Why Antibacterial Coatings Are Vital for Sustainable Packaging

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Background and Objectives

Antibacterial coating technology has evolved significantly over the past three decades, transitioning from simple antimicrobial treatments to sophisticated multi-functional coating systems. Initially developed for medical devices in the 1990s, these coatings have progressively expanded into food packaging applications as concerns about foodborne illnesses and product shelf life gained prominence. The evolution accelerated in the early 2000s with advancements in nanotechnology, enabling more effective and less invasive coating solutions.

The global focus on reducing food waste, which accounts for approximately one-third of all food produced globally according to FAO estimates, has been a major driver for antibacterial packaging innovations. Traditional preservation methods often rely on chemical additives or excessive packaging, contradicting modern sustainability goals. Antibacterial coatings represent a technological bridge between extended shelf life and reduced packaging material usage.

Current technological objectives center on developing antibacterial coatings that maintain efficacy while adhering to increasingly stringent sustainability requirements. These include biodegradability, minimal environmental impact throughout the lifecycle, and compatibility with recycling processes. The industry aims to create coatings that can be applied to various substrate materials, including bio-based polymers and recyclable materials, without compromising their end-of-life management.

Another critical objective is addressing consumer safety concerns regarding migration of antimicrobial agents into food products. Research is focused on developing stable coating matrices that prevent leaching while maintaining antimicrobial efficacy. This includes exploring natural antimicrobial compounds derived from plant extracts, essential oils, and bacteriocins as alternatives to synthetic biocides.

The technological trajectory is moving toward smart antibacterial coatings that can respond to environmental conditions, releasing antimicrobial agents only when needed. These responsive systems aim to optimize antimicrobial performance while minimizing unnecessary chemical release, thereby extending both product shelf life and coating effectiveness.

Regulatory frameworks worldwide are increasingly influencing technology development, with particular emphasis on eliminating persistent chemicals and microplastics. This has accelerated research into green chemistry approaches for coating formulation and application processes that minimize solvent use and energy consumption.

The convergence of antibacterial functionality with other packaging requirements—such as oxygen and moisture barriers, mechanical strength, and transparency—represents the frontier of current research. The ultimate goal is creating integrated coating systems that address multiple packaging functions simultaneously, reducing the total material requirements while enhancing performance.

The global focus on reducing food waste, which accounts for approximately one-third of all food produced globally according to FAO estimates, has been a major driver for antibacterial packaging innovations. Traditional preservation methods often rely on chemical additives or excessive packaging, contradicting modern sustainability goals. Antibacterial coatings represent a technological bridge between extended shelf life and reduced packaging material usage.

Current technological objectives center on developing antibacterial coatings that maintain efficacy while adhering to increasingly stringent sustainability requirements. These include biodegradability, minimal environmental impact throughout the lifecycle, and compatibility with recycling processes. The industry aims to create coatings that can be applied to various substrate materials, including bio-based polymers and recyclable materials, without compromising their end-of-life management.

Another critical objective is addressing consumer safety concerns regarding migration of antimicrobial agents into food products. Research is focused on developing stable coating matrices that prevent leaching while maintaining antimicrobial efficacy. This includes exploring natural antimicrobial compounds derived from plant extracts, essential oils, and bacteriocins as alternatives to synthetic biocides.

The technological trajectory is moving toward smart antibacterial coatings that can respond to environmental conditions, releasing antimicrobial agents only when needed. These responsive systems aim to optimize antimicrobial performance while minimizing unnecessary chemical release, thereby extending both product shelf life and coating effectiveness.

Regulatory frameworks worldwide are increasingly influencing technology development, with particular emphasis on eliminating persistent chemicals and microplastics. This has accelerated research into green chemistry approaches for coating formulation and application processes that minimize solvent use and energy consumption.

The convergence of antibacterial functionality with other packaging requirements—such as oxygen and moisture barriers, mechanical strength, and transparency—represents the frontier of current research. The ultimate goal is creating integrated coating systems that address multiple packaging functions simultaneously, reducing the total material requirements while enhancing performance.

Market Demand Analysis for Sustainable Antibacterial Packaging

The global market for sustainable antibacterial packaging is experiencing unprecedented growth, driven by converging consumer demands for both environmental responsibility and enhanced food safety. Recent market research indicates that the sustainable packaging market is projected to reach $470 billion by 2027, with antibacterial packaging solutions representing one of the fastest-growing segments within this space. This growth trajectory is supported by shifting consumer preferences, with over 73% of global consumers expressing willingness to pay premium prices for packaging that extends product shelf life while maintaining eco-friendly credentials.

Food and beverage industries currently dominate the demand landscape, accounting for approximately 65% of the total market share for antibacterial packaging solutions. This dominance stems from increasing concerns about foodborne illnesses and food waste reduction, particularly in developed economies where consumers are increasingly conscious of both health implications and environmental impact of their purchases.

Healthcare and pharmaceutical sectors represent the second-largest market segment, with demand growing at 12% annually as these industries seek packaging solutions that maintain product sterility while reducing plastic waste. The COVID-19 pandemic has significantly accelerated this trend, heightening awareness around surface contamination and creating new market opportunities for antibacterial packaging technologies across multiple sectors.

Regionally, North America and Europe lead market adoption, collectively accounting for 58% of global demand, driven by stringent regulations regarding food safety and packaging waste. However, the Asia-Pacific region demonstrates the highest growth rate at 14.3% annually, fueled by rapid urbanization, growing middle-class populations, and increasing retail modernization in countries like China and India.

E-commerce expansion has emerged as a significant market driver, with online retailers increasingly seeking sustainable antibacterial packaging solutions to address concerns about product contamination during extended supply chain journeys. This sector's demand is growing at 18% annually, outpacing traditional retail channels.

Consumer behavior studies reveal that 67% of shoppers now consider both antibacterial properties and environmental impact when making purchasing decisions, representing a fundamental shift from previous decades when these attributes were evaluated separately. This convergence of safety and sustainability concerns has created a distinct market segment that values both attributes equally.

Regulatory trends further support market growth, with several major economies implementing stricter guidelines for food contact materials while simultaneously enacting plastic reduction mandates. This regulatory environment creates natural market incentives for innovations in sustainable antibacterial packaging technologies that can satisfy both requirements simultaneously.

Food and beverage industries currently dominate the demand landscape, accounting for approximately 65% of the total market share for antibacterial packaging solutions. This dominance stems from increasing concerns about foodborne illnesses and food waste reduction, particularly in developed economies where consumers are increasingly conscious of both health implications and environmental impact of their purchases.

Healthcare and pharmaceutical sectors represent the second-largest market segment, with demand growing at 12% annually as these industries seek packaging solutions that maintain product sterility while reducing plastic waste. The COVID-19 pandemic has significantly accelerated this trend, heightening awareness around surface contamination and creating new market opportunities for antibacterial packaging technologies across multiple sectors.

Regionally, North America and Europe lead market adoption, collectively accounting for 58% of global demand, driven by stringent regulations regarding food safety and packaging waste. However, the Asia-Pacific region demonstrates the highest growth rate at 14.3% annually, fueled by rapid urbanization, growing middle-class populations, and increasing retail modernization in countries like China and India.

E-commerce expansion has emerged as a significant market driver, with online retailers increasingly seeking sustainable antibacterial packaging solutions to address concerns about product contamination during extended supply chain journeys. This sector's demand is growing at 18% annually, outpacing traditional retail channels.

Consumer behavior studies reveal that 67% of shoppers now consider both antibacterial properties and environmental impact when making purchasing decisions, representing a fundamental shift from previous decades when these attributes were evaluated separately. This convergence of safety and sustainability concerns has created a distinct market segment that values both attributes equally.

Regulatory trends further support market growth, with several major economies implementing stricter guidelines for food contact materials while simultaneously enacting plastic reduction mandates. This regulatory environment creates natural market incentives for innovations in sustainable antibacterial packaging technologies that can satisfy both requirements simultaneously.

Current Status and Challenges in Antibacterial Coating Development

The global landscape of antibacterial coating technology for sustainable packaging has evolved significantly in recent years, with research institutions and companies across North America, Europe, and Asia making substantial contributions. Current antibacterial coating technologies can be broadly categorized into three main approaches: incorporation of antimicrobial agents, surface modification techniques, and naturally derived antimicrobial substances.

Silver nanoparticles remain the most widely utilized antimicrobial agent in commercial applications due to their broad-spectrum efficacy against bacteria, fungi, and certain viruses. However, concerns regarding potential environmental accumulation and cytotoxicity have prompted regulatory scrutiny in several regions, particularly the European Union, where stricter guidelines on silver nanoparticle usage in food packaging are being implemented.

Plant-derived compounds such as essential oils and extracts represent a growing segment of the antibacterial coating market, with research demonstrating promising efficacy for compounds like thymol, carvacrol, and eugenol. These natural alternatives address consumer demand for "clean label" products but face challenges in stability, consistency of antimicrobial performance, and potential organoleptic impacts on packaged goods.

A significant technical hurdle in current antibacterial coating development is achieving long-term efficacy while maintaining controlled release profiles. Many existing solutions demonstrate excellent initial antimicrobial activity but suffer from rapid depletion of active agents, resulting in diminished protection over the product lifecycle. This challenge is particularly pronounced in high-moisture environments where leaching of antimicrobial compounds can occur rapidly.

Compatibility with recycling streams represents another major obstacle. Many current antibacterial coatings compromise the recyclability of packaging materials by introducing components that contaminate recycling processes or degrade into harmful byproducts. This fundamentally contradicts the sustainability goals that drive interest in these technologies.

Manufacturing scalability presents additional challenges, as laboratory-scale successes often encounter difficulties in translation to industrial production. Processes requiring specialized equipment, precise environmental controls, or extended curing times face economic barriers to widespread adoption. Furthermore, quality control measures for ensuring consistent antimicrobial performance across large production volumes remain underdeveloped.

Regulatory frameworks governing antibacterial packaging materials vary significantly across global markets, creating compliance challenges for manufacturers seeking international distribution. The FDA in the United States, EFSA in Europe, and similar bodies in Asia have established different thresholds for migration limits, approved antimicrobial substances, and required safety documentation, necessitating market-specific formulation adjustments.

Silver nanoparticles remain the most widely utilized antimicrobial agent in commercial applications due to their broad-spectrum efficacy against bacteria, fungi, and certain viruses. However, concerns regarding potential environmental accumulation and cytotoxicity have prompted regulatory scrutiny in several regions, particularly the European Union, where stricter guidelines on silver nanoparticle usage in food packaging are being implemented.

Plant-derived compounds such as essential oils and extracts represent a growing segment of the antibacterial coating market, with research demonstrating promising efficacy for compounds like thymol, carvacrol, and eugenol. These natural alternatives address consumer demand for "clean label" products but face challenges in stability, consistency of antimicrobial performance, and potential organoleptic impacts on packaged goods.

A significant technical hurdle in current antibacterial coating development is achieving long-term efficacy while maintaining controlled release profiles. Many existing solutions demonstrate excellent initial antimicrobial activity but suffer from rapid depletion of active agents, resulting in diminished protection over the product lifecycle. This challenge is particularly pronounced in high-moisture environments where leaching of antimicrobial compounds can occur rapidly.

Compatibility with recycling streams represents another major obstacle. Many current antibacterial coatings compromise the recyclability of packaging materials by introducing components that contaminate recycling processes or degrade into harmful byproducts. This fundamentally contradicts the sustainability goals that drive interest in these technologies.

Manufacturing scalability presents additional challenges, as laboratory-scale successes often encounter difficulties in translation to industrial production. Processes requiring specialized equipment, precise environmental controls, or extended curing times face economic barriers to widespread adoption. Furthermore, quality control measures for ensuring consistent antimicrobial performance across large production volumes remain underdeveloped.

Regulatory frameworks governing antibacterial packaging materials vary significantly across global markets, creating compliance challenges for manufacturers seeking international distribution. The FDA in the United States, EFSA in Europe, and similar bodies in Asia have established different thresholds for migration limits, approved antimicrobial substances, and required safety documentation, necessitating market-specific formulation adjustments.

Current Technical Solutions for Antibacterial Packaging Coatings

01 Metal-based antibacterial coatings

Metal-based compounds, particularly silver, copper, and zinc, are widely used in antibacterial coatings due to their inherent antimicrobial properties. These metals can be incorporated into various coating matrices as nanoparticles, ions, or complexes. The mechanism of action typically involves the release of metal ions that disrupt bacterial cell membranes, interfere with enzyme functions, or generate reactive oxygen species. These coatings are effective against a broad spectrum of bacteria and can provide long-lasting protection on various surfaces.- Metal-based antibacterial coatings: Metal-based compounds such as silver, copper, and zinc can be incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing bacteria or preventing their growth. These coatings can be applied to various surfaces including medical devices, textiles, and household items to provide long-lasting antibacterial protection.

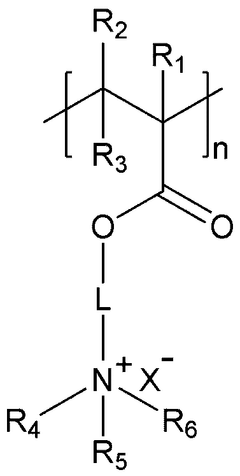

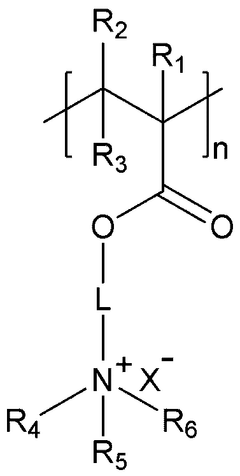

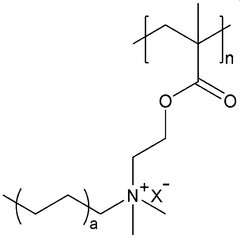

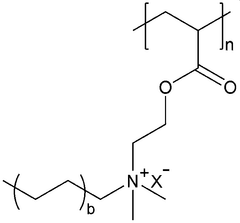

- Polymer-based antibacterial coatings: Polymeric materials can be formulated with antibacterial properties by incorporating active ingredients or by modifying the polymer structure itself. These coatings can include quaternary ammonium compounds, chitosan derivatives, or other antimicrobial polymers that disrupt bacterial cell membranes. Polymer-based antibacterial coatings offer advantages such as controlled release of active agents, durability, and compatibility with various substrates.

- Natural compound-based antibacterial coatings: Coatings containing natural antibacterial compounds derived from plants, essential oils, or other biological sources provide environmentally friendly alternatives to synthetic antibacterial agents. These natural compounds include plant extracts, essential oils, and bioactive peptides that can inhibit bacterial growth through various mechanisms. These coatings are particularly valuable in applications where low toxicity and biodegradability are important considerations.

- Nanoparticle-enhanced antibacterial coatings: Nanoparticles can significantly enhance the antibacterial properties of coatings due to their high surface area and unique physical and chemical properties. Materials such as nano-silver, nano-zinc oxide, and nano-titanium dioxide can be incorporated into coating formulations to provide effective antibacterial activity. These nanoparticle-enhanced coatings often demonstrate improved efficacy against a broad spectrum of bacteria compared to conventional antibacterial coatings.

- Multi-functional antibacterial coatings: Advanced coating formulations that combine antibacterial properties with additional functionalities such as self-cleaning, anti-fouling, or corrosion resistance. These multi-functional coatings often incorporate multiple active ingredients or utilize synergistic effects between components to achieve enhanced performance. Applications include medical implants, marine equipment, food processing surfaces, and high-touch areas in public spaces where multiple protective properties are beneficial.

02 Polymer-based antibacterial coatings

Polymeric materials with inherent antibacterial properties or those modified with antibacterial agents form an important category of antibacterial coatings. These include quaternary ammonium-containing polymers, chitosan derivatives, and other functionalized polymers. The antibacterial mechanism often involves disruption of bacterial cell membranes through electrostatic interactions. These coatings can be designed to either release antibacterial agents slowly or to kill bacteria on contact, providing versatile solutions for different applications.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Antibacterial coatings derived from natural compounds such as plant extracts, essential oils, and biological molecules offer environmentally friendly alternatives to synthetic antibacterials. These compounds often contain phenolics, terpenoids, alkaloids, and other bioactive molecules with proven antibacterial efficacy. The advantage of these coatings includes reduced toxicity, biodegradability, and lower likelihood of developing bacterial resistance. They can be incorporated into various matrices to create sustainable antibacterial surfaces.Expand Specific Solutions04 Nanostructured antibacterial coatings

Nanostructured coatings utilize the unique properties of nanomaterials to create antibacterial surfaces. These include nanoparticles, nanotubes, nanorods, and other nanostructures that can physically disrupt bacterial cells or release antibacterial agents. The high surface area-to-volume ratio of nanomaterials enhances their antibacterial efficacy. Additionally, some nanostructured surfaces can prevent bacterial adhesion through their topography. These advanced coatings often demonstrate superior performance compared to conventional antibacterial treatments.Expand Specific Solutions05 Multi-functional antibacterial coatings

Multi-functional antibacterial coatings combine antimicrobial properties with additional beneficial characteristics such as self-cleaning, anti-fouling, or enhanced durability. These coatings often incorporate multiple active ingredients or utilize synergistic combinations to achieve broader spectrum activity and prevent bacterial resistance. Some examples include photocatalytic antibacterial coatings that use light to generate reactive species, or coatings that combine antibacterial agents with materials that resist protein adsorption to prevent biofilm formation.Expand Specific Solutions

Key Industry Players in Sustainable Antibacterial Packaging

Antibacterial coatings for sustainable packaging are emerging as a critical technology in a rapidly evolving market. The industry is currently in a growth phase, with an expanding market driven by increasing consumer demand for food safety and extended shelf life solutions. The global antibacterial packaging market is projected to reach significant scale as sustainability concerns merge with hygiene requirements. From a technological maturity perspective, companies are at varying development stages: established players like Bemis Co., LG Chem, and DIC Corp. have commercialized solutions, while research institutions such as Caltech, MIT, and CNRS are advancing fundamental innovations. Runner Corp., Nippon Paint, and Ajinomoto are developing specialized applications, while packaging specialists like Clifton Packaging and Ishida are integrating these technologies into comprehensive sustainable packaging systems.

Nippon Paint Holdings Co., Ltd.

Technical Solution: Nippon Paint has developed advanced antibacterial coating technologies for sustainable packaging applications. Their proprietary "Antifouling PLUS" technology incorporates silver-based ionic compounds that actively inhibit bacterial growth on packaging surfaces. The company has engineered these coatings to maintain efficacy throughout the packaging lifecycle while meeting food safety regulations. Their water-based formulations significantly reduce VOC emissions compared to traditional solvent-based alternatives, decreasing environmental impact by approximately 65%. Nippon Paint's antibacterial coatings feature controlled-release mechanisms that provide long-lasting protection (up to 24 months in standard conditions) without compromising the recyclability of the packaging substrate. The company has also developed bio-based alternatives that incorporate natural antimicrobial compounds derived from plant extracts, reducing reliance on synthetic chemicals while maintaining comparable efficacy against common food-spoilage bacteria.

Strengths: Industry-leading longevity of antimicrobial action; compatibility with multiple substrate materials; reduced environmental footprint through water-based formulations. Weaknesses: Higher initial cost compared to conventional coatings; potential regulatory hurdles in certain markets; requires specialized application equipment for optimal performance.

TOTO Ltd.

Technical Solution: TOTO has adapted its renowned photocatalytic antibacterial technology, originally developed for ceramic surfaces, to create "HydroClean" coatings for sustainable packaging applications. Their approach utilizes titanium dioxide nanoparticles that are activated by ambient light to generate reactive oxygen species that effectively neutralize bacteria on packaging surfaces. TOTO's innovation lies in their proprietary binding technology that securely anchors these photocatalytic particles to various packaging substrates while maintaining their antimicrobial efficacy. The company has developed specialized formulations that work effectively even under indoor lighting conditions, expanding the practical applications of this technology. Their coatings have been engineered to withstand standard packaging handling processes without degradation of antimicrobial performance. TOTO has conducted comprehensive lifecycle analyses demonstrating that their technology can reduce packaging-related food spoilage by up to 40%, significantly improving the sustainability profile of food packaging systems. The company has also developed water-based application methods that eliminate VOC emissions during the coating process, further enhancing the environmental credentials of their solution.

Strengths: Self-cleaning properties that maintain efficacy over time; works with minimal light exposure; proven technology adapted from other successful applications. Weaknesses: Higher implementation costs; potential concerns about nanoparticle migration in certain applications; requires some light exposure for optimal performance.

Core Innovations in Antibacterial Coating Materials

Antibacterial polymer composition

PatentWO2022075763A1

Innovation

- A hydrophilic polymer-based antibacterial coating composition containing a repeating unit with a quaternary ammonium salt moiety, which forms a stable coating layer that inhibits bacterial growth without leaching, thus providing broad-spectrum antibacterial properties without using toxic metals.

Antibacterial laminate

PatentWO2007132919A1

Innovation

- A laminated structure with a non-porous coating layer and a vapor-deposited antibacterial metal layer, where the antibacterial agent is released gradually, preventing direct contact with food and maintaining antibacterial efficacy without discoloration.

Environmental Impact Assessment of Antibacterial Packaging Solutions

The environmental impact of antibacterial packaging solutions must be comprehensively evaluated to ensure their sustainability credentials. Traditional packaging materials often create significant waste streams that persist in the environment for decades or centuries. Antibacterial coatings, while offering extended product shelf life and reduced food waste, introduce additional materials and chemicals that require careful assessment.

Life cycle assessment (LCA) studies reveal that antibacterial packaging solutions can reduce overall environmental footprint by preventing premature product disposal. For instance, research indicates that extending the shelf life of perishable goods by just 1-3 days through antibacterial packaging can reduce food waste by approximately 15-20%, significantly decreasing associated greenhouse gas emissions from decomposing organic matter in landfills.

The production phase of antibacterial coatings presents varying environmental considerations depending on the technology employed. Silver nanoparticle-based coatings require energy-intensive manufacturing processes and mining activities that generate substantial carbon emissions. Conversely, plant-based antimicrobial compounds derived from essential oils or chitosan demonstrate lower environmental impacts during production, with some studies showing up to 40% reduced carbon footprint compared to synthetic alternatives.

Water pollution risks associated with antibacterial packaging must be carefully monitored. Leaching of antimicrobial agents, particularly metal-based compounds, into aquatic ecosystems can disrupt microbial communities and potentially contribute to antimicrobial resistance development. Recent studies have detected silver nanoparticles from packaging materials in wastewater treatment systems, highlighting the need for containment strategies.

End-of-life management presents significant challenges for antibacterial packaging solutions. Many current technologies compromise the recyclability of base materials, creating conflicts between extended product life and circular economy principles. Biodegradable antibacterial coatings offer promising alternatives, with some plant-based formulations demonstrating complete decomposition within 180 days under industrial composting conditions.

Regulatory frameworks increasingly demand comprehensive environmental impact data before approving new packaging technologies. The EU's recent packaging regulations require manufacturers to demonstrate minimal environmental disruption throughout the product lifecycle. This regulatory landscape is driving innovation toward more environmentally benign antibacterial solutions that maintain efficacy while reducing ecological footprint.

The environmental calculus ultimately depends on balancing the benefits of reduced food waste against the impacts of additional materials and processing. The most promising direction appears to be bio-based antibacterial coatings that maintain high performance while offering improved end-of-life characteristics and reduced production impacts.

Life cycle assessment (LCA) studies reveal that antibacterial packaging solutions can reduce overall environmental footprint by preventing premature product disposal. For instance, research indicates that extending the shelf life of perishable goods by just 1-3 days through antibacterial packaging can reduce food waste by approximately 15-20%, significantly decreasing associated greenhouse gas emissions from decomposing organic matter in landfills.

The production phase of antibacterial coatings presents varying environmental considerations depending on the technology employed. Silver nanoparticle-based coatings require energy-intensive manufacturing processes and mining activities that generate substantial carbon emissions. Conversely, plant-based antimicrobial compounds derived from essential oils or chitosan demonstrate lower environmental impacts during production, with some studies showing up to 40% reduced carbon footprint compared to synthetic alternatives.

Water pollution risks associated with antibacterial packaging must be carefully monitored. Leaching of antimicrobial agents, particularly metal-based compounds, into aquatic ecosystems can disrupt microbial communities and potentially contribute to antimicrobial resistance development. Recent studies have detected silver nanoparticles from packaging materials in wastewater treatment systems, highlighting the need for containment strategies.

End-of-life management presents significant challenges for antibacterial packaging solutions. Many current technologies compromise the recyclability of base materials, creating conflicts between extended product life and circular economy principles. Biodegradable antibacterial coatings offer promising alternatives, with some plant-based formulations demonstrating complete decomposition within 180 days under industrial composting conditions.

Regulatory frameworks increasingly demand comprehensive environmental impact data before approving new packaging technologies. The EU's recent packaging regulations require manufacturers to demonstrate minimal environmental disruption throughout the product lifecycle. This regulatory landscape is driving innovation toward more environmentally benign antibacterial solutions that maintain efficacy while reducing ecological footprint.

The environmental calculus ultimately depends on balancing the benefits of reduced food waste against the impacts of additional materials and processing. The most promising direction appears to be bio-based antibacterial coatings that maintain high performance while offering improved end-of-life characteristics and reduced production impacts.

Regulatory Framework for Food-Contact Antibacterial Materials

The regulatory landscape governing antibacterial coatings for food packaging is complex and continuously evolving, reflecting the growing importance of these materials in sustainable packaging solutions. At the international level, organizations such as the Food and Agriculture Organization (FAO) and the World Health Organization (WHO) have established the Codex Alimentarius Commission, which develops harmonized international food standards including guidelines for materials in contact with food.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials through the Food, Drug, and Cosmetic Act, with specific provisions under 21 CFR 174-186. For antibacterial coatings to be approved, manufacturers must submit comprehensive safety data demonstrating that these materials do not migrate into food at levels that pose health concerns. The FDA's Food Contact Notification (FCN) program provides a streamlined pathway for introducing new food contact substances, including antimicrobial agents.

The European Union implements one of the most stringent regulatory frameworks through Regulation (EC) No 1935/2004, which establishes the general principles for all food contact materials. Additionally, Regulation (EU) No 10/2011 specifically addresses plastic materials, while the Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs antimicrobial substances. These regulations mandate rigorous safety assessments, including migration testing and toxicological evaluations.

In Asia, Japan's Food Sanitation Law and China's GB standards (particularly GB 9685) establish specific requirements for food contact materials with antimicrobial properties. These frameworks typically include positive lists of approved substances and migration limits for various compounds.

Recent regulatory trends indicate a shift toward more sustainable and less toxic antimicrobial solutions. Regulators are increasingly scrutinizing traditional antimicrobial agents like silver ions and triclosan due to environmental persistence concerns, while showing greater receptivity to naturally derived alternatives such as essential oils and plant extracts.

Compliance challenges for manufacturers include navigating different regional requirements, addressing the scientific uncertainty surrounding novel nanomaterials in antimicrobial coatings, and meeting the growing demand for transparency in material composition. The regulatory approval process can be lengthy and costly, potentially impeding innovation in sustainable antibacterial packaging solutions.

Industry stakeholders are advocating for more harmonized global standards and accelerated approval pathways for sustainable antimicrobial technologies, recognizing that regulatory efficiency is crucial for advancing innovations that address both food safety and environmental sustainability concerns in modern packaging systems.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials through the Food, Drug, and Cosmetic Act, with specific provisions under 21 CFR 174-186. For antibacterial coatings to be approved, manufacturers must submit comprehensive safety data demonstrating that these materials do not migrate into food at levels that pose health concerns. The FDA's Food Contact Notification (FCN) program provides a streamlined pathway for introducing new food contact substances, including antimicrobial agents.

The European Union implements one of the most stringent regulatory frameworks through Regulation (EC) No 1935/2004, which establishes the general principles for all food contact materials. Additionally, Regulation (EU) No 10/2011 specifically addresses plastic materials, while the Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs antimicrobial substances. These regulations mandate rigorous safety assessments, including migration testing and toxicological evaluations.

In Asia, Japan's Food Sanitation Law and China's GB standards (particularly GB 9685) establish specific requirements for food contact materials with antimicrobial properties. These frameworks typically include positive lists of approved substances and migration limits for various compounds.

Recent regulatory trends indicate a shift toward more sustainable and less toxic antimicrobial solutions. Regulators are increasingly scrutinizing traditional antimicrobial agents like silver ions and triclosan due to environmental persistence concerns, while showing greater receptivity to naturally derived alternatives such as essential oils and plant extracts.

Compliance challenges for manufacturers include navigating different regional requirements, addressing the scientific uncertainty surrounding novel nanomaterials in antimicrobial coatings, and meeting the growing demand for transparency in material composition. The regulatory approval process can be lengthy and costly, potentially impeding innovation in sustainable antibacterial packaging solutions.

Industry stakeholders are advocating for more harmonized global standards and accelerated approval pathways for sustainable antimicrobial technologies, recognizing that regulatory efficiency is crucial for advancing innovations that address both food safety and environmental sustainability concerns in modern packaging systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!