Antibacterial Coating Mechanisms in Aerospace Applications

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Antibacterial Coating Evolution and Objectives

The evolution of antibacterial coatings in aerospace applications has undergone significant transformation since their initial development in the 1960s. Early iterations primarily focused on preventing microbial contamination in spacecraft environments, with NASA pioneering basic antimicrobial surface treatments to protect astronauts during extended missions. These rudimentary coatings relied heavily on silver-based compounds and basic polymer matrices with limited durability and effectiveness.

The 1980s marked a pivotal shift as researchers began exploring more sophisticated coating technologies incorporating copper, zinc oxide, and titanium dioxide as active antimicrobial agents. This period saw the emergence of the first multi-functional coatings that combined antibacterial properties with other essential characteristics such as corrosion resistance and thermal stability—critical requirements for aerospace applications.

By the early 2000s, nanotechnology revolutionized the field, enabling the development of nanoparticle-enhanced coatings with significantly improved antimicrobial efficacy and mechanical properties. These advanced formulations demonstrated superior performance in the extreme conditions encountered in aerospace environments, including resistance to UV radiation, temperature fluctuations, and vacuum exposure.

Current technological objectives in aerospace antibacterial coating research center around several key priorities. First is the development of self-regenerating coatings capable of maintaining antimicrobial efficacy throughout extended missions without degradation. Second is the creation of environmentally friendly formulations that eliminate toxic compounds while maintaining performance standards. Third is the integration of smart coating systems with real-time monitoring capabilities to detect microbial contamination and trigger appropriate responses.

The industry is also pursuing enhanced durability metrics, with goals to extend coating lifespans to match or exceed aircraft maintenance cycles, thereby reducing operational costs and downtime. Particular emphasis is being placed on coatings that can withstand the harsh conditions of space travel, including resistance to atomic oxygen erosion and micrometeoroid impacts.

Looking forward, the trajectory of antibacterial coating technology in aerospace applications is moving toward biomimetic approaches that replicate natural antimicrobial mechanisms found in biological systems. Additionally, there is growing interest in developing coatings with selective antimicrobial properties that target harmful microorganisms while preserving beneficial microbial communities that may be essential for closed ecological systems in long-duration space missions.

The 1980s marked a pivotal shift as researchers began exploring more sophisticated coating technologies incorporating copper, zinc oxide, and titanium dioxide as active antimicrobial agents. This period saw the emergence of the first multi-functional coatings that combined antibacterial properties with other essential characteristics such as corrosion resistance and thermal stability—critical requirements for aerospace applications.

By the early 2000s, nanotechnology revolutionized the field, enabling the development of nanoparticle-enhanced coatings with significantly improved antimicrobial efficacy and mechanical properties. These advanced formulations demonstrated superior performance in the extreme conditions encountered in aerospace environments, including resistance to UV radiation, temperature fluctuations, and vacuum exposure.

Current technological objectives in aerospace antibacterial coating research center around several key priorities. First is the development of self-regenerating coatings capable of maintaining antimicrobial efficacy throughout extended missions without degradation. Second is the creation of environmentally friendly formulations that eliminate toxic compounds while maintaining performance standards. Third is the integration of smart coating systems with real-time monitoring capabilities to detect microbial contamination and trigger appropriate responses.

The industry is also pursuing enhanced durability metrics, with goals to extend coating lifespans to match or exceed aircraft maintenance cycles, thereby reducing operational costs and downtime. Particular emphasis is being placed on coatings that can withstand the harsh conditions of space travel, including resistance to atomic oxygen erosion and micrometeoroid impacts.

Looking forward, the trajectory of antibacterial coating technology in aerospace applications is moving toward biomimetic approaches that replicate natural antimicrobial mechanisms found in biological systems. Additionally, there is growing interest in developing coatings with selective antimicrobial properties that target harmful microorganisms while preserving beneficial microbial communities that may be essential for closed ecological systems in long-duration space missions.

Market Demand Analysis for Aerospace Antimicrobial Solutions

The aerospace industry has witnessed a significant surge in demand for antimicrobial solutions, particularly in the post-pandemic era. Commercial airlines, military aircraft, and space exploration vehicles all face critical challenges related to microbial contamination that can compromise passenger safety, operational efficiency, and mission success. Market research indicates that the global aerospace antimicrobial coatings market was valued at approximately 30 million USD in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2030.

The primary market drivers include heightened awareness of infection control, stringent regulatory requirements for aircraft cleanliness, and the increasing complexity of long-duration space missions where microbial management becomes crucial. Commercial aviation represents the largest market segment, with airlines seeking solutions that can reduce turnaround cleaning time while ensuring passenger confidence in cabin hygiene. This segment alone accounts for nearly 65% of the total market demand.

Military and defense applications constitute the second-largest market segment, with emphasis on protecting personnel in confined spaces during extended deployments. The space exploration segment, though smaller in current market share, demonstrates the highest growth potential as missions become longer and more ambitious, requiring increasingly sophisticated antimicrobial systems.

Regional analysis reveals North America as the dominant market, followed by Europe and Asia-Pacific. The North American dominance stems from the concentration of aerospace manufacturers and the presence of stringent regulatory frameworks. However, the Asia-Pacific region is expected to witness the fastest growth due to expanding commercial aviation fleets and increasing defense budgets.

Customer requirements have evolved significantly, with aerospace clients now demanding multifunctional coatings that combine antimicrobial properties with other performance characteristics such as corrosion resistance, durability under extreme conditions, and minimal weight addition. Additionally, there is growing preference for environmentally sustainable solutions that avoid traditional biocides with potential ecological impacts.

Cost sensitivity remains a critical factor, particularly in the commercial aviation sector where fleet-wide implementation must demonstrate clear return on investment through reduced maintenance costs, extended service intervals, or enhanced passenger experience metrics. Market research indicates willingness to pay premium prices only when solutions demonstrate measurable operational benefits beyond basic antimicrobial functionality.

Emerging market opportunities include specialized coatings for air filtration systems, touchless antimicrobial technologies, and smart coatings that can indicate contamination levels or effectiveness status through visual cues. These innovative approaches are expected to drive the next wave of market growth as the aerospace industry continues to prioritize health safety alongside traditional performance metrics.

The primary market drivers include heightened awareness of infection control, stringent regulatory requirements for aircraft cleanliness, and the increasing complexity of long-duration space missions where microbial management becomes crucial. Commercial aviation represents the largest market segment, with airlines seeking solutions that can reduce turnaround cleaning time while ensuring passenger confidence in cabin hygiene. This segment alone accounts for nearly 65% of the total market demand.

Military and defense applications constitute the second-largest market segment, with emphasis on protecting personnel in confined spaces during extended deployments. The space exploration segment, though smaller in current market share, demonstrates the highest growth potential as missions become longer and more ambitious, requiring increasingly sophisticated antimicrobial systems.

Regional analysis reveals North America as the dominant market, followed by Europe and Asia-Pacific. The North American dominance stems from the concentration of aerospace manufacturers and the presence of stringent regulatory frameworks. However, the Asia-Pacific region is expected to witness the fastest growth due to expanding commercial aviation fleets and increasing defense budgets.

Customer requirements have evolved significantly, with aerospace clients now demanding multifunctional coatings that combine antimicrobial properties with other performance characteristics such as corrosion resistance, durability under extreme conditions, and minimal weight addition. Additionally, there is growing preference for environmentally sustainable solutions that avoid traditional biocides with potential ecological impacts.

Cost sensitivity remains a critical factor, particularly in the commercial aviation sector where fleet-wide implementation must demonstrate clear return on investment through reduced maintenance costs, extended service intervals, or enhanced passenger experience metrics. Market research indicates willingness to pay premium prices only when solutions demonstrate measurable operational benefits beyond basic antimicrobial functionality.

Emerging market opportunities include specialized coatings for air filtration systems, touchless antimicrobial technologies, and smart coatings that can indicate contamination levels or effectiveness status through visual cues. These innovative approaches are expected to drive the next wave of market growth as the aerospace industry continues to prioritize health safety alongside traditional performance metrics.

Current Antibacterial Coating Technologies and Limitations

The aerospace industry faces unique challenges regarding microbial contamination due to confined spaces, recirculated air systems, and extended mission durations. Current antibacterial coating technologies for aerospace applications can be categorized into several major types, each with specific mechanisms and limitations.

Metal-based antibacterial coatings, particularly those incorporating silver, copper, and zinc nanoparticles, have demonstrated significant efficacy in aerospace environments. These coatings function through ion release mechanisms that disrupt bacterial cell membranes and metabolic processes. However, their application in aerospace is limited by concerns regarding metal ion leaching over time, potential toxicity at high concentrations, and compatibility issues with sensitive electronic components.

Quaternary ammonium compound (QAC) coatings represent another widely utilized solution, functioning through electrostatic interactions that rupture bacterial cell membranes. While effective against a broad spectrum of microorganisms, these coatings suffer from diminishing efficacy over time due to the accumulation of dead bacterial matter on surfaces and potential development of microbial resistance through repeated exposure.

Photocatalytic coatings, primarily based on titanium dioxide (TiO₂), generate reactive oxygen species when exposed to light, effectively destroying microorganisms. Their application in aerospace is constrained by the requirement for light activation, making them less effective in poorly illuminated areas common in spacecraft and aircraft interiors.

Hydrophobic and superhydrophobic coatings create surfaces that repel water and prevent bacterial adhesion rather than killing microbes directly. These coatings face challenges related to mechanical durability, with performance degrading significantly after physical abrasion or chemical exposure—conditions frequently encountered in aerospace environments.

Enzyme-based and biomimetic coatings represent emerging technologies that either directly attack bacterial cell walls or mimic natural antibacterial surfaces. While promising, these solutions currently face stability issues in the extreme temperature fluctuations and radiation exposure characteristic of aerospace environments.

A significant limitation across all current technologies is the trade-off between durability and antibacterial efficacy. Coatings that maintain strong antibacterial properties often demonstrate poor mechanical resistance, while more durable formulations typically show reduced antimicrobial performance over time. This presents a critical challenge for long-duration space missions where maintenance opportunities are limited.

Additionally, most current antibacterial coatings lack the ability to self-regenerate or adapt to evolving microbial threats, necessitating periodic replacement or reapplication—a significant logistical challenge in aerospace operations.

Metal-based antibacterial coatings, particularly those incorporating silver, copper, and zinc nanoparticles, have demonstrated significant efficacy in aerospace environments. These coatings function through ion release mechanisms that disrupt bacterial cell membranes and metabolic processes. However, their application in aerospace is limited by concerns regarding metal ion leaching over time, potential toxicity at high concentrations, and compatibility issues with sensitive electronic components.

Quaternary ammonium compound (QAC) coatings represent another widely utilized solution, functioning through electrostatic interactions that rupture bacterial cell membranes. While effective against a broad spectrum of microorganisms, these coatings suffer from diminishing efficacy over time due to the accumulation of dead bacterial matter on surfaces and potential development of microbial resistance through repeated exposure.

Photocatalytic coatings, primarily based on titanium dioxide (TiO₂), generate reactive oxygen species when exposed to light, effectively destroying microorganisms. Their application in aerospace is constrained by the requirement for light activation, making them less effective in poorly illuminated areas common in spacecraft and aircraft interiors.

Hydrophobic and superhydrophobic coatings create surfaces that repel water and prevent bacterial adhesion rather than killing microbes directly. These coatings face challenges related to mechanical durability, with performance degrading significantly after physical abrasion or chemical exposure—conditions frequently encountered in aerospace environments.

Enzyme-based and biomimetic coatings represent emerging technologies that either directly attack bacterial cell walls or mimic natural antibacterial surfaces. While promising, these solutions currently face stability issues in the extreme temperature fluctuations and radiation exposure characteristic of aerospace environments.

A significant limitation across all current technologies is the trade-off between durability and antibacterial efficacy. Coatings that maintain strong antibacterial properties often demonstrate poor mechanical resistance, while more durable formulations typically show reduced antimicrobial performance over time. This presents a critical challenge for long-duration space missions where maintenance opportunities are limited.

Additionally, most current antibacterial coatings lack the ability to self-regenerate or adapt to evolving microbial threats, necessitating periodic replacement or reapplication—a significant logistical challenge in aerospace operations.

Prevalent Antibacterial Mechanism Solutions for Aerospace

01 Metal-based antibacterial coatings

Metal-based compounds such as silver, copper, and zinc can be incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of bacteria. These coatings can be applied to various surfaces including medical devices, textiles, and consumer products to provide long-lasting antimicrobial protection.- Metal-based antibacterial coatings: Metal-based compounds such as silver, copper, and zinc can be incorporated into coatings to provide antibacterial properties. These metals release ions that disrupt bacterial cell membranes and interfere with cellular processes, effectively killing or inhibiting the growth of bacteria. These coatings can be applied to various surfaces including medical devices, textiles, and household items to prevent bacterial contamination and growth.

- Polymer-based antibacterial coatings: Polymeric materials can be formulated with antibacterial agents to create durable coatings with long-lasting protection. These polymers can either inherently possess antibacterial properties or serve as carriers for antibacterial compounds. The polymers provide a controlled release mechanism for the active ingredients, ensuring sustained antibacterial activity. Applications include medical implants, food packaging, and industrial equipment where bacterial contamination is a concern.

- Natural compound-based antibacterial coatings: Antibacterial coatings can be formulated using natural compounds derived from plants, animals, or microorganisms. These include essential oils, plant extracts, chitosan, and peptides with inherent antimicrobial properties. These natural alternatives offer environmentally friendly options with reduced toxicity concerns compared to synthetic chemicals. The coatings can be applied to surfaces in healthcare settings, food processing facilities, and consumer products.

- Nanoparticle-enhanced antibacterial coatings: Nanoparticles can be incorporated into coating formulations to enhance antibacterial efficacy. Due to their high surface area to volume ratio, nanoparticles exhibit increased reactivity and interaction with bacterial cells. Various types of nanoparticles, including metal oxides, carbon-based materials, and composite structures, can be used to create coatings with superior antibacterial performance. These advanced coatings find applications in healthcare, electronics, and public spaces where bacterial contamination poses significant risks.

- Smart responsive antibacterial coatings: Advanced antibacterial coatings can be designed to respond to specific environmental triggers such as pH changes, temperature fluctuations, or the presence of bacterial enzymes. These smart coatings release antibacterial agents only when needed, improving efficiency and reducing the development of bacterial resistance. Some formulations also incorporate self-healing properties to maintain coating integrity over time. Applications include implantable medical devices, wound dressings, and surfaces in high-risk environments.

02 Polymer-based antibacterial coatings

Polymeric materials can be formulated with antibacterial agents to create effective coating systems. These polymers can either inherently possess antibacterial properties or serve as carriers for antibacterial compounds. The polymers provide controlled release of active ingredients, extending the duration of antibacterial activity. Applications include medical implants, food packaging, and industrial surfaces where bacterial contamination is a concern.Expand Specific Solutions03 Natural compound-based antibacterial coatings

Coatings incorporating natural antibacterial compounds derived from plants, essential oils, and other biological sources offer environmentally friendly alternatives to synthetic chemicals. These natural compounds, such as plant extracts and essential oils, contain various bioactive components that can inhibit bacterial growth through multiple mechanisms. These coatings are particularly valuable in applications where toxicity and environmental impact are concerns.Expand Specific Solutions04 Nanoparticle-enhanced antibacterial coatings

Nanoparticles can significantly enhance the efficacy of antibacterial coatings due to their high surface area to volume ratio and unique physical properties. Materials such as nano-silver, nano-zinc oxide, and nano-titanium dioxide can be incorporated into coating formulations to provide potent antibacterial activity. These nanoparticle-enhanced coatings offer improved durability and effectiveness compared to conventional antibacterial treatments.Expand Specific Solutions05 Smart responsive antibacterial coatings

Advanced coating technologies that respond to environmental triggers such as pH, temperature, or bacterial presence represent the cutting edge of antibacterial surface protection. These smart coatings can release antibacterial agents only when needed or change their surface properties to prevent bacterial adhesion. This targeted approach minimizes the development of bacterial resistance while maximizing efficacy and extending the useful life of the coating.Expand Specific Solutions

Leading Aerospace Coating Manufacturers and Research Institutions

The antibacterial coating market in aerospace applications is currently in a growth phase, characterized by increasing demand for antimicrobial solutions in high-touch surfaces within aircraft cabins and critical components. The global market size is expanding steadily, driven by heightened health concerns and stringent aerospace safety regulations. From a technological maturity perspective, the field shows varying levels of development across key players. Boeing and Shanghai Aerospace Equipment Manufacturing are leading with advanced implementation of antibacterial surface technologies, while research institutions like California Institute of Technology and University of Southern California are pioneering novel coating mechanisms. Companies like LG Chem and HRL Laboratories are developing specialized polymer-based solutions, creating a competitive landscape that balances established aerospace manufacturers with materials science innovators.

The Boeing Co.

Technical Solution: Boeing has developed advanced antimicrobial coating systems specifically designed for aerospace applications that combine silver nanoparticle technology with specialized polymer matrices. Their proprietary coating mechanism involves controlled ion release technology where silver ions are gradually released from the coating surface to inhibit microbial growth on high-touch areas within aircraft cabins. Boeing's research has demonstrated that these coatings can maintain antimicrobial efficacy for up to 12 months under typical aircraft operational conditions, with testing showing a 99.9% reduction in common cabin microorganisms. The company has integrated these coatings into their Boeing Clean Cabin Initiative, focusing on passenger contact surfaces such as tray tables, armrests, and lavatory fixtures. Boeing has also pioneered self-cleaning surface technologies that combine photocatalytic materials with their antimicrobial systems to provide dual-action protection against both bacteria and viruses.

Strengths: Boeing's extensive aerospace engineering expertise allows for coatings specifically optimized for aircraft environmental conditions (pressure, humidity, temperature fluctuations). Their established manufacturing infrastructure enables large-scale implementation across commercial fleets. Weaknesses: Higher implementation costs compared to standard coatings, and potential regulatory hurdles across different international aviation authorities.

California Institute of Technology

Technical Solution: Caltech has pioneered innovative research in antimicrobial surface technologies for aerospace applications through their Space Microbiology Research Group. Their approach focuses on biomimetic antimicrobial surfaces inspired by natural antimicrobial structures like cicada wings and shark skin. These surfaces employ physical killing mechanisms through nanopatterned structures that mechanically rupture bacterial cell membranes without relying on chemical agents that could degrade over time. Caltech researchers have successfully developed fabrication techniques to create these nanopatterned surfaces on aerospace-grade materials including aluminum alloys and composite materials commonly used in spacecraft construction. Testing in simulated space environments has shown these surfaces maintain antimicrobial efficacy after exposure to radiation, vacuum, and temperature cycling equivalent to conditions on the International Space Station. The research team has also developed hybrid approaches combining these physical mechanisms with controlled-release antimicrobial compounds to create multi-modal protection systems. Their work has been implemented in experimental modules on the ISS, where preliminary data shows a significant reduction in biofilm formation on treated surfaces compared to conventional materials.

Strengths: The biomimetic approach provides long-lasting antimicrobial properties without chemical depletion concerns, and the physical killing mechanism is effective against a broad spectrum of microorganisms including antibiotic-resistant strains. Weaknesses: Complex nanofabrication processes currently limit large-scale production feasibility, and the technology requires precise surface engineering that may be difficult to implement on complex geometries.

Key Patents and Scientific Breakthroughs in Antimicrobial Coatings

Antibacterial coating layer for inner wall of aviation fuel tank and preparation method of antibacterial coating layer

PatentActiveCN112876917A

Innovation

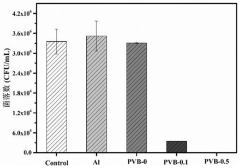

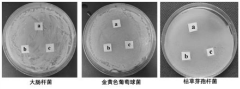

- A water-insoluble complex (PG-FA) formed by polymer guanidine (PG) and fatty acid salt (FA) is used as an antibacterial agent, combined with polyvinyl butyral (PVB) as a binder, and is applied by dipping or spraying Method to form a non-leaching long-lasting antibacterial coating on the surface of aluminum sheets.

Temperature-sensitive nano silver controlled-release smart antibacterial coating and preparation method therefor

PatentActiveUS10557043B2

Innovation

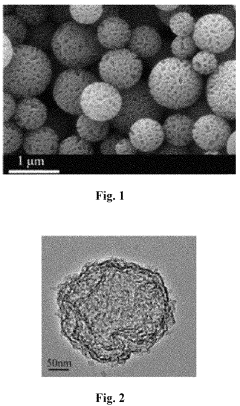

- A temperature-sensitive nano-silver controlled release antibacterial coating composite is created using nanometer mesoporous SiO2 modified with poly N-isopropyl acrylamide, which absorbs nano-silver and controls its release based on temperature, allowing for 'on-off' antibacterial performance adjustment.

Environmental Impact and Sustainability Considerations

The aerospace industry's growing adoption of antibacterial coatings raises significant environmental and sustainability concerns that warrant careful consideration. Traditional antimicrobial coatings often contain heavy metals such as silver, copper, and zinc oxide which, while effective against microorganisms, can accumulate in ecosystems and potentially disrupt natural biological processes. The leaching of these compounds during the coating's lifecycle presents a particular challenge for aerospace applications, where materials may be exposed to extreme conditions that accelerate degradation.

Recent environmental impact assessments have revealed that certain antibacterial agents used in aerospace coatings can persist in soil and water systems for extended periods. This persistence raises concerns about bioaccumulation in food chains and potential toxicity to non-target organisms. Furthermore, the manufacturing processes for these specialized coatings often involve volatile organic compounds (VOCs) and other hazardous substances that contribute to air pollution and pose occupational health risks.

The aerospace industry has begun responding to these challenges through the development of more environmentally benign alternatives. Bio-based antimicrobial compounds derived from natural sources such as plant extracts, essential oils, and peptides show promising antibacterial efficacy while offering improved biodegradability. Additionally, advanced nanotechnology approaches are enabling the creation of structured surfaces that provide physical rather than chemical antimicrobial properties, potentially reducing environmental impact.

Life cycle assessment (LCA) studies comparing conventional and emerging antibacterial coating technologies indicate that sustainability improvements can be achieved through careful material selection and process optimization. These assessments consider factors such as raw material sourcing, energy consumption during manufacturing, service life duration, and end-of-life disposal options. The extended service life offered by effective antibacterial coatings can actually improve the overall environmental footprint of aerospace components by reducing replacement frequency.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of antimicrobial technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting the use of certain biocidal substances, driving innovation toward greener alternatives. Aerospace manufacturers must navigate this evolving regulatory landscape while maintaining the performance requirements essential for flight safety and operational efficiency.

Future research directions should focus on developing antibacterial coating systems that balance antimicrobial efficacy with minimal environmental impact. This includes exploring renewable feedstocks, reducing energy-intensive processing steps, and designing for end-of-life recyclability or biodegradability. Collaborative efforts between materials scientists, microbiologists, and environmental engineers will be essential to advance truly sustainable solutions for the aerospace industry.

Recent environmental impact assessments have revealed that certain antibacterial agents used in aerospace coatings can persist in soil and water systems for extended periods. This persistence raises concerns about bioaccumulation in food chains and potential toxicity to non-target organisms. Furthermore, the manufacturing processes for these specialized coatings often involve volatile organic compounds (VOCs) and other hazardous substances that contribute to air pollution and pose occupational health risks.

The aerospace industry has begun responding to these challenges through the development of more environmentally benign alternatives. Bio-based antimicrobial compounds derived from natural sources such as plant extracts, essential oils, and peptides show promising antibacterial efficacy while offering improved biodegradability. Additionally, advanced nanotechnology approaches are enabling the creation of structured surfaces that provide physical rather than chemical antimicrobial properties, potentially reducing environmental impact.

Life cycle assessment (LCA) studies comparing conventional and emerging antibacterial coating technologies indicate that sustainability improvements can be achieved through careful material selection and process optimization. These assessments consider factors such as raw material sourcing, energy consumption during manufacturing, service life duration, and end-of-life disposal options. The extended service life offered by effective antibacterial coatings can actually improve the overall environmental footprint of aerospace components by reducing replacement frequency.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of antimicrobial technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting the use of certain biocidal substances, driving innovation toward greener alternatives. Aerospace manufacturers must navigate this evolving regulatory landscape while maintaining the performance requirements essential for flight safety and operational efficiency.

Future research directions should focus on developing antibacterial coating systems that balance antimicrobial efficacy with minimal environmental impact. This includes exploring renewable feedstocks, reducing energy-intensive processing steps, and designing for end-of-life recyclability or biodegradability. Collaborative efforts between materials scientists, microbiologists, and environmental engineers will be essential to advance truly sustainable solutions for the aerospace industry.

Regulatory Compliance and Safety Standards

Aerospace antibacterial coatings must adhere to stringent regulatory frameworks established by multiple international and national authorities. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have developed comprehensive guidelines specifically addressing materials used in aircraft interiors, with particular emphasis on fire resistance properties under FAR 25.853 standards. These regulations mandate that antibacterial coatings must not compromise the flammability characteristics of treated surfaces, maintaining compliance with smoke density and heat release requirements.

NASA has established additional specifications through its NASA-STD-6016 standard, which outlines materials and processes requirements for spacecraft systems. This standard specifically addresses outgassing properties of coatings, critical for preventing contamination of sensitive equipment in the confined environments of spacecraft. Antibacterial coatings must demonstrate low Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) values to receive approval for space applications.

The International Organization for Standardization (ISO) provides several relevant standards, including ISO 22196 for measuring antibacterial activity on surfaces and ISO 10993 for biocompatibility assessment. These standards establish testing protocols to verify both the efficacy and safety of antibacterial coatings, ensuring they deliver claimed performance without introducing biological hazards.

Environmental considerations have gained prominence in regulatory frameworks, with the European Chemical Agency's REACH regulation and the U.S. Environmental Protection Agency's guidelines restricting certain biocidal substances previously used in antibacterial formulations. This regulatory shift has accelerated research into environmentally sustainable alternatives that maintain effectiveness while reducing ecological impact.

Safety data requirements have become increasingly comprehensive, with manufacturers now required to provide detailed toxicological profiles for coating components. This includes acute toxicity assessments, sensitization potential, and long-term exposure studies. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has standardized hazard communication requirements, ensuring consistent safety information across international boundaries.

Certification processes for aerospace antibacterial coatings typically involve multi-stage testing regimes conducted by accredited laboratories. These processes evaluate not only antimicrobial efficacy but also durability under aerospace-specific conditions, including resistance to cleaning agents, UV exposure, and temperature cycling. Successful navigation of these regulatory pathways represents a significant barrier to market entry but ensures that approved coatings meet the exceptional safety standards demanded by aerospace applications.

NASA has established additional specifications through its NASA-STD-6016 standard, which outlines materials and processes requirements for spacecraft systems. This standard specifically addresses outgassing properties of coatings, critical for preventing contamination of sensitive equipment in the confined environments of spacecraft. Antibacterial coatings must demonstrate low Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) values to receive approval for space applications.

The International Organization for Standardization (ISO) provides several relevant standards, including ISO 22196 for measuring antibacterial activity on surfaces and ISO 10993 for biocompatibility assessment. These standards establish testing protocols to verify both the efficacy and safety of antibacterial coatings, ensuring they deliver claimed performance without introducing biological hazards.

Environmental considerations have gained prominence in regulatory frameworks, with the European Chemical Agency's REACH regulation and the U.S. Environmental Protection Agency's guidelines restricting certain biocidal substances previously used in antibacterial formulations. This regulatory shift has accelerated research into environmentally sustainable alternatives that maintain effectiveness while reducing ecological impact.

Safety data requirements have become increasingly comprehensive, with manufacturers now required to provide detailed toxicological profiles for coating components. This includes acute toxicity assessments, sensitization potential, and long-term exposure studies. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) has standardized hazard communication requirements, ensuring consistent safety information across international boundaries.

Certification processes for aerospace antibacterial coatings typically involve multi-stage testing regimes conducted by accredited laboratories. These processes evaluate not only antimicrobial efficacy but also durability under aerospace-specific conditions, including resistance to cleaning agents, UV exposure, and temperature cycling. Successful navigation of these regulatory pathways represents a significant barrier to market entry but ensures that approved coatings meet the exceptional safety standards demanded by aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!