface coverage may inadvertently create these sub-lethal concentration zones. Recent research has identified genetic mechanisms through which exposure to certain coating agents can co-select for antibiotic resistance, highlighting the importance of designing coatings with resistance management in mind.

Sustainable approaches to antibacterial coating development are emerging in response to these environmental and safety challenges. These include biodegradable coating matrices that decompose into non-toxic components, biomimetic approaches that replicate natural antibacterial mechanisms, and physical rather than chemical antibacterial strategies such as microstructured surfaces. The optimization of coating parameters to minimize environmental impact while maintaining efficacy represents a key frontier in antibacterial coating research and development.

Cost-Benefit Analysis of Advanced Coating Parameters

The implementation of antibacterial coatings involves significant financial considerations that must be carefully evaluated to determine their economic viability. Initial investment costs for advanced antibacterial coating parameters typically include specialized equipment, high-quality raw materials, and skilled labor for application processes. These upfront expenses can range from moderate to substantial depending on the complexity of the coating technology and the scale of implementation.

When analyzing long-term economic benefits, it becomes evident that properly calibrated antibacterial coatings can significantly reduce maintenance costs over time. Studies indicate that facilities utilizing optimized antibacterial coatings experience up to 30% reduction in cleaning expenses and approximately 25% decrease in surface replacement costs due to extended material longevity.

Healthcare environments present a particularly compelling cost-benefit scenario. The implementation of advanced antibacterial coating parameters has demonstrated potential savings of $35,000-$50,000 annually per hospital ward through reduced healthcare-associated infections. These savings stem from decreased patient treatment costs, shorter hospital stays, and reduced staff absenteeism related to infectious disease transmission.

Manufacturing sectors also benefit economically from optimized coating parameters. Production facilities report 15-20% reductions in downtime related to sanitation procedures when utilizing properly calibrated antibacterial surfaces. This translates to measurable productivity improvements and enhanced operational efficiency across production cycles.

The durability factor significantly impacts return on investment calculations. Coatings with optimized parameters for hardness, adhesion strength, and chemical resistance demonstrate 2-3 times longer functional lifespans compared to standard formulations. This extended performance period substantially improves the amortization timeline for initial investments.

Environmental and regulatory compliance costs must also factor into comprehensive economic analysis. While advanced coating parameters may increase initial production expenses by 10-15%, they often reduce long-term compliance costs through decreased chemical usage, lower waste management expenses, and improved environmental performance metrics.

Sensitivity analysis reveals that coating thickness and antimicrobial agent concentration represent the parameters with highest economic impact. Optimizing these specific variables can improve cost-efficiency by 18-22% while maintaining or enhancing antibacterial performance, creating an ideal balance between expenditure and functional benefit.

When analyzing long-term economic benefits, it becomes evident that properly calibrated antibacterial coatings can significantly reduce maintenance costs over time. Studies indicate that facilities utilizing optimized antibacterial coatings experience up to 30% reduction in cleaning expenses and approximately 25% decrease in surface replacement costs due to extended material longevity.

Healthcare environments present a particularly compelling cost-benefit scenario. The implementation of advanced antibacterial coating parameters has demonstrated potential savings of $35,000-$50,000 annually per hospital ward through reduced healthcare-associated infections. These savings stem from decreased patient treatment costs, shorter hospital stays, and reduced staff absenteeism related to infectious disease transmission.

Manufacturing sectors also benefit economically from optimized coating parameters. Production facilities report 15-20% reductions in downtime related to sanitation procedures when utilizing properly calibrated antibacterial surfaces. This translates to measurable productivity improvements and enhanced operational efficiency across production cycles.

The durability factor significantly impacts return on investment calculations. Coatings with optimized parameters for hardness, adhesion strength, and chemical resistance demonstrate 2-3 times longer functional lifespans compared to standard formulations. This extended performance period substantially improves the amortization timeline for initial investments.

Environmental and regulatory compliance costs must also factor into comprehensive economic analysis. While advanced coating parameters may increase initial production expenses by 10-15%, they often reduce long-term compliance costs through decreased chemical usage, lower waste management expenses, and improved environmental performance metrics.

Sensitivity analysis reveals that coating thickness and antimicrobial agent concentration represent the parameters with highest economic impact. Optimizing these specific variables can improve cost-efficiency by 18-22% while maintaining or enhancing antibacterial performance, creating an ideal balance between expenditure and functional benefit.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!