Comparison of Metal vs Polymer-Based Antibacterial Coatings

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antibacterial Coating Technology Evolution and Objectives

Antibacterial coatings have evolved significantly over the past several decades, transitioning from rudimentary applications to sophisticated engineered surfaces with targeted antimicrobial properties. The earliest iterations emerged in the 1950s with simple silver-based coatings, primarily used in medical settings. By the 1970s, researchers began exploring copper and zinc compounds, expanding the range of metal-based antibacterial solutions.

The 1990s marked a pivotal shift with the introduction of the first polymer-based antibacterial coatings, offering alternatives to traditional metal formulations. This period saw increased research into the mechanisms of bacterial adhesion and biofilm formation, fundamentally changing our approach to antibacterial surface design. The early 2000s witnessed the integration of nanotechnology, dramatically enhancing the efficacy and application range of both metal and polymer-based solutions.

Recent technological advancements have focused on developing "smart" antibacterial coatings with controlled release mechanisms and stimuli-responsive properties. The COVID-19 pandemic accelerated innovation in this field, with heightened interest in surfaces capable of neutralizing both bacteria and viruses. Current research increasingly emphasizes sustainable and environmentally friendly formulations, moving away from potentially toxic compounds toward greener alternatives.

The global trajectory indicates a convergence of metal and polymer technologies, with hybrid systems emerging as promising solutions that combine the strengths of both approaches. Metal-based coatings typically offer superior immediate antimicrobial action, while polymer-based systems often provide better durability and controlled release capabilities. Understanding these complementary attributes is essential for next-generation coating development.

The primary objective of current antibacterial coating research is to develop solutions that balance immediate efficacy with long-term performance. This includes creating coatings with broad-spectrum activity against multiple pathogens while minimizing the risk of antimicrobial resistance development. Additional goals include enhancing durability under various environmental conditions, reducing manufacturing costs, and ensuring compatibility with diverse substrate materials.

For metal versus polymer comparison specifically, research aims to quantify performance differences across various application environments, identify optimal combinations for hybrid systems, and develop standardized testing protocols that accurately reflect real-world performance. The ultimate goal is to establish clear selection criteria for coating technologies based on specific use cases, enabling more informed decision-making in healthcare, food processing, public spaces, and consumer products.

The 1990s marked a pivotal shift with the introduction of the first polymer-based antibacterial coatings, offering alternatives to traditional metal formulations. This period saw increased research into the mechanisms of bacterial adhesion and biofilm formation, fundamentally changing our approach to antibacterial surface design. The early 2000s witnessed the integration of nanotechnology, dramatically enhancing the efficacy and application range of both metal and polymer-based solutions.

Recent technological advancements have focused on developing "smart" antibacterial coatings with controlled release mechanisms and stimuli-responsive properties. The COVID-19 pandemic accelerated innovation in this field, with heightened interest in surfaces capable of neutralizing both bacteria and viruses. Current research increasingly emphasizes sustainable and environmentally friendly formulations, moving away from potentially toxic compounds toward greener alternatives.

The global trajectory indicates a convergence of metal and polymer technologies, with hybrid systems emerging as promising solutions that combine the strengths of both approaches. Metal-based coatings typically offer superior immediate antimicrobial action, while polymer-based systems often provide better durability and controlled release capabilities. Understanding these complementary attributes is essential for next-generation coating development.

The primary objective of current antibacterial coating research is to develop solutions that balance immediate efficacy with long-term performance. This includes creating coatings with broad-spectrum activity against multiple pathogens while minimizing the risk of antimicrobial resistance development. Additional goals include enhancing durability under various environmental conditions, reducing manufacturing costs, and ensuring compatibility with diverse substrate materials.

For metal versus polymer comparison specifically, research aims to quantify performance differences across various application environments, identify optimal combinations for hybrid systems, and develop standardized testing protocols that accurately reflect real-world performance. The ultimate goal is to establish clear selection criteria for coating technologies based on specific use cases, enabling more informed decision-making in healthcare, food processing, public spaces, and consumer products.

Market Analysis for Antimicrobial Surface Solutions

The global antimicrobial surface solutions market has experienced significant growth in recent years, driven by increasing awareness of infection control and hygiene across various sectors. Currently valued at approximately 3.6 billion USD, the market is projected to reach 6.3 billion USD by 2027, representing a compound annual growth rate (CAGR) of 9.8% during the forecast period.

Healthcare facilities remain the dominant end-users, accounting for nearly 40% of the market share, as hospitals and clinics prioritize reducing healthcare-associated infections (HAIs). The food processing industry follows closely at 25%, with consumer goods, transportation, and construction sectors collectively representing the remaining market segments.

Regionally, North America leads with 35% market share due to stringent regulatory frameworks and advanced healthcare infrastructure. Europe holds 30% of the market, while Asia-Pacific demonstrates the fastest growth rate at 12.3% annually, primarily driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene standards in countries like China, India, and Japan.

The COVID-19 pandemic has substantially accelerated market demand, with a 27% increase in antimicrobial coating applications observed in 2020 alone. This surge has particularly benefited polymer-based solutions, which saw a 32% growth compared to 22% for metal-based alternatives during the same period.

Consumer preferences are increasingly shifting toward environmentally sustainable and non-toxic antimicrobial solutions. Market research indicates that 68% of institutional buyers now consider environmental impact when selecting antimicrobial products, up from 42% in 2018. This trend has catalyzed innovation in bio-based polymer coatings, which grew at 15.4% in 2021, outpacing traditional solutions.

Price sensitivity varies significantly across market segments. While healthcare facilities prioritize efficacy and longevity over cost (with average willingness to pay premium of 30-40%), consumer goods manufacturers are more price-sensitive, accepting premiums of only 10-15% for antimicrobial properties.

The competitive landscape features both established chemical companies and emerging specialized coating manufacturers. Five major players control approximately 45% of the global market, while numerous small and medium enterprises compete through niche applications and regional focus. Recent market consolidation has been evident with 12 significant mergers and acquisitions recorded between 2019 and 2022, indicating industry maturation and strategic positioning for future growth.

Healthcare facilities remain the dominant end-users, accounting for nearly 40% of the market share, as hospitals and clinics prioritize reducing healthcare-associated infections (HAIs). The food processing industry follows closely at 25%, with consumer goods, transportation, and construction sectors collectively representing the remaining market segments.

Regionally, North America leads with 35% market share due to stringent regulatory frameworks and advanced healthcare infrastructure. Europe holds 30% of the market, while Asia-Pacific demonstrates the fastest growth rate at 12.3% annually, primarily driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about hygiene standards in countries like China, India, and Japan.

The COVID-19 pandemic has substantially accelerated market demand, with a 27% increase in antimicrobial coating applications observed in 2020 alone. This surge has particularly benefited polymer-based solutions, which saw a 32% growth compared to 22% for metal-based alternatives during the same period.

Consumer preferences are increasingly shifting toward environmentally sustainable and non-toxic antimicrobial solutions. Market research indicates that 68% of institutional buyers now consider environmental impact when selecting antimicrobial products, up from 42% in 2018. This trend has catalyzed innovation in bio-based polymer coatings, which grew at 15.4% in 2021, outpacing traditional solutions.

Price sensitivity varies significantly across market segments. While healthcare facilities prioritize efficacy and longevity over cost (with average willingness to pay premium of 30-40%), consumer goods manufacturers are more price-sensitive, accepting premiums of only 10-15% for antimicrobial properties.

The competitive landscape features both established chemical companies and emerging specialized coating manufacturers. Five major players control approximately 45% of the global market, while numerous small and medium enterprises compete through niche applications and regional focus. Recent market consolidation has been evident with 12 significant mergers and acquisitions recorded between 2019 and 2022, indicating industry maturation and strategic positioning for future growth.

Metal vs Polymer Antibacterial Coatings: Current Status and Challenges

The global landscape of antibacterial coatings is currently dominated by two major categories: metal-based and polymer-based solutions. Metal-based antibacterial coatings primarily utilize silver, copper, zinc, and titanium compounds, which have demonstrated robust antimicrobial properties through ion release mechanisms and photocatalytic effects. These coatings have established a strong market presence due to their proven efficacy against a broad spectrum of pathogens and relatively long-lasting performance. However, they face challenges related to potential cytotoxicity, environmental concerns regarding metal leaching, and higher production costs.

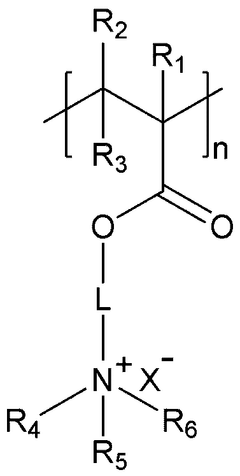

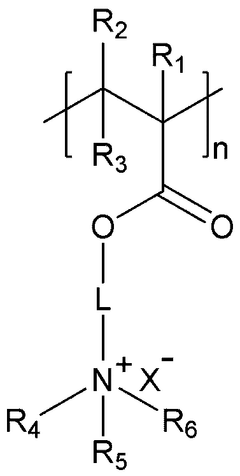

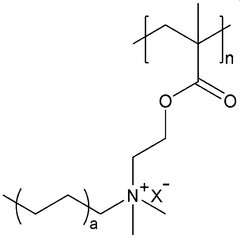

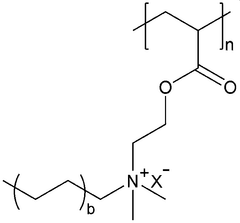

Polymer-based antibacterial coatings represent a rapidly evolving alternative, incorporating quaternary ammonium compounds, chitosan, antimicrobial peptides, and various synthetic polymers. These materials offer advantages in terms of versatility, biocompatibility, and the ability to create multifunctional surfaces. The polymer matrix can be engineered to provide controlled release of antimicrobial agents or to present contact-killing surfaces, offering design flexibility that metal-based solutions often lack.

A significant technical challenge for both categories remains the development of coatings that maintain long-term efficacy without promoting antimicrobial resistance. Metal-based coatings, particularly silver, have shown some concerning trends regarding bacterial adaptation, while polymer systems must overcome issues related to mechanical durability and stability under various environmental conditions.

The integration of these technologies with existing manufacturing processes presents another substantial hurdle. Metal-based coatings often require specialized deposition techniques that may not be compatible with all substrate materials, while polymer coatings can face adhesion issues and may alter the physical properties of the underlying material.

Regulatory frameworks worldwide are increasingly scrutinizing both approaches, with particular attention to leaching behavior, environmental persistence, and potential for unintended ecological impacts. Metal nanoparticles face growing restrictions due to concerns about bioaccumulation, while certain antimicrobial polymers are under evaluation for potential endocrine-disrupting effects.

Recent innovations are focusing on hybrid systems that combine the strengths of both approaches—incorporating metal nanoparticles within polymer matrices to achieve synergistic effects while mitigating individual limitations. These composite coatings represent a promising direction but require further optimization to balance antimicrobial efficacy, durability, cost-effectiveness, and environmental safety.

The geographical distribution of research and development in this field shows concentration in North America, Europe, and East Asia, with emerging contributions from research institutions in India, Brazil, and the Middle East, reflecting the global importance of addressing antimicrobial resistance through surface engineering approaches.

Polymer-based antibacterial coatings represent a rapidly evolving alternative, incorporating quaternary ammonium compounds, chitosan, antimicrobial peptides, and various synthetic polymers. These materials offer advantages in terms of versatility, biocompatibility, and the ability to create multifunctional surfaces. The polymer matrix can be engineered to provide controlled release of antimicrobial agents or to present contact-killing surfaces, offering design flexibility that metal-based solutions often lack.

A significant technical challenge for both categories remains the development of coatings that maintain long-term efficacy without promoting antimicrobial resistance. Metal-based coatings, particularly silver, have shown some concerning trends regarding bacterial adaptation, while polymer systems must overcome issues related to mechanical durability and stability under various environmental conditions.

The integration of these technologies with existing manufacturing processes presents another substantial hurdle. Metal-based coatings often require specialized deposition techniques that may not be compatible with all substrate materials, while polymer coatings can face adhesion issues and may alter the physical properties of the underlying material.

Regulatory frameworks worldwide are increasingly scrutinizing both approaches, with particular attention to leaching behavior, environmental persistence, and potential for unintended ecological impacts. Metal nanoparticles face growing restrictions due to concerns about bioaccumulation, while certain antimicrobial polymers are under evaluation for potential endocrine-disrupting effects.

Recent innovations are focusing on hybrid systems that combine the strengths of both approaches—incorporating metal nanoparticles within polymer matrices to achieve synergistic effects while mitigating individual limitations. These composite coatings represent a promising direction but require further optimization to balance antimicrobial efficacy, durability, cost-effectiveness, and environmental safety.

The geographical distribution of research and development in this field shows concentration in North America, Europe, and East Asia, with emerging contributions from research institutions in India, Brazil, and the Middle East, reflecting the global importance of addressing antimicrobial resistance through surface engineering approaches.

Comparative Analysis of Metal and Polymer-Based Antibacterial Mechanisms

01 Metal-based antibacterial coatings

Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into coatings as nanoparticles, ions, or compounds that release metal ions over time. The mechanism of action typically involves the metal ions disrupting bacterial cell membranes, interfering with enzyme functions, or generating reactive oxygen species that damage bacterial cells. These coatings are particularly effective for medical devices, food processing equipment, and high-touch surfaces in healthcare settings.- Metal-based antibacterial coatings: Metal-based antibacterial coatings utilize metals such as silver, copper, and zinc that have inherent antimicrobial properties. These metals can be incorporated into coatings as nanoparticles, ions, or compounds that release active metal ions upon contact with moisture. The mechanism typically involves the metal ions disrupting bacterial cell membranes, interfering with enzyme functions, or generating reactive oxygen species that damage bacterial cells. These coatings are particularly effective for medical devices, food processing equipment, and high-touch surfaces in healthcare settings.

- Polymer-based antibacterial coatings with embedded antimicrobial agents: These coatings consist of polymer matrices that contain embedded antimicrobial agents. The polymers serve as carriers that can release antimicrobial compounds in a controlled manner over time. Common antimicrobial agents include quaternary ammonium compounds, triclosan, and various antibiotics. The polymer matrix can be designed to respond to environmental triggers such as pH, temperature, or moisture to release the active ingredients. This approach provides long-lasting protection and can be tailored for specific applications in healthcare, consumer products, and industrial settings.

- Surface-modified polymer coatings with antibacterial properties: These coatings involve the chemical modification of polymer surfaces to create antibacterial properties without relying on the release of active agents. Techniques include grafting antibacterial functional groups onto the polymer surface, creating positively charged surfaces that disrupt bacterial cell membranes, or developing super-hydrophobic surfaces that prevent bacterial adhesion. These modifications can provide permanent antibacterial properties without the depletion issues associated with release-based systems, making them suitable for long-term applications in medical implants and devices.

- Hybrid metal-polymer antibacterial coating systems: Hybrid coatings combine the advantages of both metal and polymer-based antibacterial approaches. These systems typically incorporate metal nanoparticles or ions within polymer matrices to create synergistic effects. The polymer component provides durability, adhesion, and controlled release properties, while the metal component delivers potent antimicrobial activity. These hybrid systems can be designed as multilayer coatings with different functional layers or as nanocomposites with metal particles dispersed throughout the polymer. Applications include medical devices, water treatment systems, and food packaging materials.

- Environmentally responsive antibacterial coatings: These advanced coating systems can change their antibacterial activity in response to environmental conditions or external stimuli. They may release antimicrobial agents only when bacteria are present, when pH changes occur, or upon exposure to specific wavelengths of light. Some coatings incorporate enzymes that target bacterial biofilms or produce reactive oxygen species on demand. This smart approach minimizes unnecessary antimicrobial release, reducing the potential for developing bacterial resistance while extending the effective lifetime of the coating. Applications include implantable medical devices, wound dressings, and surfaces in healthcare facilities.

02 Polymer-based antibacterial coatings

Polymer-based antibacterial coatings incorporate antimicrobial agents within polymer matrices that can be applied to various surfaces. These polymers can be designed to slowly release antimicrobial compounds or have inherent antibacterial properties through positively charged functional groups that disrupt bacterial cell membranes. Common polymers used include quaternary ammonium-containing polymers, chitosan derivatives, and polyethylene glycol. These coatings provide durable protection and can be engineered for specific release profiles and surface compatibility.Expand Specific Solutions03 Hybrid metal-polymer antibacterial coatings

Hybrid coatings combine the advantages of both metal and polymer-based systems, creating synergistic antibacterial effects. These formulations typically embed metal nanoparticles or compounds within polymer matrices, allowing for controlled release of metal ions while maintaining the durability and adhesion properties of polymers. The polymer component can also be functionalized to enhance the antibacterial efficacy or provide additional properties such as self-cleaning or anti-fouling capabilities. These hybrid systems often demonstrate improved longevity and broader spectrum antimicrobial activity.Expand Specific Solutions04 Application methods for antibacterial coatings

Various application methods are employed for antibacterial coatings, including spray coating, dip coating, spin coating, and plasma deposition. Each technique offers different advantages in terms of coating thickness, uniformity, and adhesion to the substrate. Advanced methods such as layer-by-layer assembly and electrospinning allow for precise control over coating architecture and composition. The choice of application method significantly impacts the coating's performance, durability, and cost-effectiveness, and must be selected based on the specific substrate material and intended application environment.Expand Specific Solutions05 Environmental and biocompatibility considerations

Modern antibacterial coatings are increasingly designed with environmental sustainability and biocompatibility in mind. This includes developing biodegradable polymer matrices, using naturally derived antimicrobial compounds, and ensuring minimal leaching of potentially harmful substances. For medical applications, biocompatibility is critical to prevent adverse tissue reactions or systemic toxicity. Testing protocols evaluate cytotoxicity, inflammatory responses, and potential for antimicrobial resistance development. Regulatory frameworks increasingly require assessment of the environmental impact of these coatings throughout their lifecycle.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Antibacterial Coatings

The antibacterial coatings market is currently in a growth phase, with metal-based and polymer-based solutions competing for dominance. The global market is expanding rapidly, projected to reach $6.3 billion by 2026, driven by healthcare, food packaging, and consumer goods applications. Metal-based coatings (championed by Mitsubishi Materials, JFE Steel, and BASF) offer superior durability and efficacy but face environmental concerns, while polymer-based alternatives (developed by LG Chem, Parx Materials, and Mitsui Chemicals) provide flexibility and biocompatibility advantages. Research institutions like MIT, Industrial Technology Research Institute, and South China University of Technology are advancing hybrid technologies, suggesting the future lies in composite solutions that combine the strengths of both approaches while addressing their respective limitations.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered hybrid metal-polymer antibacterial coating systems that combine the advantages of both approaches. Their technology incorporates metal ions (primarily silver and copper) into specialized polymer matrices through ion-exchange mechanisms. The company's proprietary "MetaPolymer" technology creates nanocomposite coatings where metal nanoparticles are uniformly dispersed throughout polymer films, providing both contact-killing and release-killing mechanisms. LG Chem has developed processes for controlling the oxidation state of metal ions within the polymer matrix, optimizing antimicrobial efficacy while minimizing potential cytotoxicity. Their coatings demonstrate effectiveness against both Gram-positive and Gram-negative bacteria, with documented efficacy against methicillin-resistant Staphylococcus aureus (MRSA) and Escherichia coli. Recent innovations include thermally responsive polymer systems that increase metal ion release rates in response to elevated temperatures, potentially signaling infection.

Strengths: Their hybrid approach combines the durability of polymers with the potent antimicrobial properties of metals, creating synergistic effects. Extensive testing has demonstrated long-term efficacy in hospital environments. Weaknesses: Higher production costs compared to single-component systems, and potential for metal ion accumulation in environments where coatings are extensively used.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed groundbreaking approaches to antibacterial coatings through their Materials Research Laboratory and Department of Chemical Engineering. Their metal-based technologies include layer-by-layer assembled films incorporating silver nanoparticles with precisely controlled release kinetics, achieving sustained antimicrobial activity for over 30 days in simulated physiological conditions. MIT's polymer research has yielded innovative "contact-killing" surfaces using cationic polymers that physically disrupt bacterial cell membranes without relying on biocide release, addressing concerns about antimicrobial resistance development. A significant innovation from MIT is their comparative analysis framework that quantifies the environmental impact of different coating technologies throughout their lifecycle. Their studies indicate that while metal-based coatings typically have higher initial environmental footprints during production, their extended lifetime efficacy may result in lower overall impact compared to polymer systems requiring frequent replacement. MIT has also pioneered responsive antibacterial coatings that activate only when bacterial contamination is detected through pH or enzyme-triggered mechanisms, potentially representing the next generation of intelligent antimicrobial surfaces.

Strengths: Cutting-edge research incorporating nanotechnology and smart materials provides solutions that address both immediate antimicrobial needs and long-term sustainability concerns. Their quantitative comparison frameworks help guide application-specific selection. Weaknesses: Many of their most innovative technologies remain in laboratory development stages, with significant challenges remaining for cost-effective scale-up and manufacturing.

Key Patents and Scientific Breakthroughs in Coating Technologies

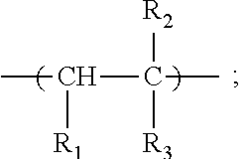

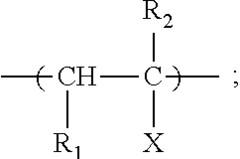

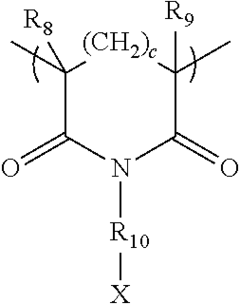

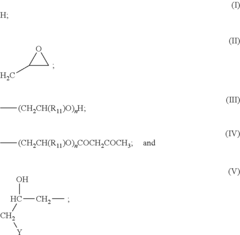

Antibacterial polymer composition

PatentWO2022075763A1

Innovation

- A hydrophilic polymer-based antibacterial coating composition containing a repeating unit with a quaternary ammonium salt moiety, which forms a stable coating layer that inhibits bacterial growth without leaching, thus providing broad-spectrum antibacterial properties without using toxic metals.

Antibacterial polymer emulsion and coating composition

PatentActiveUS20110243882A1

Innovation

- An aqueous antibacterial polymer emulsion comprising 90-99.9% polymer A, 0.002-1% metal complexed with a copolymer B, and 0.004-10% oxidant, where the metal is selected from copper, silver, gold, tin, and zinc, with a heterocyclic monomer residue, providing improved heat stability and reduced discoloration.

Environmental Impact and Sustainability Considerations

The environmental impact of antibacterial coatings represents a critical consideration in their development and application, with significant differences between metal and polymer-based solutions. Metal-based antibacterial coatings, particularly those containing silver, copper, and zinc, pose potential environmental concerns due to metal ion leaching into aquatic ecosystems. Studies have demonstrated that these ions can accumulate in water bodies, potentially disrupting aquatic life and microbial communities essential for ecological balance. For instance, silver nanoparticles have been shown to persist in the environment with bioaccumulation potential in various organisms.

Polymer-based antibacterial coatings generally present a more favorable environmental profile, especially when derived from biodegradable or bio-based materials. Recent advancements in biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) have enabled the development of antibacterial coatings with reduced environmental persistence. These materials can degrade into non-toxic components under appropriate conditions, minimizing long-term environmental burden.

Life cycle assessment (LCA) studies comparing these technologies reveal that metal-based coatings typically require more energy-intensive manufacturing processes and resource extraction, contributing to higher carbon footprints. The mining and refining of metals like silver and copper generate significant environmental impacts including habitat destruction, water pollution, and greenhouse gas emissions. Conversely, polymer-based solutions, particularly those utilizing renewable feedstocks, often demonstrate lower environmental impacts during production phases.

End-of-life considerations further differentiate these technologies. Metal-based coatings may complicate recycling processes for the underlying materials, potentially requiring specialized separation techniques. Polymer coatings, especially non-biodegradable varieties, may contribute to microplastic pollution if not properly managed at disposal. However, emerging biodegradable polymer technologies offer promising pathways for reducing this concern.

Regulatory frameworks worldwide are increasingly emphasizing sustainability metrics in material approval processes. The European Union's REACH regulations and similar frameworks in other regions have placed greater scrutiny on metal-based antimicrobials due to potential environmental persistence. This regulatory landscape is driving innovation toward more environmentally benign antibacterial solutions, with particular emphasis on reduced toxicity and improved biodegradability.

Water consumption represents another important sustainability metric, with metal-based coating processes typically requiring greater volumes for processing and waste treatment. Polymer coating technologies have generally achieved more efficient water utilization profiles, particularly with advances in solvent-free application methods and water-based formulations.

Polymer-based antibacterial coatings generally present a more favorable environmental profile, especially when derived from biodegradable or bio-based materials. Recent advancements in biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) have enabled the development of antibacterial coatings with reduced environmental persistence. These materials can degrade into non-toxic components under appropriate conditions, minimizing long-term environmental burden.

Life cycle assessment (LCA) studies comparing these technologies reveal that metal-based coatings typically require more energy-intensive manufacturing processes and resource extraction, contributing to higher carbon footprints. The mining and refining of metals like silver and copper generate significant environmental impacts including habitat destruction, water pollution, and greenhouse gas emissions. Conversely, polymer-based solutions, particularly those utilizing renewable feedstocks, often demonstrate lower environmental impacts during production phases.

End-of-life considerations further differentiate these technologies. Metal-based coatings may complicate recycling processes for the underlying materials, potentially requiring specialized separation techniques. Polymer coatings, especially non-biodegradable varieties, may contribute to microplastic pollution if not properly managed at disposal. However, emerging biodegradable polymer technologies offer promising pathways for reducing this concern.

Regulatory frameworks worldwide are increasingly emphasizing sustainability metrics in material approval processes. The European Union's REACH regulations and similar frameworks in other regions have placed greater scrutiny on metal-based antimicrobials due to potential environmental persistence. This regulatory landscape is driving innovation toward more environmentally benign antibacterial solutions, with particular emphasis on reduced toxicity and improved biodegradability.

Water consumption represents another important sustainability metric, with metal-based coating processes typically requiring greater volumes for processing and waste treatment. Polymer coating technologies have generally achieved more efficient water utilization profiles, particularly with advances in solvent-free application methods and water-based formulations.

Regulatory Framework and Safety Standards for Antimicrobial Materials

The regulatory landscape governing antimicrobial coatings varies significantly between metal and polymer-based solutions, creating a complex framework that manufacturers must navigate. For metal-based antimicrobial coatings, particularly those containing silver, copper, or zinc, the U.S. Environmental Protection Agency (EPA) requires registration under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) when specific antimicrobial claims are made. This process involves extensive efficacy testing and safety documentation, creating a significant regulatory burden.

In contrast, polymer-based antimicrobial coatings may fall under different regulatory classifications depending on their mechanism of action. Those utilizing quaternary ammonium compounds or other non-metallic biocides typically require similar EPA registration, while some novel polymer technologies that work through physical rather than chemical means may avoid certain aspects of biocide regulation.

The European Union implements more stringent controls through the Biocidal Products Regulation (BPR), which governs both metal and polymer antimicrobial technologies. The BPR requires comprehensive risk assessments and authorization for active substances before market entry, with particular attention to environmental persistence for metal-based solutions.

International Organization for Standardization (ISO) standards provide crucial testing methodologies for antimicrobial efficacy, with ISO 22196 being particularly relevant for both coating types. However, the application of these standards often reveals differences in testing requirements; metal-based coatings typically undergo more rigorous leaching tests due to concerns about ion release into the environment.

Healthcare applications face additional regulatory scrutiny, with the FDA in the United States classifying certain antimicrobial coatings as medical devices depending on their intended use and claims. Metal-based coatings in medical settings often require more extensive biocompatibility testing under ISO 10993 standards due to potential cytotoxicity concerns.

Environmental regulations increasingly impact both coating types, though metal-based solutions face greater scrutiny regarding end-of-life disposal and potential ecological impacts. The EU's REACH regulation places particular emphasis on the long-term environmental fate of metal ions, creating additional compliance requirements for manufacturers of metal-based antimicrobial coatings.

Safety data requirements also differ substantially, with metal-based coatings typically requiring more comprehensive toxicological profiles due to the potential for systemic absorption of metal ions. Polymer-based systems, particularly those using novel mechanisms rather than traditional biocides, may benefit from streamlined safety assessment pathways in certain jurisdictions, though this landscape continues to evolve as regulatory frameworks adapt to emerging technologies.

In contrast, polymer-based antimicrobial coatings may fall under different regulatory classifications depending on their mechanism of action. Those utilizing quaternary ammonium compounds or other non-metallic biocides typically require similar EPA registration, while some novel polymer technologies that work through physical rather than chemical means may avoid certain aspects of biocide regulation.

The European Union implements more stringent controls through the Biocidal Products Regulation (BPR), which governs both metal and polymer antimicrobial technologies. The BPR requires comprehensive risk assessments and authorization for active substances before market entry, with particular attention to environmental persistence for metal-based solutions.

International Organization for Standardization (ISO) standards provide crucial testing methodologies for antimicrobial efficacy, with ISO 22196 being particularly relevant for both coating types. However, the application of these standards often reveals differences in testing requirements; metal-based coatings typically undergo more rigorous leaching tests due to concerns about ion release into the environment.

Healthcare applications face additional regulatory scrutiny, with the FDA in the United States classifying certain antimicrobial coatings as medical devices depending on their intended use and claims. Metal-based coatings in medical settings often require more extensive biocompatibility testing under ISO 10993 standards due to potential cytotoxicity concerns.

Environmental regulations increasingly impact both coating types, though metal-based solutions face greater scrutiny regarding end-of-life disposal and potential ecological impacts. The EU's REACH regulation places particular emphasis on the long-term environmental fate of metal ions, creating additional compliance requirements for manufacturers of metal-based antimicrobial coatings.

Safety data requirements also differ substantially, with metal-based coatings typically requiring more comprehensive toxicological profiles due to the potential for systemic absorption of metal ions. Polymer-based systems, particularly those using novel mechanisms rather than traditional biocides, may benefit from streamlined safety assessment pathways in certain jurisdictions, though this landscape continues to evolve as regulatory frameworks adapt to emerging technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!